Fiber reinforced pipe for mine and production method thereof

A fiber-reinforced mine technology, applied to chemical instruments and methods, pipes, rigid pipes, etc., can solve the problems of high antistatic requirements and flame retardant requirements, inconvenient installation and transportation, and inability to use underground mines, etc. Flame retardant and antistatic properties, easy installation and transportation, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

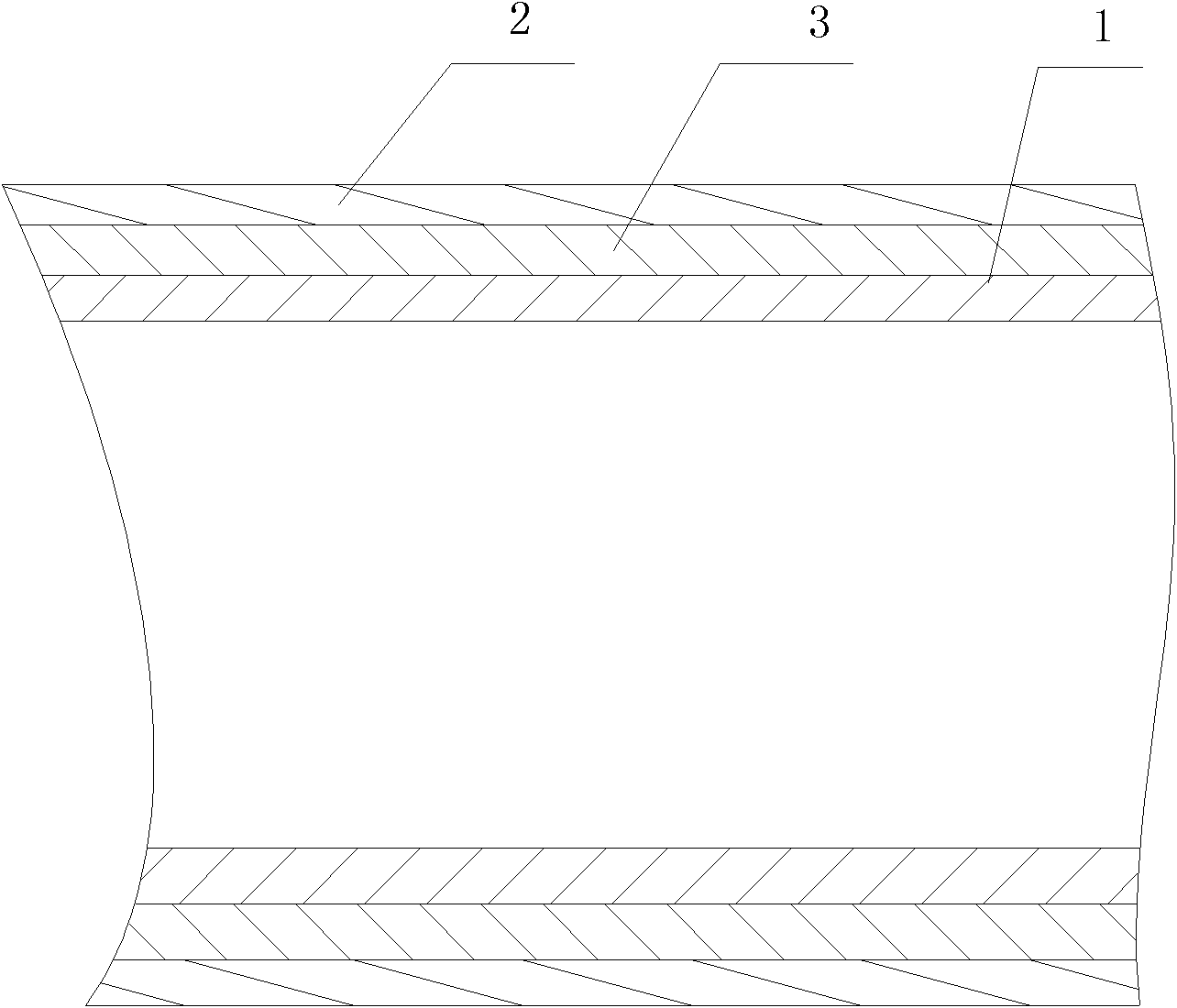

[0037] A processing method for fiber-reinforced pipes used in mines, a. processing flame-retardant and antistatic polyethylene liner pipes;

[0038] a1. Put special raw materials for flame retardant and antistatic polyethylene (polyethylene 70%, flame retardant 26%, antioxidant 2% and coupling agent 2%) into the extruder, extrude through the extruder, and heat During the process, the extrusion temperature of the flame-retardant and antistatic polyethylene pipe is controlled within the range of 160°C; after extrusion, it undergoes vacuum shaping, cooling, traction, and cutting; b. Use a winding machine to evenly cross the outer peripheral surface of the liner Winding fibers to form a fiber reinforced layer; the rotation speed of the fibers is determined according to different pipe diameters, generally 180 rpm; c, through the extruder, the flame-retardant antistatic polyethylene special material (polyethylene 70 %, flame retardant 26%, antioxidant 2% and coupling agent 2%) extru...

Embodiment 2

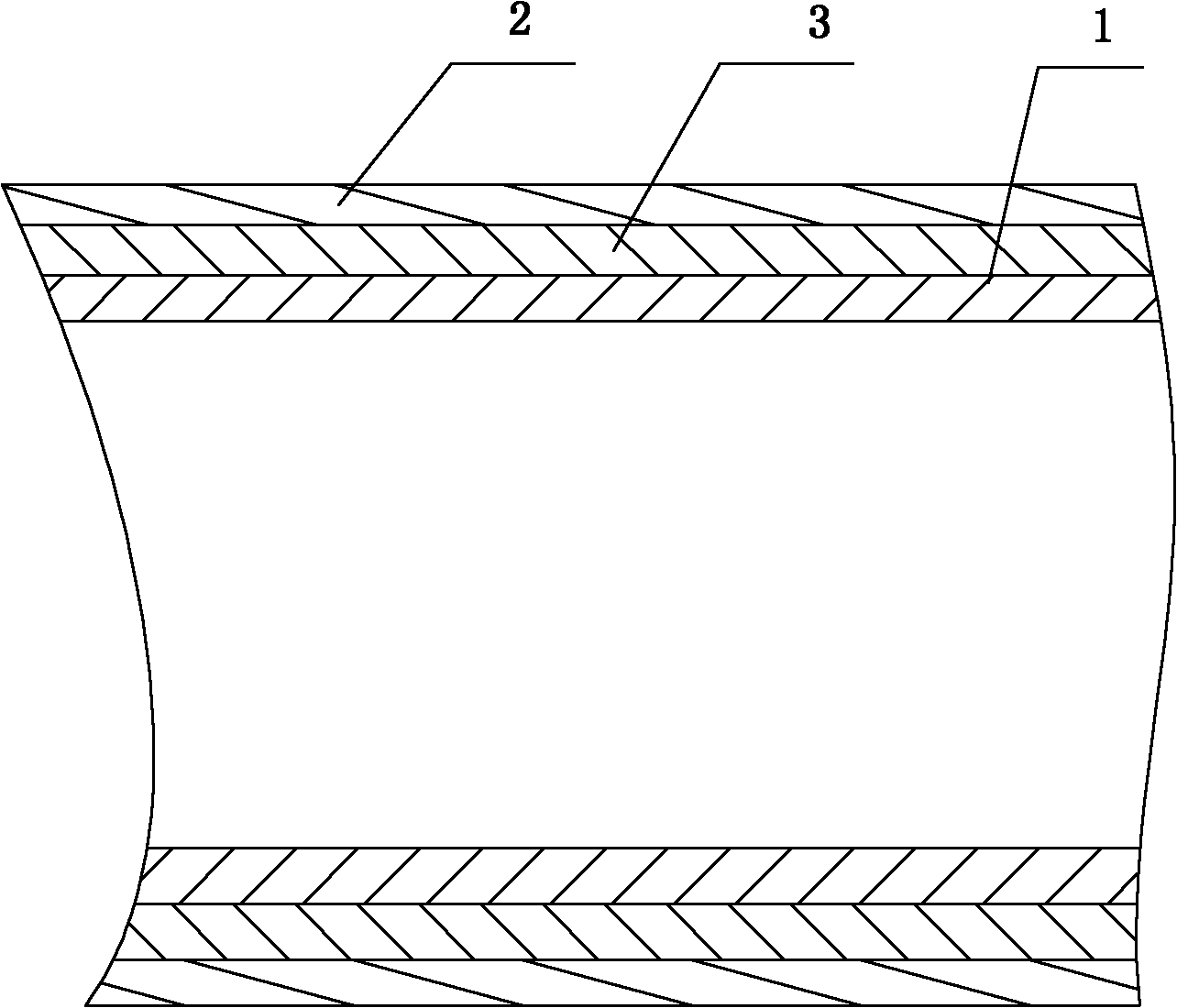

[0041] A processing method for fiber-reinforced pipes used in mines, a. processing flame-retardant and antistatic polyethylene liner pipes;

[0042] a1. Put special raw materials for flame retardant and antistatic polyethylene (polyethylene 70%, flame retardant 28%, antioxidant 1% and coupling agent 1%) into the extruder, extrude through the extruder, and heat During the process, the extrusion temperature of the flame-retardant and antistatic polyethylene pipe is controlled within the range of 160 °C; it undergoes vacuum shaping, cooling, traction, and cutting in sequence; b. Winding fibers that are uniformly crossed on the outer peripheral surface of the inner liner by a winding machine , forming a fiber reinforced layer; the rotation speed of the fiber is determined according to different pipe diameters, generally 250 revolutions per minute; c, through the extruder, the flame-retardant and antistatic polyethylene special material (polyethylene 70%, resistance Combustion agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com