Patents

Literature

39results about How to "Prevent accidental explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

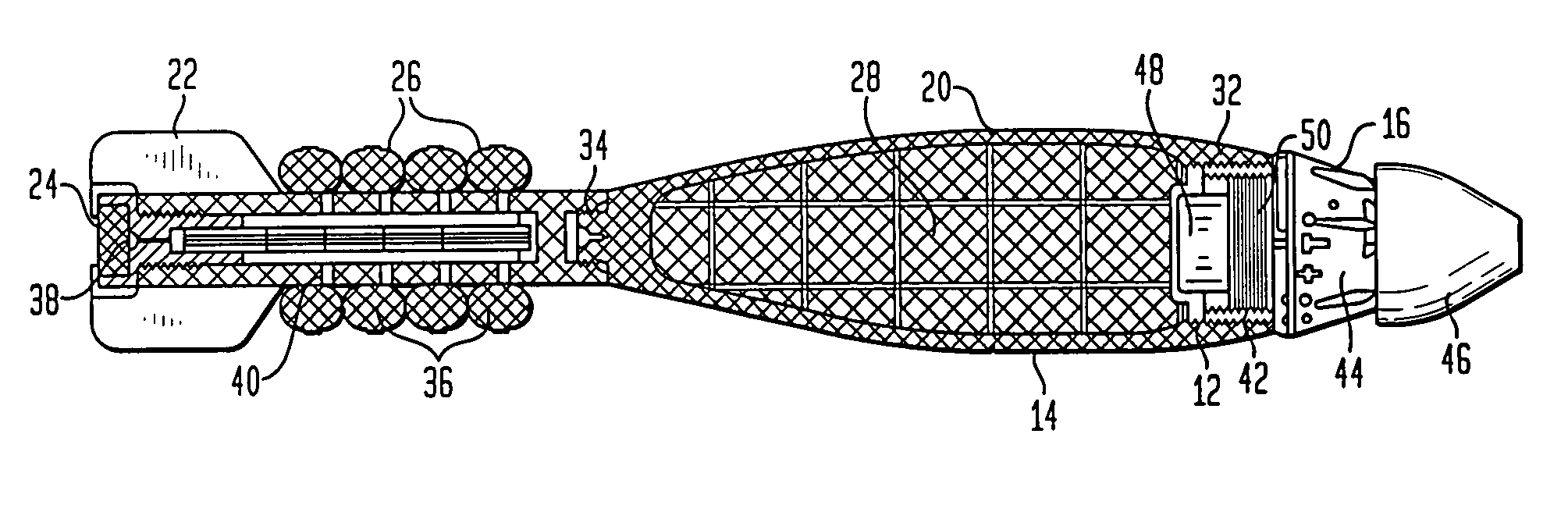

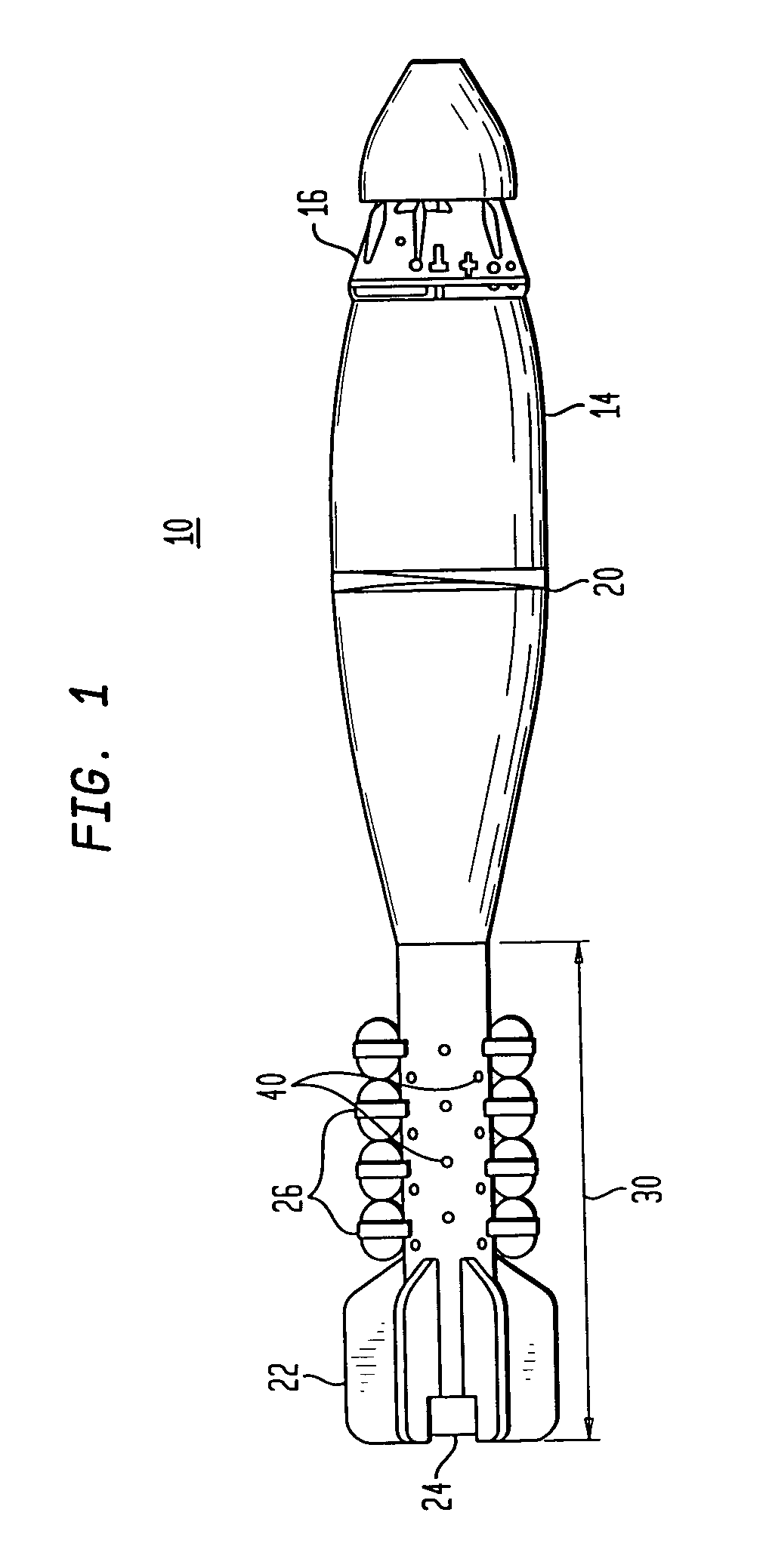

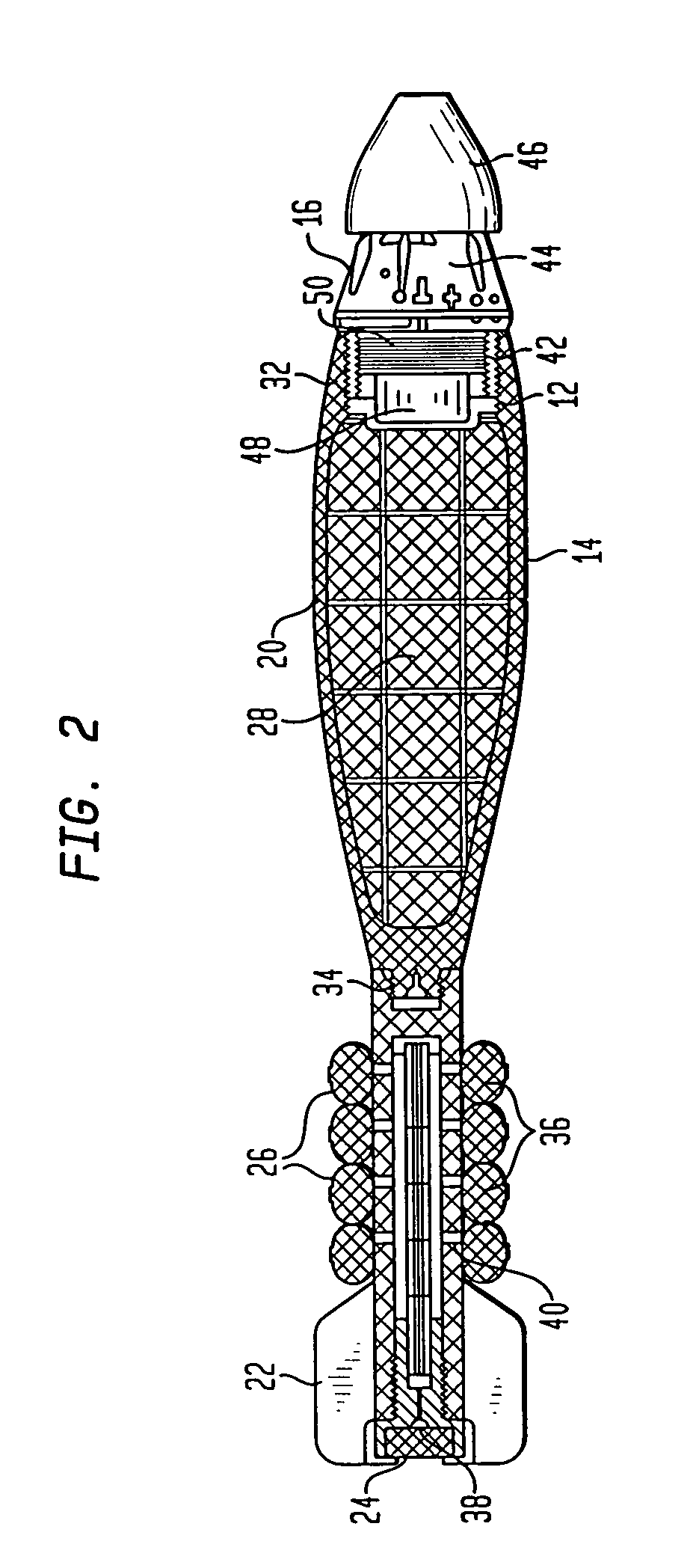

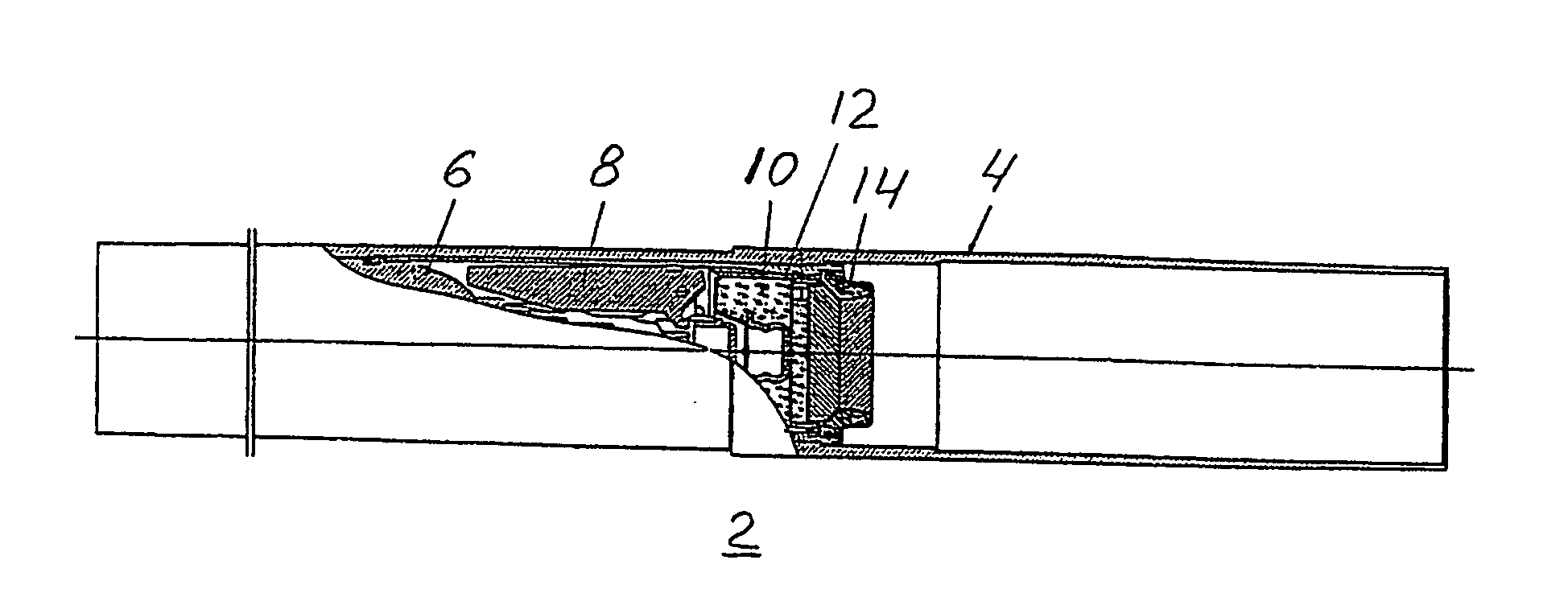

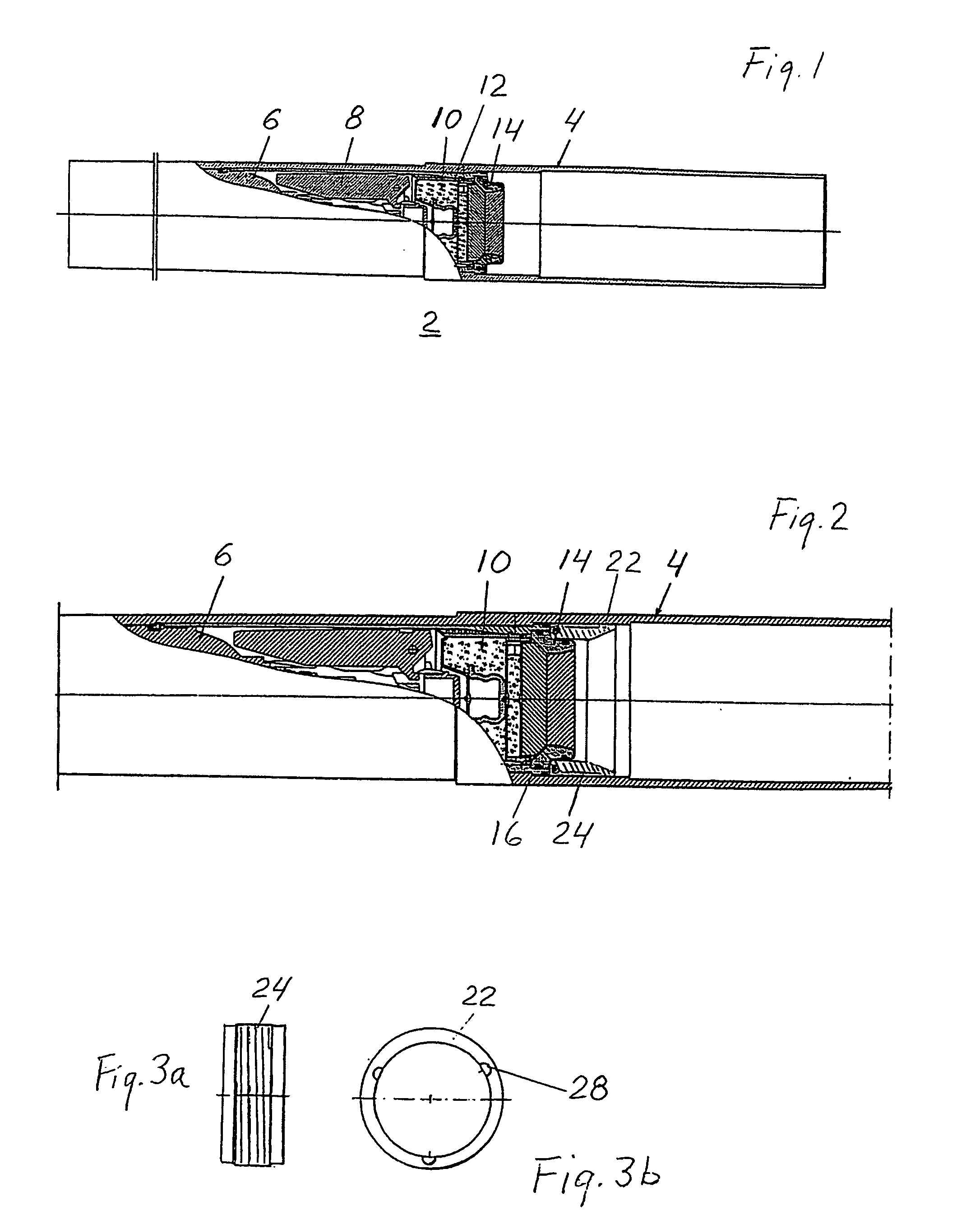

Mechanism for reducing the vulnerability of high explosive loaded munitions to unplanned thermal stimuli

InactiveUS7025000B1Reduce vulnerabilityImprove personnel safetyAmmunition storageAmmunition loadingPersonnel safetyFuze

A new mechanism substantially reduces the vulnerability of explosive load munitions to thermal stimuli, such as fire or heat during transport and storage, thus enhancing personnel safety and the survivability of adjacent munitions. The mechanism includes a threaded fuze adapter made of plastic and having a melting temperature that is lower than the auto-ignition temperature of the explosive. The adapter secures a fuze or metal closing plug to an explosive loaded projectile and is designed to permit venting of combustion gases through the nose of the projectile upon auto-ignition of the explosive, thereby preventing detonation of the explosive and fragmentation of the projectile body. A plastic or metal ring is utilized to support the body of an explosive loaded projectile within a fiberboard packing tube, thus allowing the fuze to readily separate from the projectile body upon the melting of the plastic threaded fuze adapter and subsequent combustion of the explosive during an unplanned thermal stimulus event. An intumescent coating is deposited on the metal ammunition container that is used to package explosive loaded cartridges, to reduce the rate of thermal stimuli to the munitions, thereby ensuring that the plastic fuze adapter of the present invention reaches its melting temperature prior to the explosive attaining its auto-ignition temperature.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

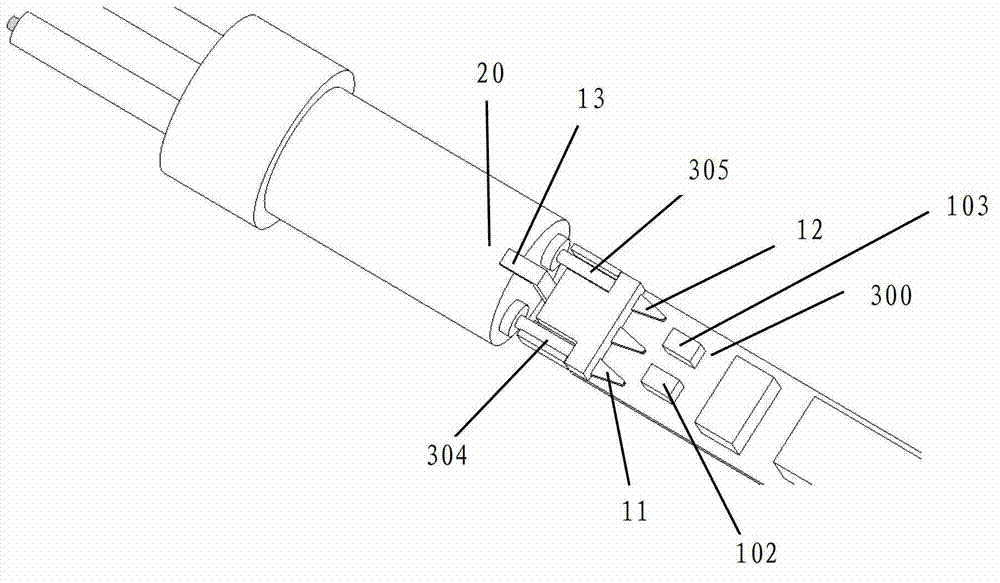

Anti-static structure of electronic detonator

ActiveCN103033100AAvoid damagePrevent accidental explosionAmmunition fuzesDetonatorElectrical resistance and conductance

The invention provides an anti-static structure of an electronic detonator, wherein two leg wires of the electronic detonator are electrically connected with a control circuit of a control circuit board. The anti-static structure of the electronic detonator is characterized by further comprising a discharge metal connecting piece; one end of the discharge metal connecting piece is electrically connected with a metal casing of the electronic detonator; two anti-static electronic devices are connected between the other end of the discharge metal connecting piece and one leg wire, as well as between the other end of the discharge metal connecting piece and the other leg wire respectively; and the anti-static electronic devices are transient suppression diodes, discharge tubes or voltage dependent resistors. By additionally arranging the anti-static structure on the electronic detonator, electricity can be preferentially discharged through the anti-static devices when the electronic detonator carries out electrostatic discharge, so that an error explosion can be prevented in the production and use processes; and moreover, one leg wire of the electronic detonator is connected with a first metal connecting piece and a second metal connecting piece in a manner of metal compression joint, the connecting operation is simple, tensile resistance is strong, and the electronic detonator can be prevented from being damaged by an external force in the production and use processes.

Owner:BEIJING QAML OF SCI & TECH CO LTD

Passive flameproof device of shock wave triggered touch type instantaneous open valve

The invention provides a passive flameproof device of a shock wave triggered touch type instantaneous open valve. A shock wave receiving disk is connected with a bolt at the back end of an impacting guide rod. An adjusting column is used for fixing the impacting guide rod. The front end of the impacting guide rod is connected with an impacting pin. A pressure storage barrel is inserted inside a powder storage barrel in sleeve. The upper and lower ports of the pressure storage barrel pass through the outside of the powder storage barrel and a pressure gauge and an inflatable valve are respectively arranged outside the powder storage barrel. Jet holes are arranged at the end of the pressure storage barrel. A sealing diaphragm is used for sealing between the pressure storage barrel and a touch type trigger. A contact piston and a spring are arranged at the end of pressure storage barrel. The front end of the powder storage barrel is provided with the sealing diaphragm for sealing. The passive flameproof device of the shock wave triggered touch type instantaneous open valve can achieve rapid spraying of fire extinguishing medium within 20 milliseconds and high-efficiency concentrationfire extinguishing of 110g / m3, and form a flameproof fog surface lasting more than 1500 milliseconds to extinguish combustion and explosion flame. The passive flameproof device of the shock wave triggered touch type instantaneous open valve has good sealing performance, effectively avoids the occurrence of false alarm and false attack and has good stability, practicability, reliability, advancement and safety.

Owner:SHANXI XINSIBEI TECH

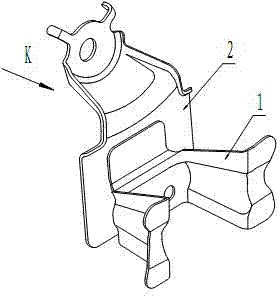

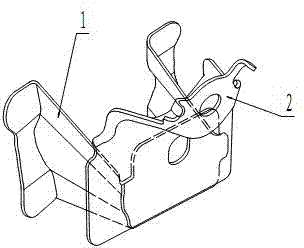

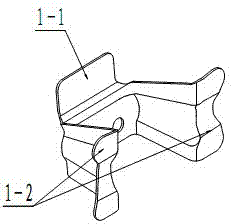

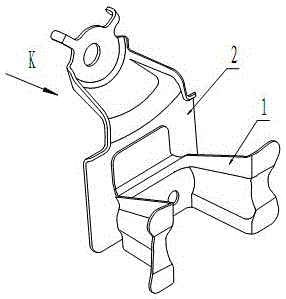

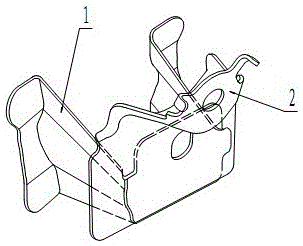

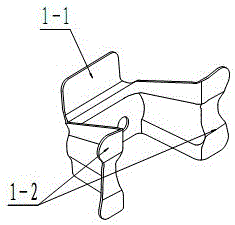

Automobile safety belt retractor installation structure

The invention discloses an automobile safety belt retractor installation structure and belongs to the technical field of automobile body accessories. The automobile safety belt retractor installation structure comprises a safety belt retractor support and safety belt retractor support reinforcing plates. The safety belt retractor support, the safety belt retractor support reinforcing plates and an automobile body B-pillar inner plate are connected together through three-layer welding spots. The safety belt retractor support and the automobile body B-pillar inner plate are further fixedly connected through other two-layer welding spots. The safety belt retractor support reinforcing plate and an automobile body B-pillar inner plate reinforcing plate are fixedly connected through other two-layer welding spots. The automobile safety belt retractor installation structure has the advantages of being simple in structure, low in cost, convenient to install and beneficial to engineered mass production; in addition, the automobile safety belt retractor installation structure meets installation requirements of an automobile safety belt retractor, improves rigidity of the safety belt retractor support, avoids the phenomenon of sudden spontaneous firing of side air bags and improves safety in automobile driving.

Owner:GREAT WALL MOTOR CO LTD

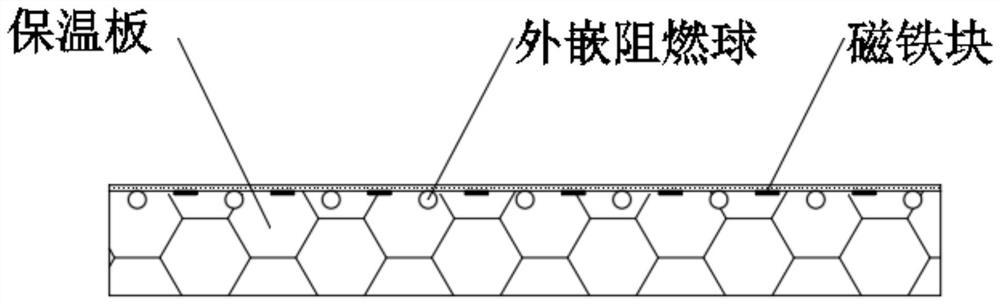

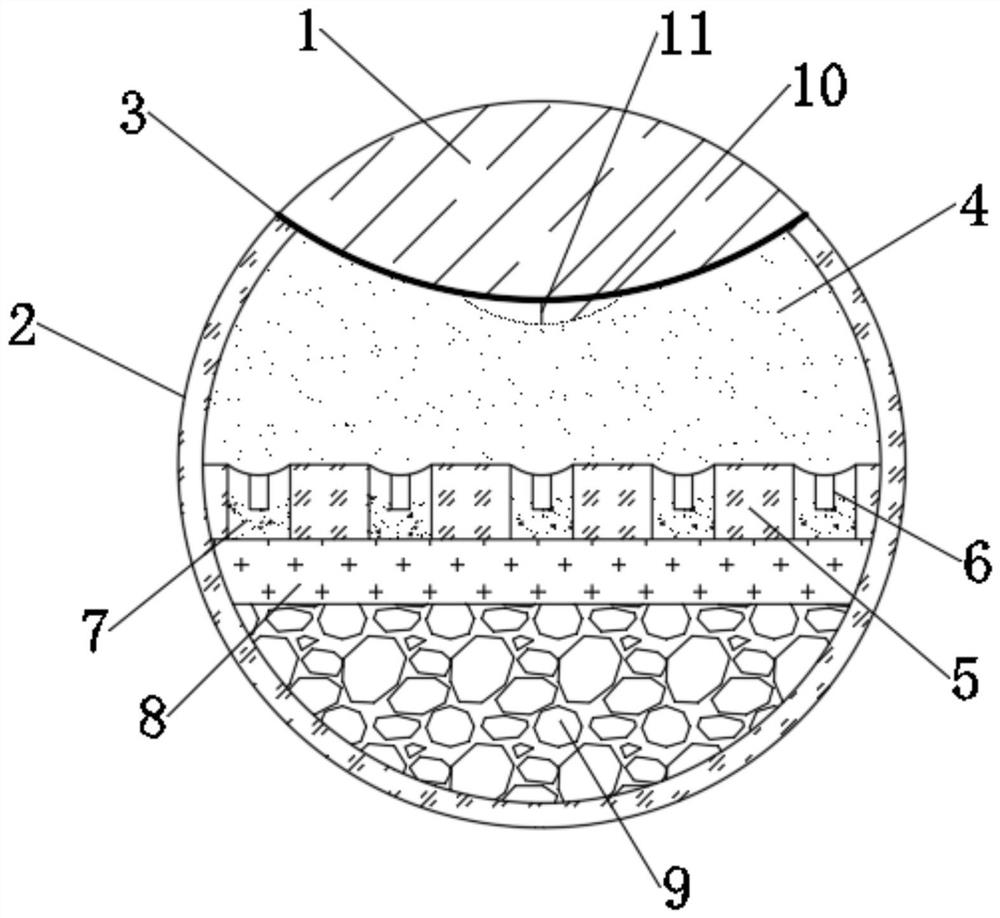

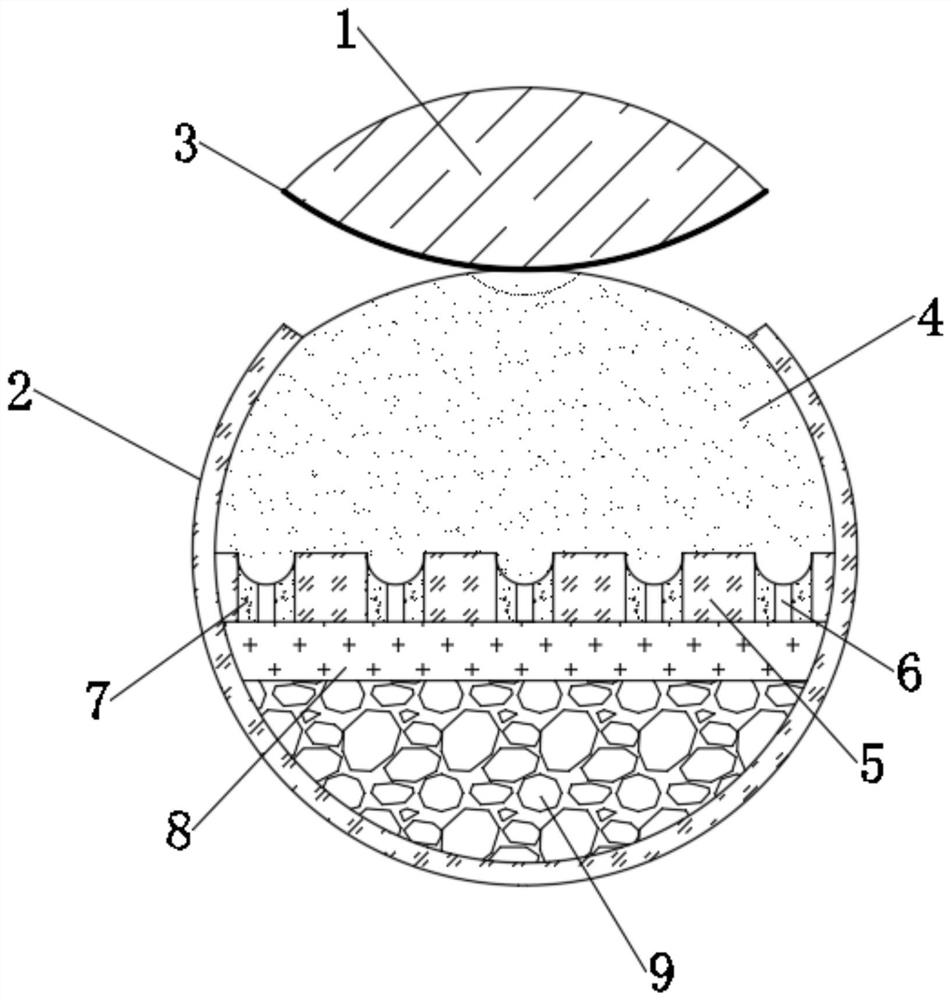

Fabricated building structure insulation board

InactiveCN112961443AImprove fire and flame retardant effectBroaden applicationOpen fireMechanical engineering

The invention discloses a fabricated building structure insulation board, and belongs to the technical field of fabricated constructions. According to the fabricated building structure insulation board, raw materials of an existing insulation board are improved, magnet blocks are inlaid in the surface of the insulation board in a staggered mode, and flame-retardant balls are externally embedded in the surface of the insulation board, so when the insulation board encounters open fire, the externally-embedded flame-retardant balls sense the high temperature firstly and then expand gradually; the fire extinguishing material is released to extinguish open fire until the fire extinguishing material expands to a certain degree and then explodes; once the fire is large and cannot be extinguished, the externally-embedded flame-retardant balls can be further disintegrated and release magnetic flame-retardant materials, and then the magnetic flame-retardant materials are transferred out of the externally-embedded flame-retardant balls and cover the surface of the heat preservation plate under the magnetic attraction effect of the magnet blocks, and an integral fireproof layer is formed to carry out flame-retardant protection on the insulation board; compared with an existing insulation board, the fireproof and flame-retardant effects of the insulation board are remarkably improved, and the application of the insulation board in the field of prefabricated buildings is effectively expanded.

Owner:程伟

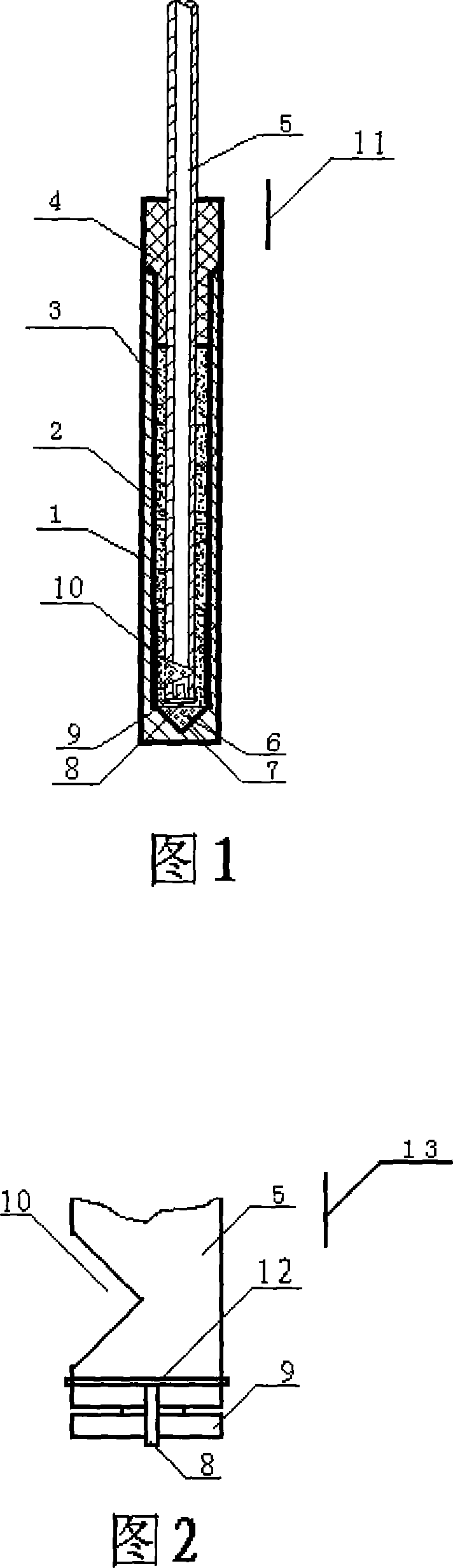

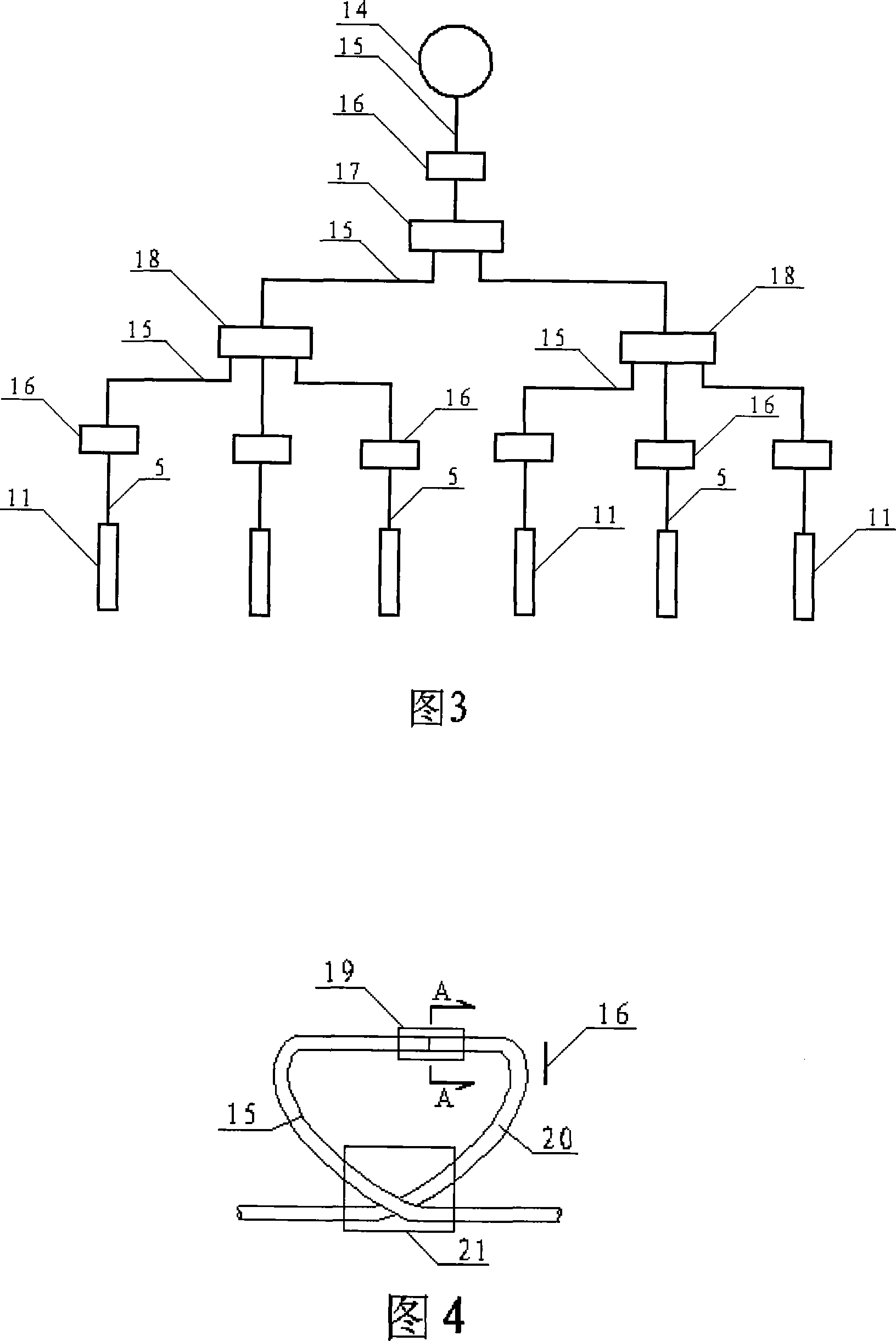

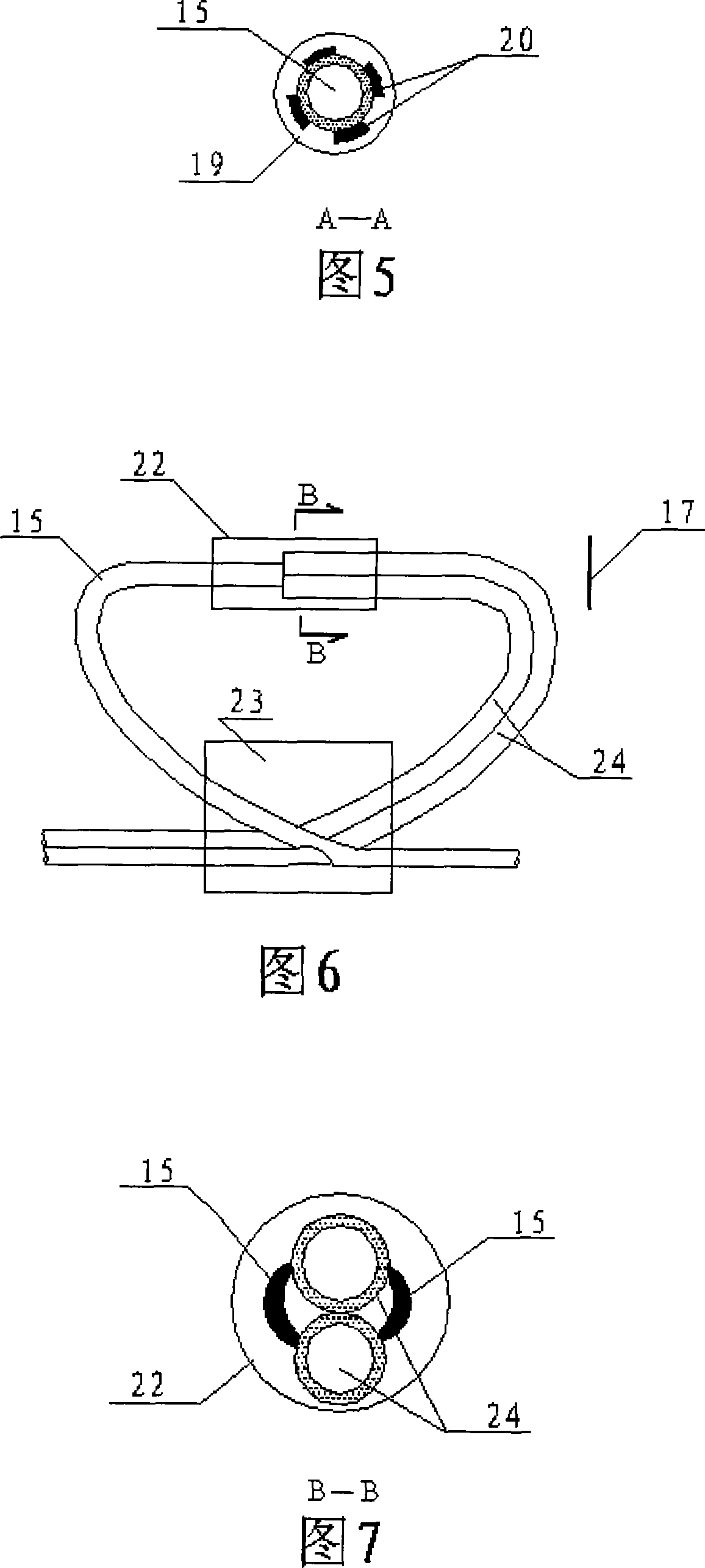

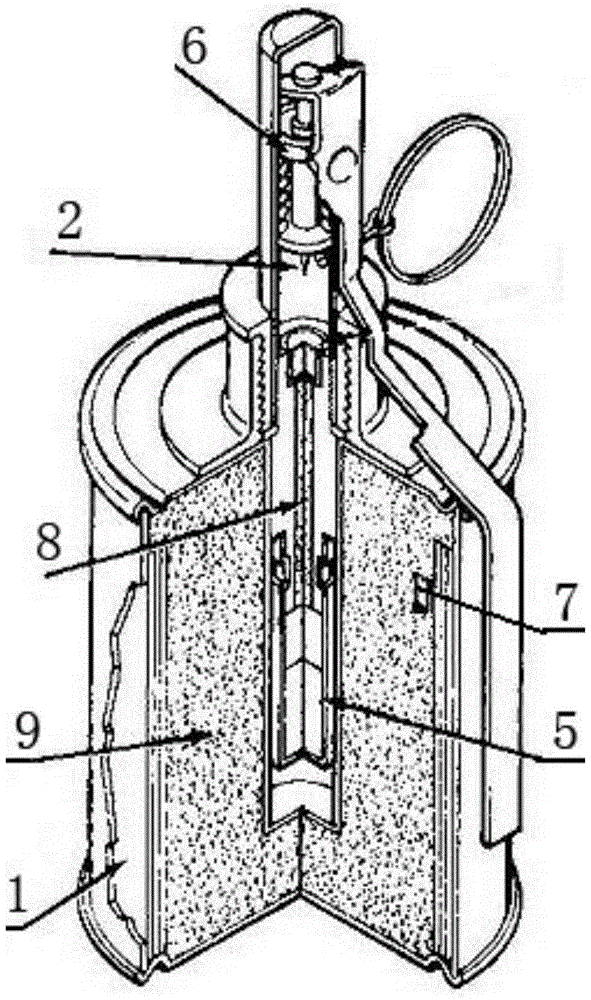

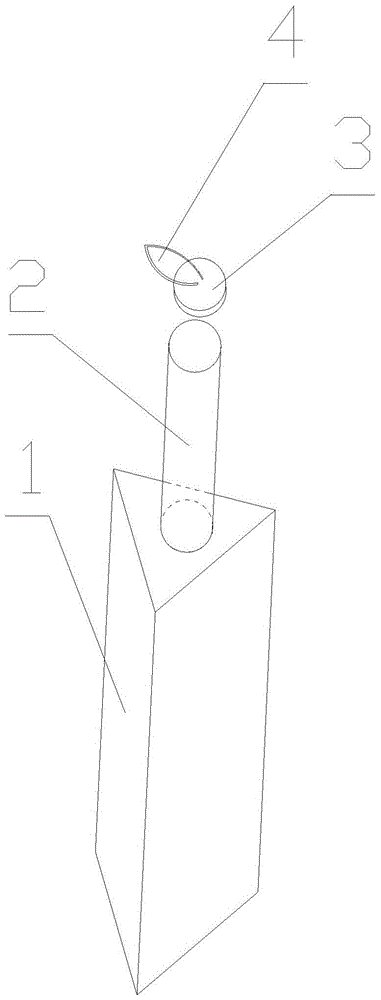

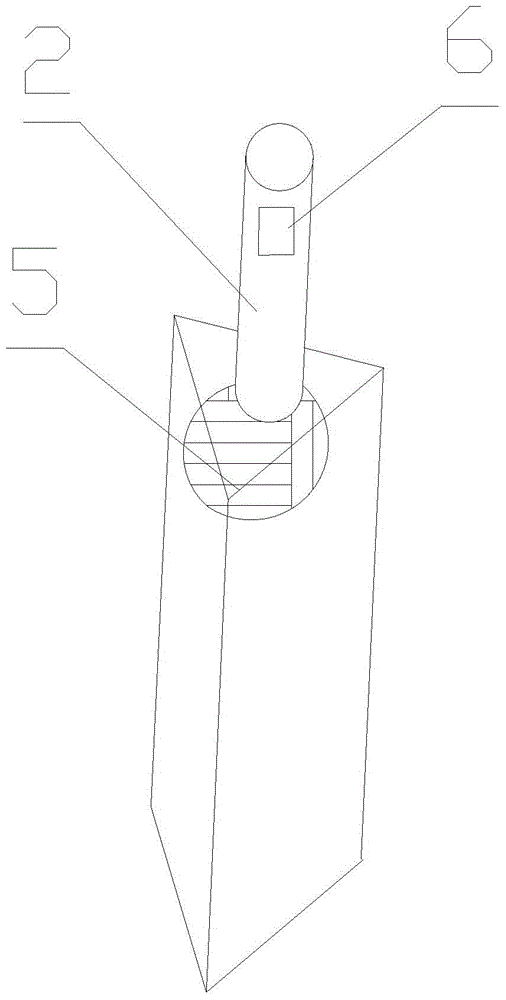

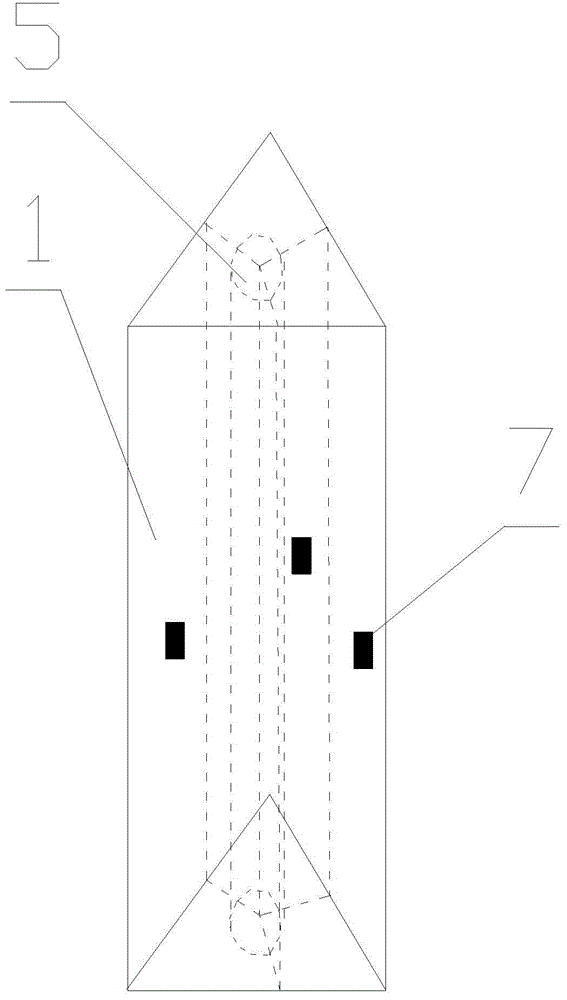

Detonator type nonpriming material detonator and non-electric detonating system thereof

InactiveCN101206105APrevent accidental explosionAvoid complex assemblyBlasting cartridgesBlastingEngineeringTubes types

The invention provides a detonating tube type non-priming detonator and a non-electric detonating connecting method and is characterized in that: a detonator comprises a detonator shell and a detonating tube for inserting to the detonator shell and also comprises a tapered energy collecting hole arranged on the bottom of the detonator shell, a back valve arranged on the bottom of the detonating tube which is inserted to the detonator shell and an explosive mixture with high explosive which is filled among the energy collecting hole, the inner side of the detonator shell and the plastic detonating tube. A detonating system comprises a firing gear and a detonating tube; one end of the detonating tube is connected with the firing gear; the detonating system also comprises a one-to-one joint, a one-to-two joint and a one-to-three joint which are formed by that the detonating tube is connected with each branch detonating tubes; each joint is connected with each branch detonating tube to form a detonating tube branch with different level; the bottom end of each branch detonating tube of the bottom level is connected with the detonator. The non-priming detonator of the invention avoids unsafe factors of pollution, transportation, processing and use and has good detonating system performance and convenient use. The invention is suitable for various detonating operations and salute firing.

Owner:莫福荣

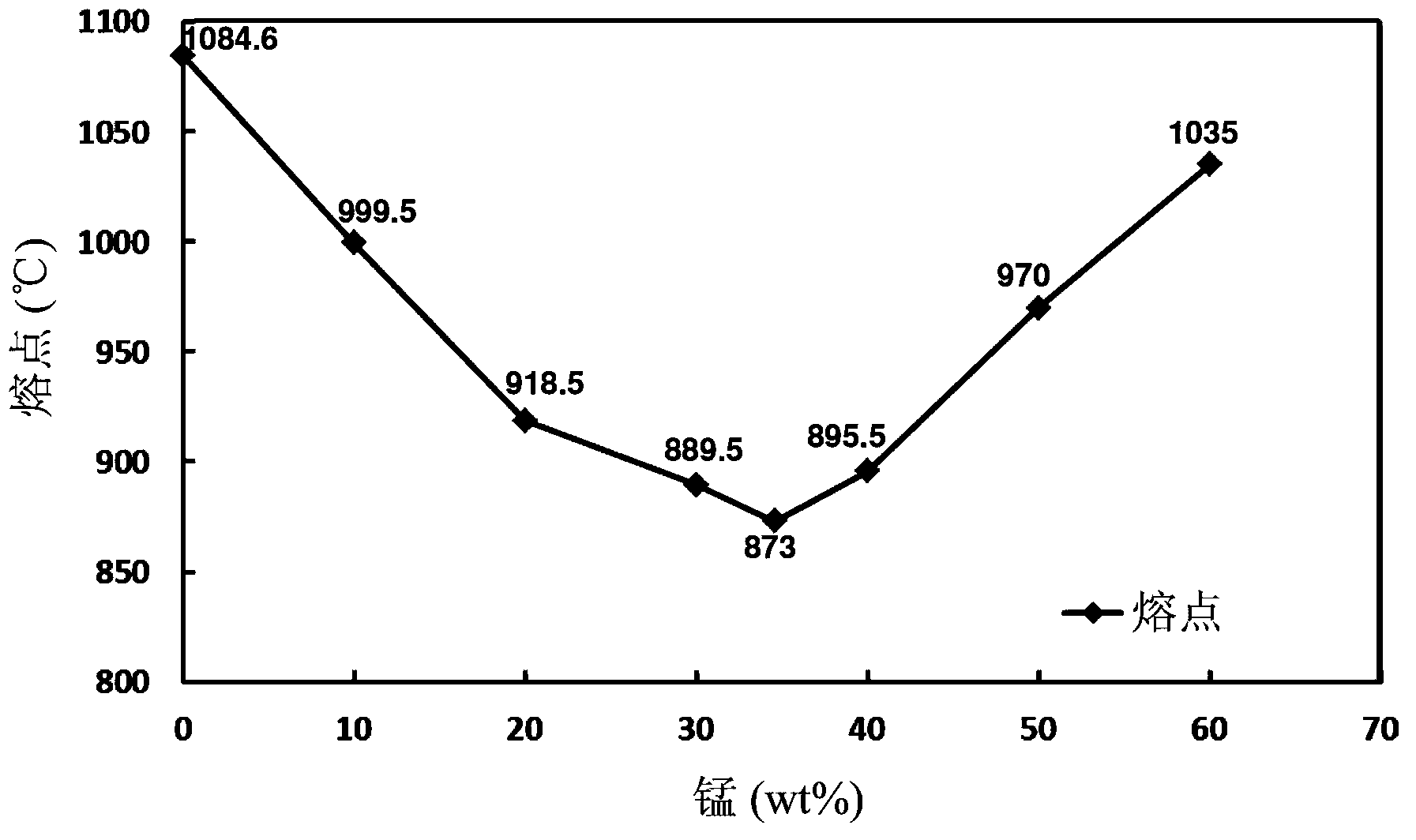

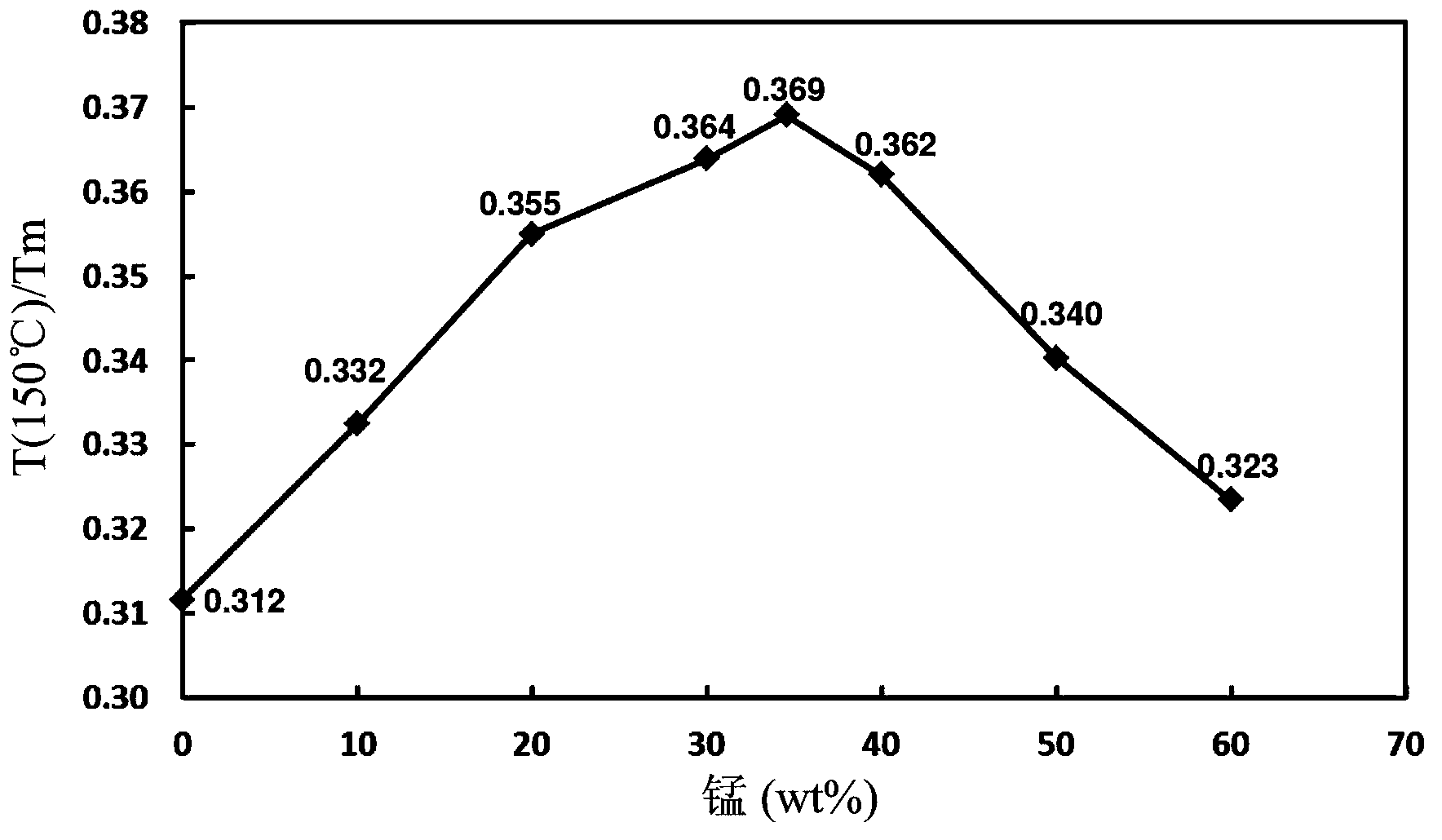

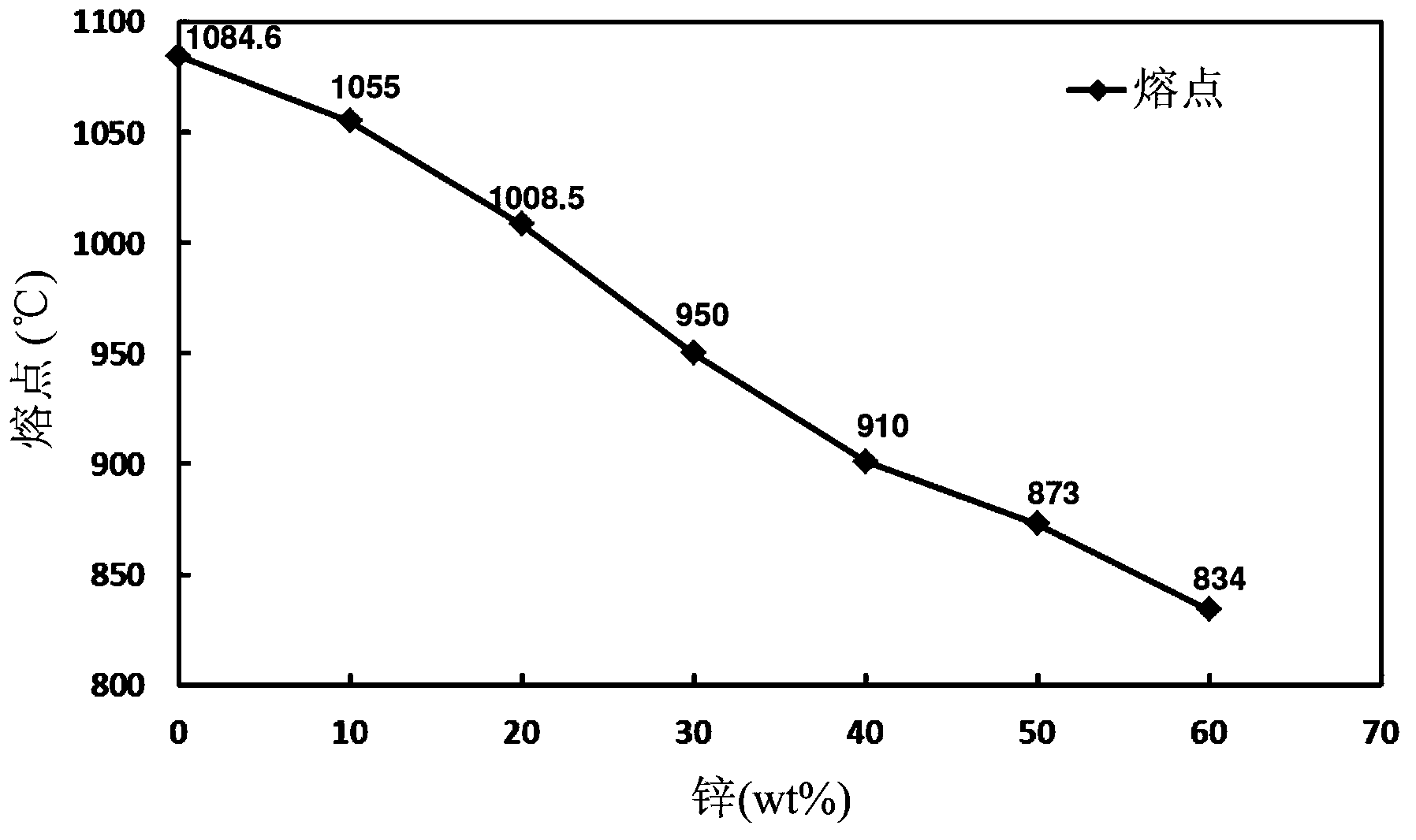

Copper alloy wire used for semiconductor devices

InactiveCN103849795AImprove physical and chemical propertiesImprove antioxidant capacityCopper wireManganese

The invention discloses a copper alloy wire used for semiconductor devices. The copper alloy wire comprises, by weight, 20 to 40% of manganese, 20 to 30% of zinc, or 20 to 30% of zinc and manganese, and the balance copper. According to the copper alloy wire, relatively cheap manganese and / or zinc is added into copper base material according to the weight ratio so as to improve copper wire physico-chemical properties relating to wire bonding technology, wire melting point is reduced, wire oxidation resistance and corrosion resistance are improved, wire thermal softening degree at a working temperature is increased, and wire material cost is reduced; and in addition, oxidation resistance of the copper alloy wire is increased, so that reducing protective gas is not necessary in wire bonding processes, using of nitrogen is enough, and accidents are avoided.

Owner:ADVANCED SEMICON ENG INC

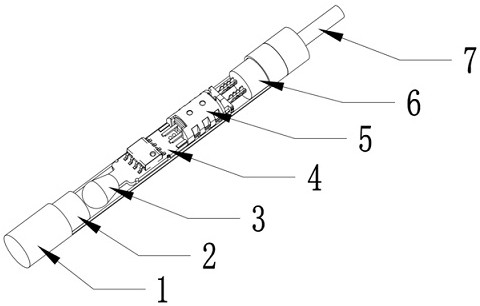

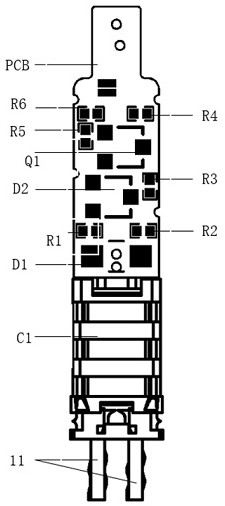

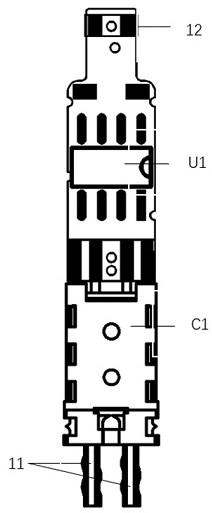

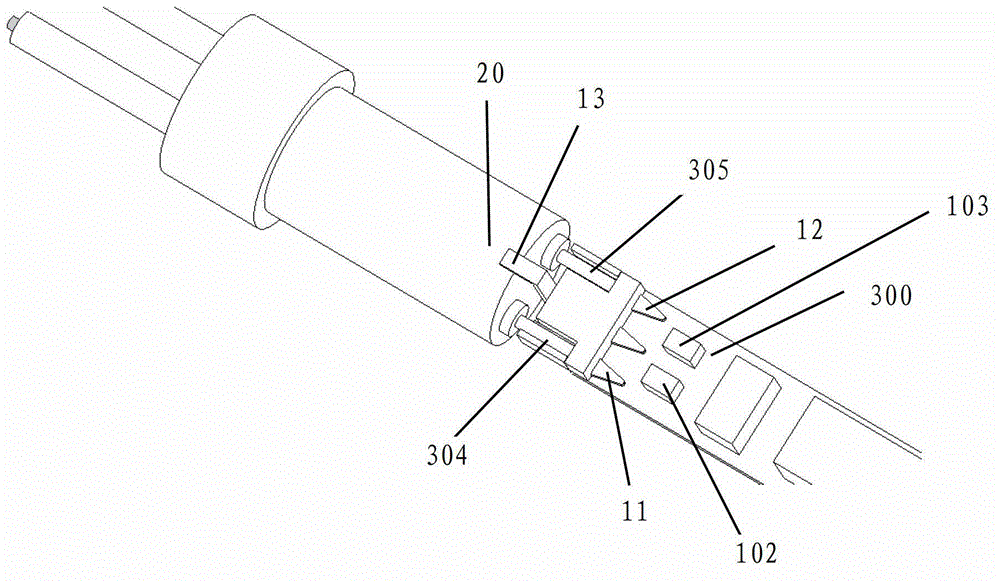

Digital electronic detonator based on solid-state aluminum capacitor

InactiveCN111750747ASolve the problem of module eccentricityPrevent accidental explosionAmmunition fuzesCapacitanceTantalum capacitor

The invention discloses a digital electronic detonator based on a solid-state aluminum capacitor. The digital electronic detonator mainly comprises a detonator shell, a leg wire, a bayonet plug, an electronic control module, an ignition element and a basic detonator, and is characterized in that an energy storage capacitor on the electronic control module adopts the solid-state aluminum capacitor,so that the problems of high cost, limited raw materials, low withstand voltage and low capacity of a tantalum capacitor are solved; an injection molding rubber coating process is adopted, the solid-state aluminum capacitor is processed into an injection molding terminal, and the injection molding terminal is welded on a PCB of the electronic control module through pins of a capacitor assembly, so that the problem of module eccentricity caused by the overlarge size of the solid-state aluminum capacitor is solved; in addition, the invention adopts a transient voltage suppressor for electrostatic protection, compared with a traditional point discharge electrostatic protection scheme, the mode does not generate electric sparks due to air breakdown, so that the detonator is prevented from being mistakenly exploded due to the electric sparks.

Owner:WUXI SHENGJING ELECTRONICS TECH CO LTD

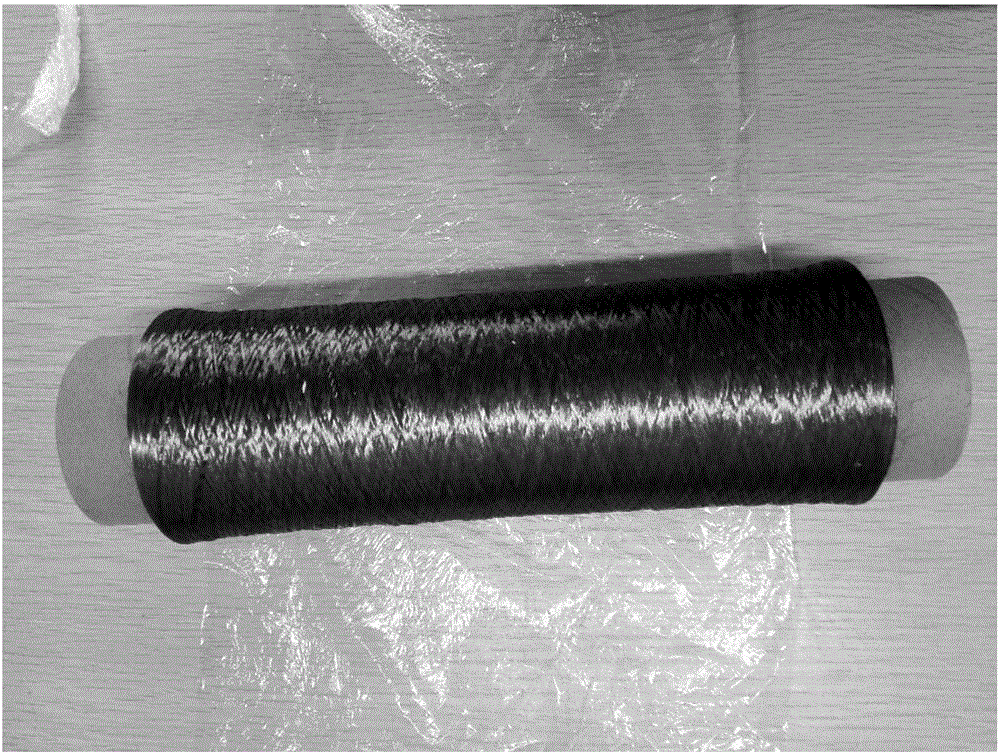

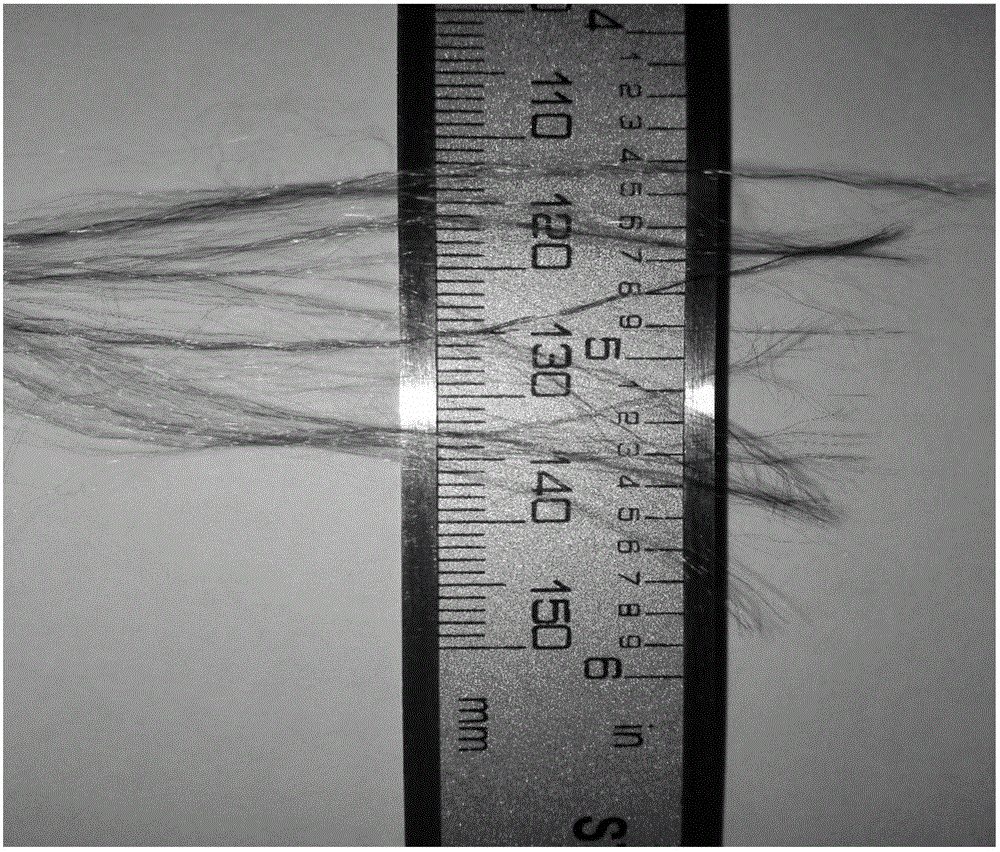

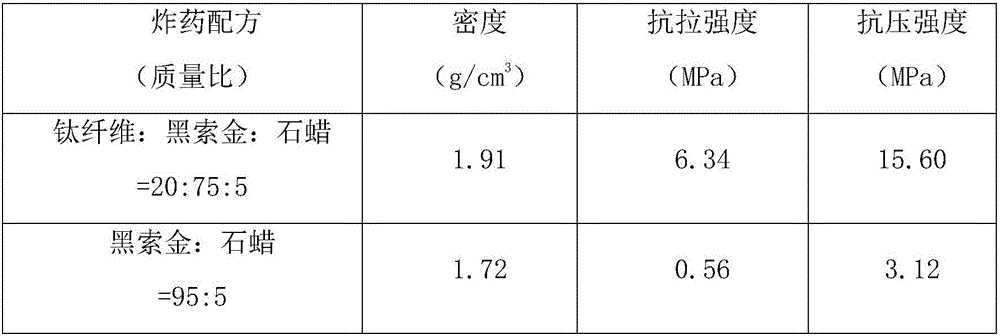

High-strength titanium-based fiber explosive

ActiveCN106045799AImprove tensile propertiesVolume energy increaseExplosivesSingle substanceHigh intensity

The invention discloses a high-strength titanium-based fiber explosive. The high-strength titanium-based fiber explosive is characterized in that titanium fibers or titanium alloy fibers are added to a single substance explosive or a mixed explosive as a metal additive, wherein the fibers can be titanium fibers, and also can be titanium alloy fibers or a titanium fiber and titanium alloy fiber mixture. The high strength characteristic of the titanium fibers and the titanium alloy fibers are fully used to improve the mechanical performances of the titanium-based fiber explosive, so the safety of the explosive in the production, storage and transportation process is greatly enhanced, and the volume energy density of the explosive is obviously improved.

Owner:UNIV OF SCI & TECH OF CHINA

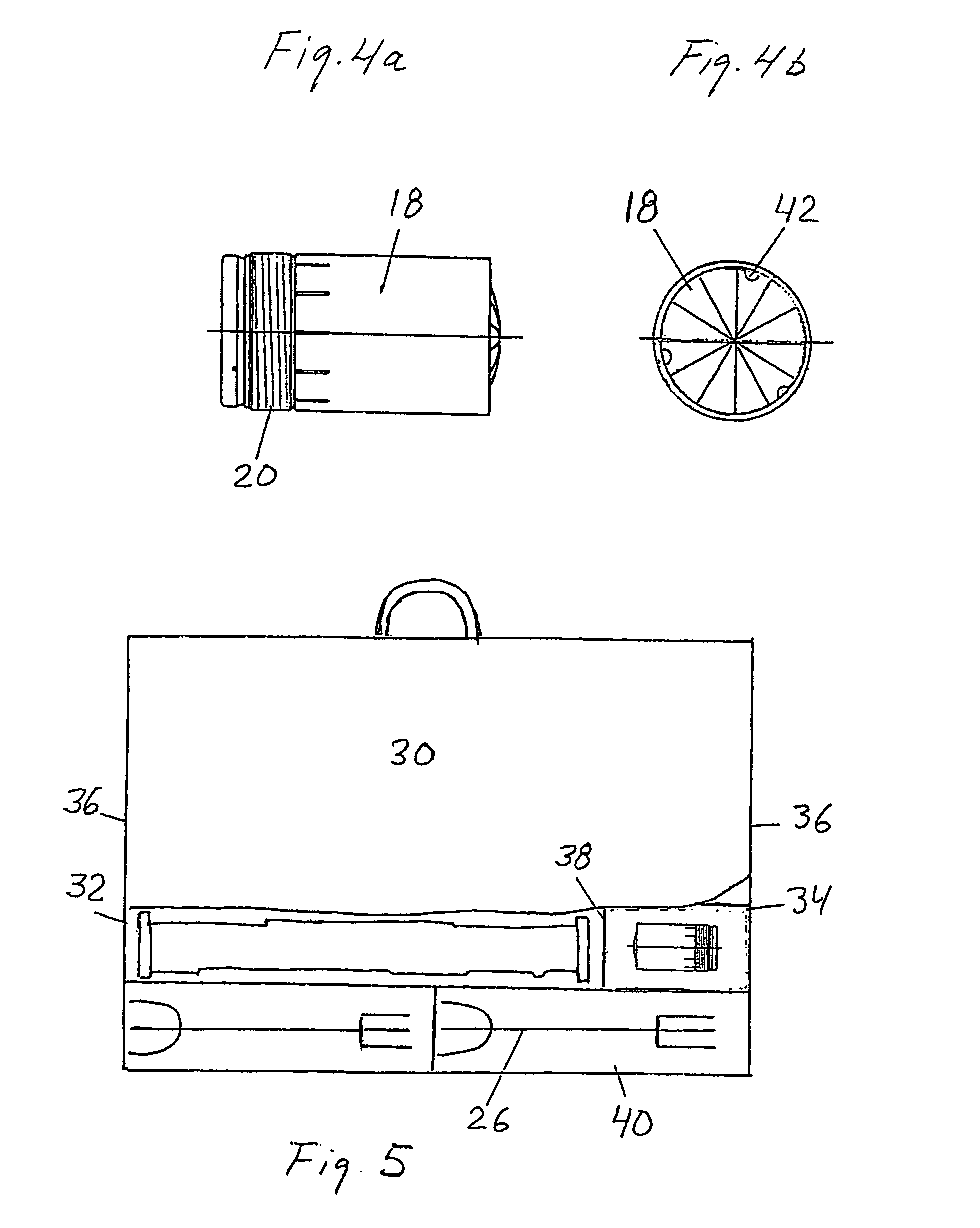

Method of configuring weapon

InactiveUS20100031809A1Prevent accidental explosionRocket launchersFiring/trigger mechanismsEngineeringMechanical engineering

A method of configuring a preloaded anti-armour weapon of the disposable type and including a countermass container in transport mode for restraining a shell loaded in a barrel of the weapon. The countermass container is replaced with a locking ring and the loaded barrel is placed in a first compartment and the countermass container is placed in a second compartment of a transport box.

Owner:SAAB AB

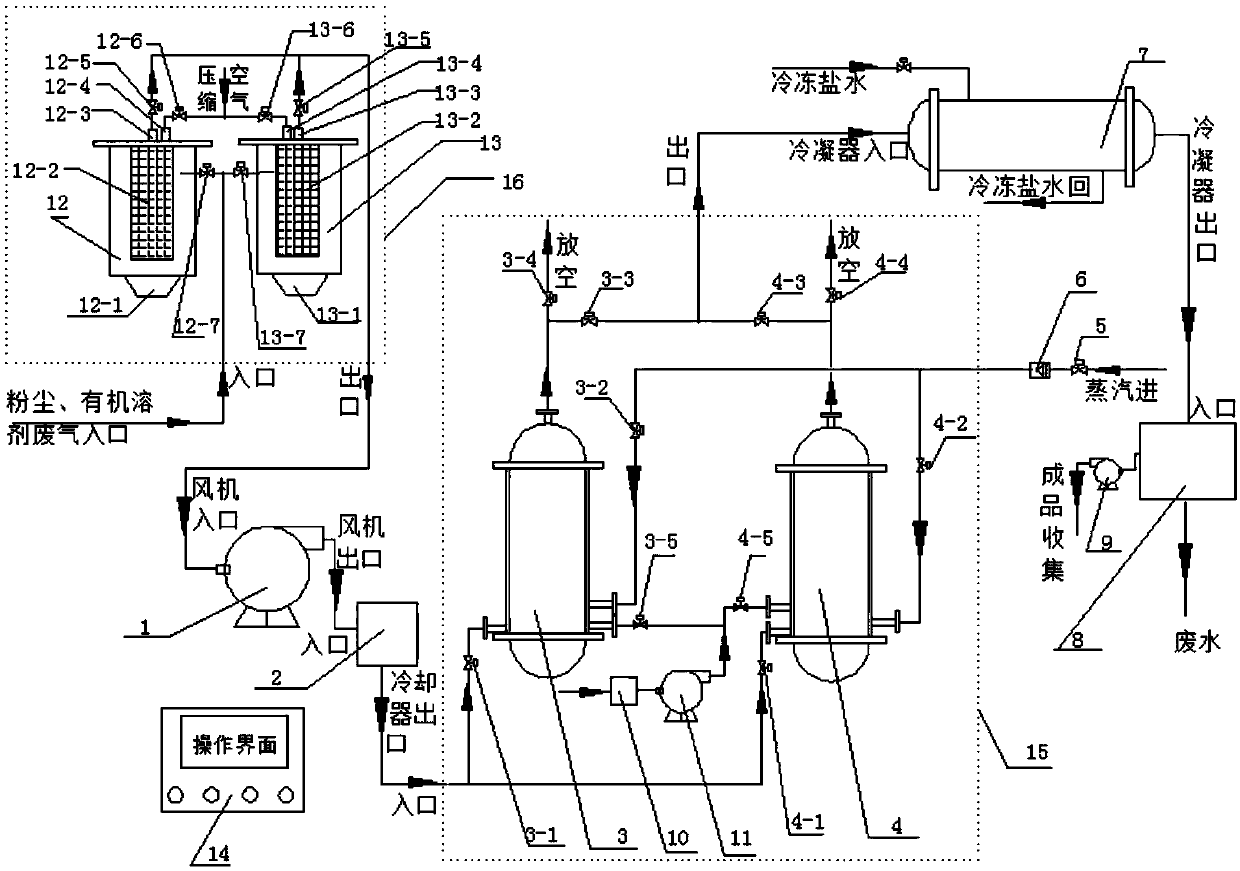

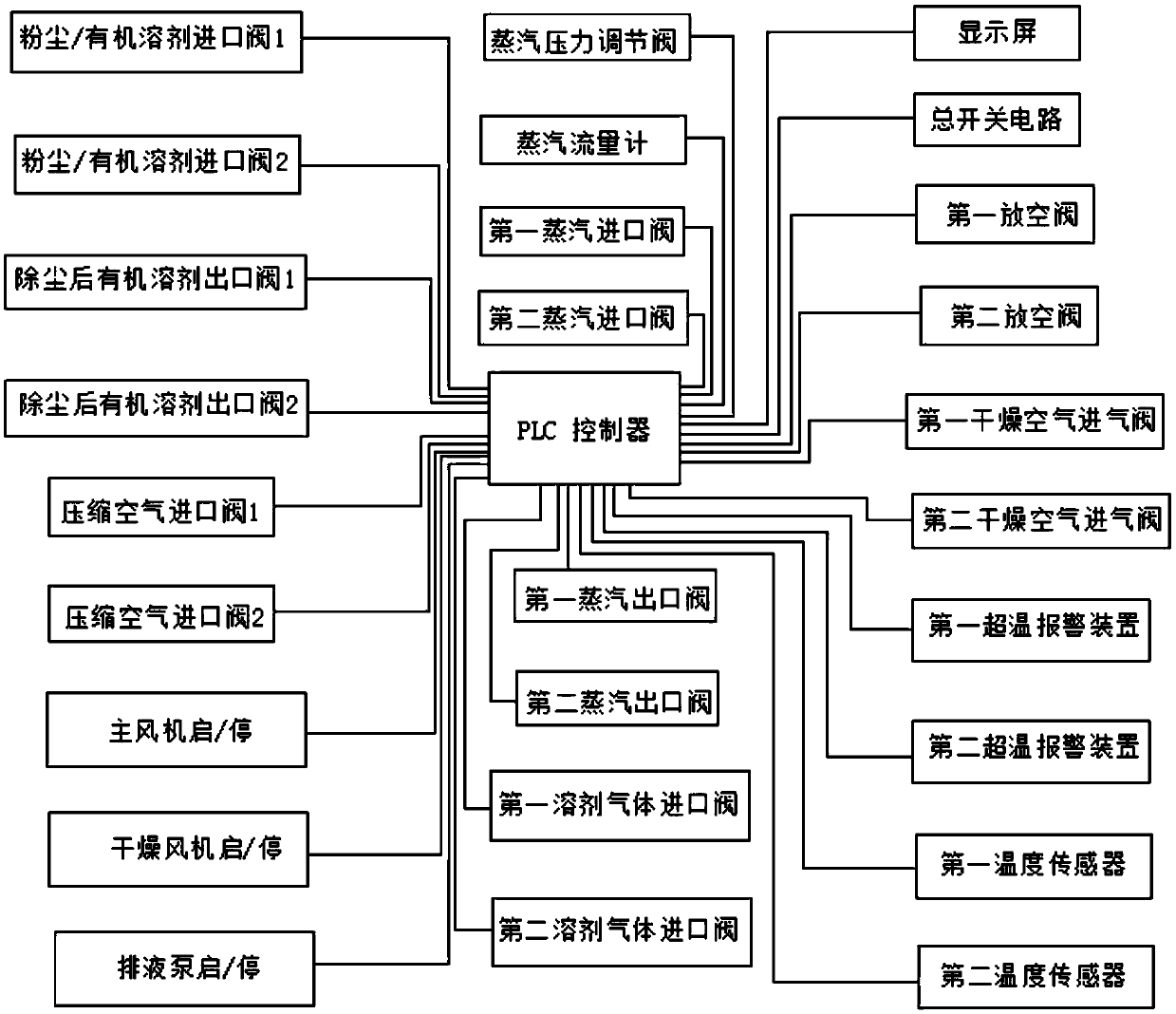

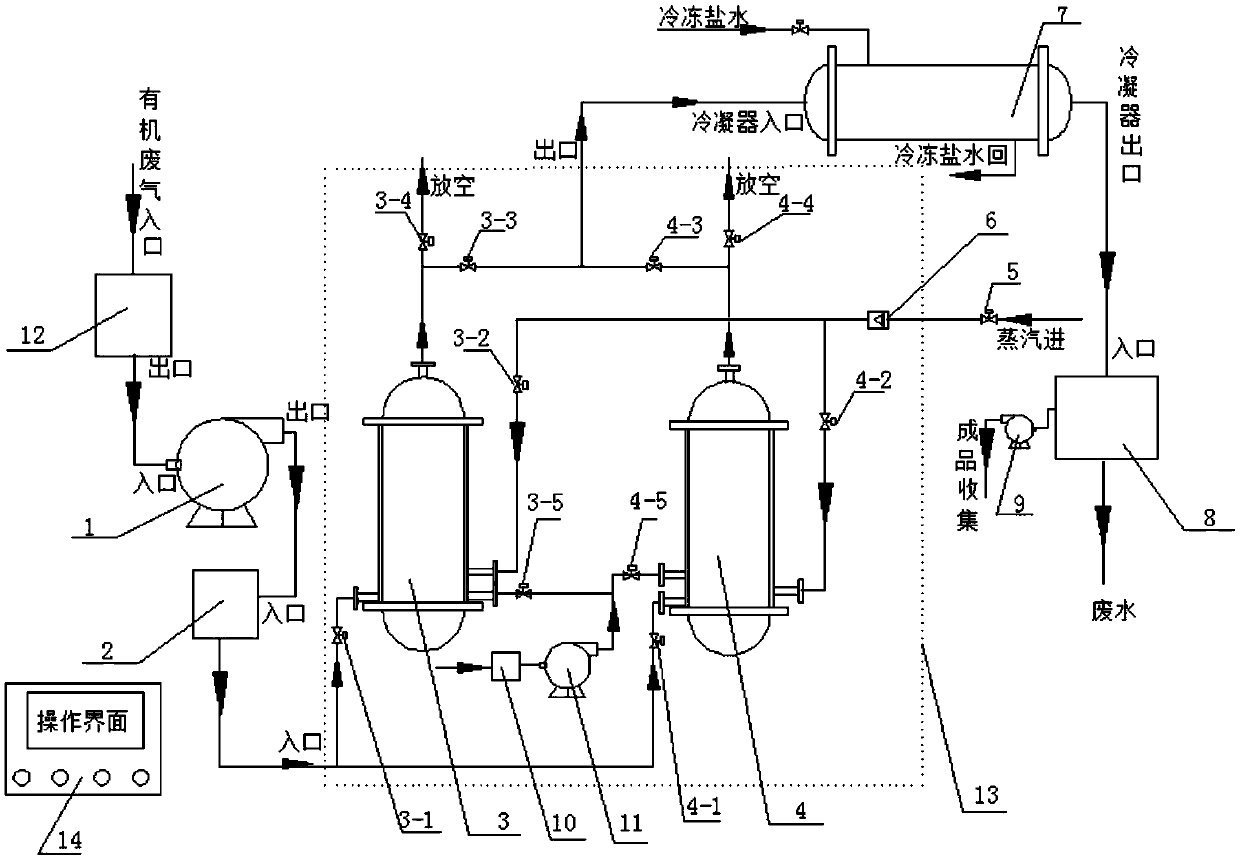

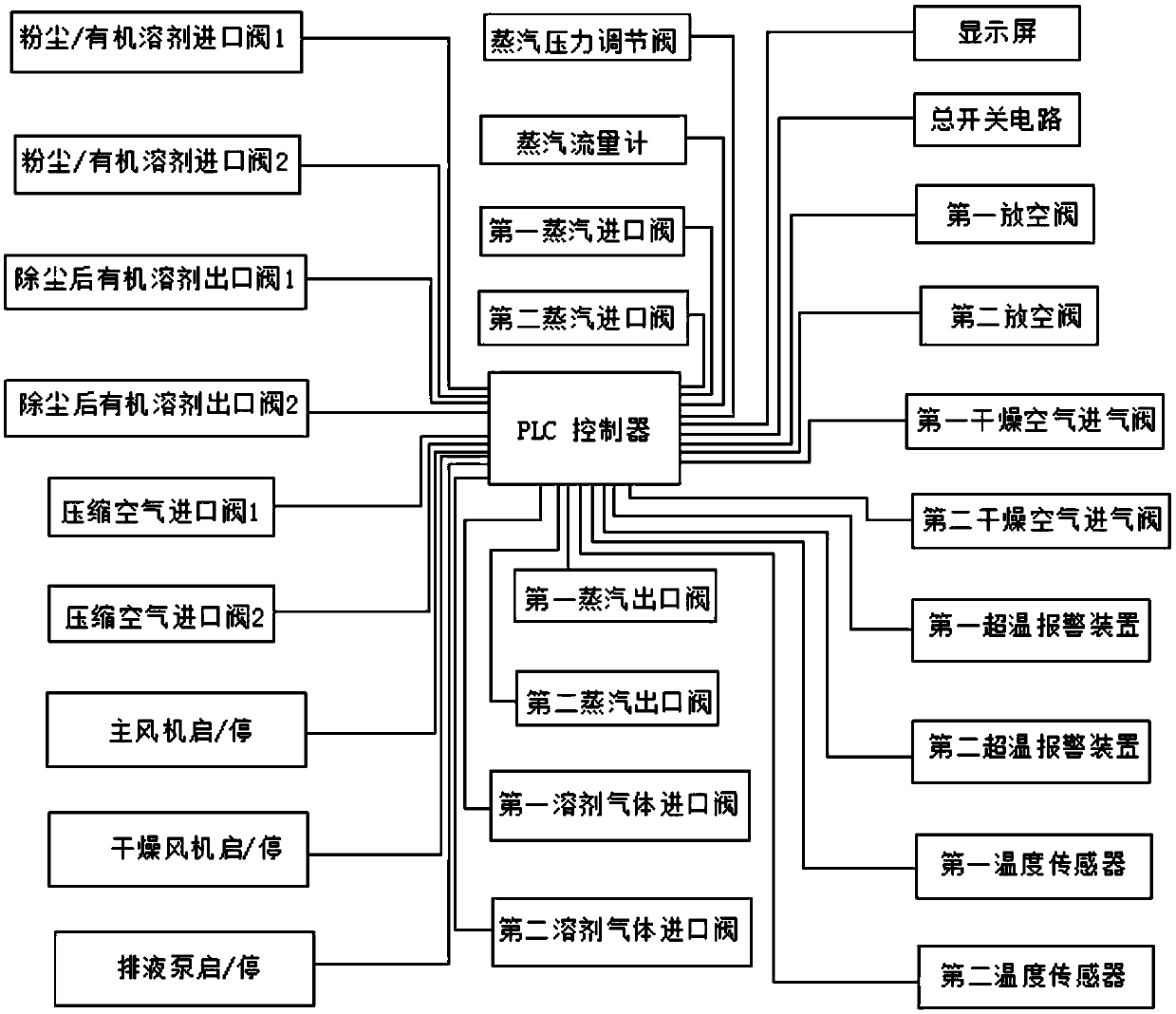

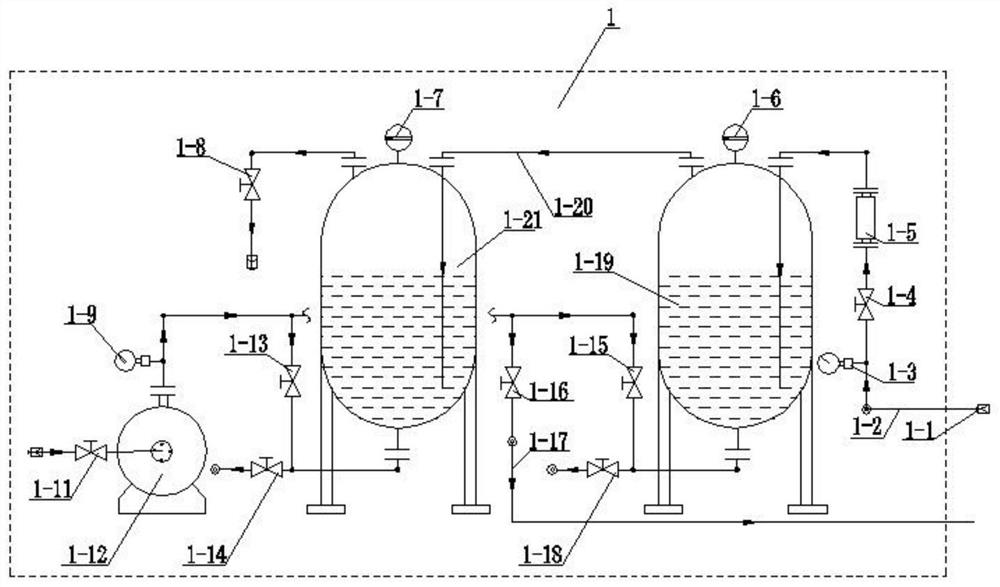

PLC controlled dust and organic waste gas treatment equipment

InactiveCN109603322AIncrease productivityReduce maintenance costsGas treatmentDispersed particle filtrationExhaust gasChiller

The invention relates to PLC controlled dust and organic waste gas treatment equipment. The equipment comprises a dust removal system, a fan, a cooler, an adsorption system, a condenser, a stratification tank and a PLC. The inlet and outlet of the dust removal system are respectively connected to a dust and organic waste gas inlet and a fan inlet, a fan outlet pipe is connected to a cooler inlet pipe, the inlet and outlet of the adsorption system are respectively connected to a cooler outlet and a condenser inlet, the condenser outlet is connected to a stratification tank inlet, the PLC is connected to all executing agencies through a data bus, dust and organic waste gas enter the equipment through a dust removal system inlet, the dust removal system filters dust and impurity particles, the adsorption system adsorbs organic gas in the waste gas, and the clean tail gas is discharged from an emptying valve of the adsorption system, steam is utilized to desorb the adsorbed and saturated organic gas, and after condensation by the condenser, the product then flows into the stratification tank for standing, thus obtaining a clean organic solvent. The equipment can achieve continuous, automatic and safe operation, and is maintenance-free and cost-saving.

Owner:XIAN MODERN CHEM RES INST

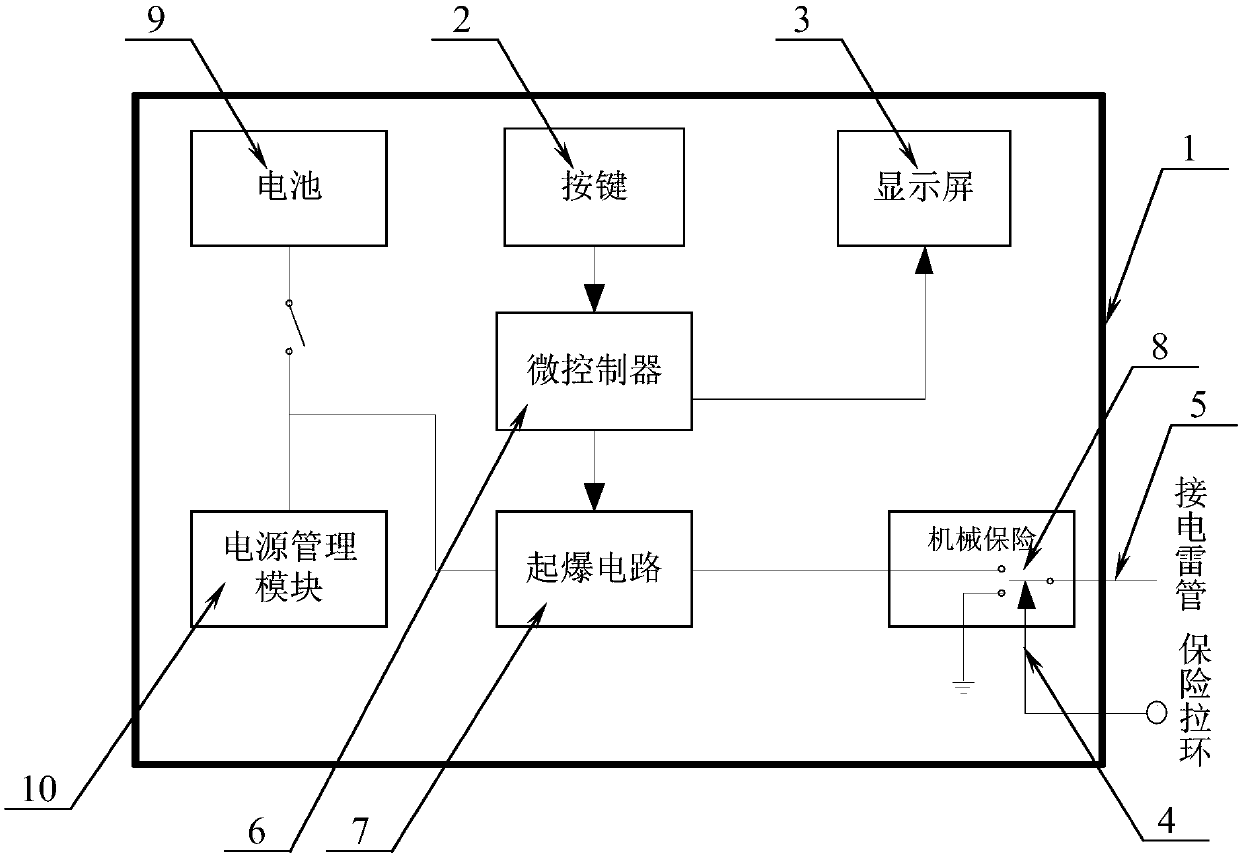

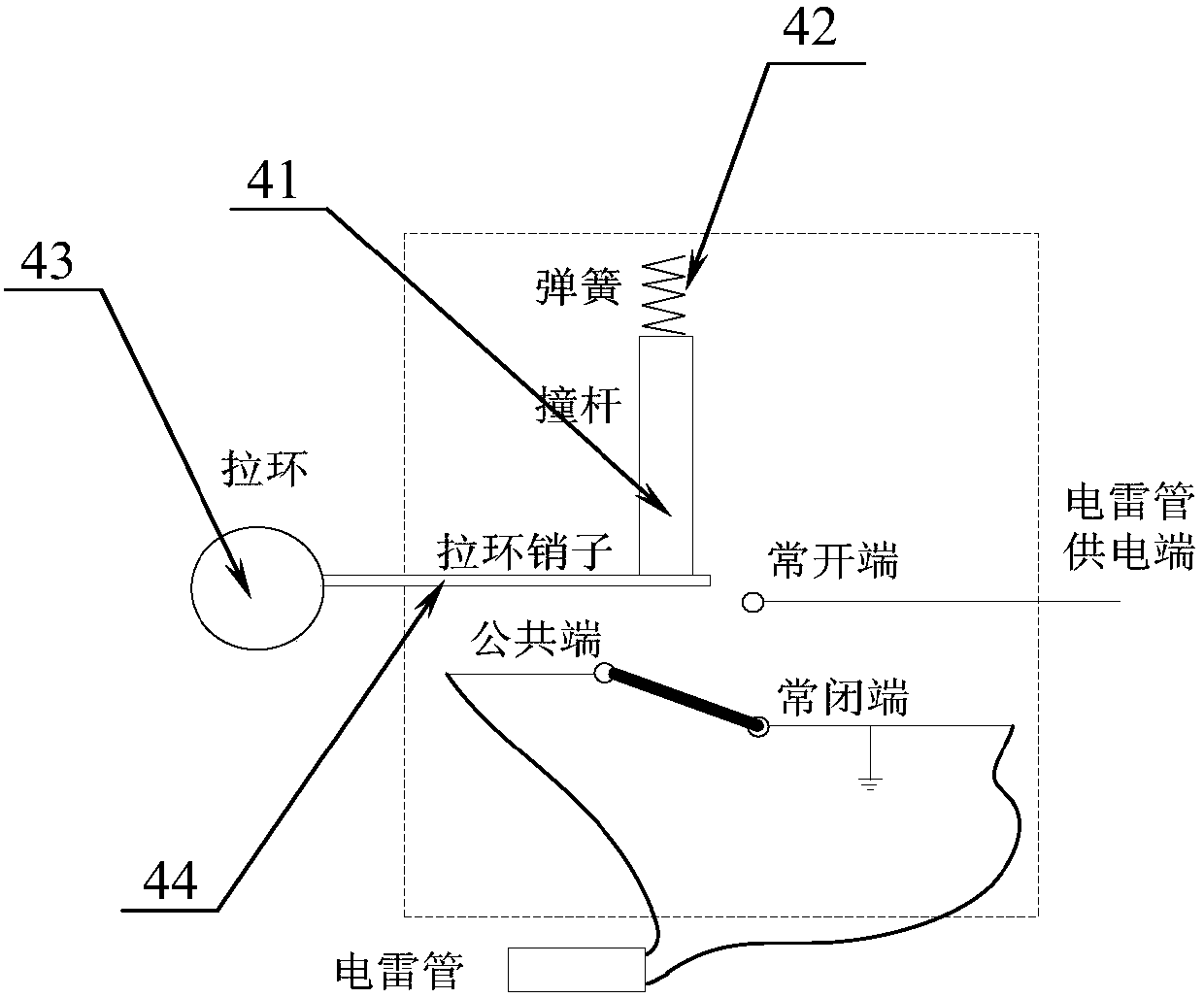

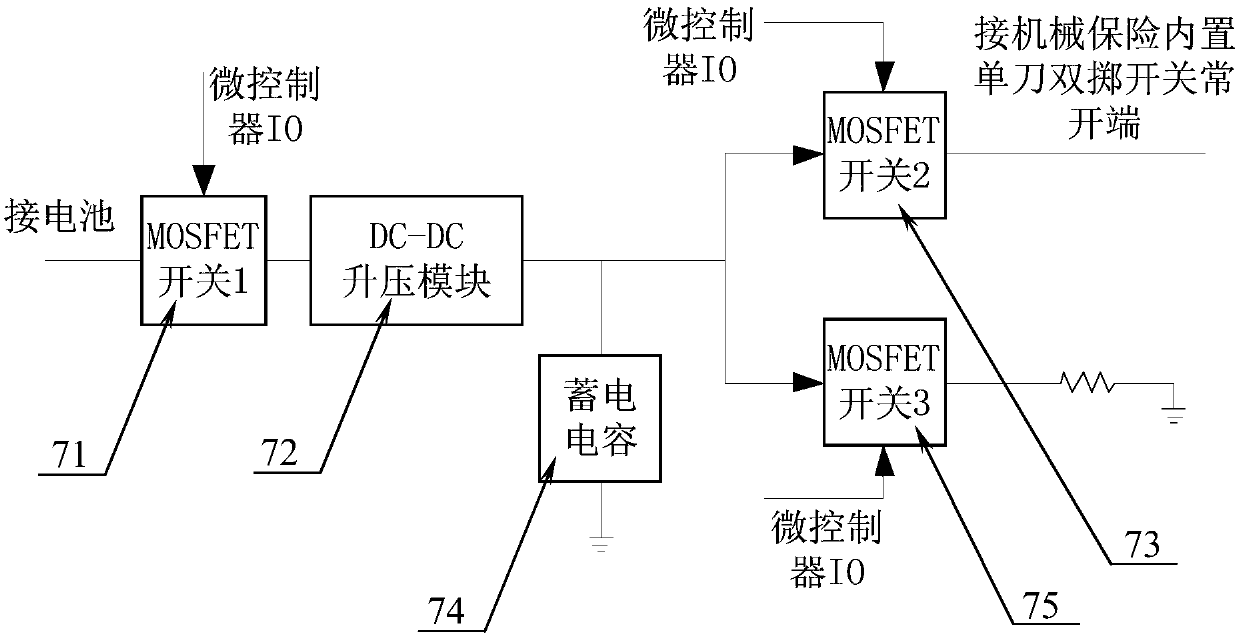

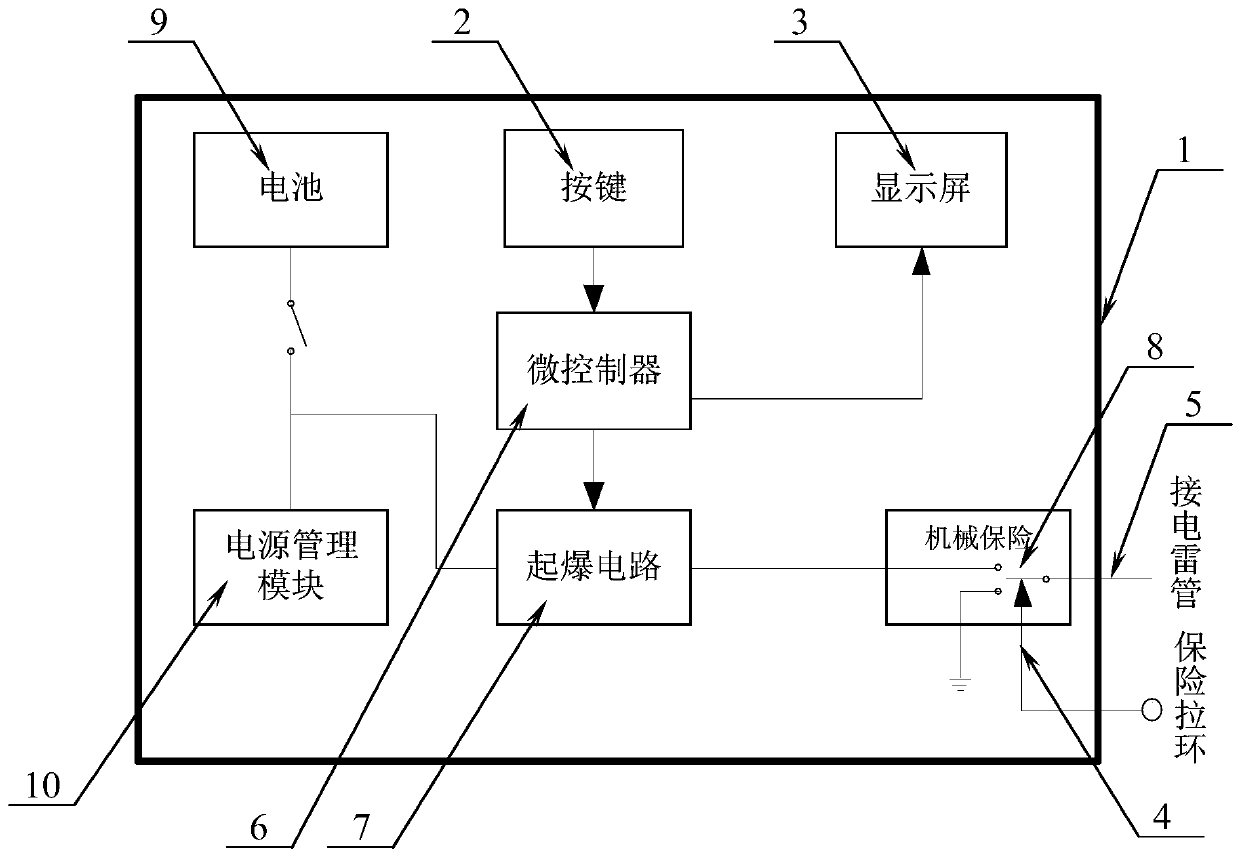

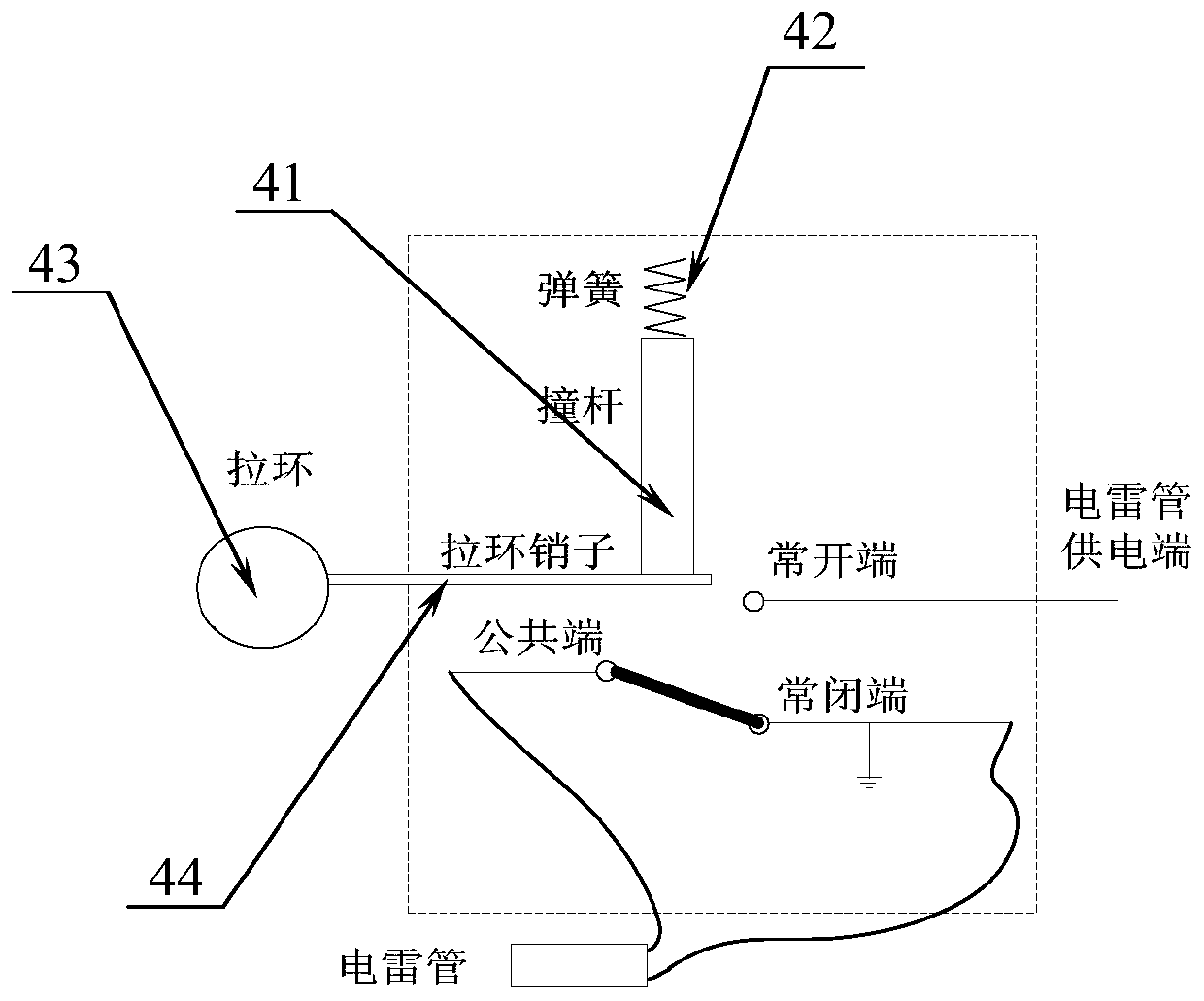

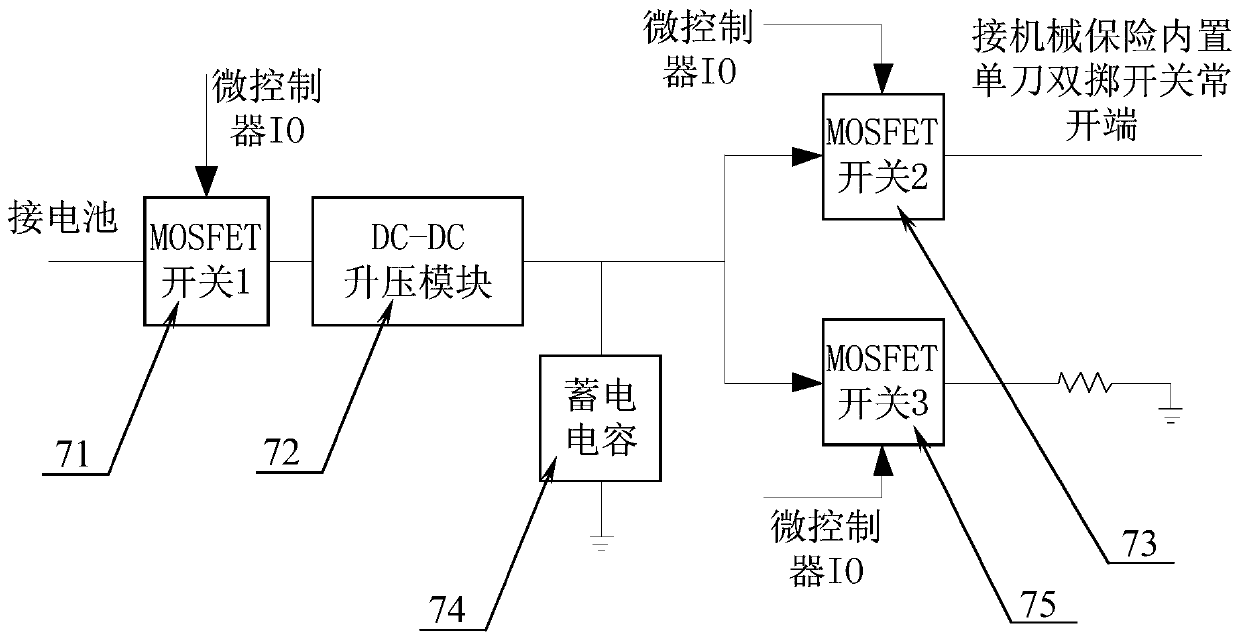

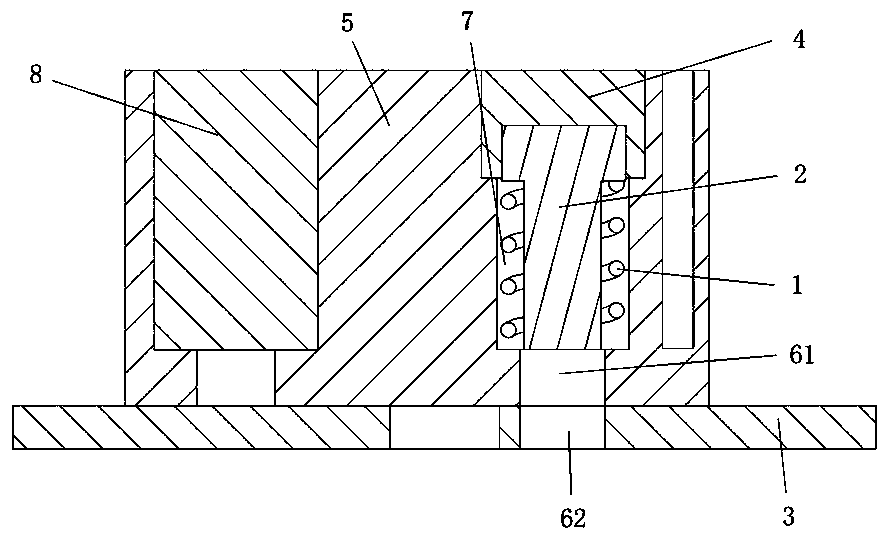

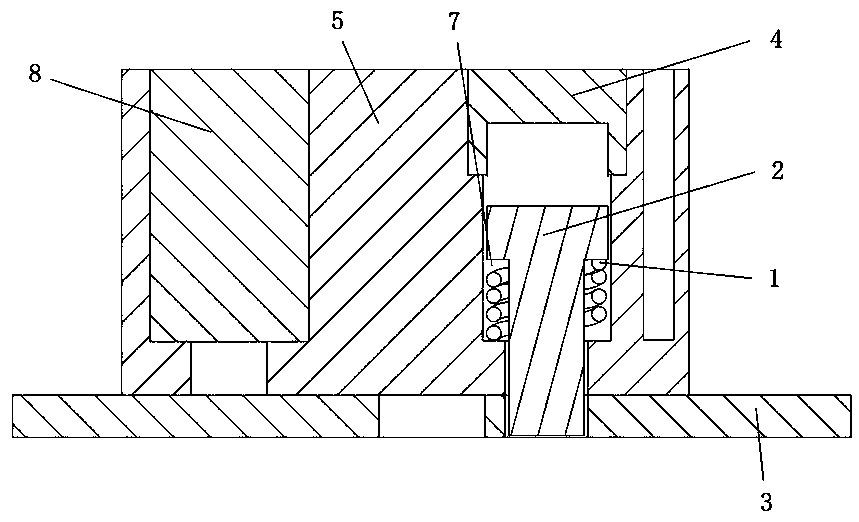

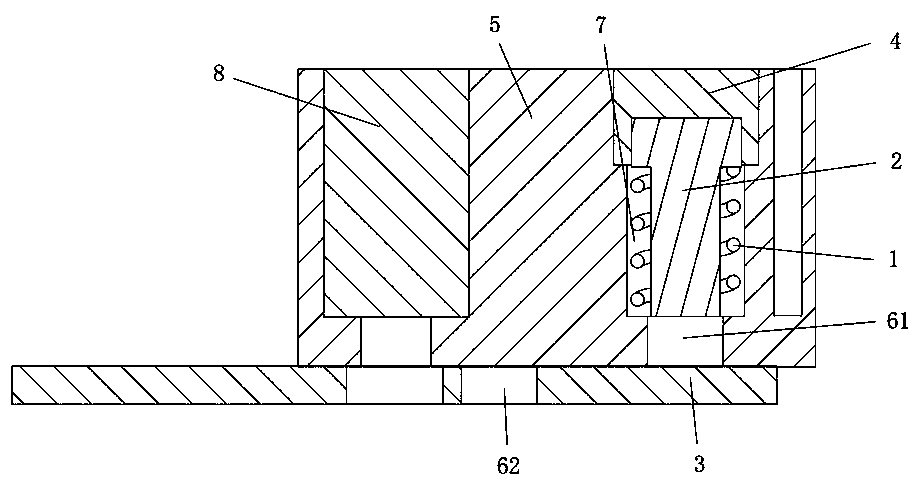

Timing initiation device and method

The invention discloses a timing initiation device and method. The device comprises a shell; the shell is provided with a key, a display screen, a mechanical fuse and an electric detonator socket connected with an electric detonator; a microcontroller electrically connected with the key and the display screen and an initiation circuit electrically connected with the microcontroller are mounted inthe shell; a common end of a single-pole double-throw switch is electrically connected with the electric detonator socket, a normally closed end is grounded, and a normally open end is electrically connected with the initiation circuit; a poking piece of the single-pole double-throw switch is defaulted to communicate with the common end and the normally closed end; under the condition of relievingthe mechanical fuse, the poking piece communicates with the common end and the normally open end; and a battery supplies electricity to the device through a power supply management module. The timinginitiation device is small in size, low in weight, simple in operation, high in automation degree and convenient to carry; users can autonomously set the timing time; and the electric detonator is initiated to realize initiation after timing.

Owner:中国电波传播研究所 +1

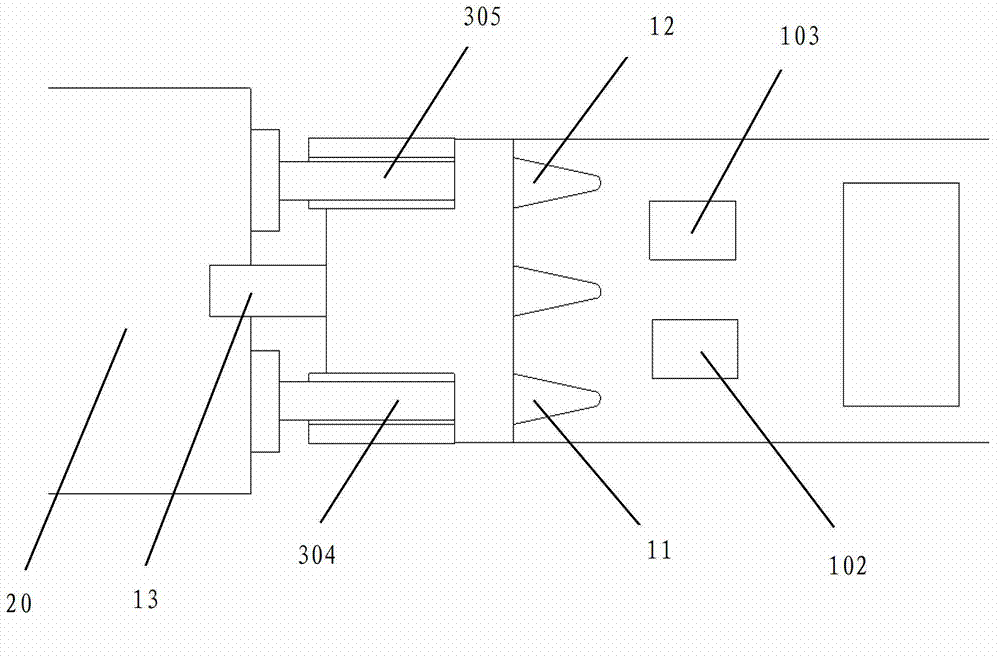

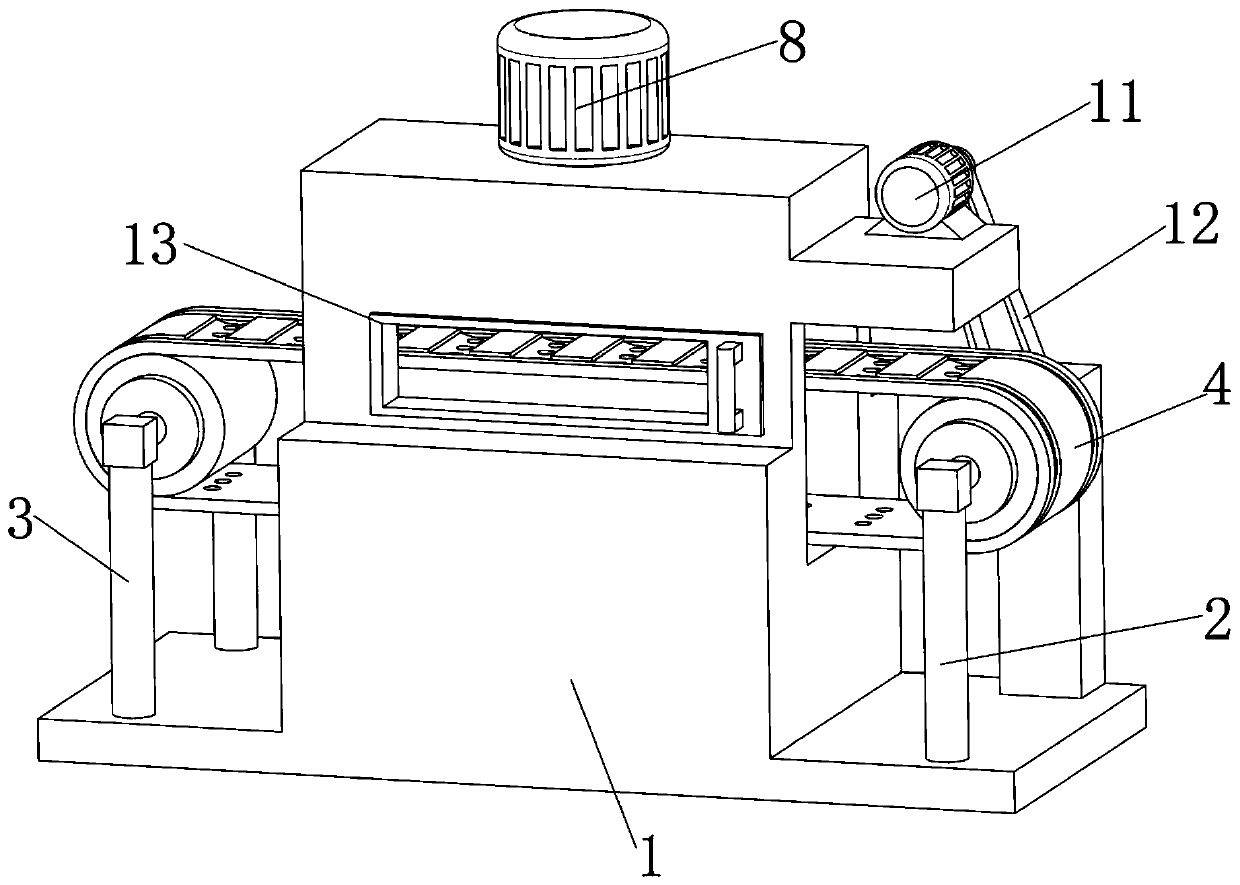

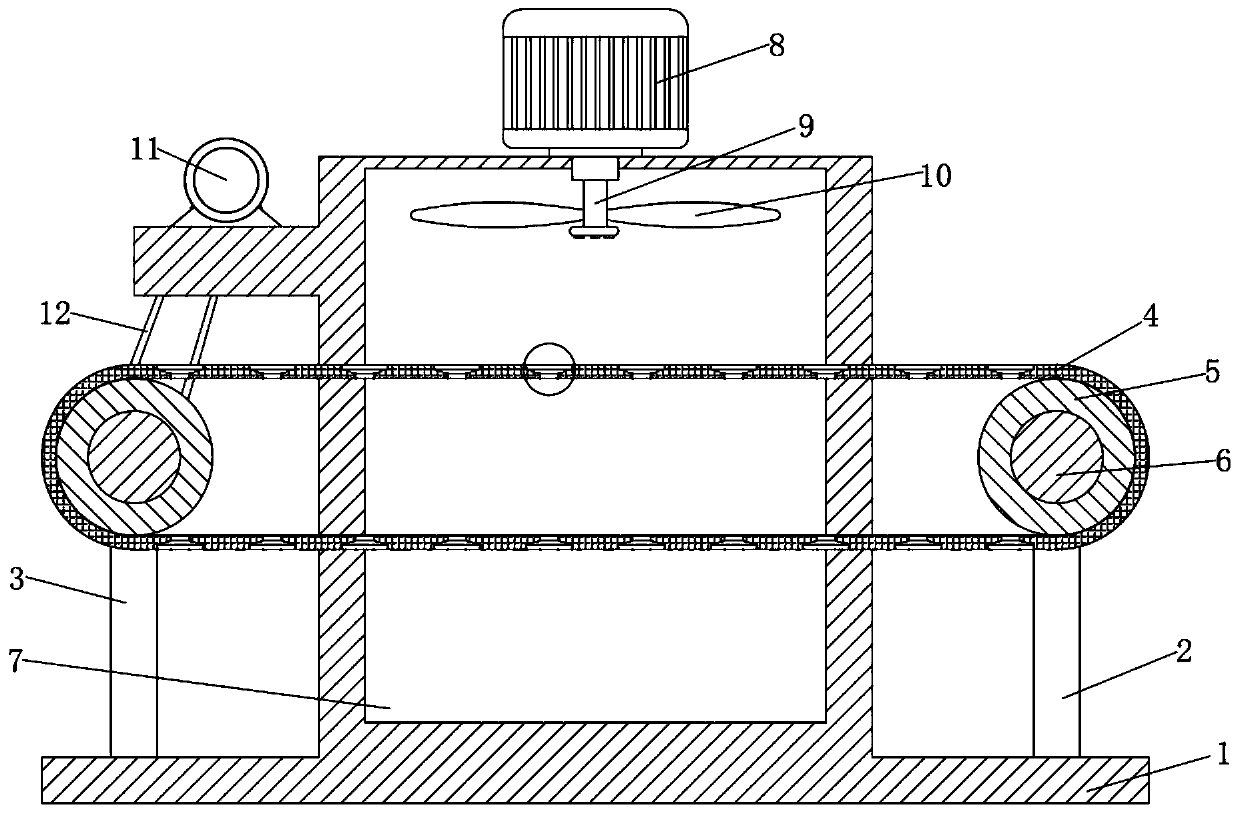

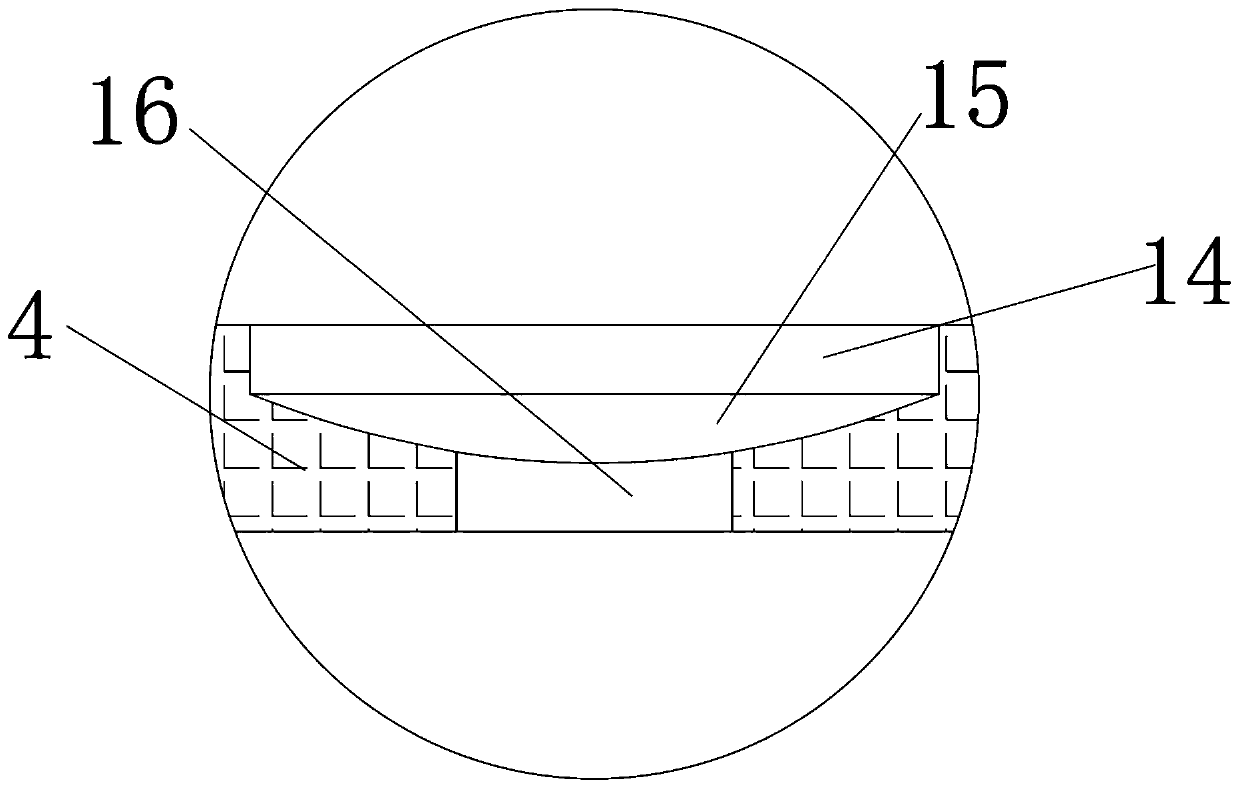

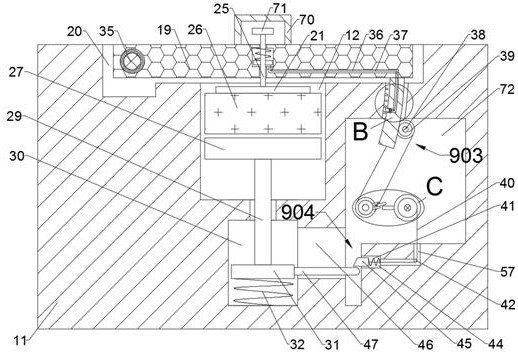

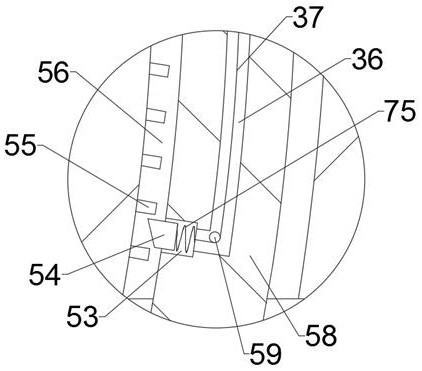

Blow-drying apparatus for emulsion explosive production line

ActiveCN110511103AAchieve dryingEasy dischargeExplosive working-up apparatusProduction lineEmulsion explosive

The invention discloses a blow-drying apparatus for an emulsion explosive production line. The blow-drying apparatus comprises a blow-drying box main body, wherein a left bracket and a right bracket are vertically installed on the left end and the right end of the blow-drying box main body, a through hole is arranged in the middle section of the blow-drying box main body, a first driving motor isarranged in the middle of the upper end surface of the blow-drying box main body, a second driving motor is fixed on the left end of the upper end surface of the blow-drying box main body through bolts, a water collecting inner cavity is arranged in the blow-drying box main body, and rollers are rotatably installed on the upper ends of the left bracket and the right bracket through rotating shafts. According to the present invention, by limiting the position of the emulsion explosive during blow-drying, the safety of the production process is improved, the blow-drying efficiency is improved, and the high practical value is achieved.

Owner:重庆神斧锦泰化工有限公司

PLC controlled organic waste gas treatment equipment

InactiveCN109603355AAvoid manual cleaningIncrease productivityGas treatmentDispersed particle filtrationOrganic solventEngineering

The invention relates to PLC controlled organic waste gas treatment equipment. The equipment comprises: a dust removal system, a fan, a cooler, an adsorption system, a condenser, a stratification tankand a PLC. The inlet and outlet of the dust removal system are respectively connected to a dust and organic waste gas inlet and a fan inlet, a fan outlet pipe is connected to a cooler inlet pipe, theinlet and outlet of the adsorption system are respectively connected to a cooler outlet and a condenser inlet, and the condenser outlet is connected to a stratification tank inlet. The PLC is connected to all executing agencies through a data bus. Gas containing organic waste gas enters the equipment through the inlet of the dust removal system, the dust removal system filters dust and impurity particles, the adsorption system adsorbs organic gas in the waste gas, and clean tail gas is directly exhausted, steam is utilized to desorb the adsorbed and saturated organic gas in the adsorption device, the desorbed organic gas is condensed by the condenser, and then the product flows into the stratification tank for standing, thus obtaining reusable organic solvent. The equipment can achieve continuous, automatic and safe operation, and is maintenance-free and cost-saving.

Owner:XIAN MODERN CHEM RES INST

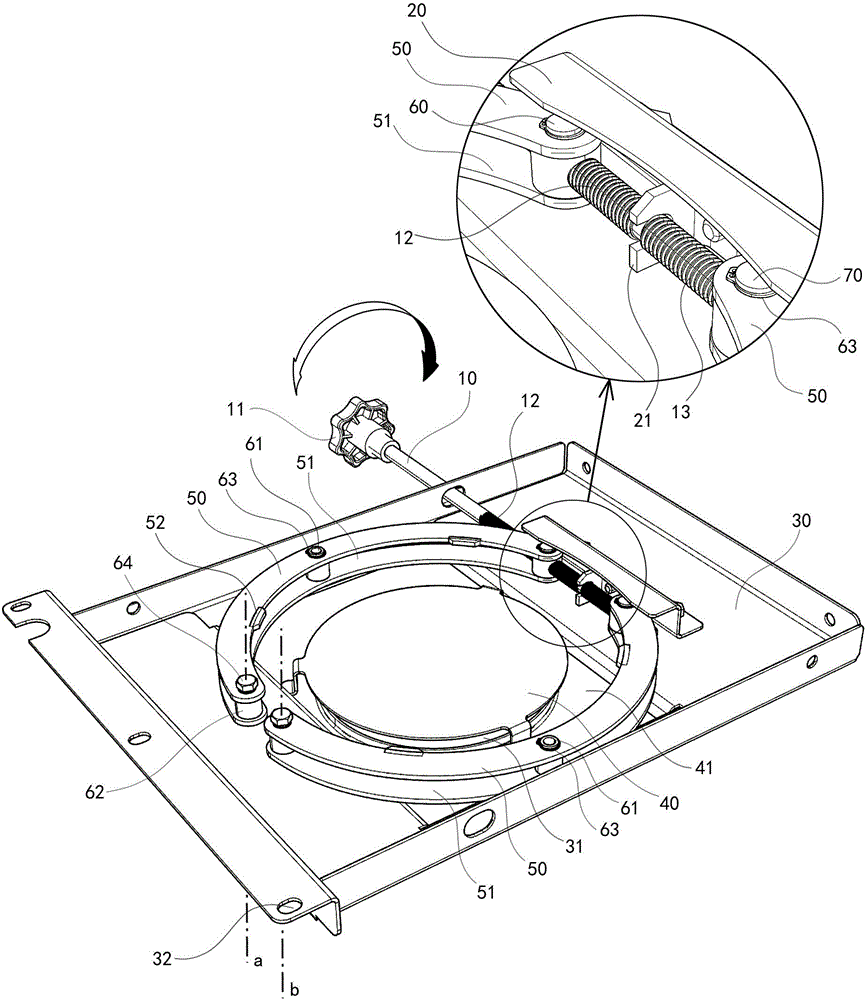

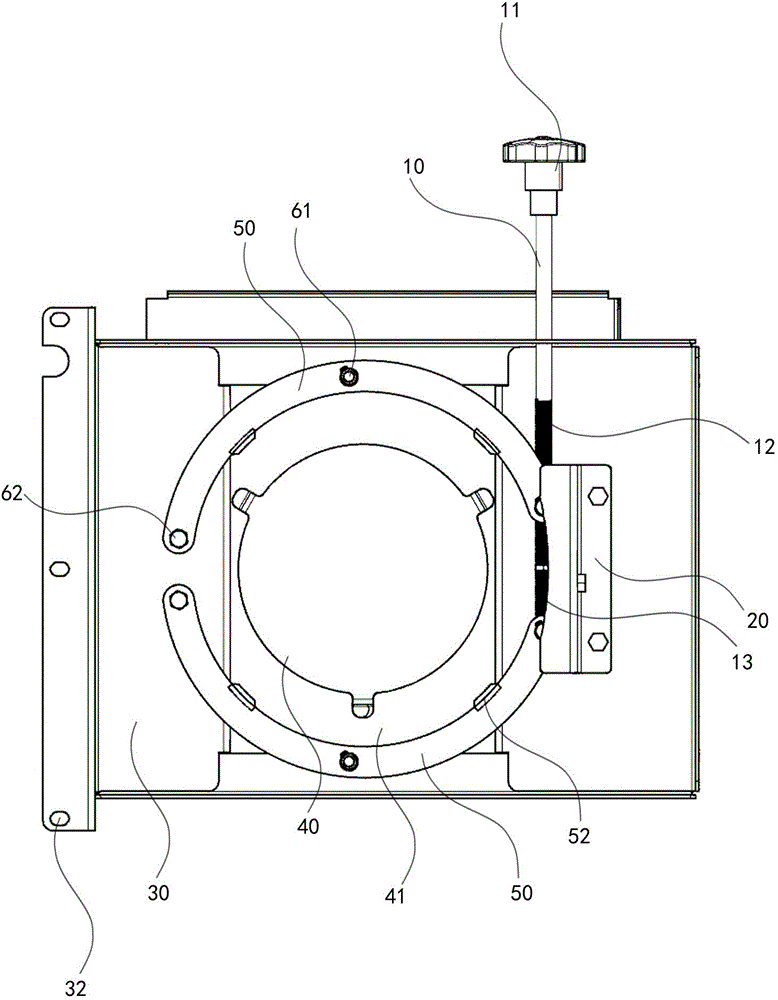

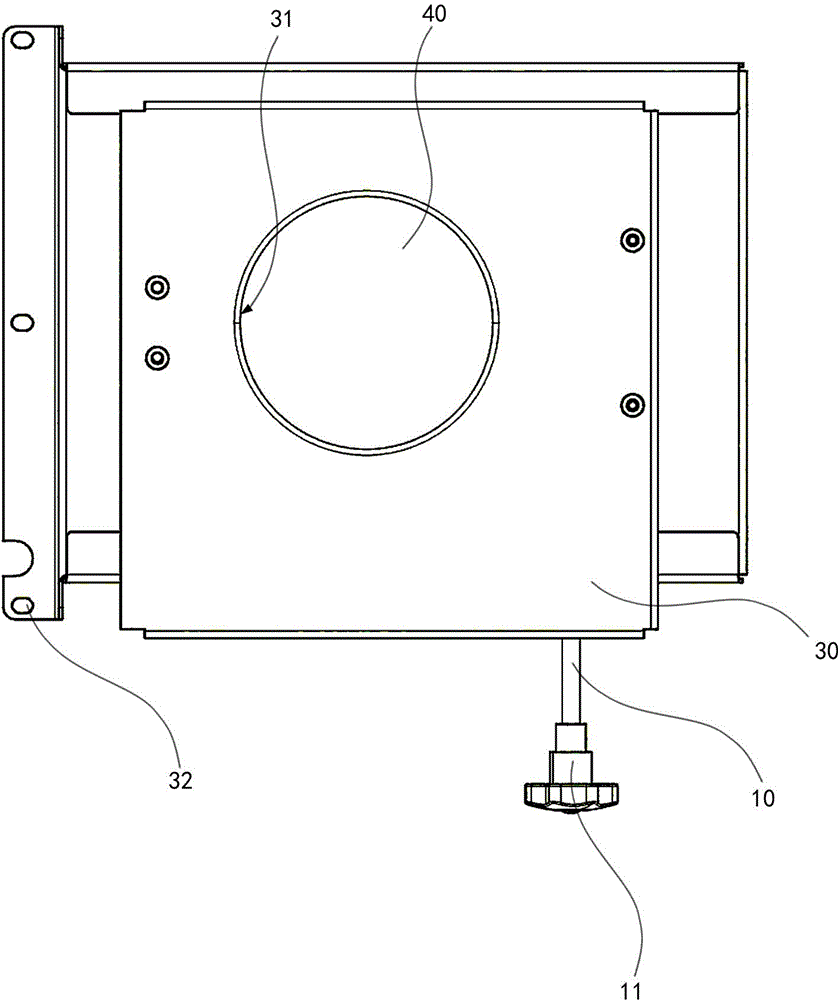

Vertical positioning carrier of gas cylinders special for small-sized gas generator sets

ActiveCN104632401AImprove securityPrevent accidental explosionInternal combustion piston enginesFuel supply apparatusWater storageGas cylinder

A vertical positioning carrier of gas cylinders special for small-sized gas generator sets comprises a screw, a guard plate, a bottom plate, a wearproof cover plate, a cylinder-limiting hoop, a left threaded limiting pin and a right threaded limiting pin. The vertical positioning carrier is characterized in that one end of the screw is provided with a handle, the other end thereof is provided with a left thread and a right thread in order, the bottom plate is provided with mounting holes, the guard plate and a water storage and guide plate are fixed, the water storage and guide plate is provided with a hot air riser duct, and the edge of the water storage and guide plate is provided with a water retainer edge facing up. The hot air generated by the generator set is guided to flow up around the gas cylinder, below the gas cylinder; the heat generated by the generator set is made full use to heat and pressurize the gas cylinder; the vertical positioning carrier is especially suitable for use in cold areas.

Owner:CHONGQING DAJIANG POWER EQUIP MFG

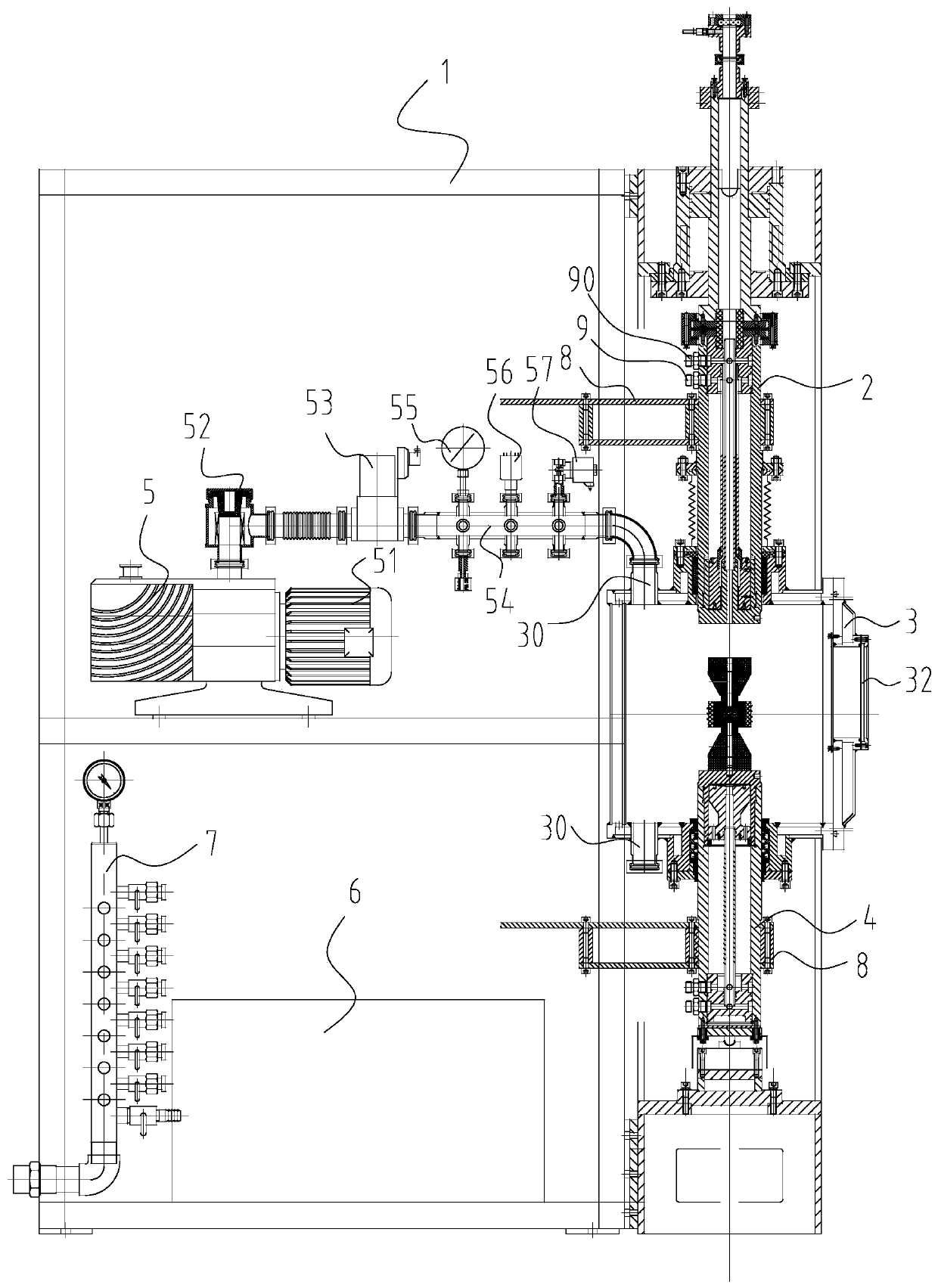

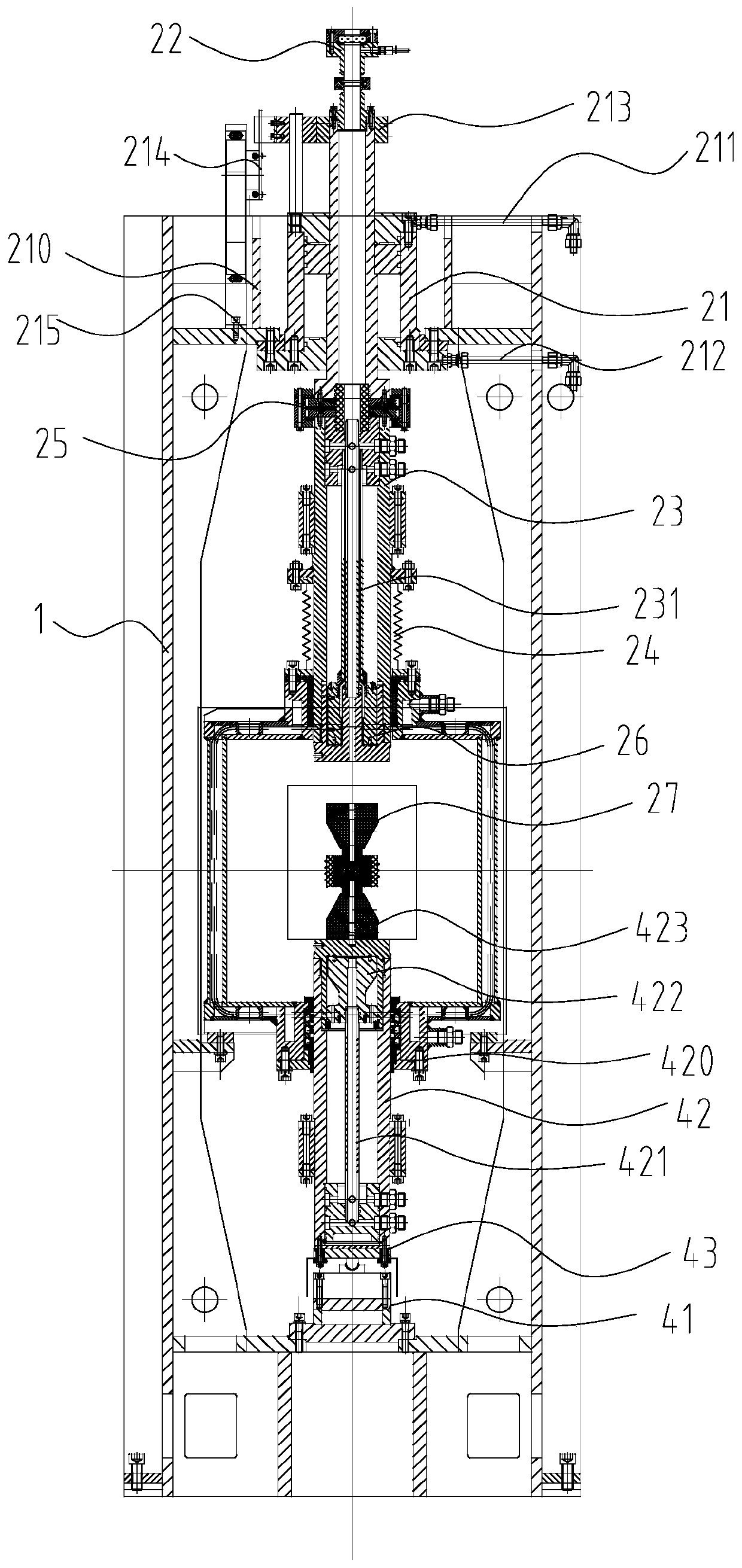

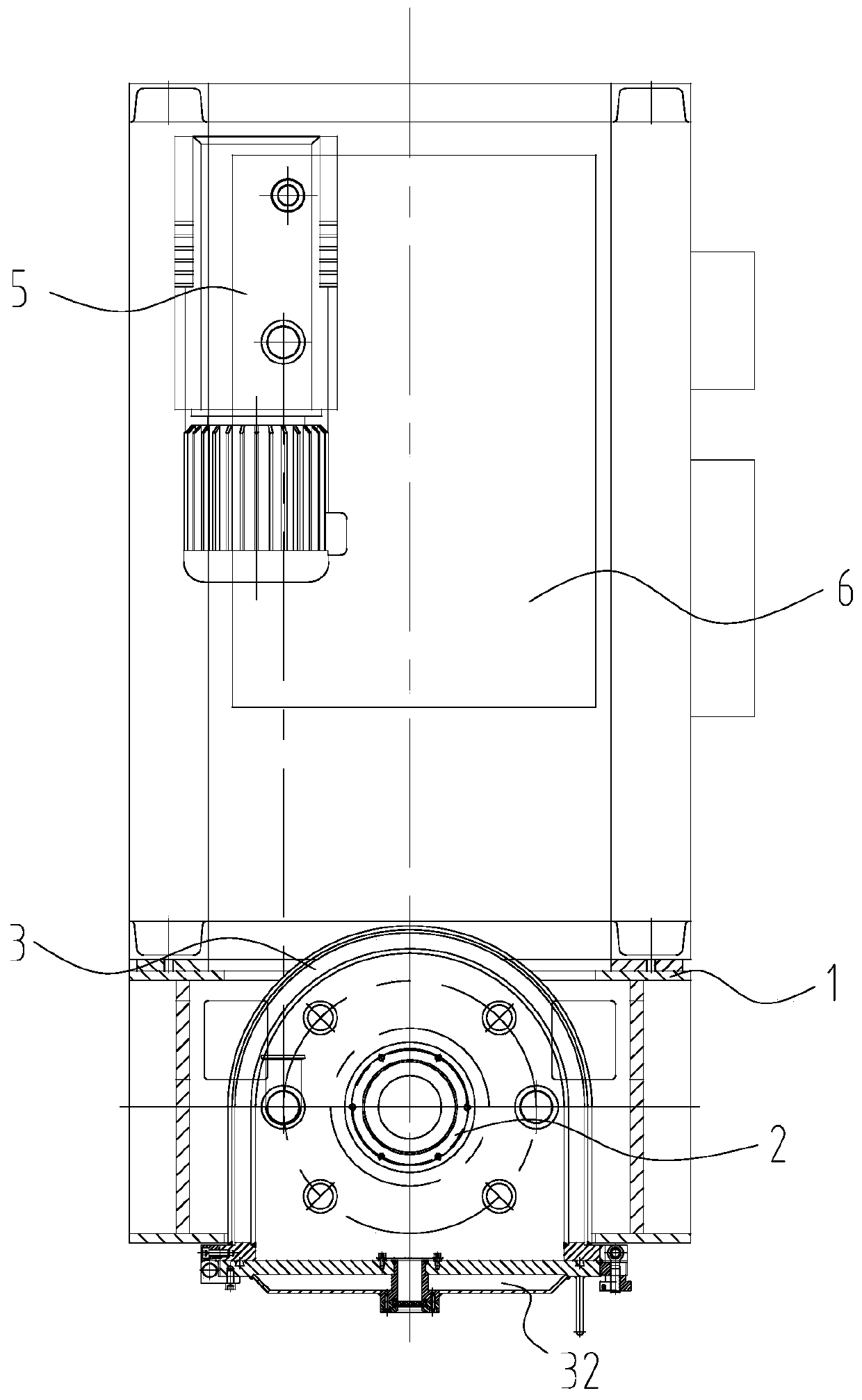

Vacuum sintering furnace

InactiveCN110595202AImprove stabilityEffective controlMuffle furnacesCharge composition/stateVacuum pumpingTemperature control

The invention relates to the technical field of ceramic vacuum sintering furnace. A vacuum sintering furnace comprises a rack, an upper part pressing device, a furnace body, a lower part supporting device, a vacuum device, a hydraulic device, a water cooling device; the upper part pressing device, the furnace body and the lower part supporting device are arranged at the front part of the rack; theupper part pressing device is arranged at the top of the furnace body, and the upper part pressing device penetrates through the top of the furnace body and used for pressing materials; the lower part supporting device is arranged in the bottom of the furnace body, and the lower supporting device penetrates through the bottom of the furnace body for supporting materials and is matched with the upper part pressing device; the vacuum device is arranged at the rear part of the rack, and the vacuum device is communicated with the furnace body; the hydraulic device and the water cooling device arerespectively arranged at the lower side of the rear of the rack; and the hydraulic device is used for performing hydraulic control, and the water cooling device for cooling control. This patent has the advantage of improving the ceramic material in the sintering process, improve the stability of the vacuum pumping effect to prevent the occurrence of accidental explosion, temperature control effect is improved, and the sintering efficiency is improved.

Owner:陈美香

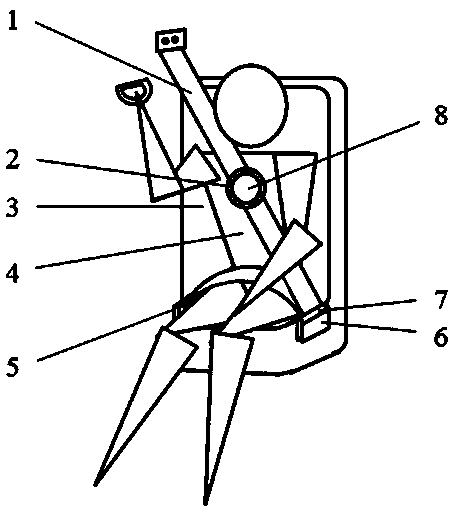

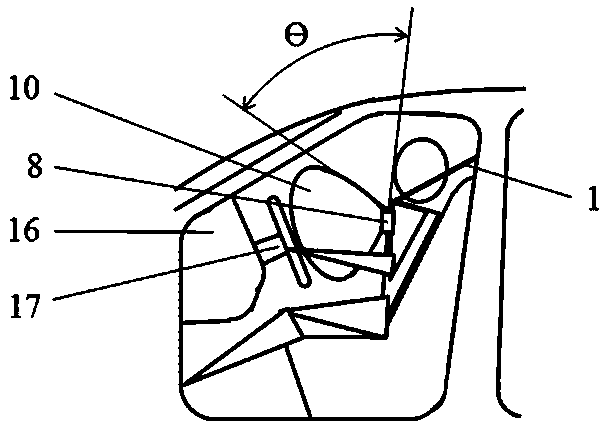

Wearable type airbag system

PendingCN110239473AReduce collisionAvoid holding your breathPedestrian/occupant safety arrangementEnergy-absorbing device incorporationSteering wheelEngineering

The invention discloses a wearable type airbag system. A novel connection or installation method is adopted, particularly, under the support of a wireless sensor network WSN technology, an airbag assembly is worn on a body of a passenger, and some disadvantages that in a traditional scheme, an airbag assembly is fixedly installed in the middle of a steering wheel or in a central console are overcome. A airbag (10) is fixed to the front of the chest of the passenger, the unfolding direction is the same as the direction of movement of a human body, the recoil force can slow down the speed of forward rush of the human body, and even if the airbag (10) collides with the human body during the rapid expansion phase, the impact on the human body is further less than that of the case of opposite-direction collision. A chest cushion airbag (13) of the airbag system can reduce the impact on the chest of the human body, and can further be inflated to contract a seat belt. The airbag (10) is internally provided with a tubular inner container (19), and an included angle theta exists between the unfolded airbag and the human body to enable the head to move, the head of the passenger is prevented from being crush-injured in the unfolding process, and long-time suffocation and burning are avoided. The airbag assembly adopts a connection structure with convenient assembly and disassembly and position adjustment.

Owner:周承岗

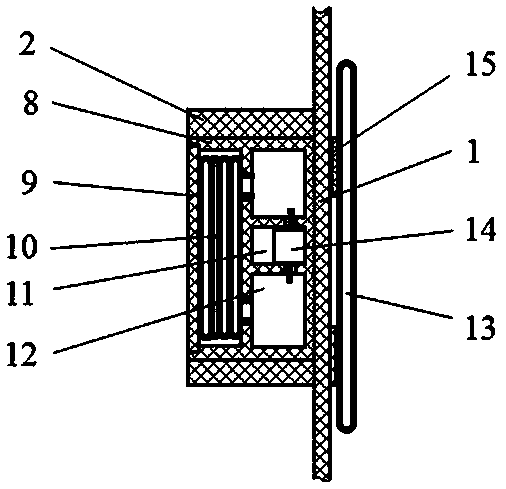

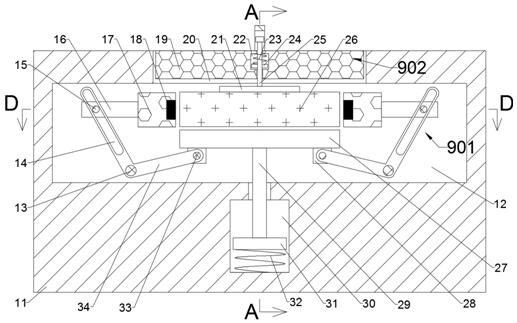

Charging device capable of popping up lithium battery in case of abnormal expansion

ActiveCN112583085APrevent accidental explosionProtection securityElectric powerSafety/protection circuitsEngineeringMechanical engineering

The invention discloses a charging device capable of popping up a lithium battery in case of abnormal expansion. The charging device comprises a working box body, the working box body is internally provided with a working cavity, and the working box body is internally provided with an elastic cavity located in the lower side of the working cavity. The charging device can seal the lithium battery in the charging process, so that the lithium battery can be protected to a certain extent; meanwhile, when the lithium battery expands in the charging process, the sealing state of the lithium batteryis immediately relieved, and the lithium battery is popped out of the device, so that the device is protected while accidental explosion caused by continuous charging of the lithium battery is prevented, and the charging assembly is prevented from being damaged by accidental explosion of the lithium battery; and the safety of the charging device is maintained to a certain extent.

Owner:深圳盛齐能源技术有限公司

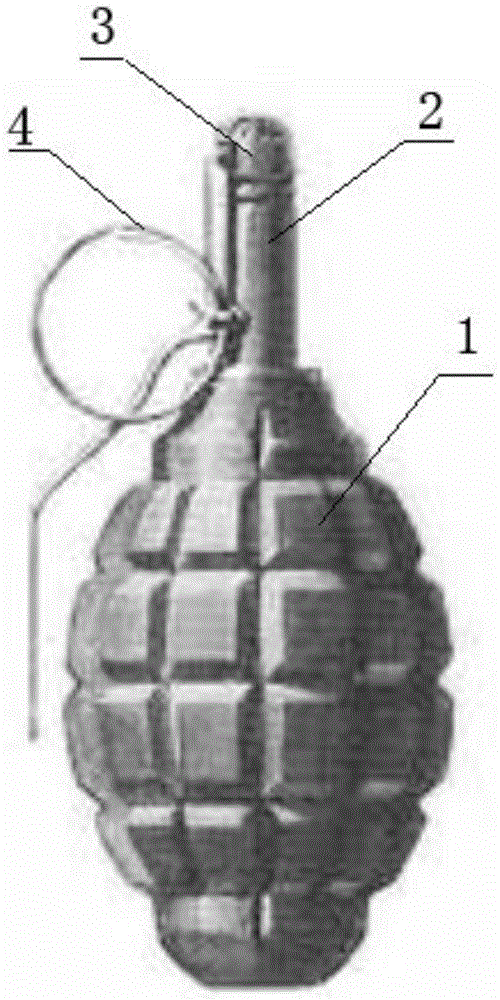

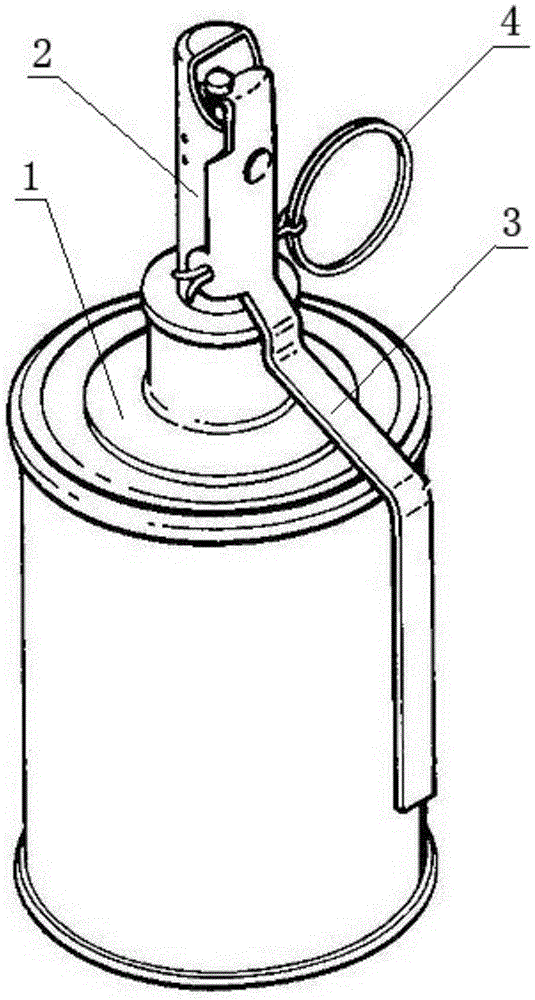

A grenade throwing fire extinguishing bomb

The invention provides a novel grenade type throwing fire extinguishing bomb which comprises an upper cover, a control piece, a control cavity, an explosion cavity and a hollow cavity, wherein the control cavity and the explosion cavity are positioned in the hollow cavity; the explosion cavity is divided into multiple inner cavities corresponding to igniters; the control piece comprises a temperature sensor, an upper cover sensor, a controller and an electric detonator; the upper cover sensor is connected with a detonation signal receiving component of the controller; the temperature sensor is connected with a time delay signal receiving component of the controller; sensing heads of the temperature sensor are arranged on the outer walls of different inner cavities of the hollow cavity; igniters of the electric detonator correspond to the sensing heads; the controller sets corresponding igniter temperature time delay values according to a temperature sequence. According to the novel grenade type throwing fire extinguishing bomb, a detonation signal is actuated by pulling the upper cover with a hand of a user, so that the phenomenon of mis-explosion or non-explosion is avoided; furthermore, detonation time delay differences in different directions are finely adjusted according to the surrounding temperature differences, so that a single fire extinguishing device automatically moves to a region with high temperature.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

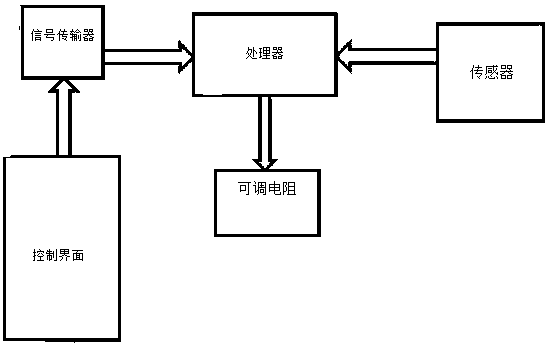

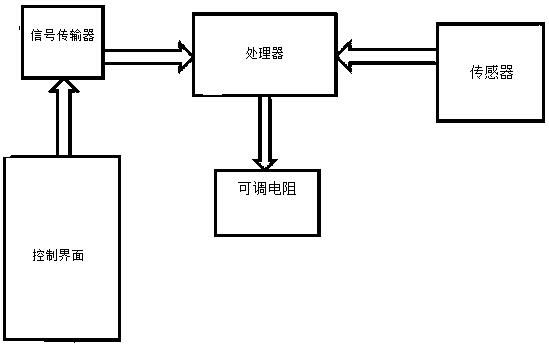

Energy-saving loss-prevention power bank

PendingCN109980702APrevent accidental explosionExtended service lifeCircuit monitoring/indicationDifferent batteries chargingElectrical resistance and conductanceTransmitter

An energy-saving loss-prevention power bank comprises a box body, a battery and a circuit board, and is characterized by further comprising a control interface, a signal transmitter, a processor, a sensor and a variable resistor; the control interface sends a signal to the processor through the signal transmitter; the processor is used for analyzing the signal; the sensor receives various signalsin the box body and transmits the signals to the processor, and the processor feeds back data to the control interface for display; the battery is connected with the variable resistor; and the processor controls the resistance of the variable resistor.

Owner:NANJING INST OF TECH

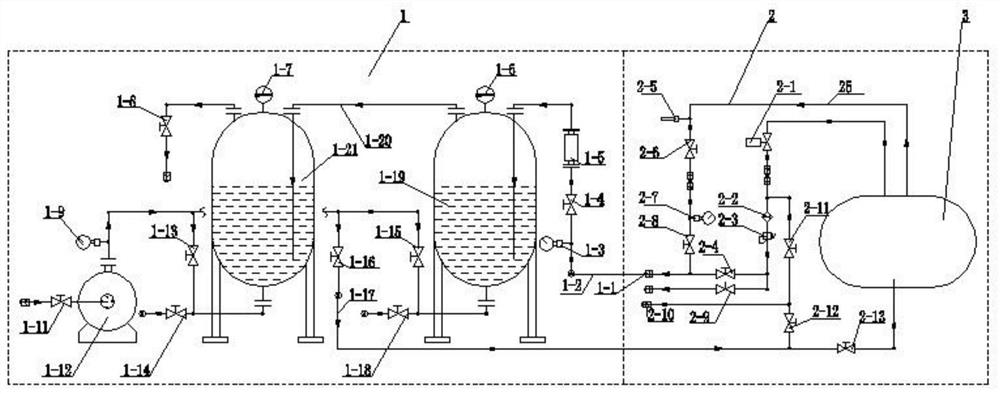

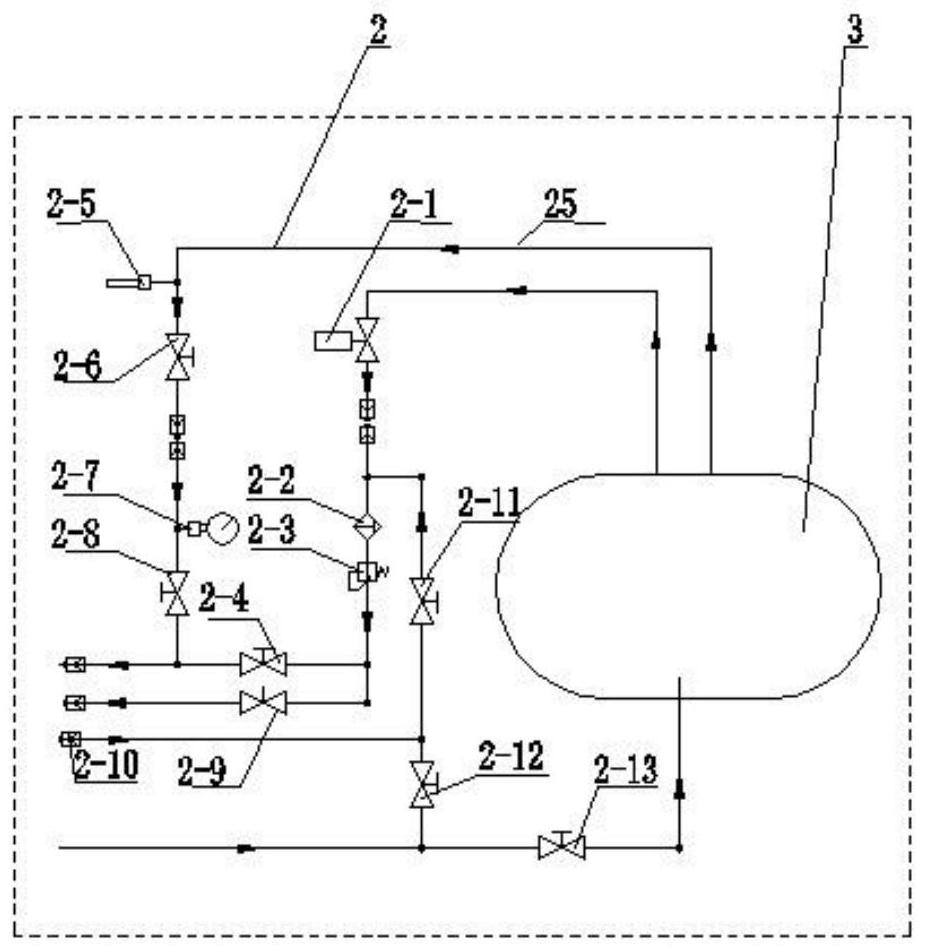

Anti-explosion and decontamination integrated treatment system used for suspected biochemical explosives

PendingCN112875072AAvoid Secondary DisastersSlow down the flowHollow article cleaningLarge containersLiquid storage tankEnvironmental engineering

The invention relates to an anti-explosion and decontamination integrated treatment system used for suspected biochemical explosives. The system comprises a chemical-defense anti-explosion storage and transportation tank, and is characterized in that the system further comprises a decontamination treatment device, a tank opening locking mechanism assembly of the chemical-defense anti-explosion storage and transportation tank is connected at the opening part of a tank body and the opening part of a tank cover in a sleeving manner at the same time, a pressure-reducing unloading assembly and an emergency unloading assembly of a pressure-reducing unloading cleaning assembly of the chemical-defense anti-explosion storage and transportation tank are connected with the top of the tank body in a sealed manner, and a cleaning assembly communicates with the bottom of the tank body in a sealed manner; and a harmful gas and liquid inlet of the decontamination treatment device is connected with a discharge port of the chemical-defense anti-explosion storage and transportation tank in a sealed manner, an outlet is discharged to the outside, a decontamination liquid inlet of the decontamination treatment device is connected with a decontamination liquid storage tank in a sealed manner, and a decontamination liquid outlet of the decontamination treatment device is connected with a filling port of a primary decontamination assembly, a filling port of a secondary decontamination assembly and a filling port of the chemical defense anti-explosion storage and transportation tank in a sealed manner.

Owner:中国人民解放军61699部队 +1

A timing detonation device and method

The invention discloses a timing initiation device and method. The device comprises a shell; the shell is provided with a key, a display screen, a mechanical fuse and an electric detonator socket connected with an electric detonator; a microcontroller electrically connected with the key and the display screen and an initiation circuit electrically connected with the microcontroller are mounted inthe shell; a common end of a single-pole double-throw switch is electrically connected with the electric detonator socket, a normally closed end is grounded, and a normally open end is electrically connected with the initiation circuit; a poking piece of the single-pole double-throw switch is defaulted to communicate with the common end and the normally closed end; under the condition of relievingthe mechanical fuse, the poking piece communicates with the common end and the normally open end; and a battery supplies electricity to the device through a power supply management module. The timinginitiation device is small in size, low in weight, simple in operation, high in automation degree and convenient to carry; users can autonomously set the timing time; and the electric detonator is initiated to realize initiation after timing.

Owner:中国电波传播研究所 +1

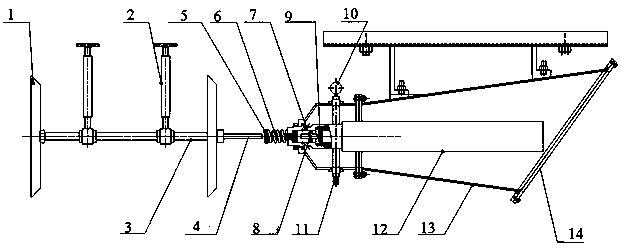

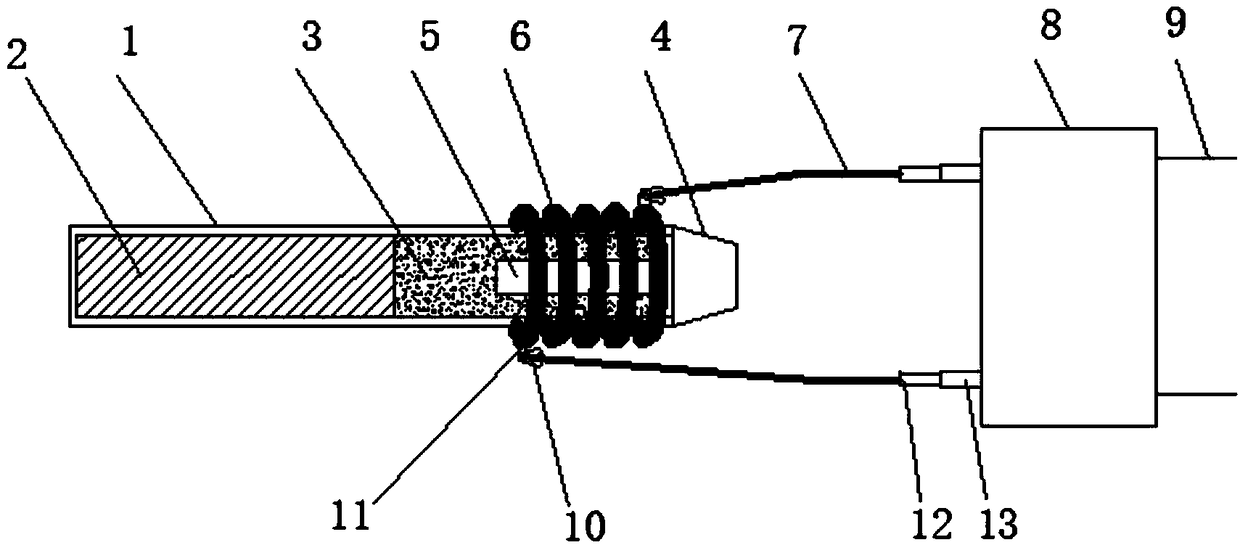

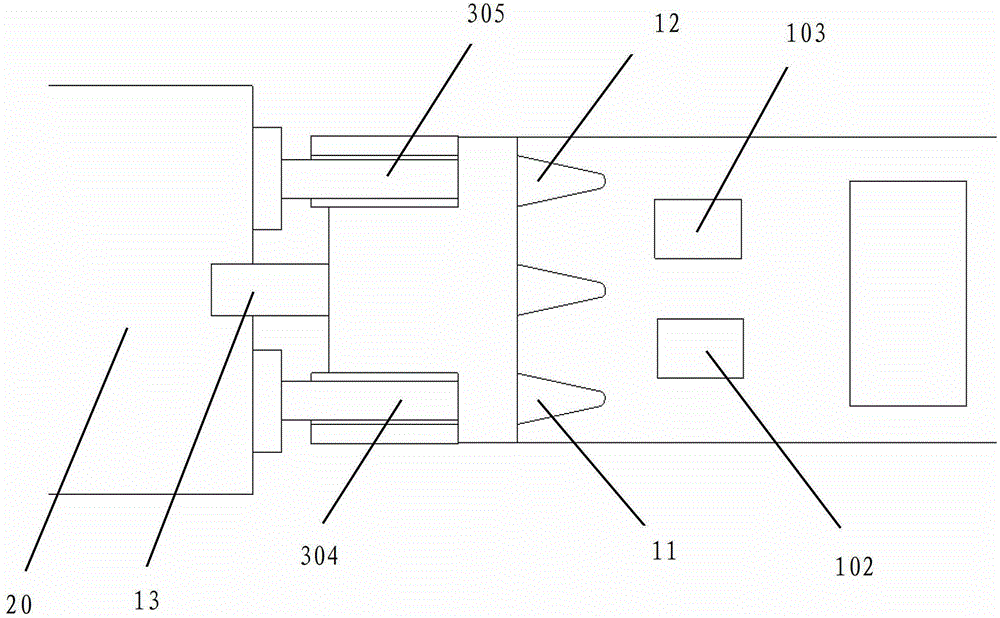

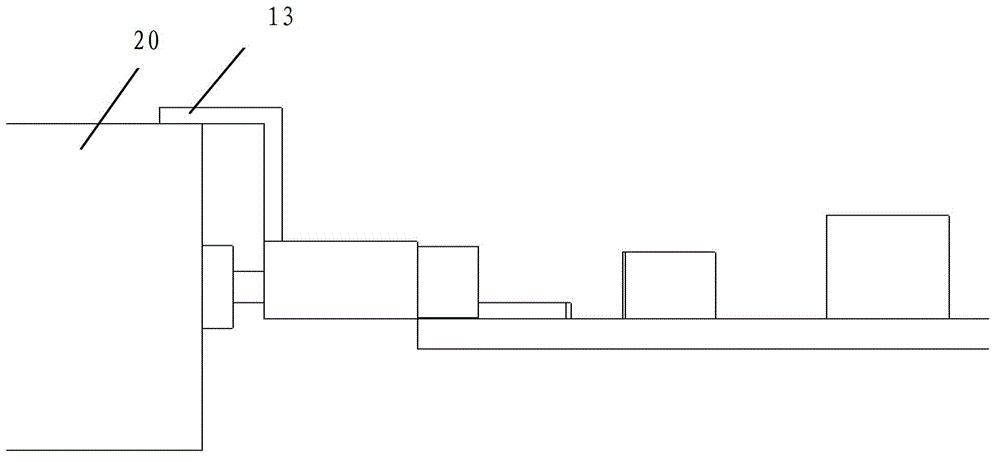

A method and device for ensuring safety in the chamber of small-caliber ammunition

InactiveCN107388908BPrevent accidental explosionGuaranteed safety in the boreAmmunition fuzesIsolating mechanismsEngineering

The invention provides a method and device for ensuring in-chamber safety of small-caliber ammunition. The method comprises the steps that a the device used for ensuring the in-chamber safety is arranged in a small-caliber ammunition fuse, the device acts under the action of in-chamber recoil force in the shooting process for preventing a fuse isolating mechanism from moving, and then the fuse isolating mechanism is made in an isolated state; and after the ammunition is out of the chamber, the device is reset, and a restriction on the fuse isolating mechanism is removed. The device comprises a base, a limiting body, a safety pin, an elastic part, a containing groove, a first locating hole and a second locating hole, wherein a fastening part is arranged at one end of the containing groove, the elastic part enables the safety pin to be located in the containing groove or the containing groove and the first locating hole at ordinary times, and the safety pin compresses the elastic part to move under the action of the in-chamber recoil force to enable the first locating hole to be fixedly connected with the second locating hole in an inserted manner in the shooting process. According to the method and device for ensuring the in-chamber safety of the small-caliber ammunition, it is guaranteed that isolation cannot be removed through the fuse isolating mechanism in the chamber, and therefore an in-chamber explosion is avoided, and the in-chamber safety in the shooting process is guaranteed.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

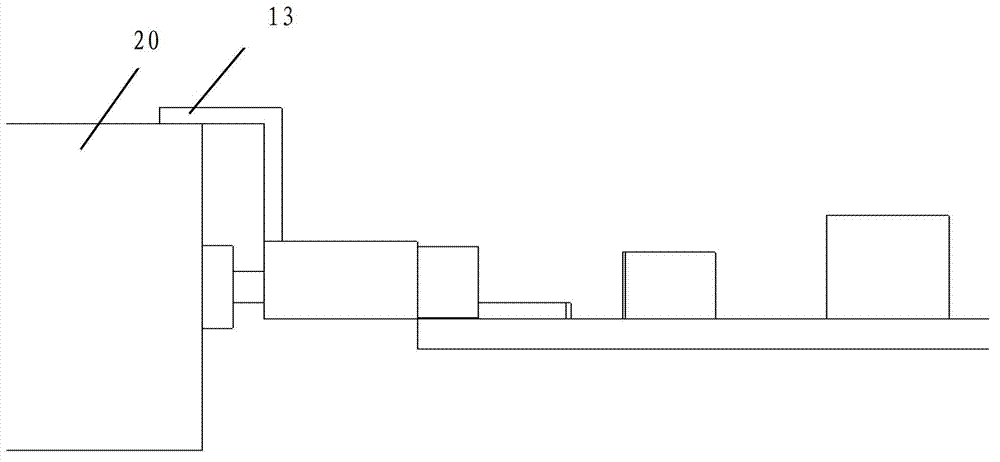

Installation structure of a car seat belt retractor

The invention discloses an automobile safety belt retractor installation structure and belongs to the technical field of automobile body accessories. The automobile safety belt retractor installation structure comprises a safety belt retractor support and safety belt retractor support reinforcing plates. The safety belt retractor support, the safety belt retractor support reinforcing plates and an automobile body B-pillar inner plate are connected together through three-layer welding spots. The safety belt retractor support and the automobile body B-pillar inner plate are further fixedly connected through other two-layer welding spots. The safety belt retractor support reinforcing plate and an automobile body B-pillar inner plate reinforcing plate are fixedly connected through other two-layer welding spots. The automobile safety belt retractor installation structure has the advantages of being simple in structure, low in cost, convenient to install and beneficial to engineered mass production; in addition, the automobile safety belt retractor installation structure meets installation requirements of an automobile safety belt retractor, improves rigidity of the safety belt retractor support, avoids the phenomenon of sudden spontaneous firing of side air bags and improves safety in automobile driving.

Owner:GREAT WALL MOTOR CO LTD

An induction detonation system

The invention discloses a sympathetic detonation system. The sympathetic detonation system comprises a detonator outer shell, an initiating explosive, an insulation base, a metal column, a coil, a high-frequency alternating current generator and the like. A high-frequency alternating current is introduced into the coil wound around the detonator outer shell, and the metal column contained in the detonator outer shell is sympathetically heated; as the surface temperature can be rapidly increased through the skin effect, the temperature-sensitive initiating explosive is rapidly detonated to achieve the aim of detonating a detonator; related circuits are not in contact with the initiating explosive at all, and the dangerous condition of a fault explosion caused when static electricity is generated in the transportation or use process is avoided; in addition, the sympathetic detonator system can be suitable for multiple environments; as the requirement of temperature increasing of the metal column for the frequency of the current is special and cannot be influenced by thunderstorm weather and static electricity environments, the influences of surrounding power frequency circuits on the temperature of the metal column are tiny, the application range is wide, the structure is simple, and the cost is low.

Owner:SOUTHWEAT UNIV OF SCI & TECH

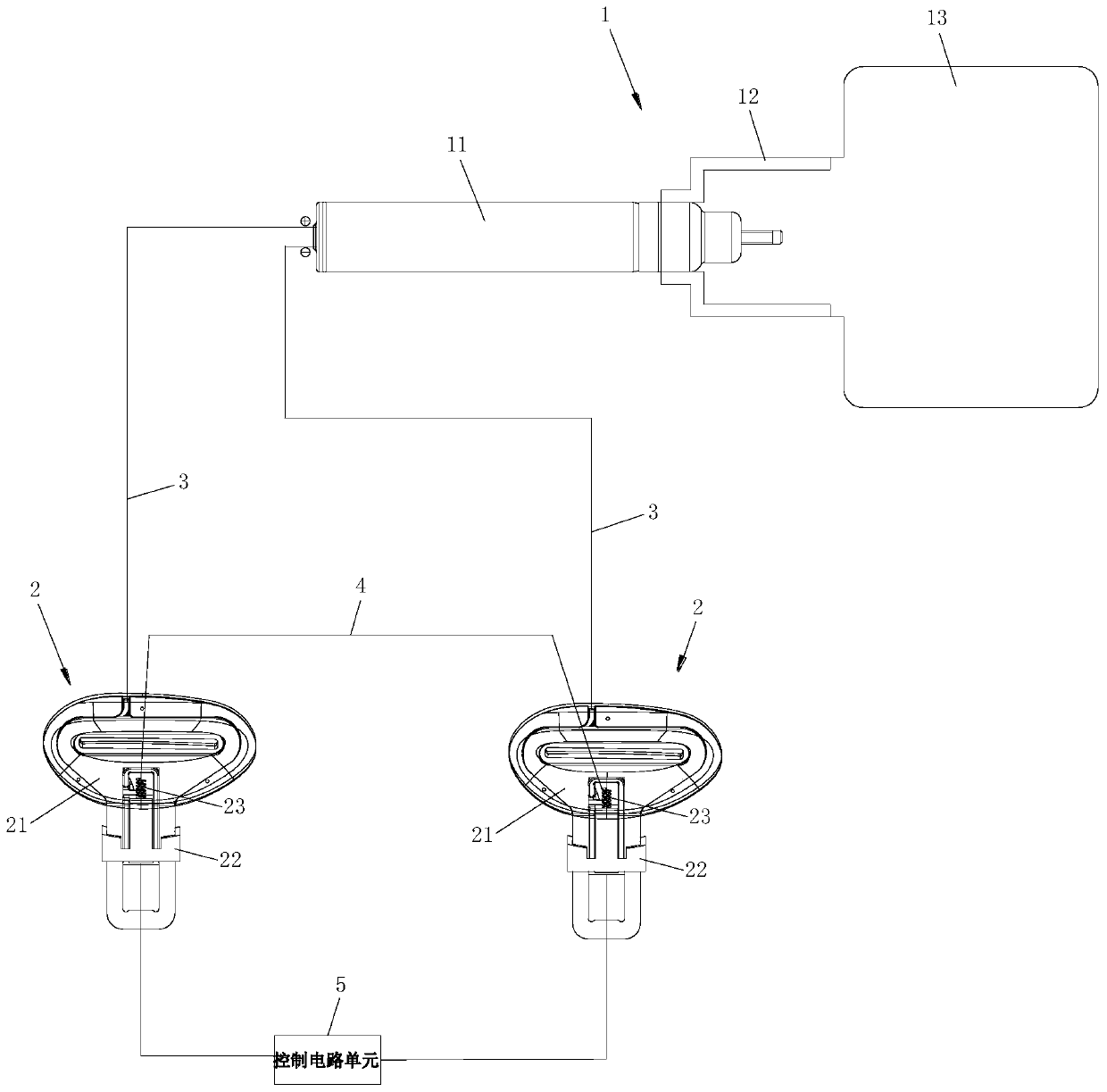

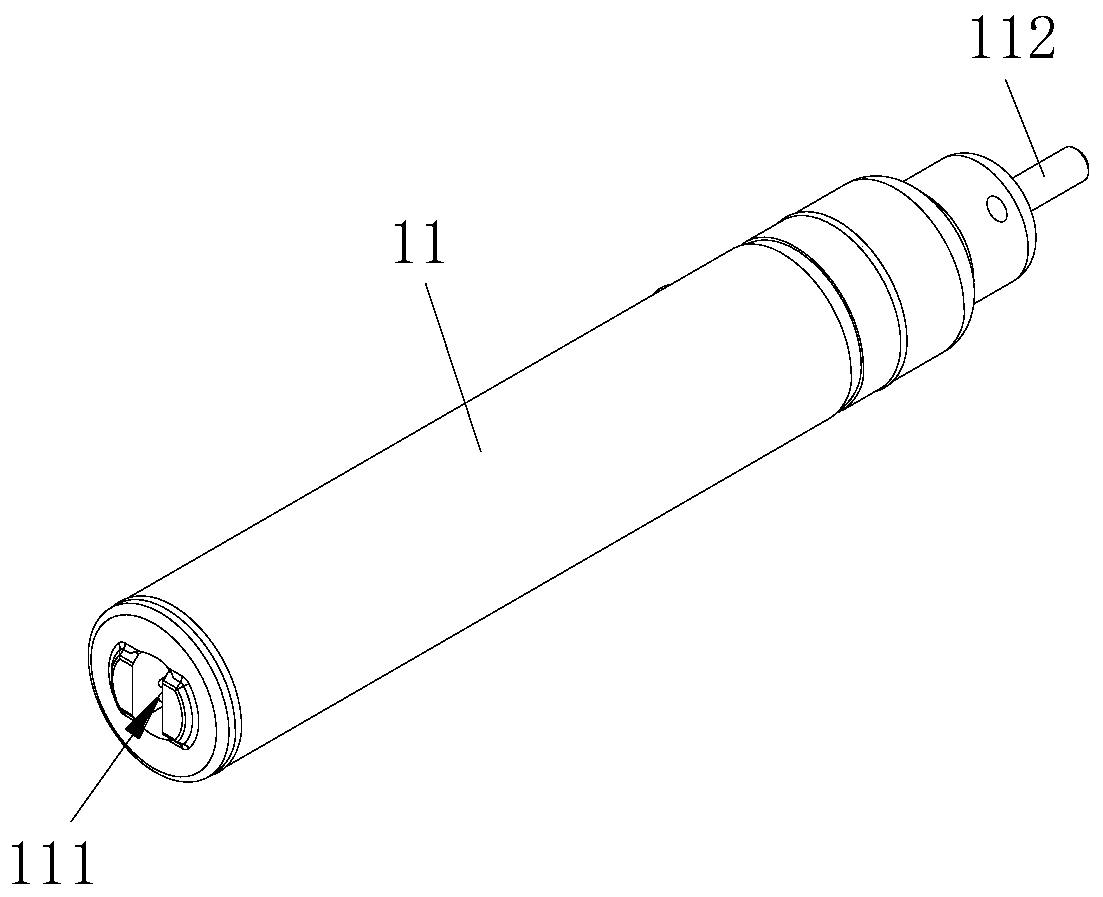

A detonator laser coding line

InactiveCN103664429BIncrease productivityGuaranteed coding qualityDetonatorsDetonatorProgrammable logic controller

The invention discloses a primer laser coding line which is characterized by comprising an antistatic strap, a coding worktable, a coding mold, a barrier strip, an upper mold photoelectric tube, an upper mold cylinder, a positioning cylinder, a safety gate (AND gate) cylinder, a laser coding head, a horizontal pushing magnetic cylinder, a lower mold photoelectric tube, a lower mold cylinder, a laser control cabinet and a gas source, wherein the laser control cabinet comprises a main control box, a laser power supply box, a laser head, a computer and a safety protection case; an industrial control box comprises a PLC (programmable logic controller) programmer, a switching power supply and a protection circuit; and the inside of the laser control cabinet is additionally provided with the safety protection case in which laser power overload protection, X and Y galvanometer motor deflection shutdown protection, laser time protection and filtration stray current protection are set. In case of an abnormal condition, a laser power supply is automatically cut off, thus ensuring coding safety. The primer laser coding line prevents accidental explosion in the coding process, and achieves the purposes of stability, high quality, reliability, safety and high production efficiency in laser coding.

Owner:HUNAN SHENFU GRP XIANGHONG MACHINERY CHEM

Child safety seat

The invention discloses a child safety seat which comprises a passive protection device, two controllers, a wire and a control circuit unit, wherein the two ends of the wire are connected with the twocontrollers respectively, and the two ends of the control circuit unit are connected with the two controllers respectively. The passive protection device comprises a triggered device, and the two ends of the triggered device are detachably connected with the two controllers respectively. Each controller has a first working state and a second working state which can be switched with each other. When the two controllers are both in the first working state, the two ends of the wire are connected with the two ends of the triggered device through the two controllers respectively, and the passive protection device is in a closed state; and when the two controllers are both in the second working state, the two controllers enable the two ends of the wire to be disconnected from the two ends of the triggered device respectively, the two ends of the control circuit unit are connected with the two ends of the triggered device through the two controllers respectively, and the passive protection device is in a to-be-triggered state.

Owner:GOODBABY CHILD PROD CO LTD

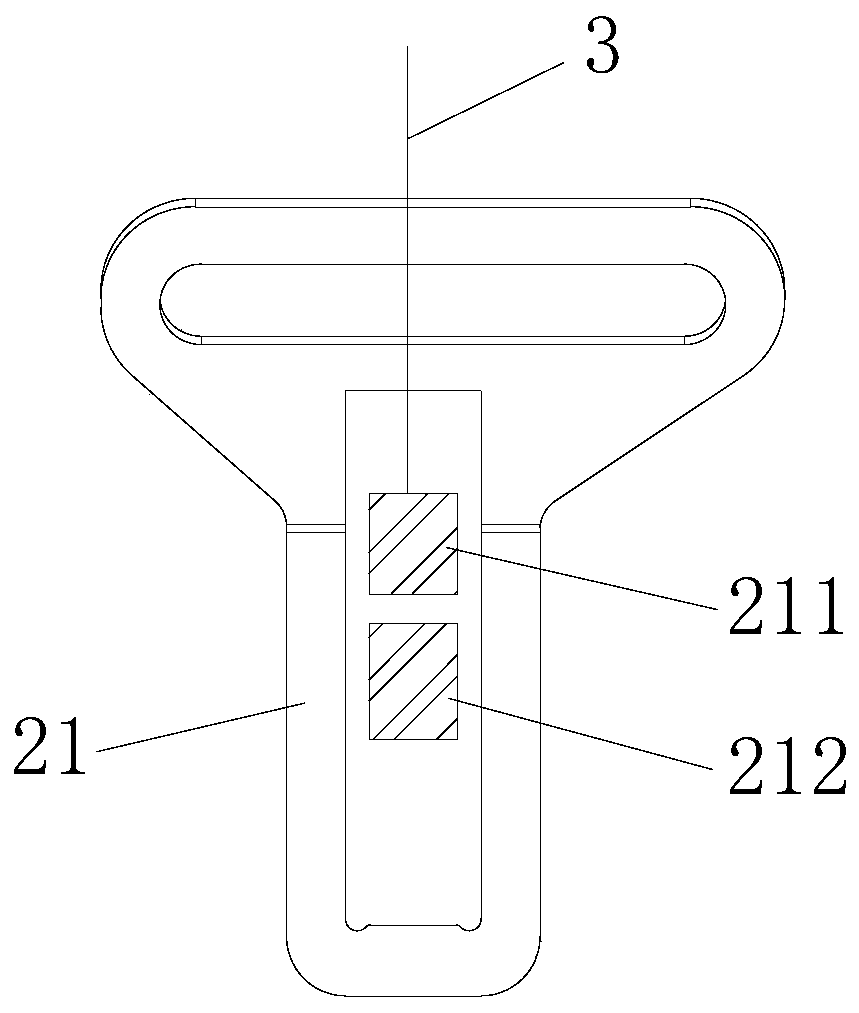

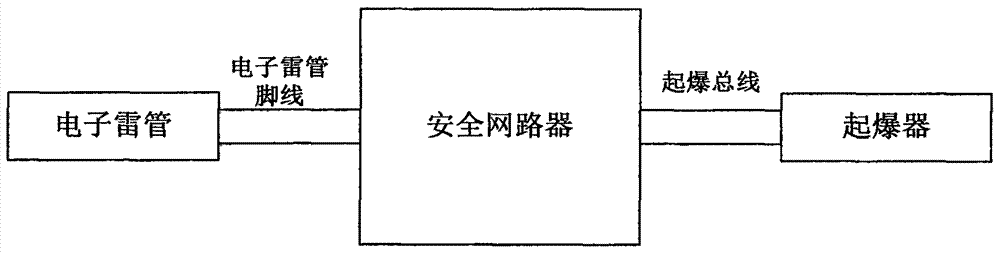

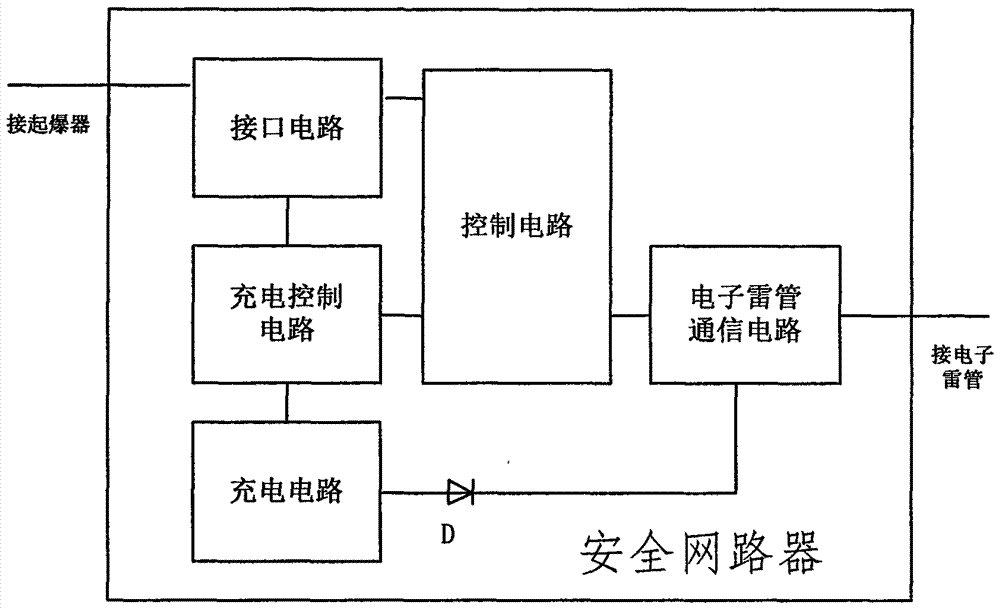

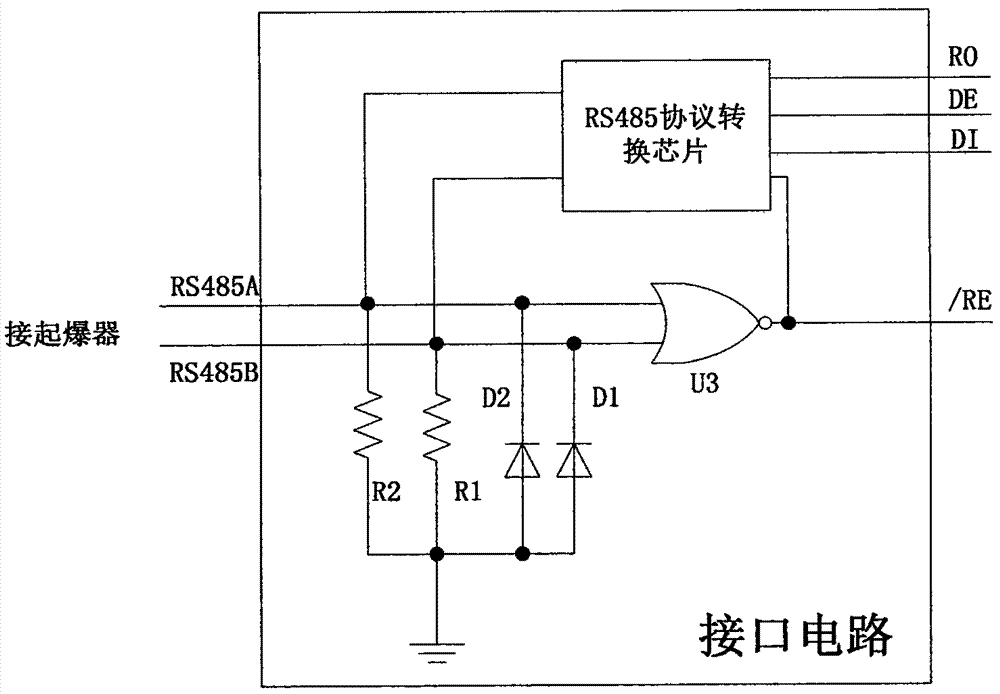

Safety network device for electronic detonator detonation system and its application method

ActiveCN105043178BImprove securityAvoid the possibility of accidental explosionBlastingDetonatorCharge control

The invention discloses a secure network device for an electronic detonator initiation system and relates to the technical field of electronic detonator initiation system security design. The secure network device is connected with an initiator and an electronic detonator and is characterized by comprising an interface circuit, a control circuit, a charging control circuit, a charging circuit and an electronic detonator communication circuit, the charging control circuit comprises a first switch and a second switch, and the electronic detonator communication circuit comprises a third switch and a fourth switch. The invention further discloses a use method of the secure network device for the electronic detonator initiation system. The security of the charging process of the electronic detonator is improved and use and construction cost is reduced.

Owner:陈默

Hand-held fire extinguishing bomb

InactiveCN103977522BPrevent accidental explosionPriority fightFire rescueEngineeringTemperature difference

The invention provides a novel handle-dripping type hand-launched fire extinguishing bomb. The novel handle-dripping type hand-launched fire extinguishing bomb comprises an upper cover, a control part, a control cavity, an explosive cavity, and a hollow cavity body; the explosive cavity is positioned into the hollow cavity body and divided into a plurality of inner cavities corresponding to igniters; the control part comprises a temperature sensor, an upper cover sensor, a controller and an electric igniter; the upper cover sensor is connected with an igniting signal receiving part of the controller; the temperature sensor is connected with a delay signal receiving part of the controller; sensing heads of the temperature sensor are arranged on the outer walls of different inner cavities of the hollow cavity body; flame lighters of the electric igniter correspond to the sensing heads; the flame lighter temperature delay corresponding to the minimum temperature value is set to be the minimum value through the controller, and the flame lighter temperature delay corresponding to the maximum temperature value is set to be the maximum value. According to the novel handle-dripping type hand-launched fire extinguishing bomb, the upper cover is manually pulled to start an igniting signal to avoid error exploding or exploding failure; in addition, the igniting delay difference in different directions is slightly adjusted according to the surrounding temperature difference, and thus single fire extinguishing device can automatically move toward an area with relatively high temperature.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

An antistatic structure of an electronic detonator

ActiveCN103033100BAvoid damagePrevent accidental explosionAmmunition fuzesElectrical resistance and conductanceMetallic enclosure

The invention provides an anti-static structure of an electronic detonator, wherein two leg wires of the electronic detonator are electrically connected with a control circuit of a control circuit board. The anti-static structure of the electronic detonator is characterized by further comprising a discharge metal connecting piece; one end of the discharge metal connecting piece is electrically connected with a metal casing of the electronic detonator; two anti-static electronic devices are connected between the other end of the discharge metal connecting piece and one leg wire, as well as between the other end of the discharge metal connecting piece and the other leg wire respectively; and the anti-static electronic devices are transient suppression diodes, discharge tubes or voltage dependent resistors. By additionally arranging the anti-static structure on the electronic detonator, electricity can be preferentially discharged through the anti-static devices when the electronic detonator carries out electrostatic discharge, so that an error explosion can be prevented in the production and use processes; and moreover, one leg wire of the electronic detonator is connected with a first metal connecting piece and a second metal connecting piece in a manner of metal compression joint, the connecting operation is simple, tensile resistance is strong, and the electronic detonator can be prevented from being damaged by an external force in the production and use processes.

Owner:BEIJING QAML OF SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com