Novel flexible textile fabric, round-net continuous printing production technology and equipment

A technology of textile fabrics and production technology, which is applied in the direction of screen printing machines, printing machines, printing machines, etc., can solve the problems of insufficient skin affinity and comfort, poor quality of printed products, and poor use effects, etc., to achieve skin affinity Satisfied with comfort, quality assurance of printed products, excellent elasticity and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

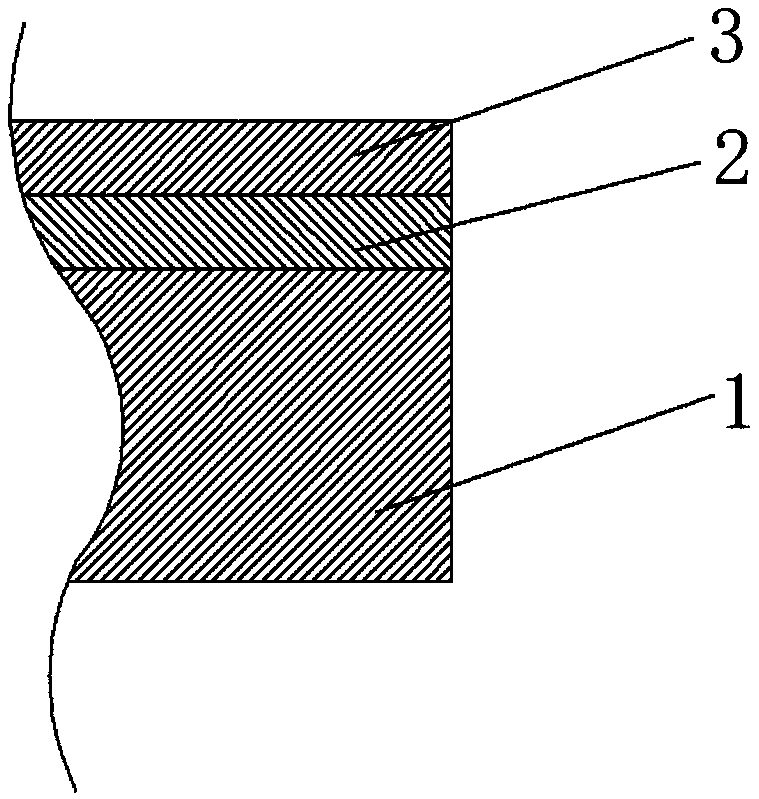

[0028] see figure 1 , figure 1 It is a structural schematic diagram of a novel flexible textile fabric according to the embodiment of the present invention.

[0029] This embodiment provides a new type of flexible textile fabric (hereinafter referred to as textile fabric), which is used in the field of clothing such as clothing. The textile fabric in this embodiment includes a basic fabric layer 1, a silicone fabric layer 2, and a flocking fabric layer 3 . Wherein, the silicone fabric layer 2 is arranged on the upper surface of the base fabric layer 1, and the flocking fabric layer 3 is arranged on the upper surface of the silicone fabric layer 2, that is to say, the base fabric layer 1, the silicone fabric layer 2, and the flocking fabric layer 3 set in sequence. Specifically, in this embodiment, the basic fabric layer 1 is a fabric layer, and the silicone fabric layer 2 is a single-layer silicone fabric layer arranged on the upper surface of the fabric layer, that is to s...

Embodiment 2

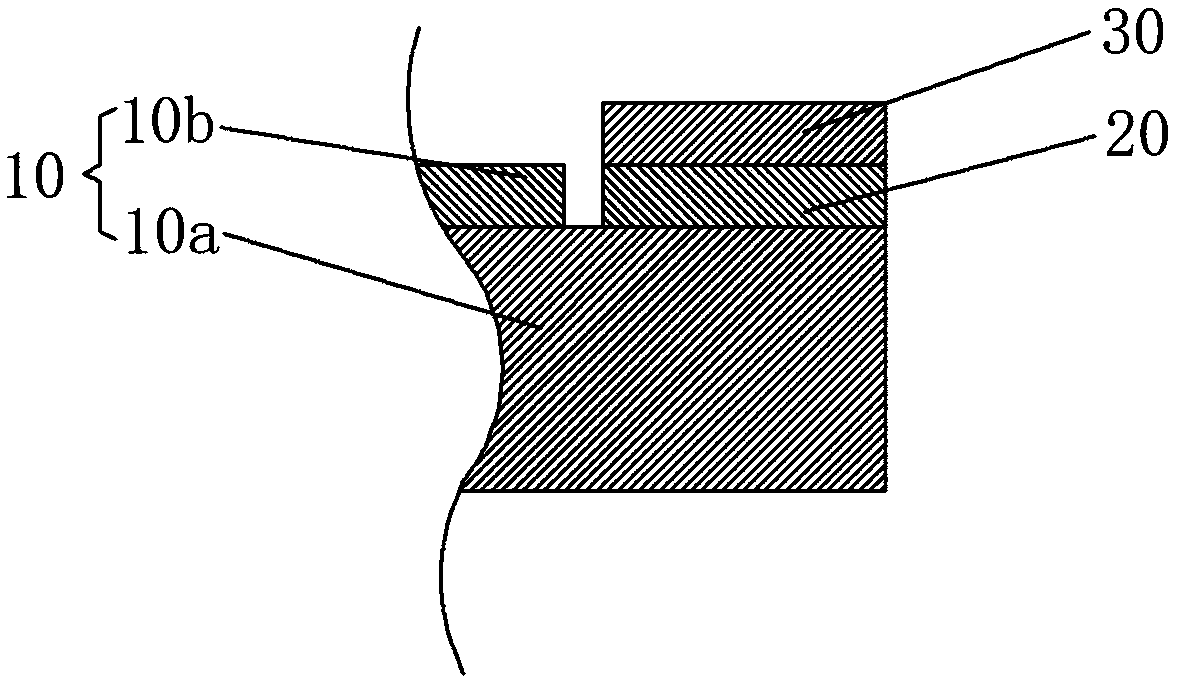

[0032] see figure 2 , figure 2 It is a structural schematic diagram of the new flexible textile fabric of the second embodiment of the present invention.

[0033] This embodiment provides a new type of flexible textile fabric (hereinafter referred to as textile fabric), which includes a basic fabric layer 10 , a silicone fabric layer 20 , and a flocking fabric layer 30 . Wherein, the silicone fabric layer 20 is arranged on the upper surface of the base fabric layer 1, and the flocking fabric layer 30 is arranged on the upper surface of the silicone fabric layer 20, that is to say, the base fabric layer 10, the silicone fabric layer 20, and the flocking fabric layer 30 are set in turn. In this embodiment, the basic fabric layer 10 comprises a cloth layer 10a and a color paste fabric layer 10b, the color paste fabric layer 10b is arranged on the upper surface of the cloth layer 10a, and the color paste fabric layer 10b is formed by printing on the upper surface of the cloth ...

Embodiment 3

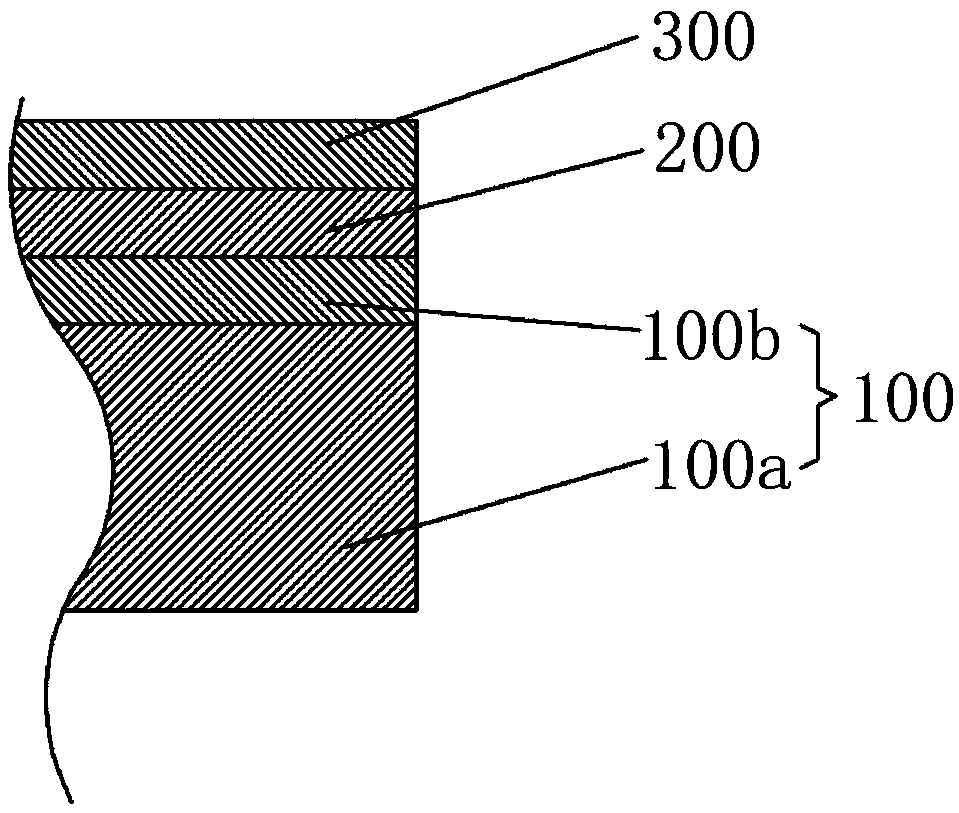

[0035] see image 3 , image 3It is a structural schematic diagram of the third novel flexible textile fabric of the present invention. The basic fabric layer includes a fabric layer and a basic silicone fabric layer, and the basic silicone fabric layer is arranged on the upper surface of the fabric layer.

[0036] This embodiment provides a new type of flexible textile fabric (hereinafter referred to as textile fabric), which includes a base fabric layer 100 , a silicone fabric layer 200 , and a flocking fabric layer 300 . Wherein, the silicone fabric layer 200 is arranged on the upper surface of the base fabric layer 100, and the flocking fabric layer 300 is arranged on the upper surface of the silicone fabric layer 200, that is to say, the base fabric layer 100, the silicone fabric layer 200, and the flocking fabric layer 300 are set in sequence. In this embodiment, the basic fabric layer 100 includes a fabric layer 100a and a basic silicone fabric layer 100b, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com