A kind of super-flexible spunbond non-woven double reinforcement molding process

A technology of spunbond non-woven fabric and molding process, which is applied in the directions of non-woven fabrics, textiles and papermaking, and the configuration of equipment for processing textile materials, etc. Bacterial properties and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

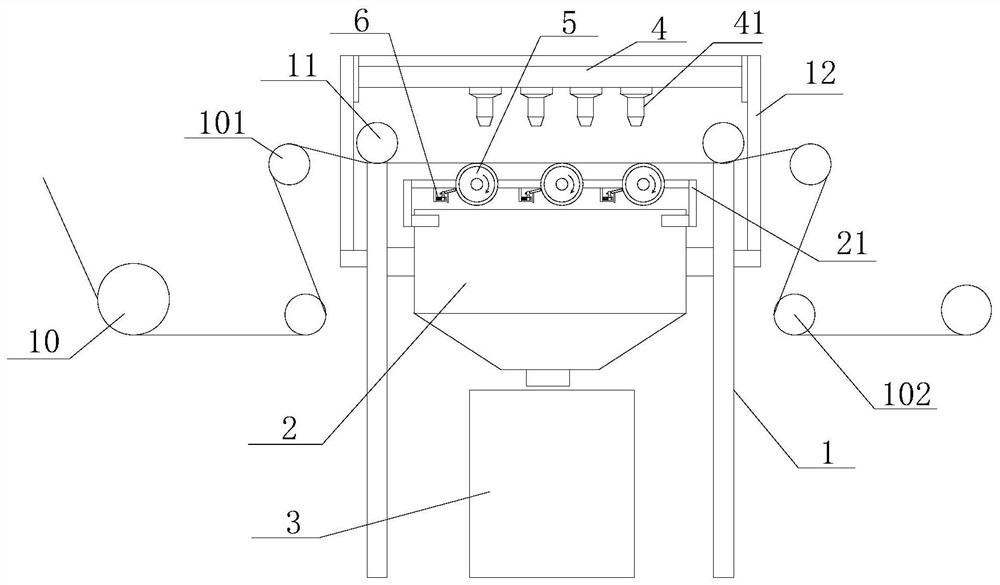

[0021] A kind of ultrasoft spunbonded non-woven double reinforcement molding process of the present invention comprises the following steps:

[0022] a) Melting and mixing of raw materials: The raw materials are fully mixed and fed into the hopper, and the raw materials are extruded and melted by a twin-screw extruder to obtain a melt. The ratio of each component in the raw materials: polypropylene PP 81-86.5 parts, propylene-based elastomer 12.5-16 parts, soft masterbatch 0.5-1.5 parts, titanium dioxide 0.5-1.5 parts;

[0023] b) Melt filtration: Extrude and melt the raw material chips obtained in step a) through a twin-screw extruder to obtain a melt, remove impurities online through a filter, and then enter the spinning system;

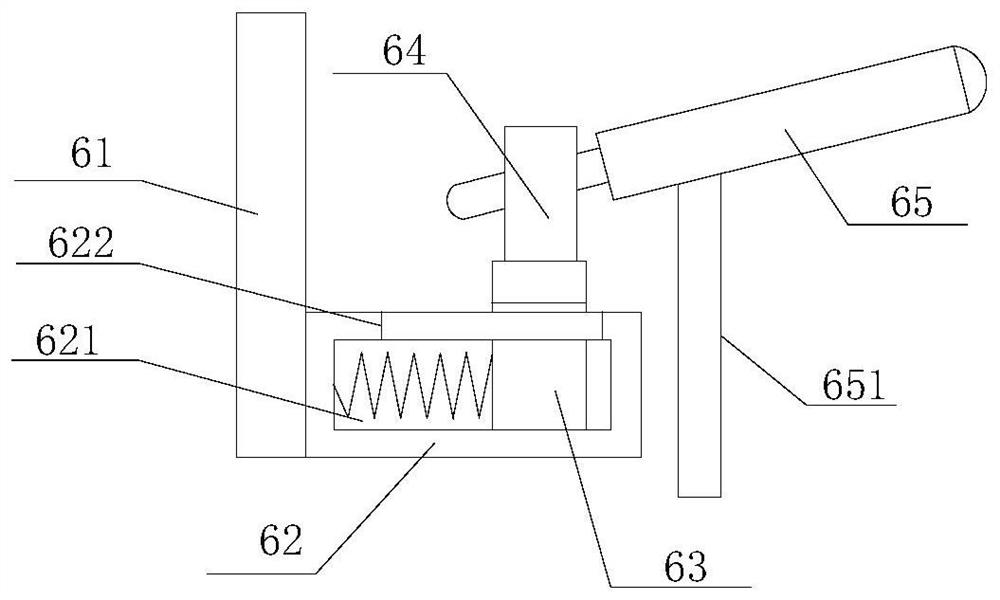

[0024] c) Spinning into a web: the melt filtered in step b) is quantitatively sent to the spinning assembly by a metering pump, and the spun silk is cooled by a side cold air to obtain a primary growth filament, and the primary growth filament is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com