Texture liquid for preparing submicron suede-like monocrystalline silicon wafer and preparation method thereof

A sub-micron, single-crystal silicon wafer technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problem of unfavorable uniformity of metal-silicon contact, affecting texture stability, and high cell fragmentation rate. problems, to achieve the effect of increasing the light absorption specific surface area, increasing the nucleation density, and reducing the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the texture liquid is as follows: first, deionized water is added into the velvet-making tank, and inorganic bases, lower alcohols, anionic or nonionic surfactants, inorganic bases, lower alcohols, anions or The weight ratio of non-ionic surfactant and deionized water is: 1-5:2-10:0.1-1:100, continue stirring for 10-30 minutes to fully dissolve and mix, and obtain the prepared submicron velvet Texturing fluid for planar monocrystalline silicon wafers.

[0016] Immerse the monocrystalline silicon wafer for solar cells in the above texturing solution for surface texturing. The texturing temperature is 80 degrees and the texturing time is 15 minutes. A uniform, sub-micron pyramid structure can be formed on the surface of the silicon wafer.

[0017] , so as to prepare a single crystal silicon wafer with a uniform, submicron textured structure. No sodium silicate is added during the texturing process, which reduces the corrosion of single crystal s...

Embodiment 1

[0020] First add 100 kg of deionized water into the velvet tank, then add 1.5 kg of sodium hydroxide, 4 kg of isopropanol, and 0.2 kg of sodium dodecylsulfonate in sequence under stirring, and continue stirring for 20 minutes to fully Dissolve, mix. The monocrystalline silicon wafer for solar cells is immersed in the above texturing liquid to carry out surface texturing, the texturing temperature is 80 degrees, and the texturing time is 15 minutes.

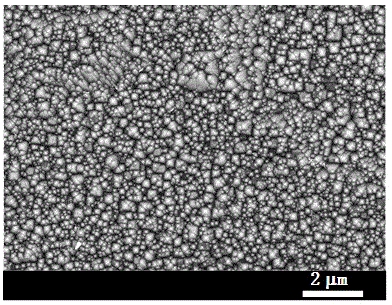

[0021] figure 1 The scanning electron microscope photos of the silicon wafers etched by the texture solution prepared in this example are given. It can be seen from the figure that the size of the formed pyramids is about 0.2 microns, and the distribution is uniform and the coverage is high.

Embodiment 2

[0023] First add 100 kg of deionized water into the velvet tank, then add 1 kg of sodium hydroxide, 2 kg of ethanol, and 0.1 kg of sodium dodecylbenzenesulfonate in turn under stirring conditions, and continue stirring for 10 minutes to fully dissolve it ,mix. Immerse the monocrystalline silicon wafer for solar cells in the above texturing liquid for surface texturing, the texturing temperature is 80°C, and the texturing time is 15 minutes, to obtain a monocrystalline silicon wafer with a uniform submicron textured structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com