High temperature resistant electrical soft composite material and manufacturing method thereof

A composite material and high-temperature-resistant technology, which is applied in the field of electrical soft composite materials, high-temperature resistant electrical soft composite materials and their manufacturing, can solve the problems of poor product quality, low cross-linking density, poor thermal adhesion and heat resistance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

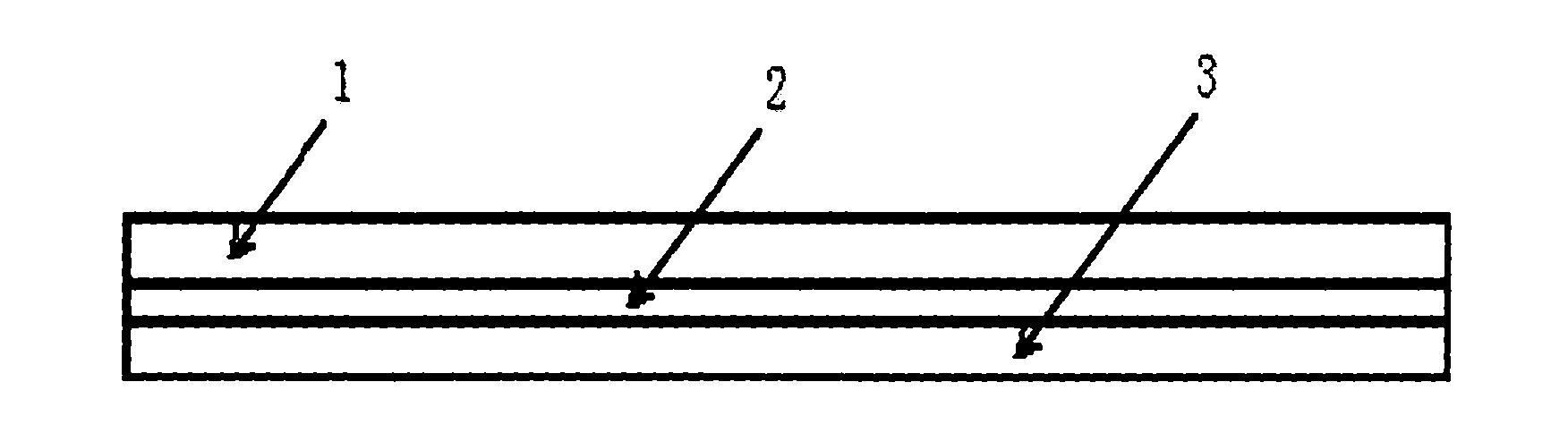

[0071] A high-temperature-resistant polyester film polyaramid fiber paper soft composite material (that is, a high-temperature resistant electrical soft composite material), which is sequentially composed of polyaramid fiber paper layer, adhesive layer, polyester film layer, adhesive layer, polyaramide Composed of amide fiber paper layers.

[0072] The polyaramid fiber paper layer is polym-phenylene isophthalamide fiber paper (thickness is 0.05mm~0.13mm);

[0073] The polyester film layer is polyethylene terephthalate film (thickness is 0.025mm~0.35mm);

[0074] The adhesive composition of the adhesive layer is composed of hydroxyl-terminated polyethylene adipate polyurethane (D101 component A produced by Sichuan Dongcai Technology Group Co., Ltd.), isocyanate prepolymer synthesized by TDI and glycerin (Sichuan Dongcai Technology D101 B component produced by the Group Co., Ltd.), polyglycidyl modified diuretyl resin and acetone are mixed. See Table 2 for the amount of each c...

Embodiment 7~12

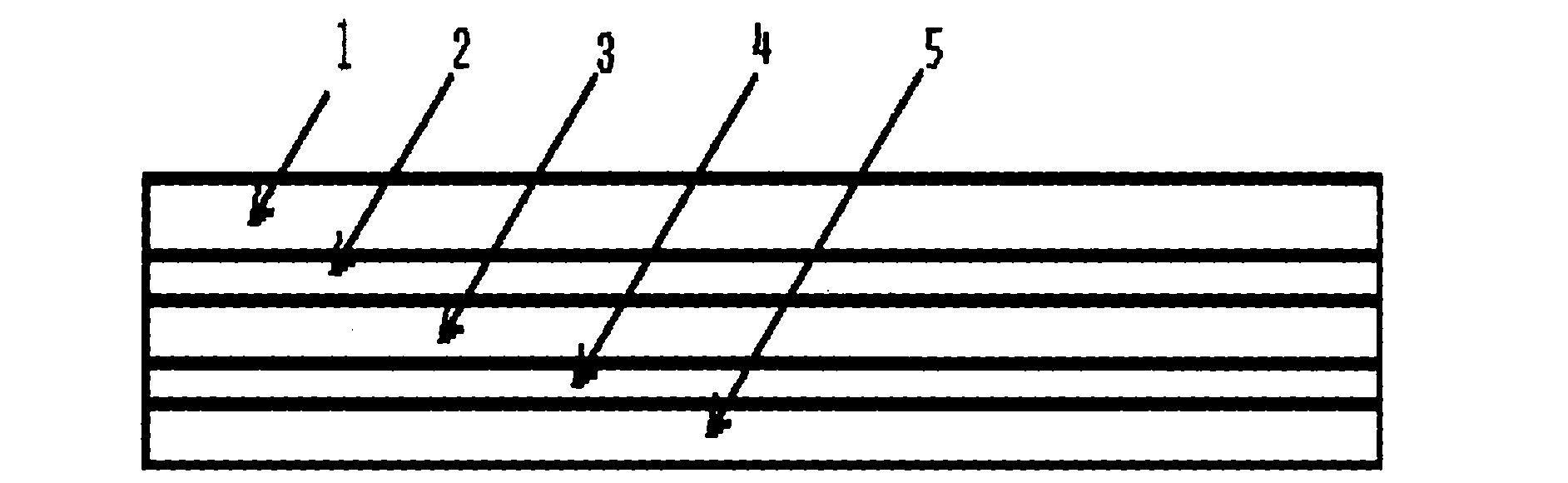

[0081] A high temperature-resistant polyimide film polyaramid fiber paper soft composite material (that is, a high temperature resistant electrical soft composite material), which is sequentially composed of polyaramid fiber paper layer, adhesive layer, polyimide film layer, adhesive layer, polyaramid fiber paper layer.

[0082]The polyaramid fiber paper layer is polym-phenylene isophthalamide fiber paper (thickness is 0.05mm~0.25mm);

[0083] The polyimide film layer is a film processed by pyromellitic dianhydride and diaminodiphenyl ether synthetic resin (thickness is 0.025mm~0.25mm);

[0084] The adhesive composition of the adhesive layer is composed of hydroxyl-terminated polyethylene adipate polyurethane (D101 component A produced by Sichuan Dongcai Technology Group Co., Ltd.), isocyanate prepolymer synthesized by TDI and glycerin (Sichuan Dongcai Technology D101 B component produced by the Group Co., Ltd.), polyglycidyl modified diuretyl resin and acetone are mixed. Th...

Embodiment 13~18

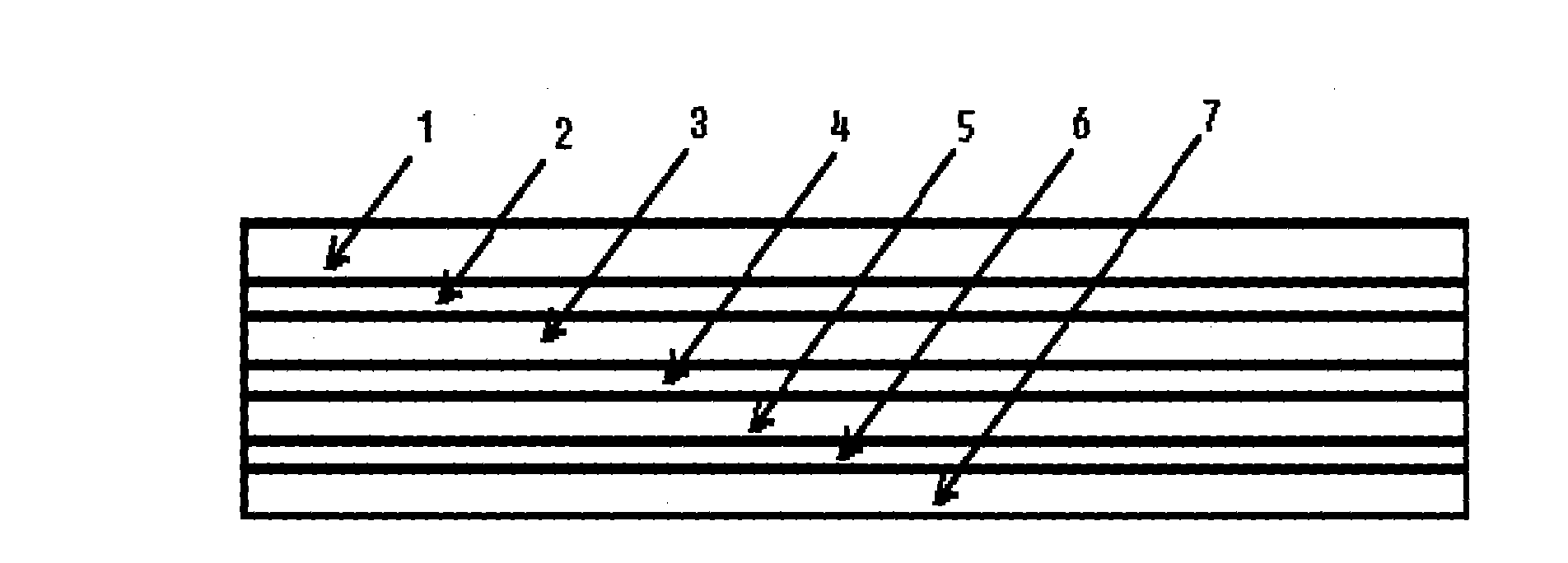

[0093] A high-temperature-resistant electrical soft composite material (two-layer high-temperature-resistant electrical soft composite material), consisting of: a first synthetic fiber paper layer, a first film layer, and a bonded first film layer and one side of the first synthetic fiber paper layer The first adhesive layer is composed.

[0094] The first adhesive layer is composed of an adhesive composition, and consists of 115 to 230 parts by weight of a hydroxyl-terminated prepolymer, 30 to 83 parts by weight of a multifunctional isocyanate prepolymer, and 70 parts by weight of a polyglycidyl modified diuretyl resin , mixed with 150 to 300 parts by weight of solvent;

[0095] The hydroxyl-terminated prepolymer is a polyurethane adhesive 101 glue A component;

[0096] The polyfunctional isocyanate prepolymer is the second component of the polyurethane adhesive 101;

[0097] Described solvent is any in acetone, ethyl acetate, toluene or xylene;

[0098] Component and weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com