Oiling device on draw texturing machine

A texturing machine and oil tank technology, which is used in textiles and papermaking, etc., can solve the problems of inconsistent oiling uniformity of tow, difficult adjustment of height consistency, and difficulty in consistent oil level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

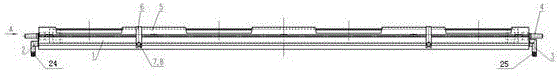

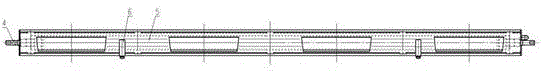

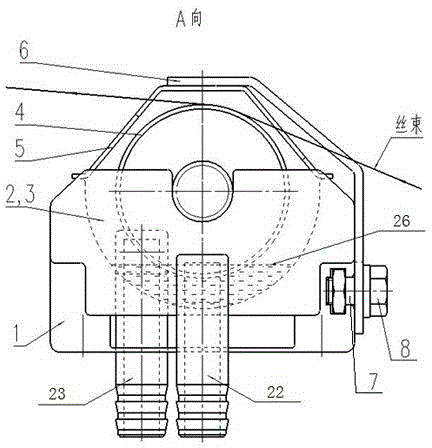

[0021] Such as Figure 1-Figure 4 As shown, the oiling device 10 of the present invention consists of an aluminum alloy profile oil tank 1, a stainless steel pipe oiling roller 4, end plates 2 and 3 on both sides of the oil tank, a stainless steel plate oil tank cover 5, an oil tank pressure plate 6, and bolts 7 for fixing the oil tank pressure plate 6 And nut 8 composition.

[0022] The oil groove 1 inwall is a long groove with an arc, and the oiling roller 4 is filled with spinning oil in the arc groove. The two ends of the oil tank 1 are respectively welded with aluminum alloy end plates 2 and 3, and the end plate 2 on one side has a rectangular or circular oil inlet hole 24, and the highest opening of the oil inlet hole 24 is basically flush with the oil level surface 26; There is a rectangular or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com