Method for bonding adhesive tape, apparatus for bonding adhesive tape and method for transporting adhesive tape

A joining method and joining device technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve problems such as interruption of operation of belt pasting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

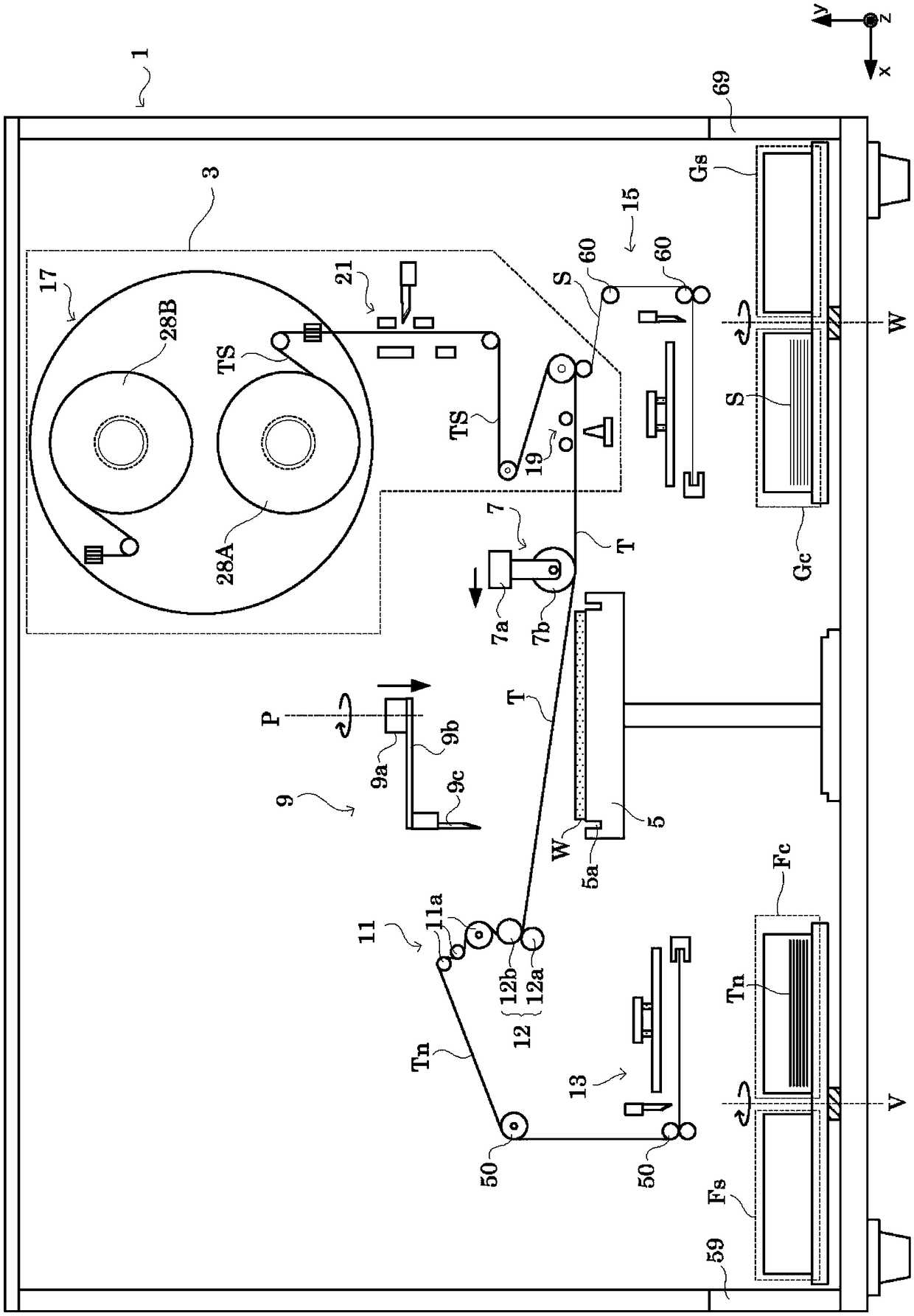

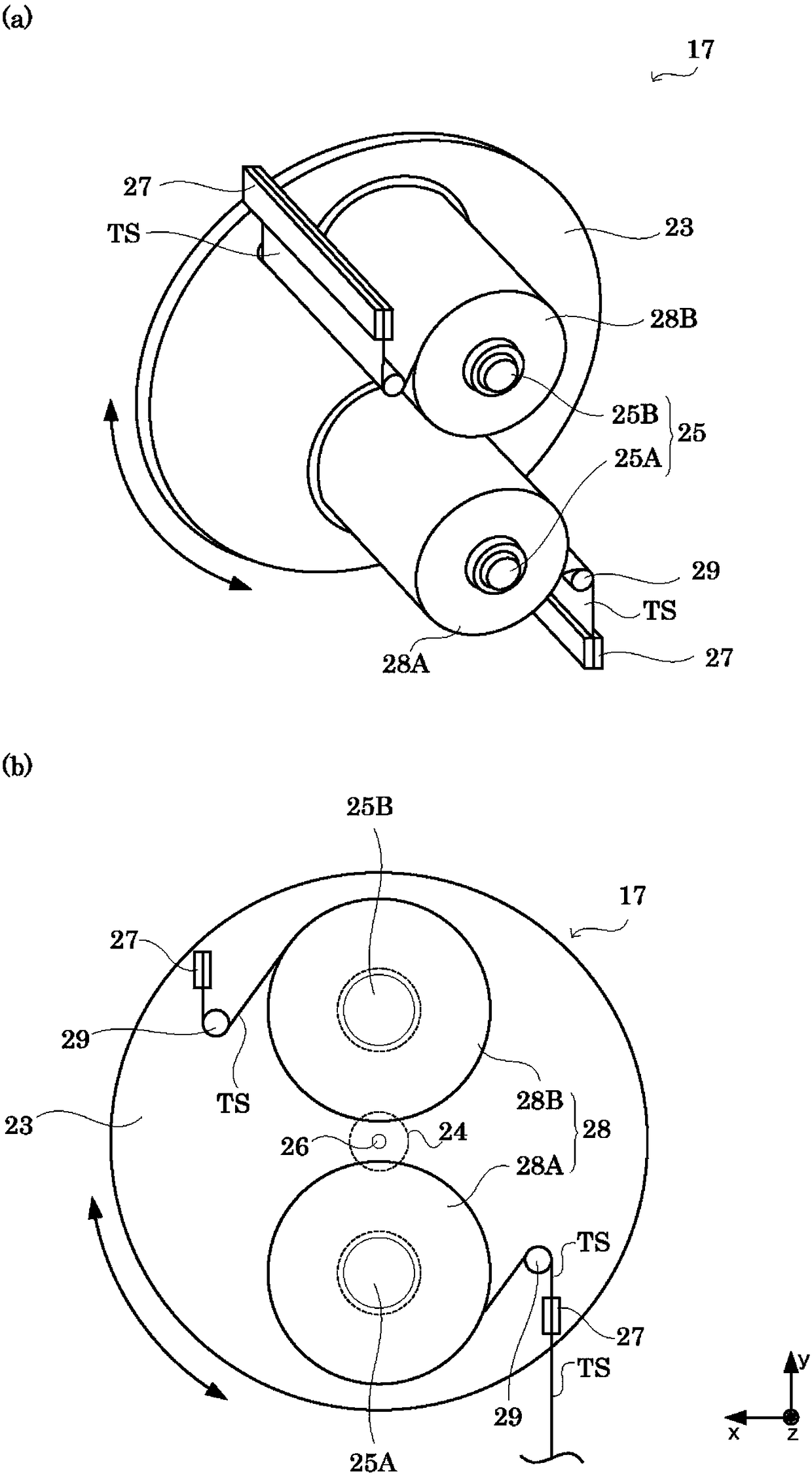

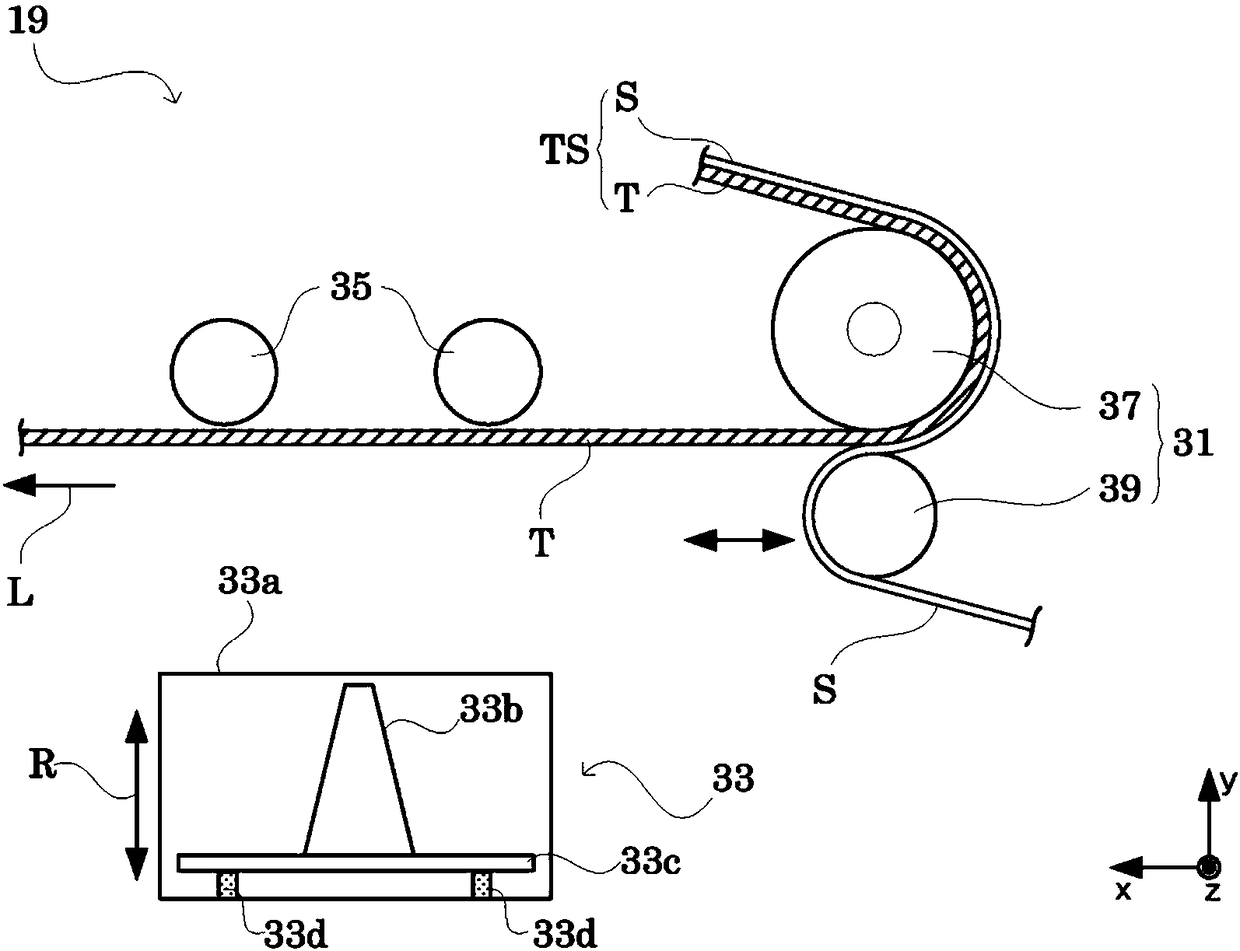

[0081] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a front view which shows the basic structure of the adhesive tape sticking apparatus 1 provided with the tape splicing apparatus of an Example. In addition, in the figure which shows the adhesive tape sticking apparatus 1, illustration about the support member which supports various structures, the drive member which drives various structures, etc. is abbreviate|omitted.

[0082] In the present embodiment, the case where a surface protection surface to be attached to various substrates such as semiconductor wafers (hereinafter simply referred to as "wafers") is supplied in a longitudinal shape to which a separator S is bonded is described as an example. Use the adhesive tape T and cut it into a specified shape on the downstream side. That is, in this embodiment, the lengthwise adhesive tapes are joined to each other.

[0083] In addition, in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com