Conductive composition

A technology of conductivity and composition, applied in the direction of conductive adhesives, circuits, electrical components, etc., can solve the problems of difficult performance of conductivity and other properties, low thermal fatigue resistance, low stress relaxation, etc., and achieve no solder Omission defects, excellent reflow resistance, and excellent heat resistance

Inactive Publication Date: 2018-02-16

FURUKAWA ELECTRIC CO LTD

View PDF10 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, even diffusion sintering type solder has slightly poorer wettability than lead solder, so bonding 5mm 2 For the above large-area components, there is still the risk of solder leakage, and the sintered body is hard and brittle, and the stress relaxation is low. Therefore, it has the disadvantages of low thermal fatigue resistance and short component life.

[0005] In addition to the above-mentioned lead-free solder, Ag paste and the like are also used, but the material cost becomes very high, and contamination due to the migration of Ag ions becomes a problem

[0006] In addition, in many lead solders and lead-free solders, fluxes composed of carboxylic acids and alcohols are usually added for the purpose of removing metal oxide films. Both the oozing of flux and the oozing part of the flux have a negative impact on the reflow resistance reliability (MSL) after moisture absorption in the hermetic package of the semiconductor device. In the past, it was necessary to clean the flux after soldering, and the handling and cleaning waste liquid treatment was as a problem

However, in order to reduce moisture absorption and bleeding, if carboxylic acid and alcohol are not added, the ability to remove the oxide film is insufficient, and it is difficult to express conductivity and other properties

[0007] Moreover, in Patent Document 4, it is described that mercaptans and thioethers are used as fluxes in an adhesive composition using silver as an inorganic filler for semiconductor devices, but silver is expensive and ion migration is likely to occur. , there is a greater risk of an undesired short circuit between the electrodes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4

[0105] Based on the composition in Table 1, add toluene to a mixture of 92wt% metal particles, 4.5wt% resin, and 3.5wt% flux to make a slurry, stir it with a planetary mixer, and spread it thinly on the PET that has been released from the mold. It was applied and dried at 120° C. to obtain an adhesive film with a thickness of 40 μm. In addition, in the table, BMI-3000 has the following structure (n=1-10).

[0106] [compound 5]

[0107]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

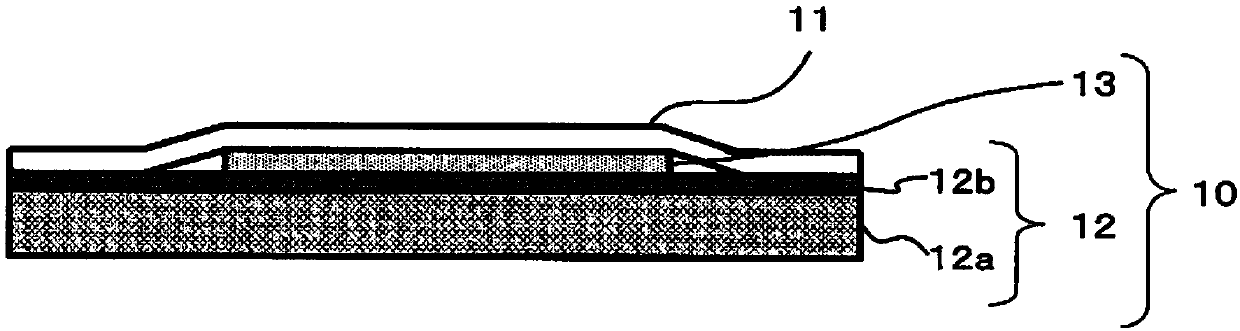

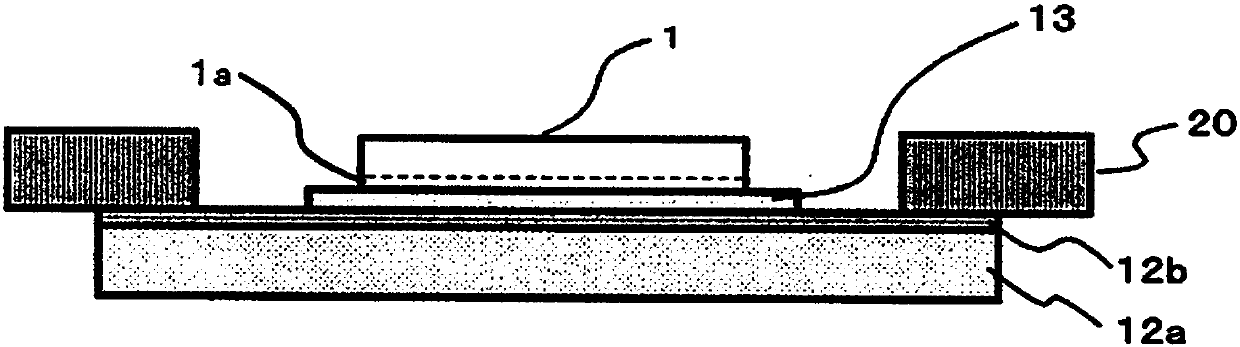

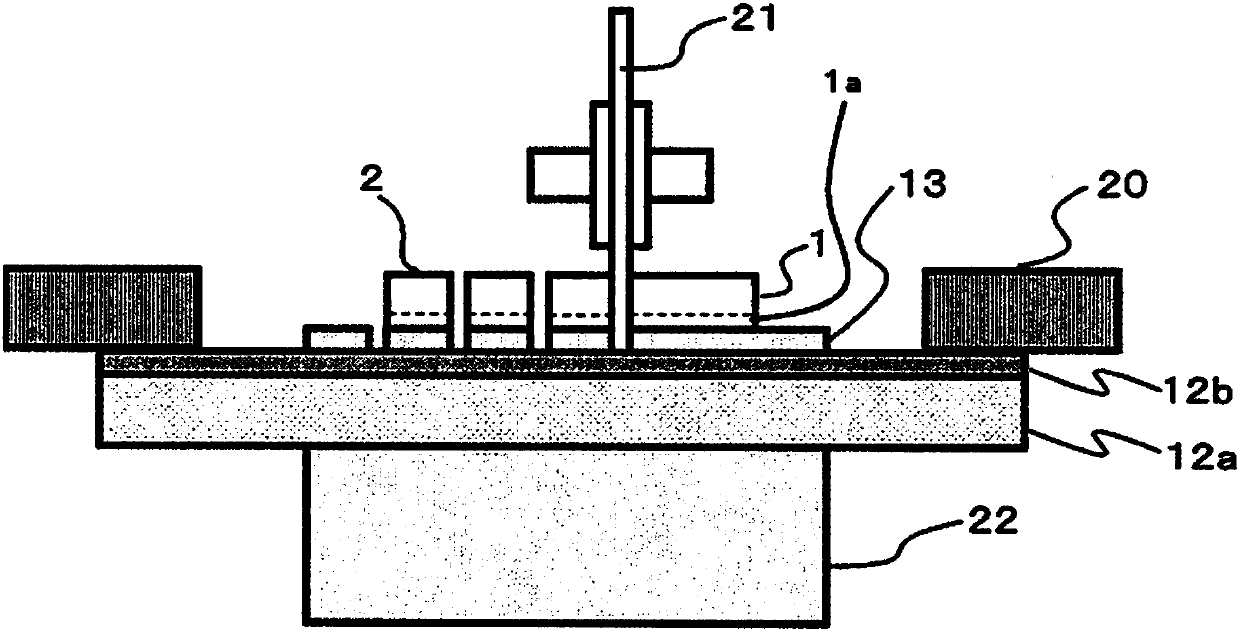

The purpose of the present invention is to provide a means which exhibits excellent heat resistance and mounting reliability when a semiconductor power element is bonded to a metal lead frame, and which is free from lead, thereby placing little burden on the environment. Namely, a conductive composition that contains, as essential components, at least a sulfide compound represented by R-S-R' (wherein R is an organic group containing at least carbon; R' is an organic group that is the same as or different from the R moiety; and the R and R' moieties may combine with each other to form a so-called cyclic sulfide) and metal particles containing at least Cu, Sn or Ni. A conductive paste and a conductive bonding film, each of which is produced using this conductive composition; and a dicing diebonding film which is obtained by bonding the conductive bonding film and an adhesive tape.

Description

technical field [0001] The present invention relates to a conductive composition. Specifically, it relates to a conductive paste, a conductive adhesive composition, a conductive adhesive film made of the same, and a dicing die-bonding film bonded to an adhesive tape. Background technique [0002] Lead-free solders have been widely used in the past to join semiconductor power devices such as IGBTs (Insulated Gate Bipolar Transistors) and MOS-FETs (Field Effect Transistors) to metal lead frames. However, the harmfulness of lead has recently become a problem. In addition, in recent years, in the context of seeking higher density energy control, research on power elements using wide bandgap semiconductors such as SiC and GaN that can withstand junction temperatures of 200°C or higher is underway. The crystal melting point is low, and the insufficient heat resistance of the joint part becomes a bottleneck. [0003] Based on the above background, various types of lead-free solde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B1/22C09J7/24C09J9/02C09J11/04C09J11/06C09J163/00C09J179/04C09J201/00H01L21/52C09J7/10C09J7/35

CPCC09J9/02C09J11/06C09J163/00C09J179/085C09J7/30C09J7/255H01B1/22H01L21/6836C08K2003/085C08K2201/001C09J2203/326H01L2221/68327C08K3/08C08K5/375C08K5/45H01L2924/181H01L2224/32245H01L2224/48091H01L2224/48247H01L2224/73265H01L2224/29318H01L2224/29366H01L2224/29324C08K5/372C09J11/02H01L24/05H01L24/27H01L24/45H01L24/48H01L24/73H01L24/92C08K2003/0862C09J2463/00C09J2479/08H01L2224/04026H01L2224/05644H01L2224/27436H01L2224/2929H01L2224/29309H01L2224/29311H01L2224/29339H01L2224/29344H01L2224/29347H01L2224/29355H01L2224/45124H01L2224/83191H01L2224/8384H01L2224/83855H01L2224/83906H01L2224/92247C09J7/35C09J7/10C08G73/1082C08G73/128H01L2221/68381H01L2221/6839H01L2924/13055H01L24/29H01L24/83H01L2224/83851H01L2924/13091H01L2224/94C09J2301/408H01L2924/00014H01L2924/00012H01L2924/0665H01L2924/0705H01L2924/00H01L2224/27C09J7/20C08K5/16C08L63/00C09J11/04H01L21/52C09J201/00C08K3/10C09J179/08H01L2224/2919H01L2224/29209H01L2224/29211H01L2224/29218H01L2224/29224H01L2224/29239H01L2224/29244H01L2224/29247H01L2224/29255H01L2224/29266

Inventor 三原尚明切替德之杉山二朗

Owner FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com