Antibacterial sanitary ceramic glaze and preparation method

A sanitary ceramic and composite antibacterial technology, applied in the field of ceramics, can solve the problems of poor antibacterial performance, high production cost, poor antibacterial durability, etc., and achieve the effect of ensuring the antibacterial performance of glazed surfaces, low raw material costs, and eliminating odor and oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

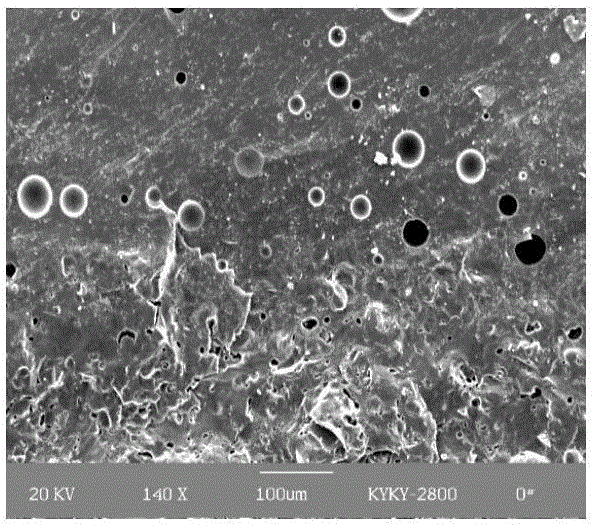

[0033] A. Preparation of composite antibacterial powder

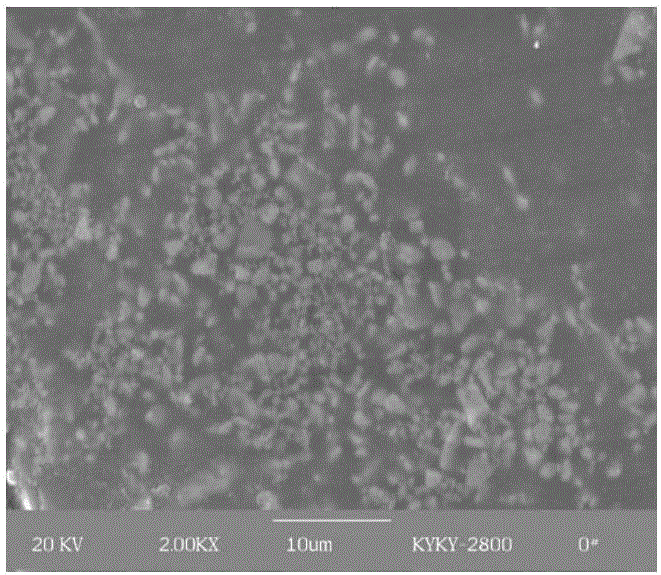

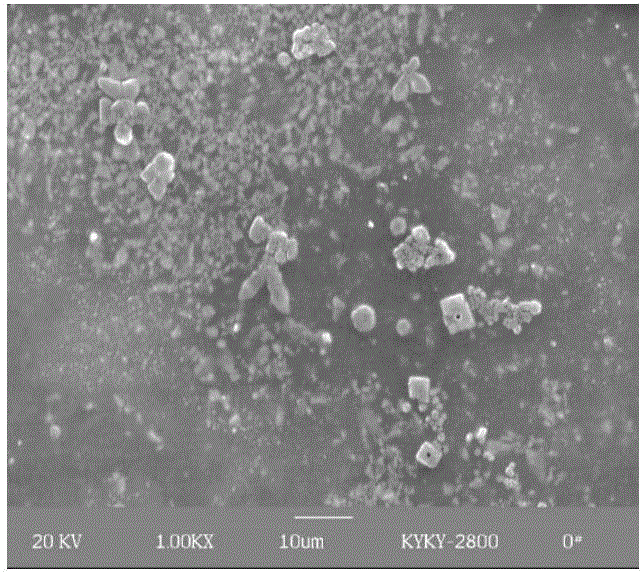

[0034] Preparation of silver molybdate powder: Silver nitrate and ammonium molybdate were added to deionized water at a molar ratio of 2:1 to prepare silver nitrate solution and ammonium molybdate solution, and the above two solutions were mixed and stirred in the reactor for 10 minutes. Then heat the reaction in a microwave oven with a power of 800W for 3 minutes, wash the obtained pale yellow precipitate with distilled water, filter, and dry at a constant temperature of 60°C for 10 hours to obtain silver molybdate powder with a particle size of 2 μm;

[0035] Preparation of zinc molybdate powder: add zinc nitrate and ammonium molybdate into deionized water at a molar ratio of 1:1.2 to prepare zinc nitrate solution and ammonium molybdate solution, and then slowly add the zinc nitrate solution to the ammonium molybdate solution , stirred for 20 minutes, the resulting white precipitate was washed with distilled water, fi...

Embodiment 2

[0042] A. Preparation of composite antibacterial powder

[0043] Preparation of silver molybdate powder: Silver nitrate and ammonium molybdate were added to deionized water at a molar ratio of 2:1.1 to prepare silver nitrate solution and ammonium molybdate solution, and the above two solutions were mixed and stirred in the reactor for 13 minutes. Then heat and react in a microwave oven with a power of 900W for 4min, the obtained pale yellow precipitate is washed with distilled water, filtered, and dried at a constant temperature of 65°C for 11h to obtain silver molybdate powder with a particle size of 3μm;

[0044] Preparation of zinc molybdate powder: add zinc nitrate and ammonium molybdate into deionized water at a molar ratio of 1:1.2 to prepare zinc nitrate solution and ammonium molybdate solution, and then slowly add the zinc nitrate solution to the ammonium molybdate solution , stirred for 25 minutes, the resulting white precipitate was washed with distilled water, filte...

Embodiment 3

[0051] A. Preparation of composite antibacterial powder

[0052] Preparation of silver molybdate powder: Silver nitrate and ammonium molybdate were added to deionized water at a molar ratio of 2:1.2 to prepare silver nitrate solution and ammonium molybdate solution, and the above two solutions were mixed and stirred in the reactor for 15 minutes. Then heat and react in a microwave oven with a power of 1000W for 5min, the obtained pale yellow precipitate is washed with distilled water, filtered, and dried at a constant temperature of 70°C for 12h to obtain silver molybdate powder with a particle size of 4μm;

[0053] Preparation of zinc molybdate powder: add zinc nitrate and ammonium molybdate into deionized water at a molar ratio of 1:1.2 to prepare zinc nitrate solution and ammonium molybdate solution, and then slowly add the zinc nitrate solution to the ammonium molybdate solution , stirred for 30 minutes, the resulting white precipitate was washed with distilled water, filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com