Method for preparing environmentally friendly paper coating agent by using water dispersible resin of ethylene-(meth)acrylic acid polymer, and use thereof

A methacrylic acid copolymer, methacrylic acid technology, applied in paper coatings, water repellent addition, material mixture addition and other directions, can solve the problem of mixing alkali metal compounds and ammonia, alkylamines with low volatility, bad odor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

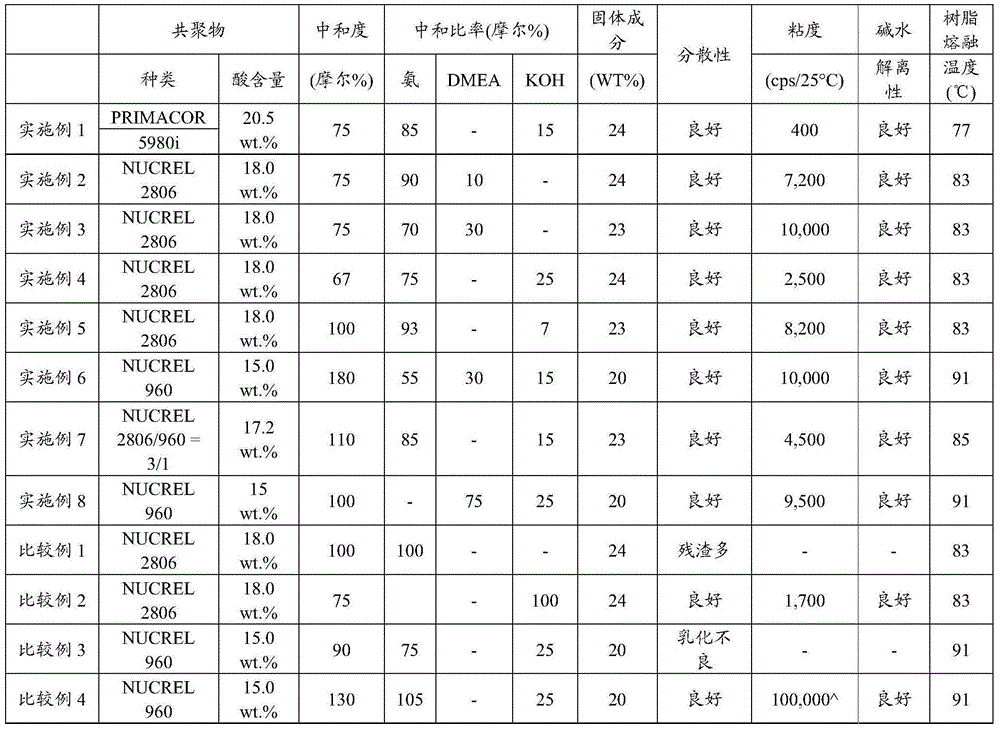

Embodiment 1

[0094] 240 g of PRIMACOR 5980i (acrylic acid content: 20.5% by mass, MFR=300 g / 10 minutes), 728.48 g of ion-exchanged water, 5.07 g of KOH, and 26.45 g of ammonia water were charged into a 1500 ml autoclave, and stirred at a temperature of 100° C. at a stirring speed of 1200 rpm for 2 hours. At this time, the degree of neutralization (neutralization ratio with respect to the number of moles of carboxyl groups of the ethylene-acrylic acid copolymer) (KOH+ammonia) was 75 mol%, and the molar ratio of KOH / ammonia was 15 / 85. Thereafter, after cooling to 50° C. or lower, the aqueous dispersion was obtained by packaging. The solid content concentration of the obtained aqueous dispersion liquid was 24 mass %, and the viscosity was 400 cps / 25 degreeC.

Embodiment 2

[0096] 240 g of NUCREL2806 (acrylic acid content: 18% by mass, MFR=60 g / 10 minutes), 731.40 g of ion-exchanged water, 4.00 g of DMEA, and 24.59 g of ammonia water were added to a 1500 ml autoclave, and stirred at a temperature of 100° C. at a stirring speed of 1200 rpm for 2 hours. At this time, the degree of neutralization (neutralization ratio to the number of moles of carboxyl groups in the ethylene-acrylic acid copolymer) (DMEA+aqueous ammonia) was 75 mol%, and the mol% ratio of DMEA / aqueous ammonia was 10 / 90. After that, it is cooled to below 50° C., and then packaged to obtain an aqueous dispersion. The solid content concentration of the obtained aqueous dispersion liquid was 24 mass %, and the viscosity was 7,200 cps / 25 degreeC.

Embodiment 3

[0098] 230 g of NUCREL2806 (acrylic acid content: 18% by mass, MFR=60 g / 10 minutes), 740.16 g of ion-exchanged water, 11.51 g of DMEA, and 18.33 g of ammonia water were added to a 1500 ml autoclave, and stirred at a temperature of 100° C. at a stirring speed of 1200 rpm for 2 hours. At this time, the degree of neutralization (neutralization ratio with respect to the number of moles of carboxyl groups of the ethylene-acrylic acid copolymer) (DMEA+aqueous ammonia) was 75 mol%, and the mol% ratio of DMEA / aqueous ammonia was 30 / 70. After that, it is cooled to below 50° C., and then packaged to obtain an aqueous dispersion. The solid content concentration of the obtained aqueous dispersion liquid was 23 mass %, and the viscosity was 10,000 cps / 25 degreeC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com