High temperature resistant electrical soft composite material and manufacturing method thereof

A composite material and soft technology, applied in the field of electrical soft composite materials, electrical soft composite materials and their manufacturing, can solve the problems of low crosslink density, poor thermal adhesion and heat resistance, poor product quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

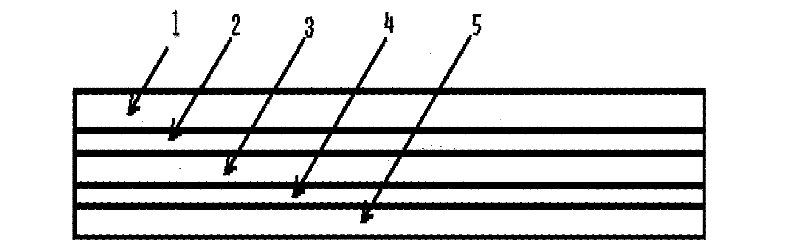

[0072] A high temperature-resistant polyester film polyaramid fiber paper soft composite material (i.e. a kind of electrical soft composite material), which is sequentially composed of polyaramid fiber paper layer, adhesive layer, polyester film layer, adhesive layer, polyaramid fiber Composition of paper layers.

[0073] The polyaramid fiber paper layer is polym-phenylene isophthalamide fiber paper (thickness is 0.05mm~0.13mm);

[0074] The polyester film layer is polyethylene terephthalate film (thickness is 0.025mm~0.35mm);

[0075] The adhesive composition of the adhesive layer is composed of hydroxyl-terminated polyethylene adipate polyurethane (D101 component A produced by Sichuan Dongcai Technology Group Co., Ltd.), isocyanate prepolymer synthesized by TDI and glycerin (Sichuan Dongcai Technology D101 B component produced by the Group Co., Ltd.), polyglycidyl modified diuretyl resin and acetone are mixed. See Table 2 for the amount of each component (weight, in kilogr...

Embodiment 7~12

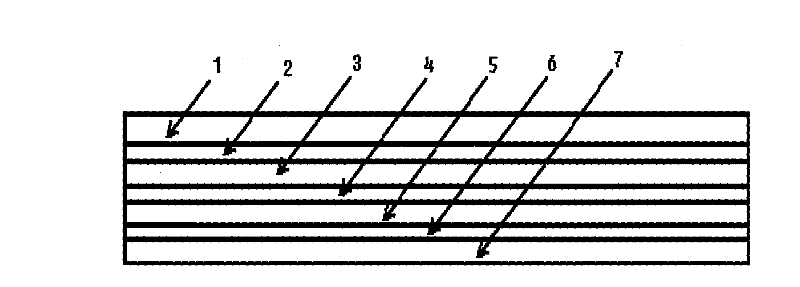

[0082] A high temperature resistant polyimide film polyaramid fiber paper soft composite material (i.e. a kind of electrical soft composite material), which is sequentially composed of polyaramid fiber paper layer, adhesive layer, polyimide film layer, adhesive layer, Composed of polyaramid fiber paper layers.

[0083] The polyaramid fiber paper layer is polym-phenylene isophthalamide fiber paper (thickness is 0.05mm~0.25mm);

[0084] The polyimide film layer is a film processed by pyromellitic dianhydride and diaminodiphenyl ether synthetic resin (thickness is 0.025mm~0.25mm);

[0085] The adhesive composition of the adhesive layer is composed of hydroxyl-terminated polyethylene adipate polyurethane (D101 component A produced by Sichuan Dongcai Technology Group Co., Ltd.), isocyanate prepolymer synthesized by TDI and glycerin (Sichuan Dongcai Technology D101 B component produced by the Group Co., Ltd.), polyglycidyl modified diuretyl resin and acetone are mixed. The dosage ...

Embodiment 13~18

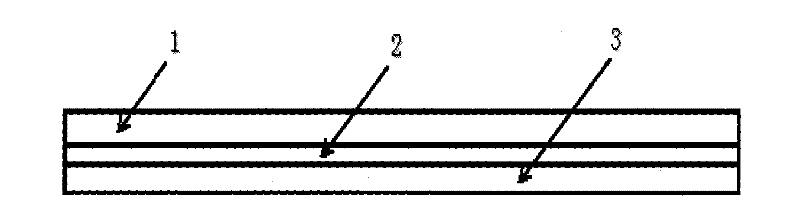

[0094] An electrical soft composite material (two-layer electrical soft composite material), consisting of: a first synthetic fiber paper layer, a first film layer, and a first adhesive layer for bonding the first film layer and one side of the first synthetic fiber paper layer composition.

[0095] The first adhesive layer is composed of an adhesive composition, and consists of 115 to 230 parts by weight of a hydroxyl-terminated prepolymer, 30 to 83 parts by weight of a multifunctional isocyanate prepolymer, and 70 parts by weight of a polyglycidyl modified diuretyl resin , mixed with 150 to 300 parts by weight of solvent;

[0096] The hydroxyl-terminated prepolymer is a polyurethane adhesive 101 glue A component;

[0097] The polyfunctional isocyanate prepolymer is the second component of the polyurethane adhesive 101;

[0098] Described solvent is any in acetone, ethyl acetate, toluene or xylene;

[0099] Component and weight (kg) composition of described adhesive compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com