High-strength titanium-based fiber explosive

A high-strength, fiber-based technology, applied in explosives and other directions, can solve the problems of improving the mechanical properties of incapable explosives, poor mechanical properties of explosives, and life, and achieve the effects of improving overall combat capability, improving safety performance, and reducing accident rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

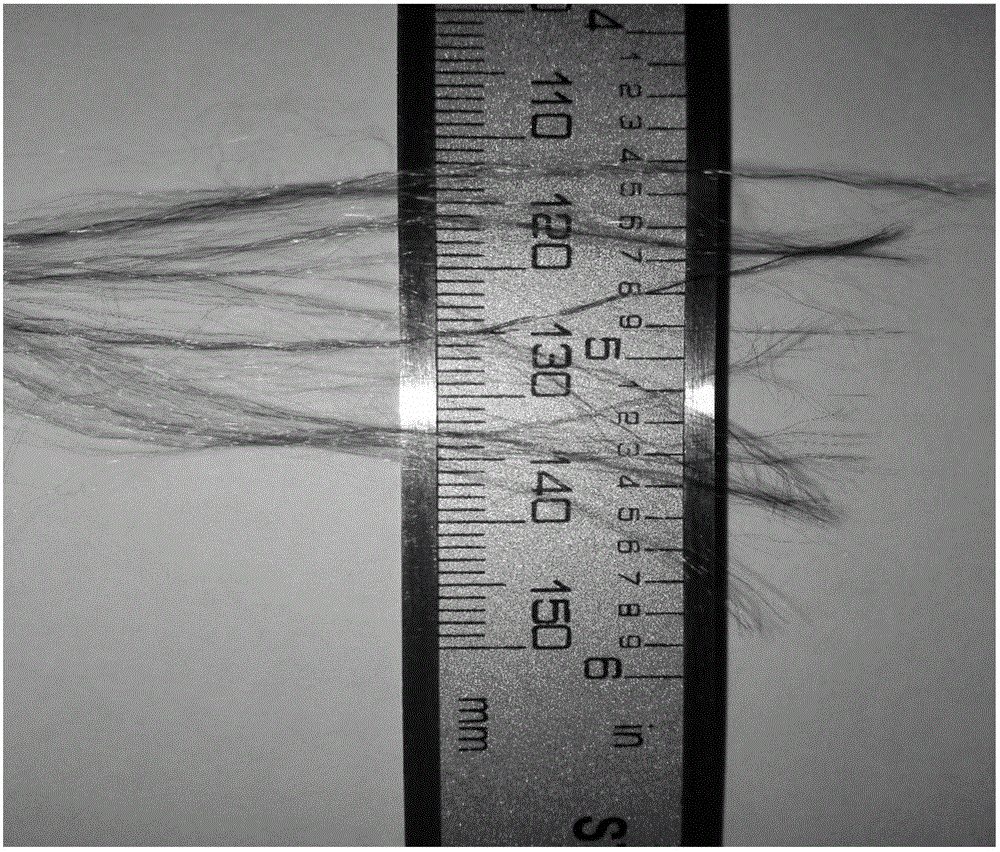

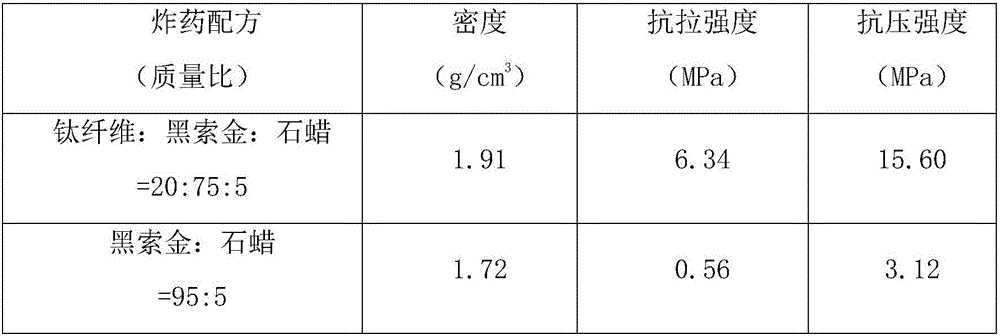

[0017] The high-strength titanium-based fiber explosive of this embodiment is made of the following components in mass percentage: 20% of titanium metal fiber, 75% of RDX, and 5% of paraffin. Among them, the diameter of the titanium metal fiber is 8 μm, the length is 2 cm, and the total mass of the explosive is 10 g. The diameter of the explosive column is 1.5 cm, the height is 2.96 cm, and the density is 1.91 g / cm 3 . The RDX explosive in this embodiment is made of the following components in mass percentage: 95% RDX and 5% paraffin. The mass is 10 grams, the diameter of the explosive column is 1.5cm, the height is 3.29cm, and the density is 1.72g / cm 3 .

[0018] In the experiment, the WDW4100 universal testing machine was used to test the compressive performance of the powder column. The experiment was loaded in a controlled speed mode, and the loading speed was 1mm / min. The following table is the experimental data.

[0019] Table 1 Example 1 tensile and compressive perfo...

Embodiment 2

[0026] The high-strength titanium-based fiber explosive of this embodiment is made of the following components in mass percentage: 20% of titanium-magnesium alloy metal fiber, 75% of RDX, and 5% of paraffin. Among them, the diameter of the titanium-magnesium alloy metal fiber is 8 μm, the length is 2 cm, and the total mass of the explosive is 10 g. The diameter of the explosive column is 1.5 cm, the height is 3.06 cm, and the density is 1.85 g / cm 3 . The RDX explosive in this embodiment is made of the following components in mass percentage: 95% RDX and 5% paraffin. The mass is 10g, the diameter of the explosive column is 1.5cm, the height is 3.29cm, and the density is 1.72g / cm 3 . In the experiment, the WDW4100 universal testing machine was used to test the compressive performance of the powder column. The experiment was loaded in a controlled speed mode, and the loading speed was 1mm / min. The following table is the experimental data.

[0027] Table 3 Example 2 tensile and...

Embodiment 3

[0034] The high-strength titanium-based fiber explosive of this embodiment is made of the following components in mass percentage: 20% of titanium-aluminum alloy metal fiber, 75% of RDX, and 5% of paraffin. Among them, the titanium-aluminum alloy metal fiber has a diameter of 8 μm, a length of 2 cm, and a total explosive mass of 10 g. The resulting explosive column has a diameter of 1.5 cm, a height of 3.01 cm, and a density of 1.88 g / cm 3 . The RDX explosive in this embodiment is made of the following components in mass percentage: 95% RDX and 5% paraffin. The mass is 10g, the diameter of the explosive column is 1.5cm, the height is 3.29cm, and the density is 1.72g / cm 3 . In the experiment, the WDW4100 universal testing machine was used to test the compressive performance of the powder column. The experiment was loaded in a controlled speed mode, and the loading speed was 1mm / min. The following table is the experimental data.

[0035] Table 5 Example 3 tensile and compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com