Antimicrobial self-cleaning PPR pipe

A self-cleaning and pipe technology, applied in the field of pipes, can solve the problems that the antibacterial properties cannot be exerted normally, the antibacterial effect cannot be achieved, and the pipes have no self-cleaning function, etc., and the effect of lasting antibacterial effect and obvious shrinkage and expansion can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] To make an antibacterial self-cleaning PPR pipe, including the pipe body, first prepare 880kg of random copolymerized polypropylene (PPR), 60kg of polyolefin elastomer (POE), nanosilica-loaded nano-silver antibacterial agent (nanosilver SiO 2 ) 20kg. Prepare tubing as follows.

[0038] 60kg of POE material and 6kg of nano-silver SiO 2 Melt blending first, and then melt blending with 880kg of PPR material, which can make the PPR blending material have more obvious shrinkage and expansion, and increase the coefficient of thermal expansion; then blend the blending material with the remaining 14kg of nano-silver SiO 2 Melt blending, which can make the PPR blended material have antibacterial properties; then put it into an extruder for extrusion granulation to obtain granular materials.

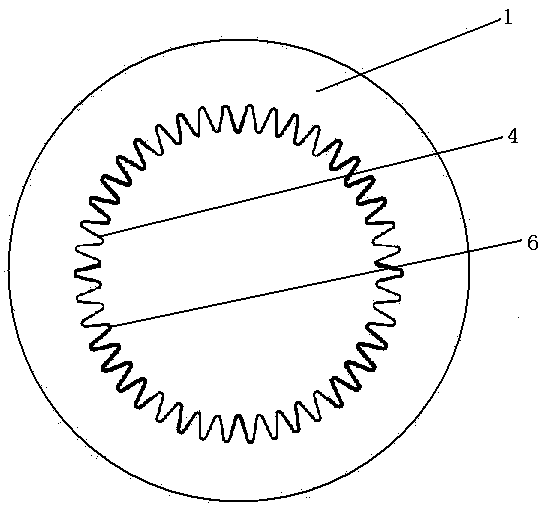

[0039] Put the granular material into the hopper of the pipe extruder, and replace the die mandrel of the pipe extruder with an arc-turned surface die mandrel in advance, and the arc-tur...

Embodiment 2

[0043] To make an antibacterial self-cleaning PPR pipe, including the pipe body, first prepare 890kg of random copolymerized polypropylene (PPR), 70kg of polyolefin elastomer (POE), nano-silica loaded nano-silver antibacterial agent (nanosilver SiO 2 ) 30kg. Prepare tubing as follows.

[0044] 70kg of POE material and 7.0kg of nano-silver SiO 2 Melt blending first, then melt blending with 890kg of PPR material, and then blending the blended material with 23.0kg nano-silver SiO 2 Melt blending; then put into an extruder for extrusion granulation to obtain granular materials.

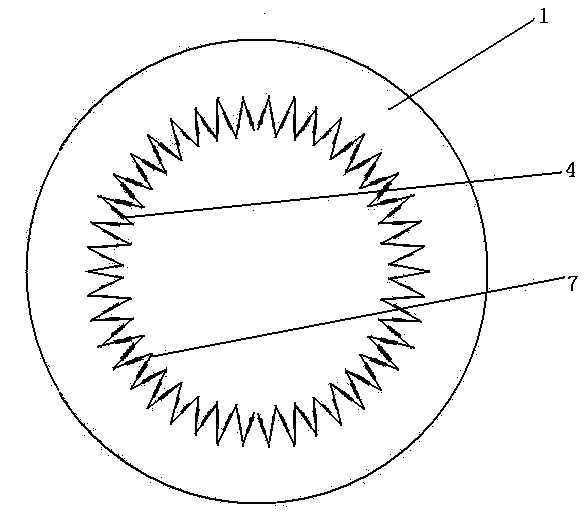

[0045] Put the granular material into the hopper of the pipe extruder; and replace the mandrel of the pipe mold with a straight-rotating surface mandrel, which is to make the outer surface into a straight-rotation fold from the longitudinal direction Then set the mold temperature at 195°C, melt and extrude the PPR blended material to obtain a PPR pipe, and then pass it through a vacuum setting machine...

Embodiment 3

[0047] To make an antibacterial self-cleaning PPR pipe, including the pipe body, first prepare 900kg of random copolymerized polypropylene (PPR), 80kg of polyolefin elastomer (POE), nanosilica-loaded nano-silver antibacterial agent (nanosilver SiO 2 ) 40kg. Prepare tubing as follows.

[0048] Put POE material 80kg and 8kg nano silver SiO 2 Melt blending first, then melt blending with 900kg of PPR material, and then blending the blended material with 32kg of nano-silver SiO 2 Melt blending; then put into an extruder for extrusion granulation to obtain granular materials.

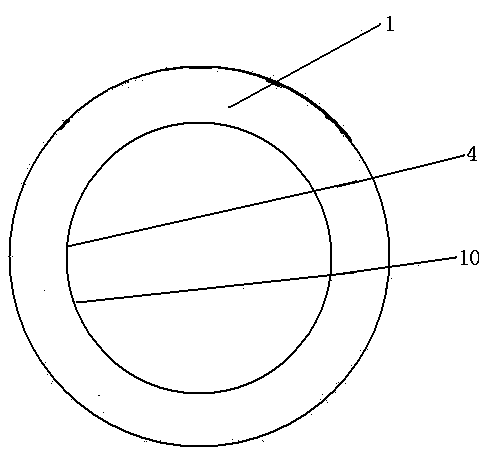

[0049] Add the granular material into the hopper of the pipe extruder, and the mandrel of the pipe mold in the extruder adopts a conventional smooth surface mandrel; then set the mold temperature to 205°C, and melt and extrude the PPR blended material. The PPR pipe is prepared, then shaped by a vacuum setting machine, and pulled out by a tractor after cooling to obtain an antibacterial self-cleaning PPR p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com