Preparation method of efficient and antibacterial composite film with water-meeting sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

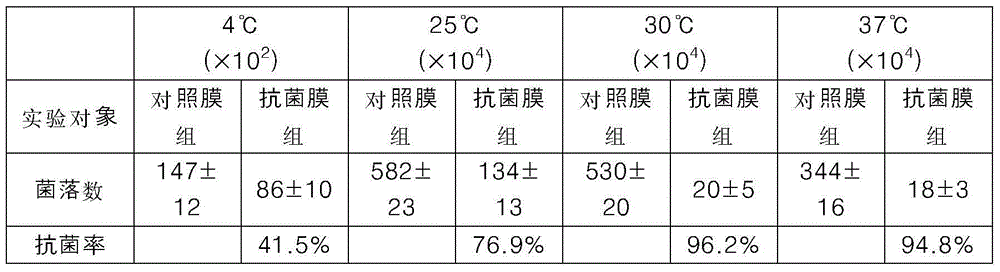

Embodiment 1

[0037] The preparation of embodiment 1 natural essential oils polyethylene antibacterial film:

[0038] Realize the immobilization of natural essential oils in polyethylene films, rely on the volatilization of natural essential oils, and effectively improve the antibacterial efficiency of antibacterial films through the atmosphere-type antibacterial effect; due to the use of natural essential oils as antibacterial agents, their own safety and stability More reliable, and then realized the non-toxic characteristics of the antibacterial film.

[0039] The specific implementation steps are as follows:

[0040] (1) Preparation of high-concentration natural essential oil masterbatch with natural essential oil and low melting point polymer:

[0041] In this example, mustard oil is used as a typical natural essential oil for description:

[0042] Mix the antioxidant into 20 kg of mustard oil and stir evenly; add 70 kg of ethylene-vinyl acetate copolymer and 10 kg of ethylene-propyl...

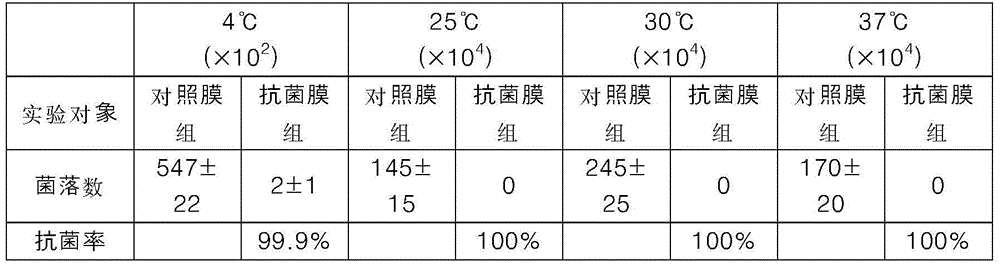

Embodiment 2

[0059] The preparation of embodiment 2 natural essential oil / solid chlorine dioxide class polyethylene antibacterial film

[0060] (1) Preparation of high-concentration natural essential oil masterbatch with natural essential oil and low melting point polymer:

[0061] In this example, mustard oil is used as a typical natural essential oil for description:

[0062] Mix the antioxidant into 20 kg of mustard oil and stir evenly; add 70 kg of ethylene-vinyl acetate copolymer and 10 kg of ethylene-propylene copolymer into the kneader, and then add the mustard oil into the kneader batch by batch. Knead well until the mustard oil is absorbed into the polymer resin matrix.

[0063] (2) Preparation of natural essential oil masterbatch: Add the above-prepared resin directly into a single-screw extruder, extrude and granulate below 120°C, and use air cooling as the main cooling method to prepare natural essential oil with a concentration of 20%. Essential oil masterbatch (granule 0). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com