Conductive adhesive tape

An adhesive tape, conductive technology, applied in the direction of conductive adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem of inability to ensure electrical conductivity, unsatisfactory corrosion resistance, resistance increase, etc. problem, to achieve the effect of excellent long-term corrosion resistance, stable electrical conductivity, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

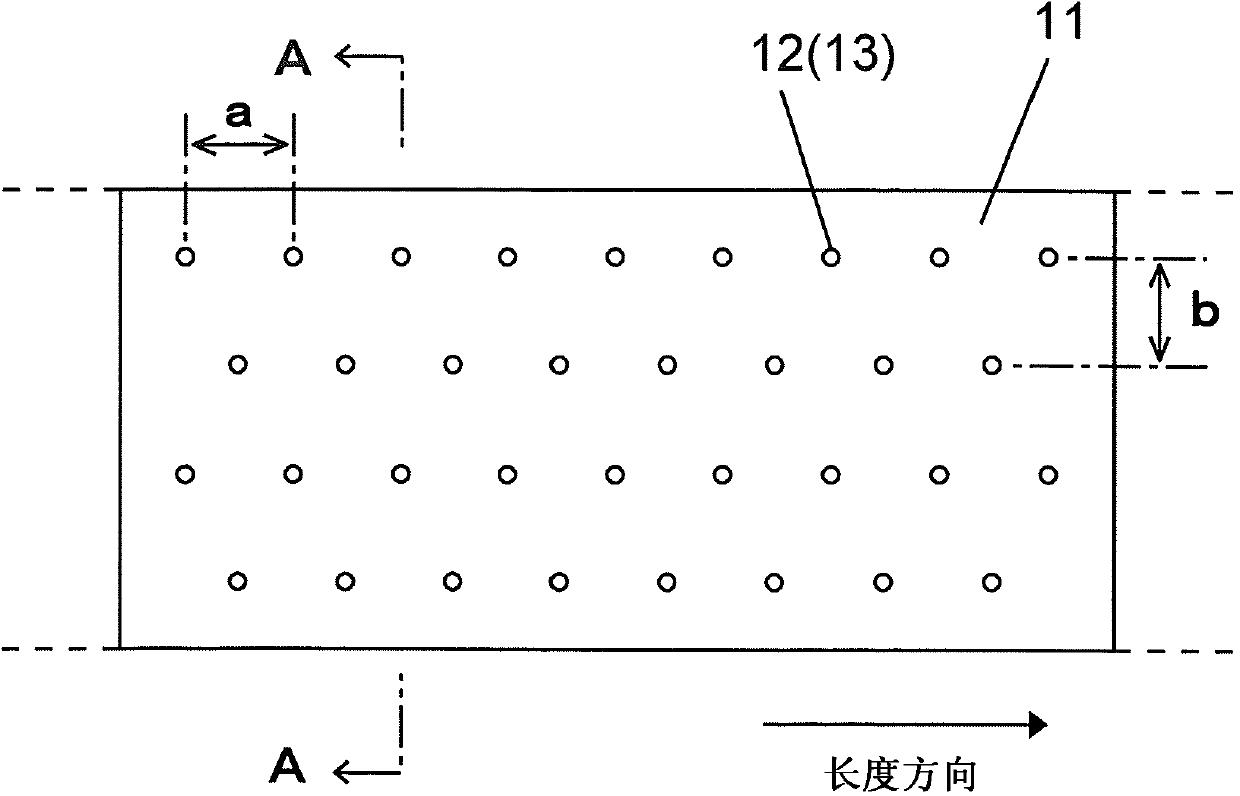

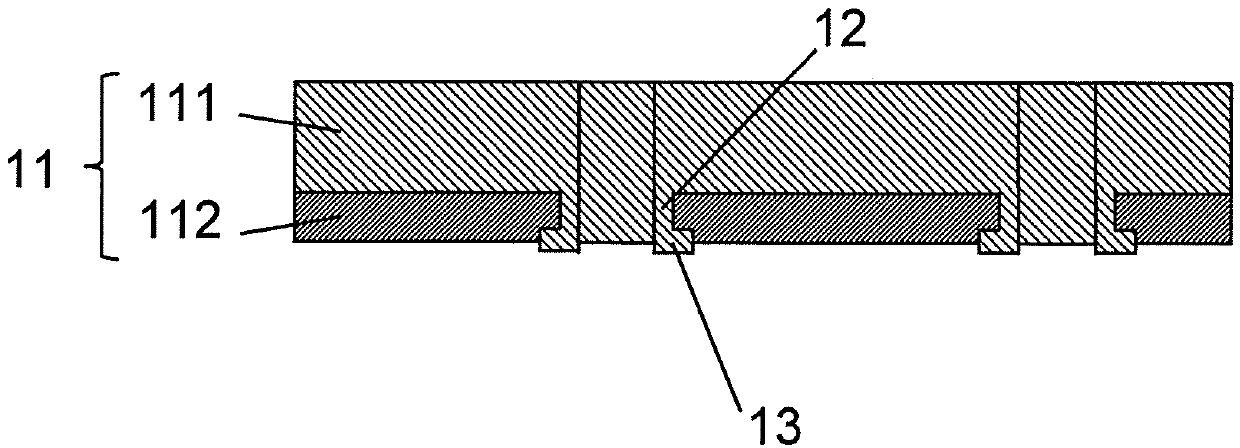

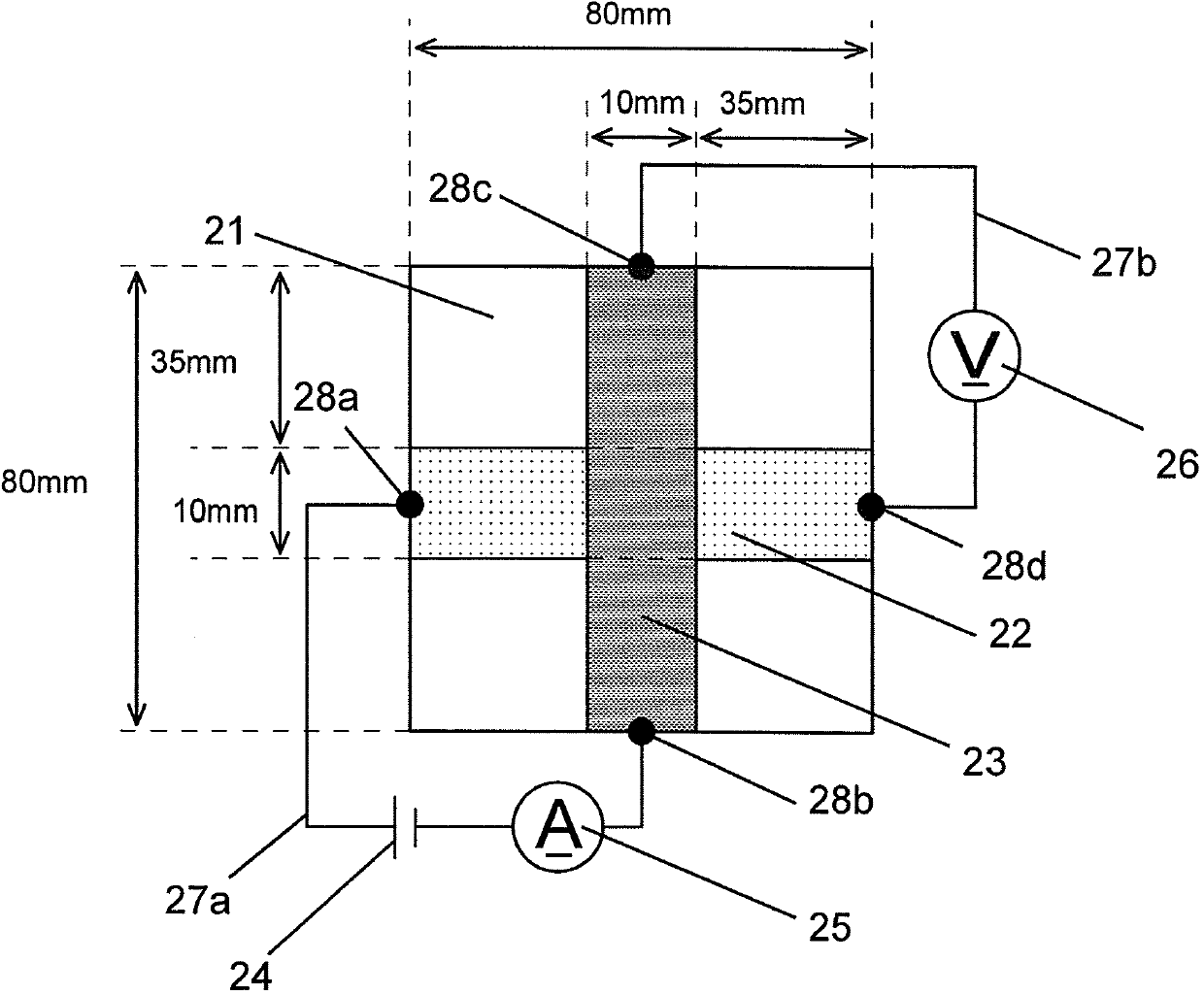

[0107] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples. In addition, the conductive adhesive tapes obtained in Examples 1 to 4 described later have the same characteristics as the above-mentioned "conductive adhesive tape T 1 (First specific embodiment)" The same configuration. In addition, the conductive adhesive tape obtained in Examples 5 to 8 has the same structure as the above-mentioned "conductive adhesive tape T 2 (Second specific method) "The same composition.

manufacture example

[0109] 100 parts by weight of a monomer mixture composed of 70 parts by weight of 2-ethylhexyl acrylate (2EHA), 30 parts by weight of n-butyl acrylate (BA), and 3 parts by weight of acrylic acid (AA), as a polymerization initiator 0.2 parts by weight of 2,2'-azobisisobutyronitrile (AIBN) and 186 parts by weight of ethyl acetate as a polymerization solvent were put into a separable flask, and stirred for 1 hour while blowing in nitrogen. Thus, the oxygen in the polymerization system was removed, and the temperature was raised to 63°C to react for 10 hours, and then toluene was added to adjust the concentration to obtain an acrylic polymer solution with a solid content of 30% by weight (sometimes referred to as "acrylic polymer solution A" ). The weight average molecular weight of the acrylic polymer (sometimes referred to as “acrylic polymer A”) in the acrylic polymer solution A was 520,000.

[0110] Production example of acrylic polymer B

[0111] Except that the monomer mixture ...

Embodiment 1

[0121] In the acrylic polymer solution A, with respect to 100 parts by weight of the acrylic polymer A, 2 parts by weight of "Coloret L" (manufactured by Nippon Polyurethane Industry Co., Ltd., isocyanate crosslinking agent) as a crosslinking agent is added And mixing, thereby preparing an adhesive composition solution. In addition, the compounding amount (addition amount) of Corolet L is expressed in terms of the addition amount (parts by weight) in terms of solid content, and the same applies to the following description.

[0122] The adhesive composition obtained above was applied to a release paper (separator) with a thickness of 163 μm (manufactured by Oji Paper Co., Ltd., "110EPS(P) ブル一") so that the thickness after drying became 40 μm. It was heated and dried at 120°C under pressure for 5 minutes to form an adhesive layer. Then, a toughened copper foil (tuffet copper foil) with a thickness of 35 μm was stuck on the surface of the adhesive layer, and aged at 40°C for one d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com