Optimization method of heat exchanger pickling process

An optimization method and heat exchanger technology, applied in the field of heat exchanger cleaning, can solve the problems of improper proportioning, production delay and high repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for optimizing the pickling process of a heat exchanger, comprising the steps of:

[0020] 1. Firstly, according to the scale composition of the heat exchanger, use the overlay diagram of the data statistical analysis software to comprehensively screen and find the suitable cleaning acid;

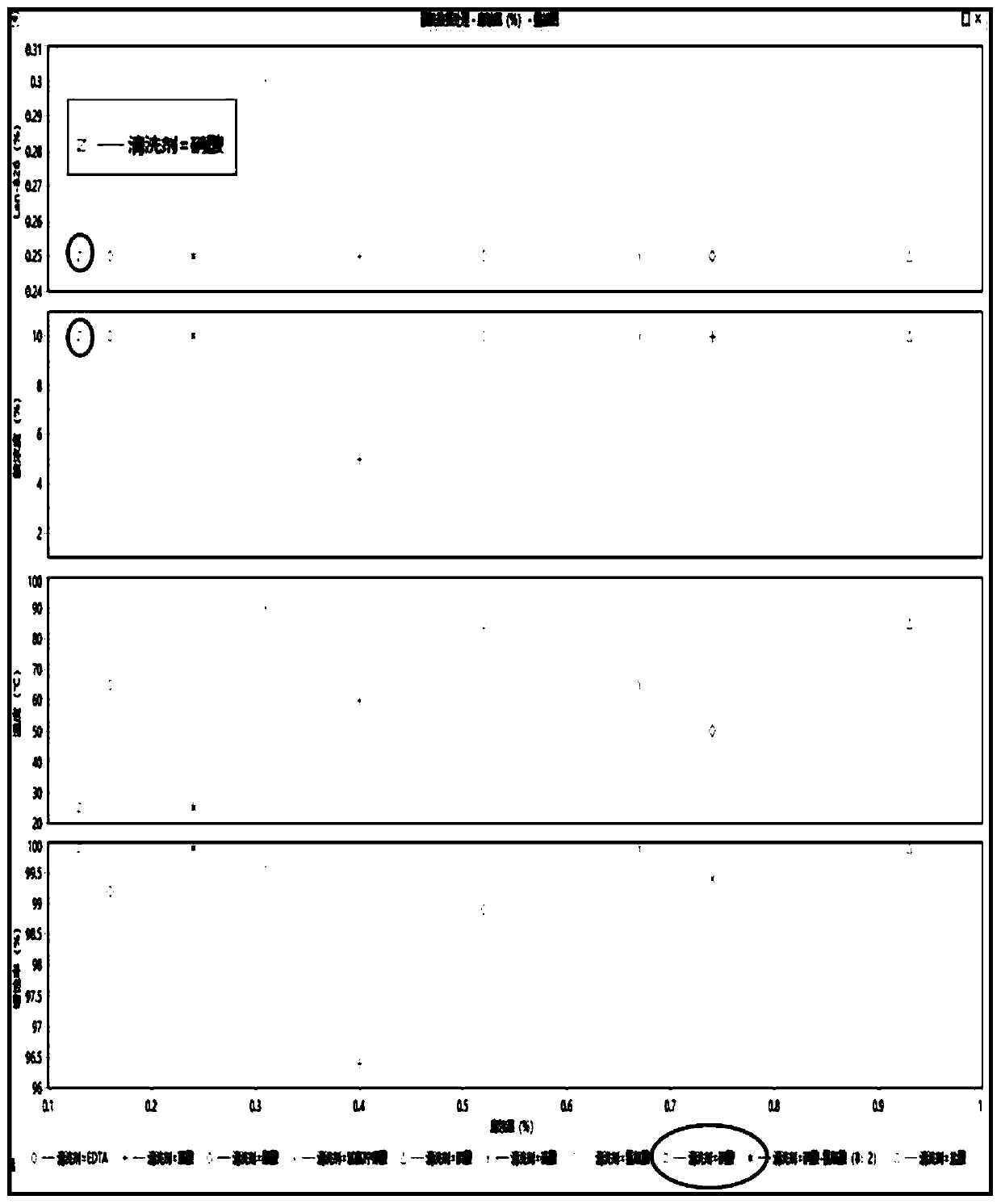

[0021] Taking Lan826 corrosion inhibitor as an example, the effective cleaning acid according to the corrosion inhibitor is shown in Table 1, and the overlay diagram is used for comprehensive screening. figure 1 .

[0022] Table 1 Screening of cleaning acids

[0023]

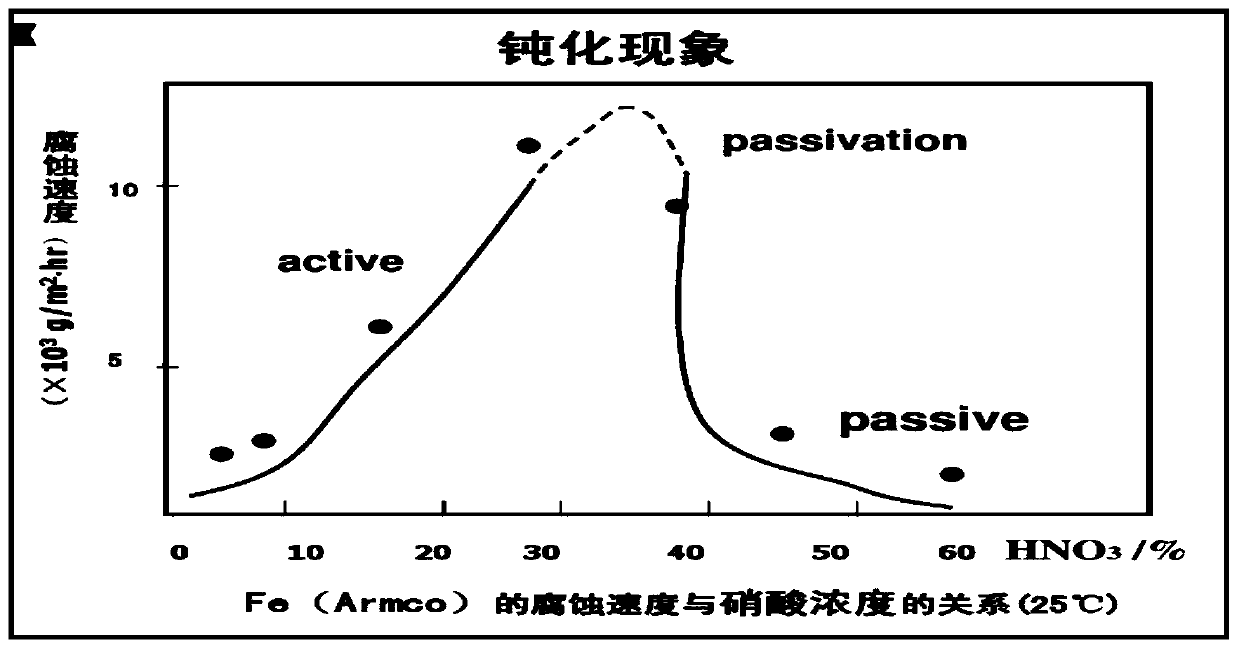

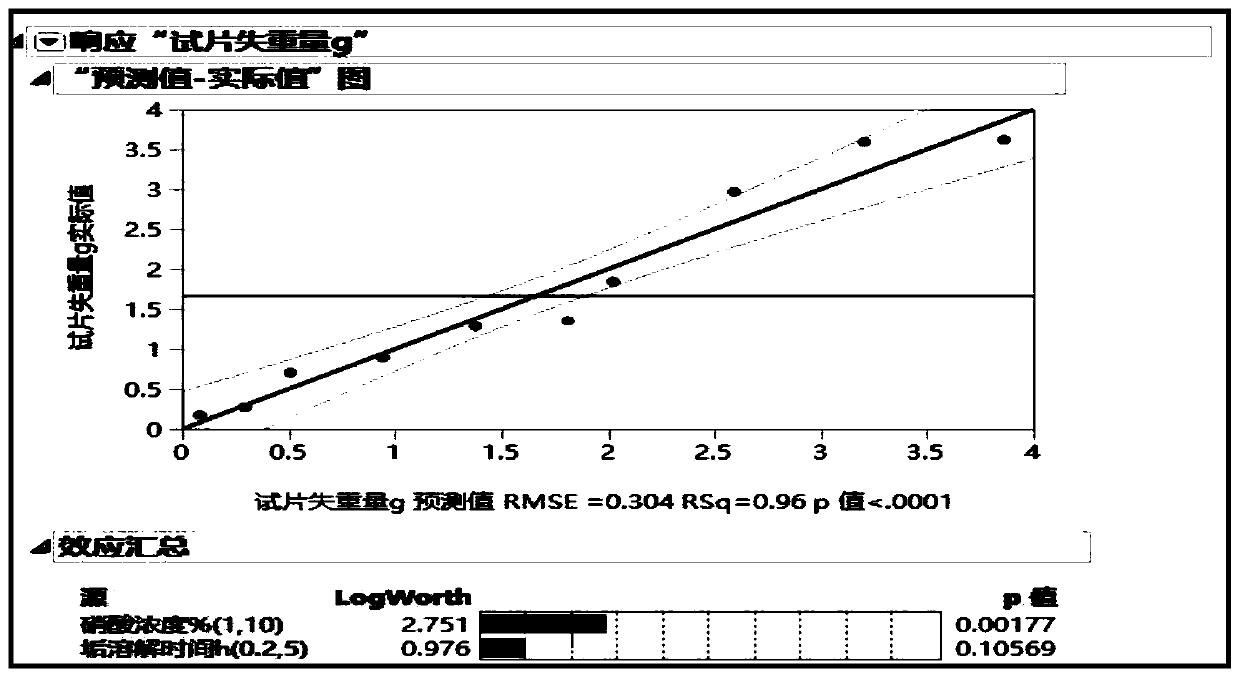

[0024] Considering the corrosion inhibition rate on the ordinate, the concentration of Lan-826, the operating temperature, the acid concentration and the corrosion rate on the abscissa by using the superimposed graph, it can be seen that the corrosion rate of using Lan-826 as a corrosion inhibitor and nitric acid as a cleaning acid is the smallest and slowest. The corrosion rate is the largest, and it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com