Method of suction of object to be worked upon suction unit and method of manufacture of ceramic capacitor

A technology for ceramic capacitors and operating objects, which is applied in capacitor manufacturing, capacitors, laminated capacitors, etc., and can solve problems such as scratches on the adsorption surface and defective ceramic capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

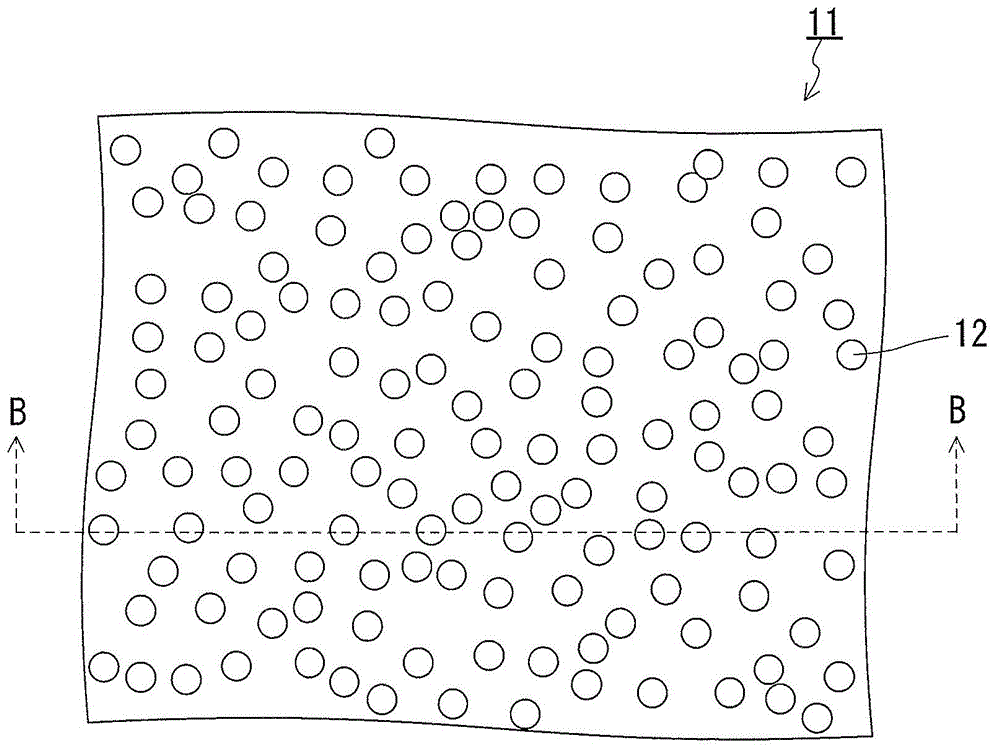

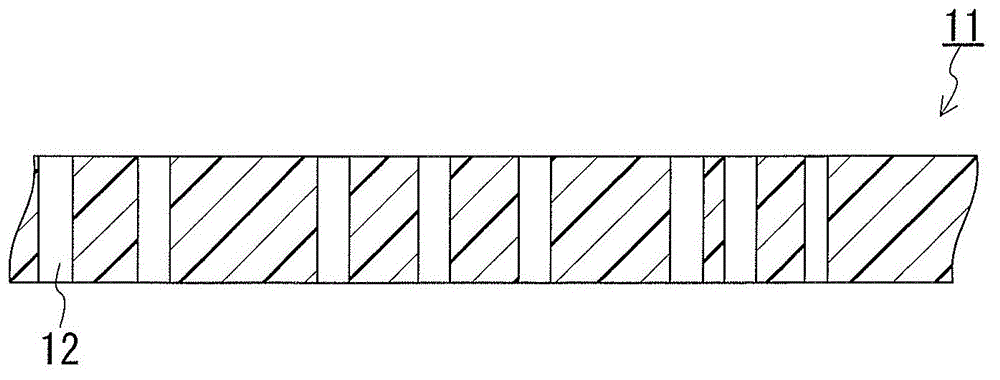

[0058] As the resin sheet A, a resin sheet (manufactured by Oxyfen Co., OxyDisk) having a plurality of through holes (opening diameter: 0.8 μm) formed on a non-porous substrate (thickness: 22 μm) made of PET by ion beam irradiation and etching was used. . The through hole is a straight hole having an axis in the thickness direction of the substrate and having a substantially constant inner diameter. The SEM image of the surface of the resin sheet is shown in Figure 6 middle. The Gurley number (Gurley number in the thickness direction) of the resin sheet measured in accordance with JIS P8117 was 2.7 seconds / 100 mL. The porosity of this resin sheet was 29.8% (area %). Based on the above-mentioned shape of the through-hole, the porosity of the resin sheet is set as the ratio of the area of the opening of the through-hole to the surface of the resin sheet. This ratio is calculated|required by binarizing the SEM image of the surface of a resin sheet by image processing. The...

Embodiment 2

[0060] As the resin sheet A, a resin sheet (manufactured by Oxyfen Co., Ltd., OxyDisk) having a plurality of through holes (opening diameter: 10 μm) formed on a non-porous substrate (thickness: 22 μm) made of PET by ion beam irradiation and etching was used. The through hole is a straight hole having an axis in the thickness direction of the substrate and having a substantially constant inner diameter. The SEM image of the surface of the resin sheet is shown in Figure 7 middle. The Gurley number (Gurley number in the thickness direction) of the resin sheet measured in accordance with JIS P8117 was 0.06 sec / 100 mL. In addition, the porosity of this resin sheet was 11.4% (area %).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com