TiNiAg memory alloy with antibacterial function and preparation method thereof

A memory alloy and functional technology, applied in the field of shape memory alloys, can solve the problems of inability to prepare TiNi alloys, low solid solubility, and no TiNiAg alloy patent reports, and achieve excellent antibacterial properties, small ion dissolution, and excellent corrosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail:

[0025] 1. Preparation of Ti 48.5 Ni 48.5 Ag 3 alloy:

[0026] Step 1: Weigh titanium with a purity of 99.9%, nickel with a purity of 99.9%, and silver with a purity of 99.9% according to the proportioning ratio;

[0027] Step 2: Put the titanium, nickel, and silver raw materials weighed in step 1 into a non-consumable vacuum melting furnace with a vacuum degree of 5×10 -4 Pa, filled with high-purity argon to 5×10 4 Pa, repeated smelting 3 to 6 times to obtain Ti 48.5 Ni 48.5 Ag 3 alloy ingot;

[0028] Step 3: Put the TiNiAg alloy ingot obtained in Step 2 into a heat treatment furnace, heat it at 800° C. for 2 hours, and water-cool to obtain a TiNiAg alloy ingot with uniform grain size;

[0029] Step 4: the Ti obtained in Step 3 48.5 Ni 48.5 Ag 3 The alloy ingot is rolled to obtain the desired shape of TiNiAg alloy plate;

[0030] Step five: the Ti obtained in step four 48.5 Ni 48.5 Ag...

PUM

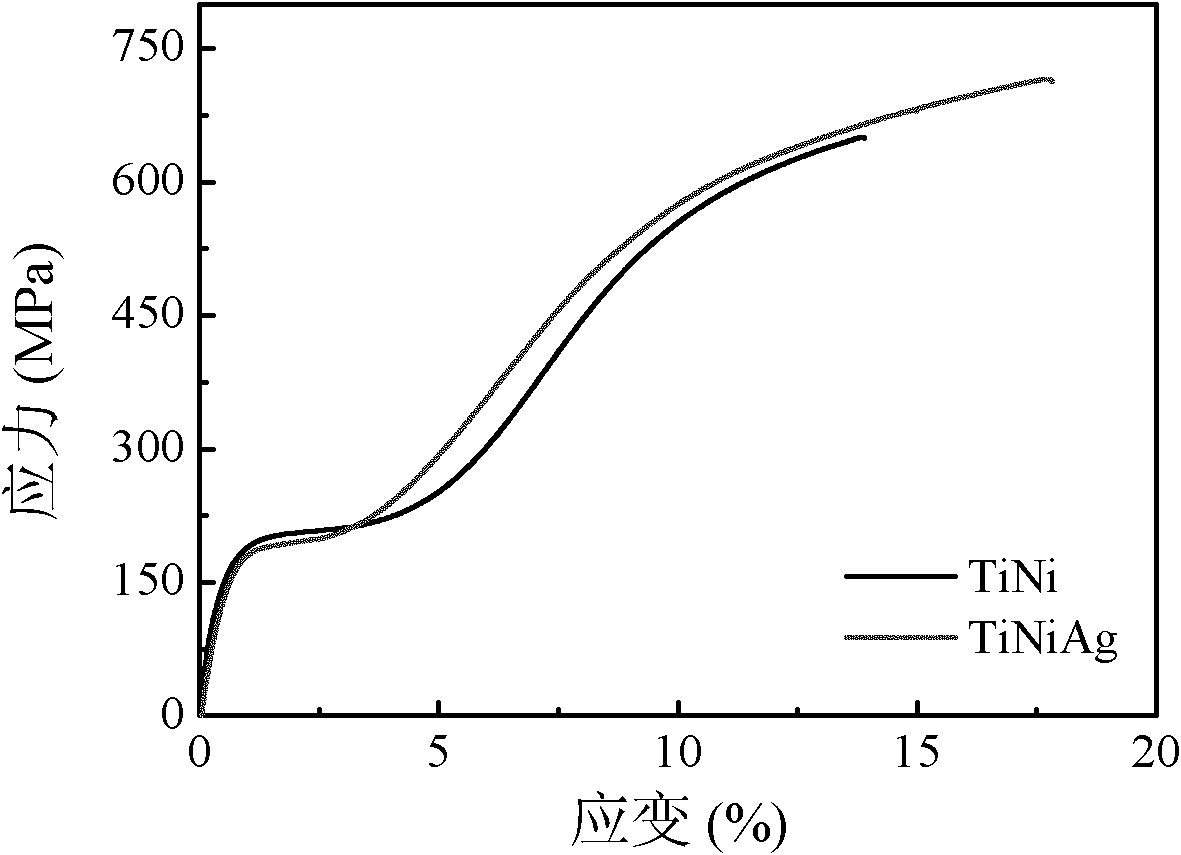

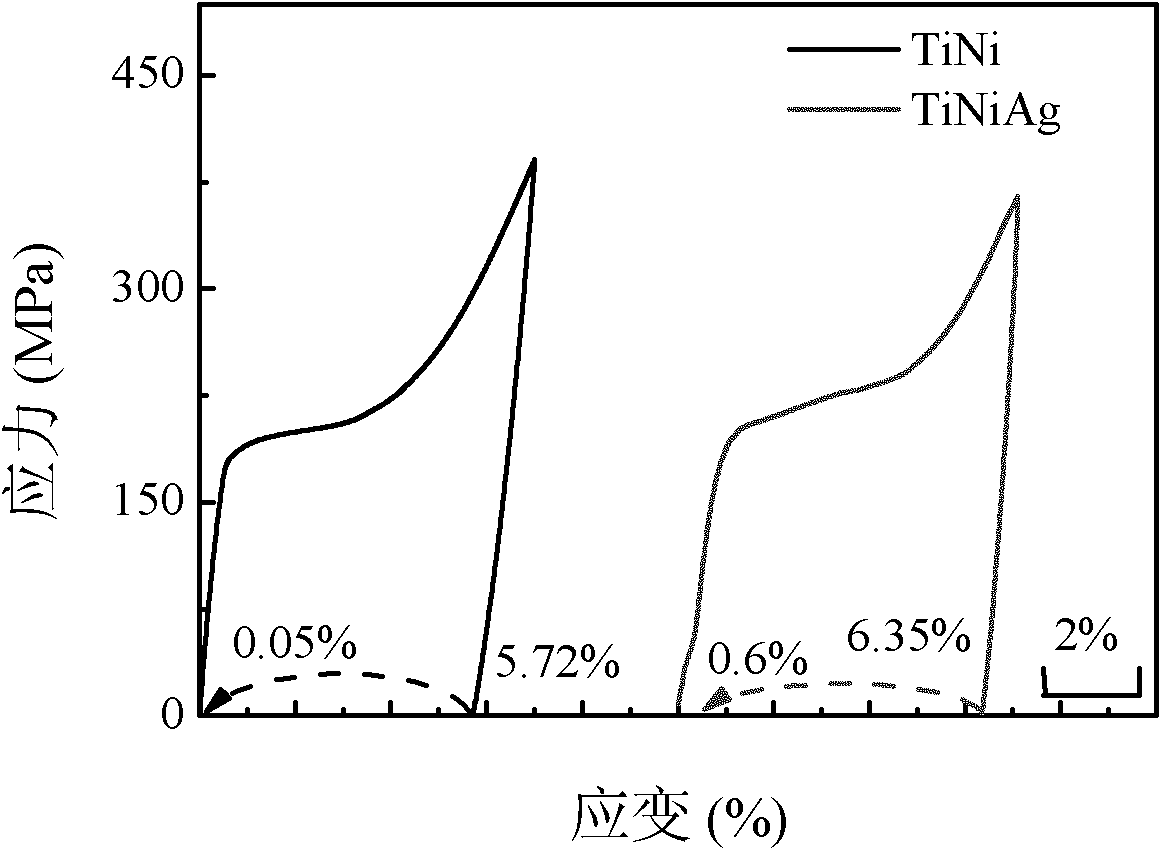

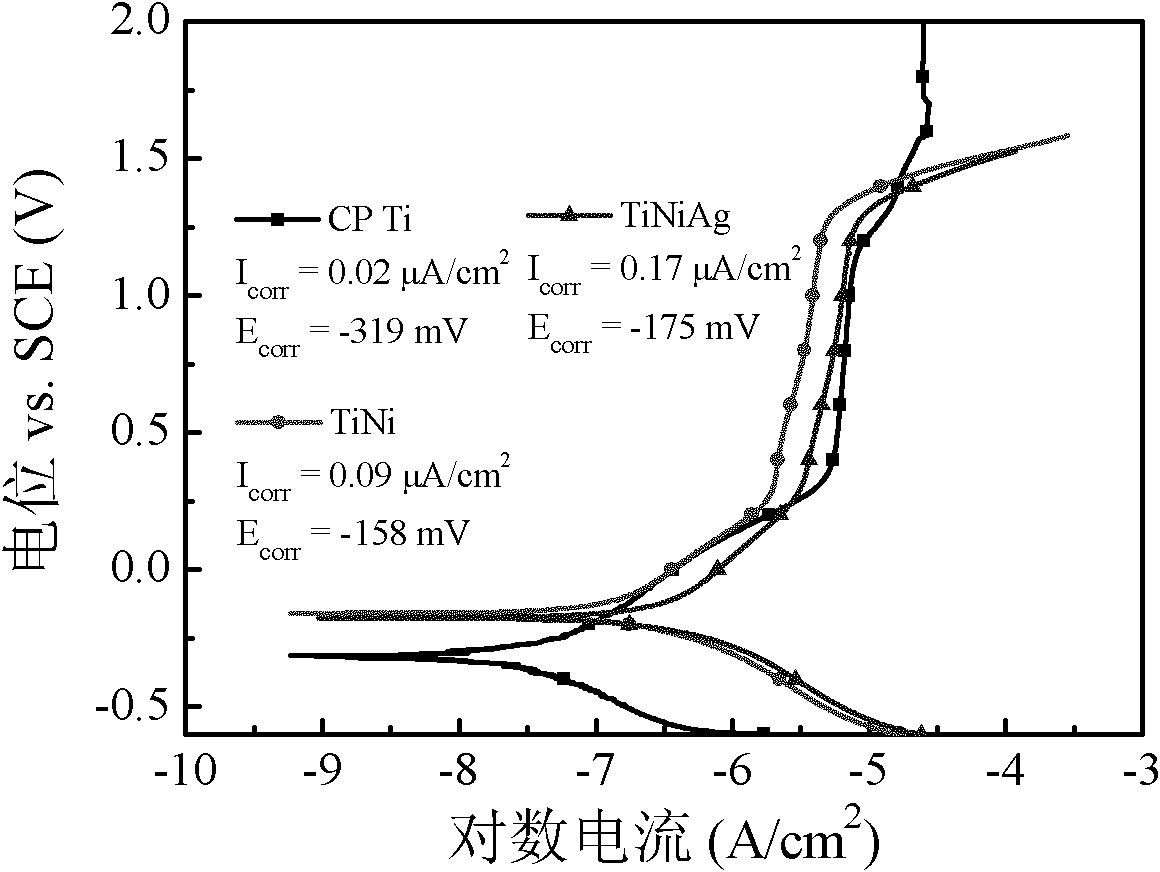

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Passivation current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com