Chip pickling device

A pickling device and chip technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of small contact area, poor pickling effect, and low pickling efficiency of chips, so as to increase the contact area and prevent The effect of twisting and misalignment and full pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

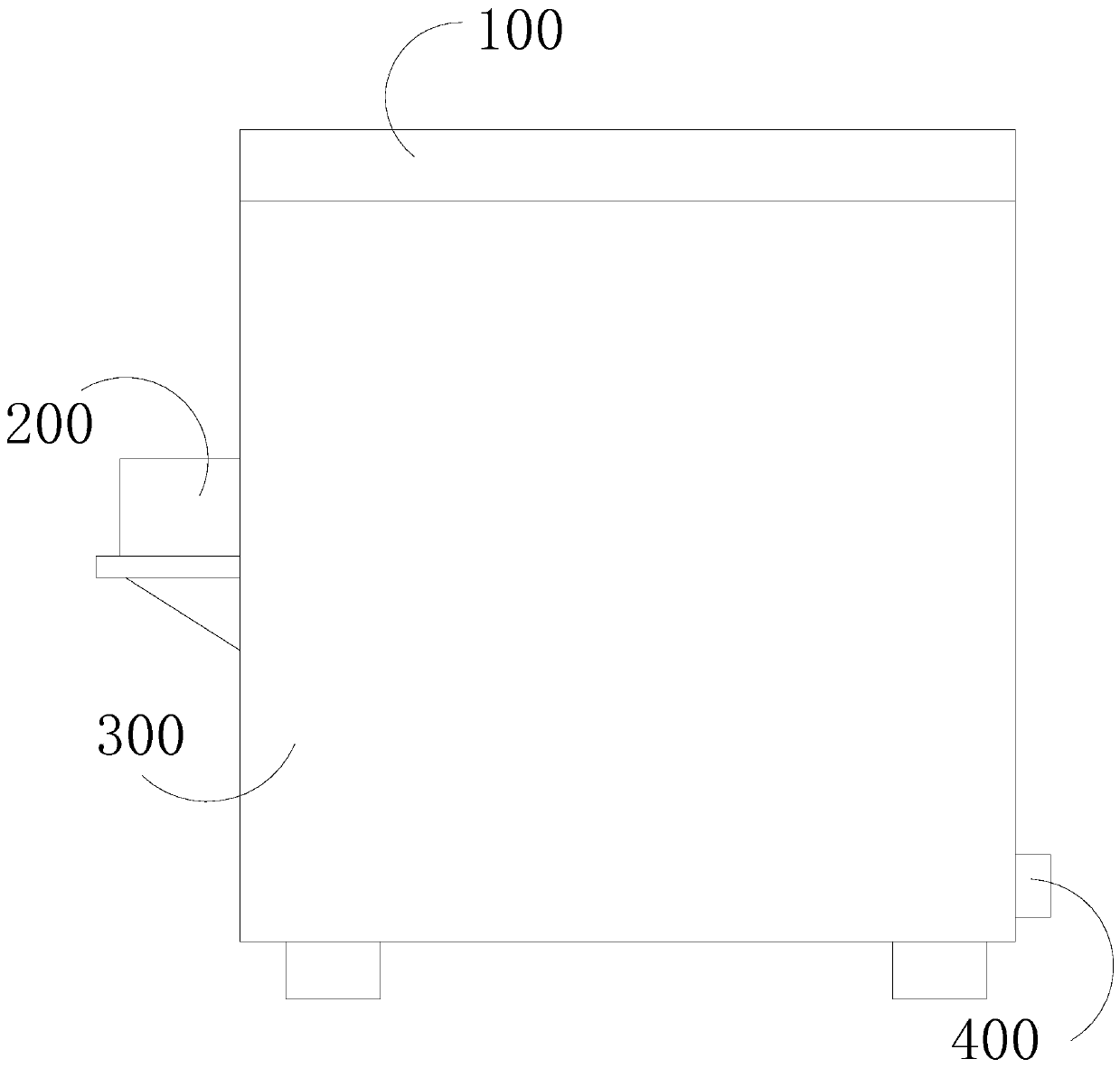

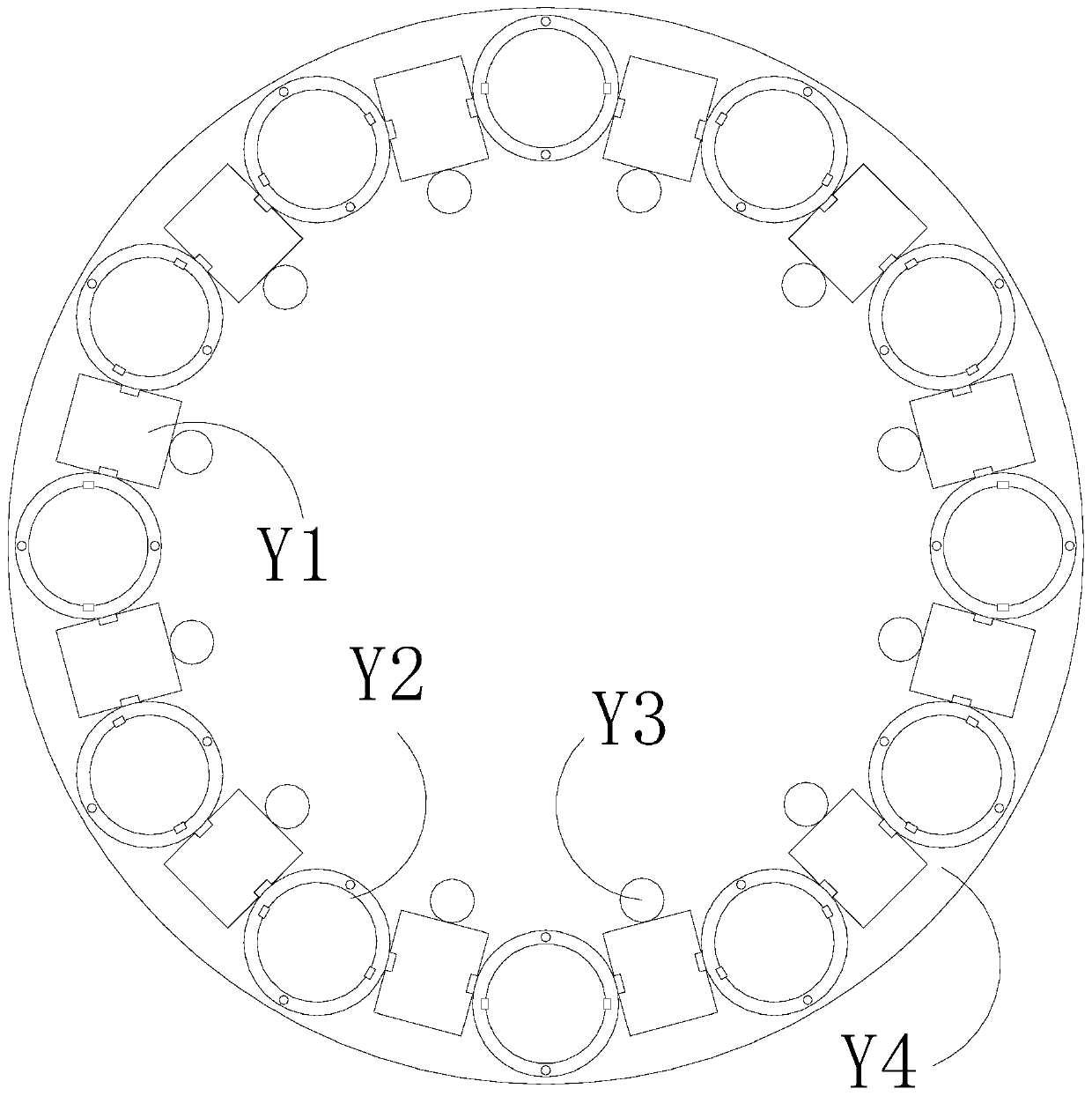

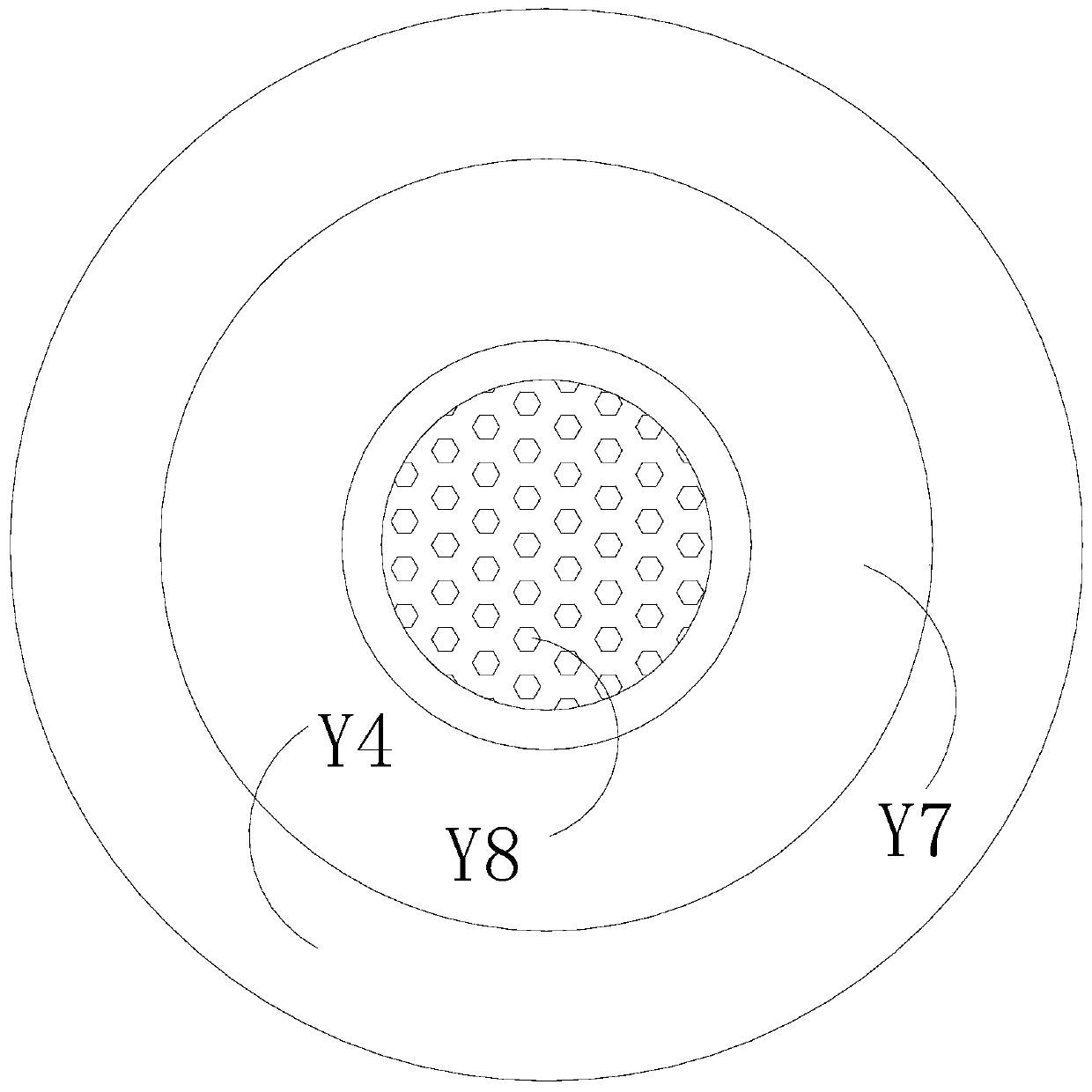

[0031] see Figure 1-6 , the present invention provides a technical scheme of a chip pickling device: its structure includes a top cover 100, a chip placement rotating mechanism 200, a pickling machine body 300, and a pickling liquid discharge pipe 400, and the top of the pickling machine body 300 is hinged to There is a top cover 100, the pickling machine body 300 is provided with a chip placement rotating mechanism 200, and the bottom of one side of the pickling body 300 is connected with a pickling solution discharge pipe 400, and the chip placement rotating mechanism 200 is set to be able to Place the chips to be pickled so that the chips are placed independently one by one to avoid area overlap when the chips are stacked, which helps to improve the efficiency and effect of pickling.

[0032] The chip placing and rotating mechanism 200 is coated with a strong oxidation-resistant coating, which can prevent corrosion by pickling solution and help to improve the service life ...

Embodiment 2

[0038] see Figure 1-12 , the present invention provides a technical scheme of a chip pickling device: its structure includes a top cover 100, a chip placement rotating mechanism 200, a pickling machine body 300, and a pickling liquid discharge pipe 400, and the top of the pickling machine body 300 is hinged to There is a top cover 100, the pickling machine body 300 is provided with a chip placement rotating mechanism 200, and the bottom of one side of the pickling body 300 is connected with a pickling solution discharge pipe 400, and the chip placement rotating mechanism 200 is set to be able to Place the chips to be pickled so that the chips are placed independently one by one, avoiding area overlap when chips are stacked, and helping to improve the efficiency and effect of pickling.

[0039] The chip placing and rotating mechanism 200 is coated with a strong oxidation-resistant coating, which can prevent corrosion by pickling solution and help to improve the service life of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com