An electrospinning device

An electrospinning and equipment technology, applied in the field of electrospinning equipment, can solve the problems of difficult fiber collection, low effective productivity, and low collection efficiency, and achieve the effects of uniform spinning, improved film quality, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

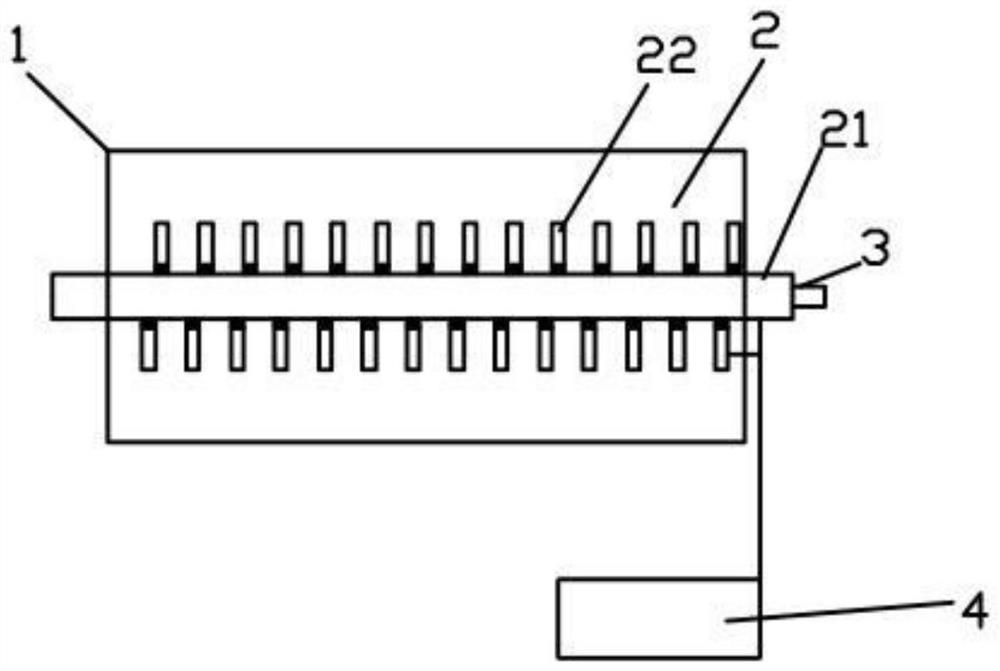

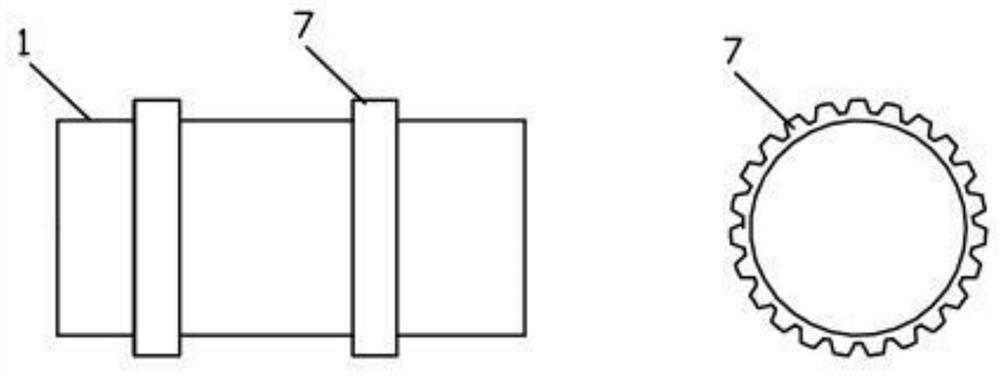

[0041] 1) Prepare a liquid dispenser with a diameter of 4 cm and a double-layer structure liquid dispenser with a sleeve diameter of 8 cm. The liquid dispenser is provided with a plurality of needles, and the needles are fixed on the liquid pipe and pass through the surface of the sleeve. The needles are distributed in a ring on the surface of the liquid pipe and the sleeve. Eight needles are distributed in a circumferential direction of the liquid pipe and the sleeve. The angle between two adjacent needles on the same ring is 45 degrees. The distance between the rings is 6cm, and the assembled liquid dispenser is installed on the second supporting device, wherein the second supporting device is a lifting platform. And connect the dispenser with the liquid pushing device and the high-voltage electrostatic generating device.

[0042] 2) Prepare a cylindrical receiver with an inner diameter (radius) of 30 cm, and install it on the first support device, which is also a rotating d...

Embodiment 2

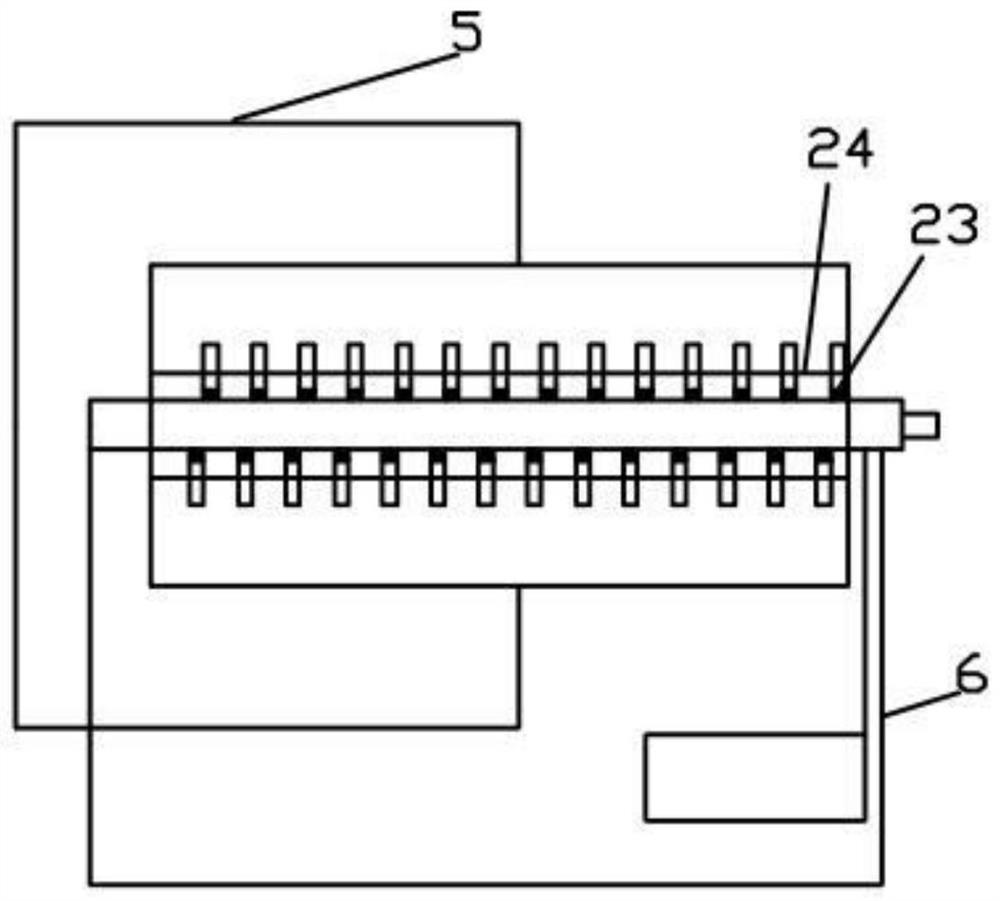

[0054] 1) Prepare a liquid dispenser with a diameter of 6 cm and a sleeve diameter of 10 cm. The liquid dispenser is provided with a plurality of needles, and the needles are fixed on the liquid pipe and pass through the surface of the sleeve. The needles are distributed in a ring on the surface of the liquid pipe and the sleeve, and 6 needles are distributed in a circumferential direction of the liquid pipe and the sleeve, which are distributed in a ring. The angle between two adjacent needles on the same ring is 60 degrees. The ring spacing between the two rings is 6 cm, and the assembled liquid dispenser is installed on the second supporting device, wherein the second supporting device is a lifting platform. And connect the dispenser with the liquid pushing device and the high-voltage electrostatic generating device.

[0055] 2) Prepare a cylindrical receiving tube with an inner diameter (radius) of 36 cm, and install it on the first supporting device, which is also a rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com