Electrostatic spinning device

An electrospinning and wire electrode technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of troublesome cleaning of the liquid coating device, low efficiency of the moving mechanism, and low spinning efficiency, etc., to achieve The reciprocating motion process is stable, the spinning efficiency is high, and the liquid supply is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

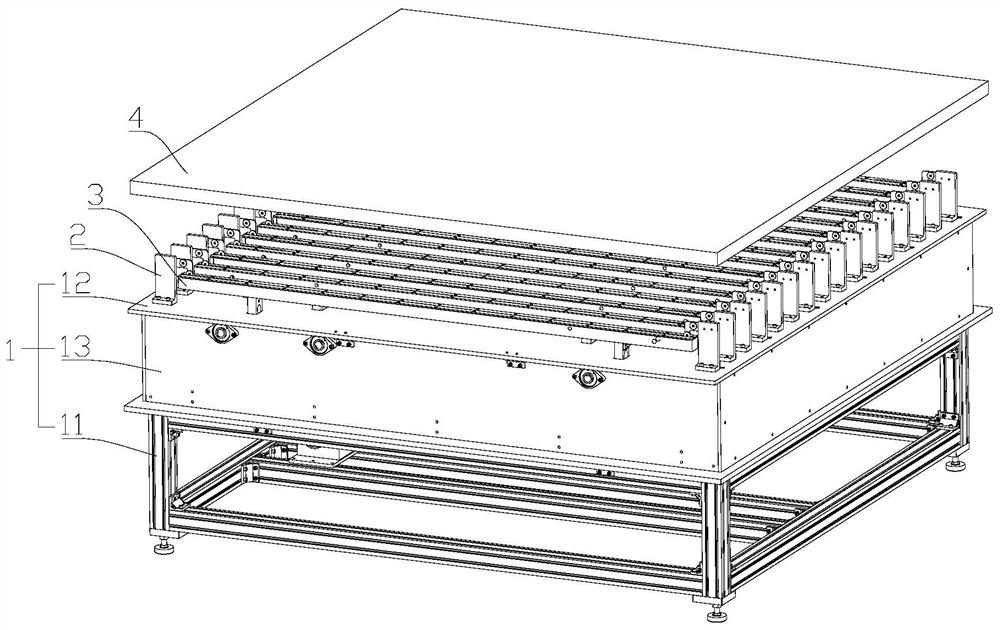

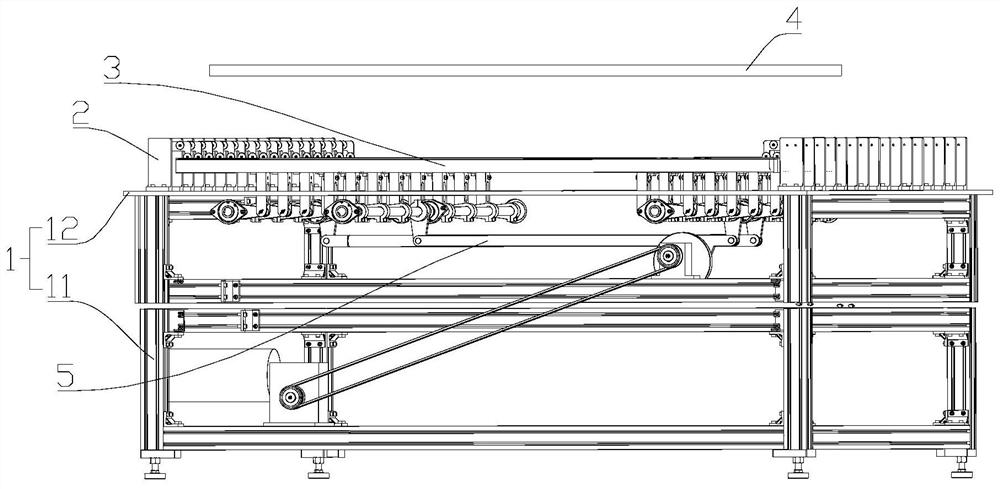

[0033] Such as Figure 1-Figure 8 As shown, the present embodiment relates to an electrospinning device, including a frame 1, on which a plurality of wire electrodes 6 extending in the transverse direction are fixed, and the plurality of wire electrodes 6 are arranged in rows along the longitudinal direction, and each wire electrode 6 are all connected to a positive high-voltage power supply 7, and a receiving terminal 4 is arranged above the plurality of wire electrodes 6, and the receiving terminal 4 is connected to a negative high-voltage power supply 8 (it should be noted that the receiving terminal 4 can also be grounded); the bottom of each wire electrode 6 They are all correspondingly equipped with a liquid tank 3 filled with spinning solution. The liquid tank 3 and the wire electrode 6 have the same extension direction and arrangement. The liquid tank 3 can reciprocate up and down relative to the wire electrode 6, so that the wire electrode 6 is immersed Switch back an...

Embodiment 2

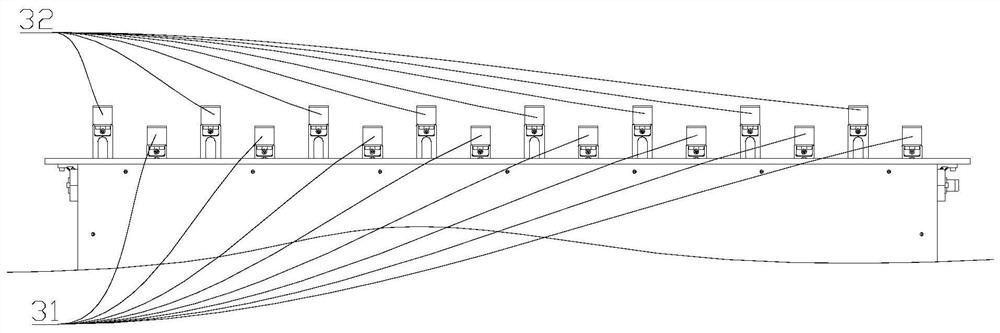

[0043] The difference between this embodiment and Embodiment 1 is that: Figure 10 As shown, in this embodiment, the first liquid tank 31 and the second liquid tank 32 are arranged in such a way that two second liquid tanks 32 are provided every two first liquid tanks 31; correspondingly, as Figure 11 As shown, the arrangement of the first transmission assembly 504 and the third transmission assembly 506 on the first rotating shaft 501 is that two third transmission assemblies 506 are provided every two first transmission assemblies 504, and every two third transmission assemblies 506 on the second rotating shaft 502 Each second transmission assembly 505 and every two fourth transmission assemblies 507 on the third rotating shaft 503 are arranged alternately.

[0044] It can be understood that the embodiment of the present invention is not limited to the arrangement of the first liquid tank 31 and the second liquid tank 32 adopted in the first and second embodiments, and thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com