An induction detonation system

A technology of inductive detonation and priming charge, which is applied in the direction of blasting, etc., can solve problems such as rejection of blasting, inappropriateness, high environmental requirements, etc., and achieve the effect of solving cost and safety problems and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

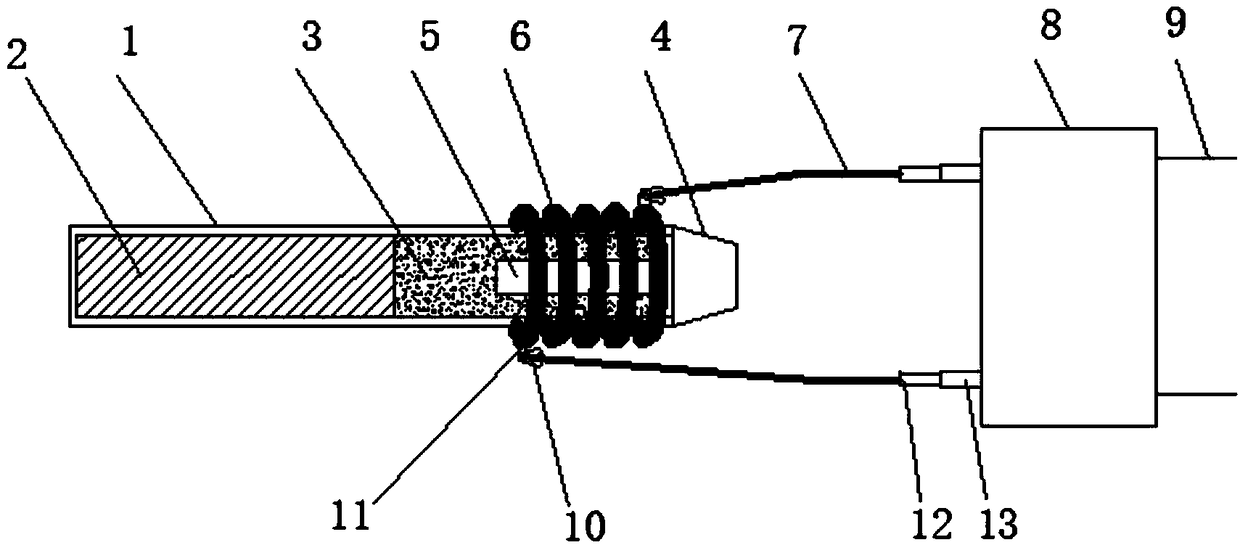

[0017] see figure 1 , the present invention provides a technical solution:

[0018] A DC 36V high-power DC power supply is used as an external power supply to connect with the external wire 9, the high-frequency AC generator 8 is a 36V, 500W high-frequency AC generator, the output frequency is adjusted to 10KHz, and the length of the detonator shell 1 is not less than 55mm , and the inner diameter of the detonator shell is 6.15mm, the detonator shell 1 is filled with reinforcing powder 2 and priming charge 3 from left to right, and the priming charge 3 is heat-sensitive, and a metal column 5 is buried in the priming charge 3, And the metal column 5 is placed in the middle of the right side of the primer 3. The material of the metal column 5 is chrome-plated medium carbon steel, which can heat up rapidly under the action of high alternating current and is not easy to rust and corrode. The primer 3 used should match the selected metal. It has good compatibility, the diameter of...

Embodiment 2

[0020] see figure 1 , the present invention provides a technical solution:

[0021] Use DC 36V high-power DC power supply as the external power supply to connect with the external wire 9, the high-frequency AC generator 8 is a 36V, 500W high-frequency AC generator, the output frequency is adjusted to 200KHz, and the length of the detonator shell 1 is not less than 55mm , and the inner diameter of the detonator shell is 6.25mm. The detonator shell 1 is filled with reinforcing powder 2 and priming charge 3 from left to right. The metal column 5 is made of chrome-plated medium carbon steel, which can quickly heat up under the action of alternating current and is not easy to heat up. Rust and corrosion, the primer 3 is heat-sensitive, and the primer 3 used should have good compatibility with the selected metal. The metal pillar 5 is buried in the primer 3 and the metal pillar 5 is placed on the right side of the primer 3 The middle part of the metal column 5 has a diameter of 2mm...

Embodiment 3

[0023] see figure 1 , the present invention provides a technical solution:

[0024] Use DC 36V high-power DC power supply as the external power supply to connect with the external wire 9, the high-frequency AC generator 8 is a 36V, 500W high-frequency AC generator, the output frequency is adjusted to 300KHz, and the length of the detonator shell 1 is not less than 55mm , and the inner diameter of the detonator shell is 6.35mm. The detonator shell 1 is filled with reinforcing powder 2 and priming charge 3 from left to right. The metal column 5 is made of chrome-plated medium carbon steel, which can heat up rapidly under the action of alternating current and is not easy to generate Rust and corrosion, and the primer 3 used should have good compatibility with the selected metal, the primer 3 is heat-sensitive, the metal column 5 is buried in the primer 3 and the metal column 5 is placed on the right side of the primer 3 In the middle part, the diameter of the metal post 5 is 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com