Super-soft spunbond nonwoven cloth double reinforcing and forming technology

A technology of spun-bonded non-woven fabrics and non-woven fabrics, which is applied in non-woven fabrics, textiles, papermaking, and equipment configuration for processing textile materials. Bacteriostasis and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of ultra-soft spunbonded non-woven double reinforcement molding technology of the present invention comprises the following steps:

[0022] a) Melting and mixing of raw materials: The raw materials are fully mixed and fed into the hopper, and the raw materials are extruded and melted by a twin-screw extruder to obtain a melt. The ratio of each component in the raw materials: polypropylene PP 81-86.5 parts, propylene-based elastomer 12.5-16 parts, soft masterbatch 0.5-1.5 parts, titanium dioxide 0.5-1.5 parts;

[0023] b) Melt filtration: Extrude and melt the raw material slices obtained in step a) through a twin-screw extruder to obtain a melt, remove impurities online through a filter, and then enter the spinning system;

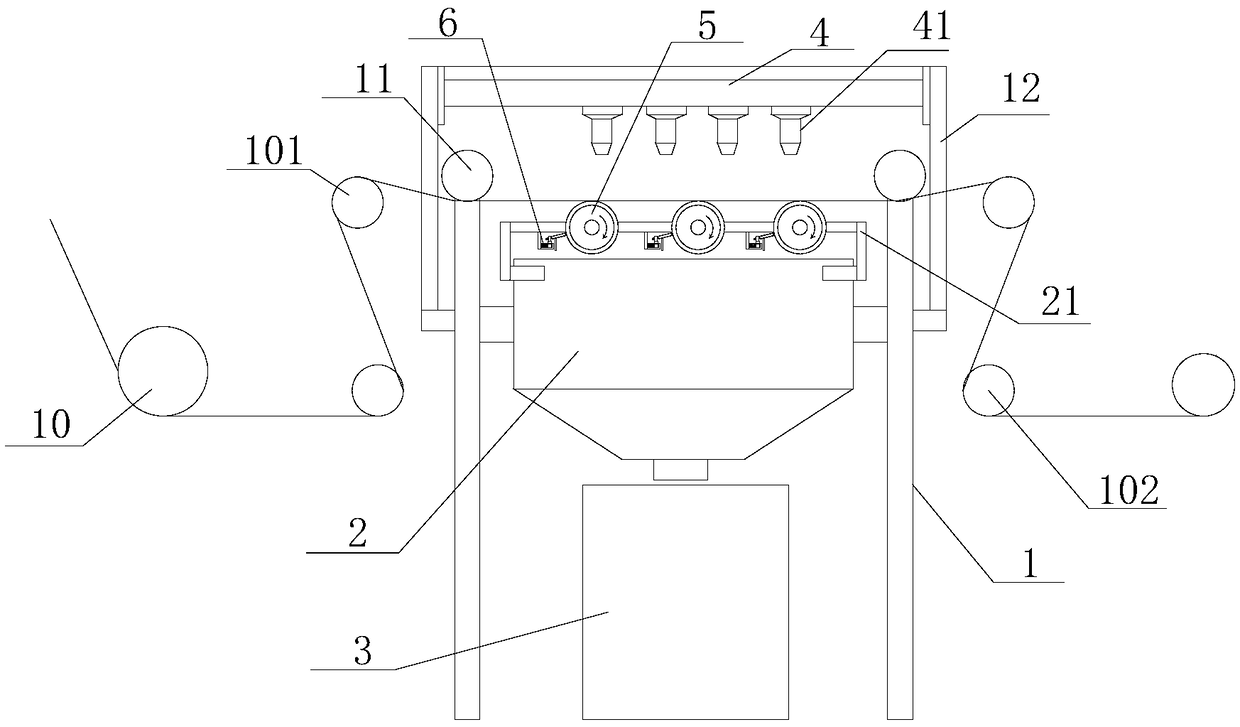

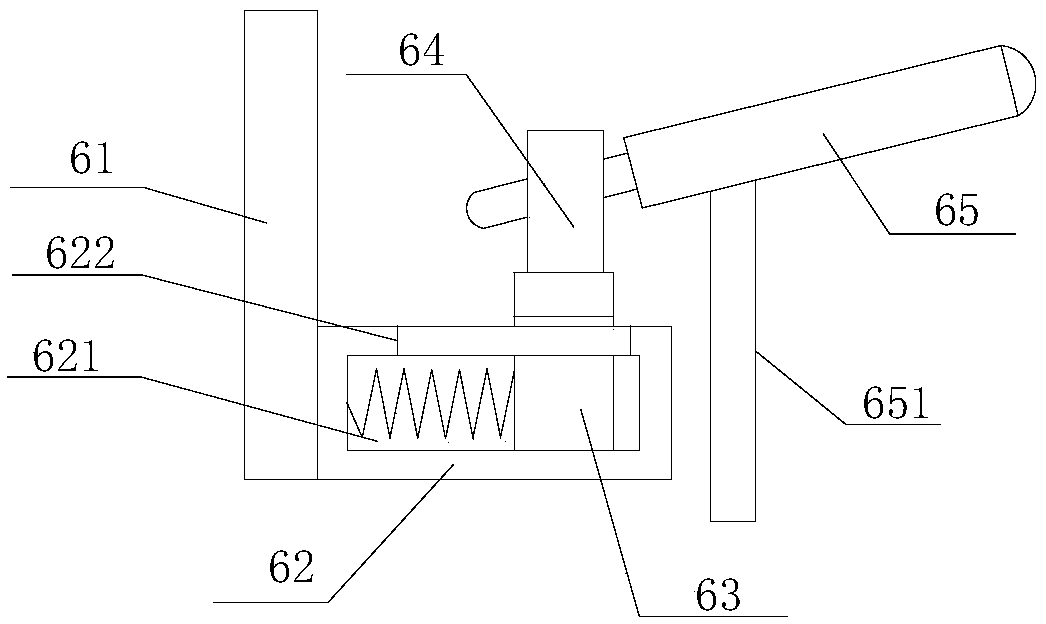

[0024] c) Spinning into a web: the melt filtered in step b) is quantitatively sent to the spinning assembly by a metering pump, and the spun silk is cooled by side cooling air to obtain a primary growth filament, and the primary growth filamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com