Wear-resisting anti-microbial sweat-absorbing fabric and preparation method thereof

A fabric and antibacterial layer technology, applied in the field of textile fabrics, can solve the problems of short antibacterial time limit, poor antibacterial performance of wear-resistant antibacterial deodorant socks, etc., achieve good antibacterial performance, improve stability and long-term performance, and wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

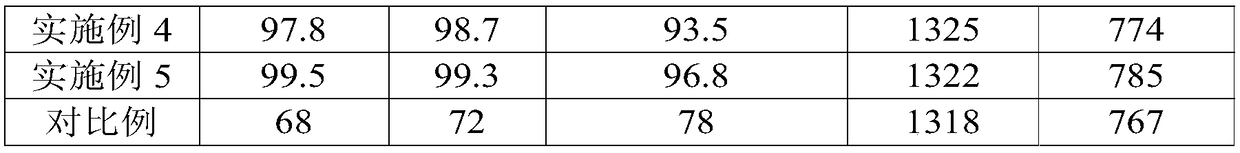

Examples

Embodiment 1

[0031] A kind of wear-resisting antibacterial sweat-absorbing fabric and preparation method thereof

[0032] The wear-resistant, antibacterial and sweat-absorbing fabric includes a wear-resistant layer and an antibacterial layer; the wear-resistant layer is made of the following fiber blends: nylon fiber 30kg, polyester fiber 35kg and bamboo fiber 15kg; the antibacterial layer is made of the following fiber blends: cotton fiber 45kg, Flax fiber 20kg.

[0033] The wear-resistant, antibacterial and sweat-absorbing fabric is prepared by the following method:

[0034] Step S10, preparing the wear-resistant layer: blending the nylon fiber, polyester fiber and bamboo fiber in the above weight ratio to obtain the wear-resistant layer fiber, and weaving it into a knitted fabric layer through a circular machine to obtain the wear-resistant layer;

[0035] Step S20, preparing an antibacterial layer:

[0036] Step S21, blending the cotton fiber and flax fiber in the above weight ratio ...

Embodiment 2

[0045] A kind of wear-resisting antibacterial sweat-absorbing fabric and preparation method thereof

[0046]The wear-resistant, antibacterial and sweat-absorbing fabric includes a wear-resistant layer and an antibacterial layer; the wear-resistant layer is made of the following fiber blends: nylon fiber 40kg, polyester fiber 20kg and bamboo fiber 12kg; the antibacterial layer is made of the following fiber blends: cotton fiber 40kg, Flax fiber 45kg.

[0047] The wear-resistant, antibacterial and sweat-absorbing fabric is prepared by the following method:

[0048] Step S10, preparing the wear-resistant layer: blending the nylon fiber, polyester fiber and bamboo fiber in the above weight ratio to obtain the wear-resistant layer fiber, and weaving it into a knitted fabric layer through a circular machine to obtain the wear-resistant layer;

[0049] Step S20, preparing an antibacterial layer:

[0050] Step S21, blending the cotton fiber and flax fiber in the above weight ratio t...

Embodiment 3

[0059] A kind of wear-resisting antibacterial sweat-absorbing fabric and preparation method thereof

[0060] The wear-resistant, antibacterial and sweat-absorbing fabric includes a wear-resistant layer and an antibacterial layer; the wear-resistant layer is made of the following fiber blends: nylon fiber 60kg, polyester fiber 25kg and bamboo fiber 5kg; the antibacterial layer is made of the following fiber blends: cotton fiber 55kg, Flax fiber 15kg.

[0061] The wear-resistant, antibacterial and sweat-absorbing fabric is prepared by the following method:

[0062] Step S10, preparing the wear-resistant layer: blending the nylon fiber, polyester fiber and bamboo fiber in the above weight ratio to obtain the wear-resistant layer fiber, and weaving it into a knitted fabric layer through a circular machine to obtain the wear-resistant layer;

[0063] Step S20, preparing an antibacterial layer:

[0064] Step S21, blending the cotton fiber and flax fiber in the above weight ratio t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com