Rust-removing sample holder

A sample holder and door-shaped frame technology, applied in the field of sample holder, can solve the problems of easy falling off of samples, damage, and less rust removal at one time, avoiding contact between samples, good pickling, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

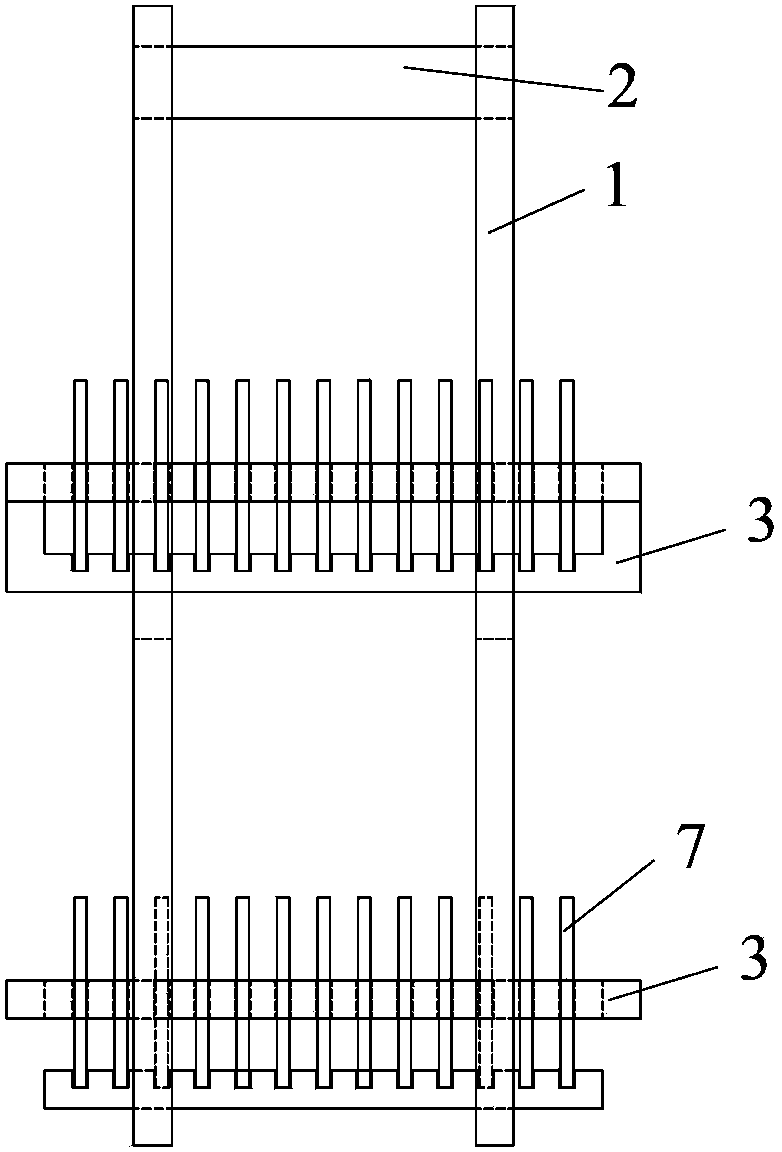

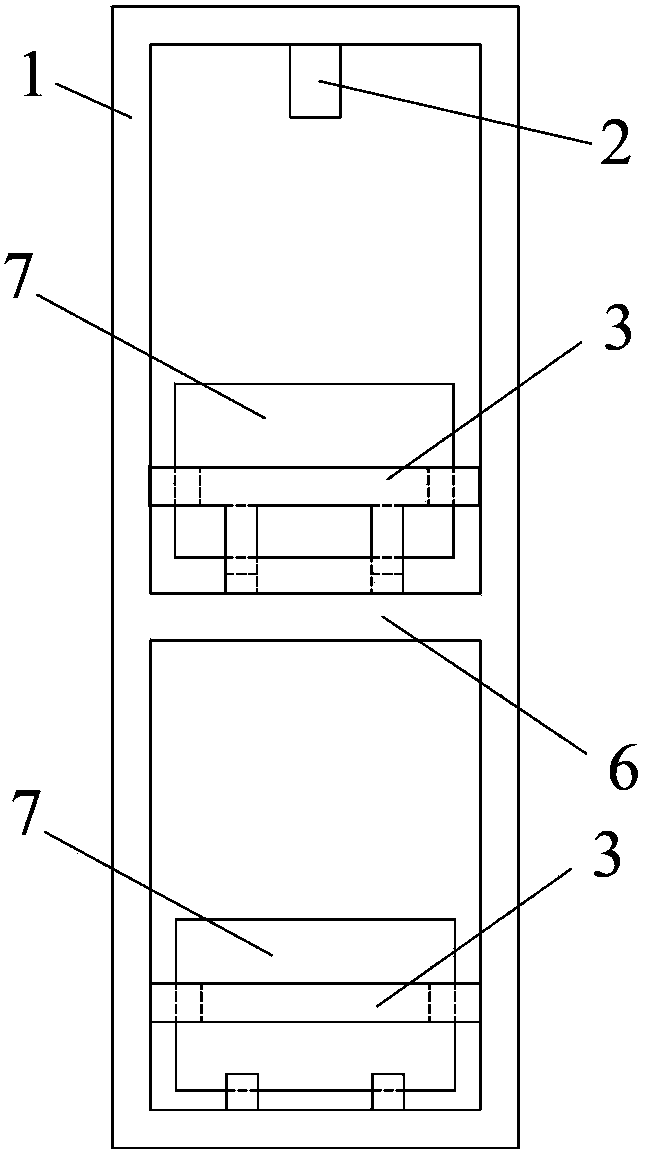

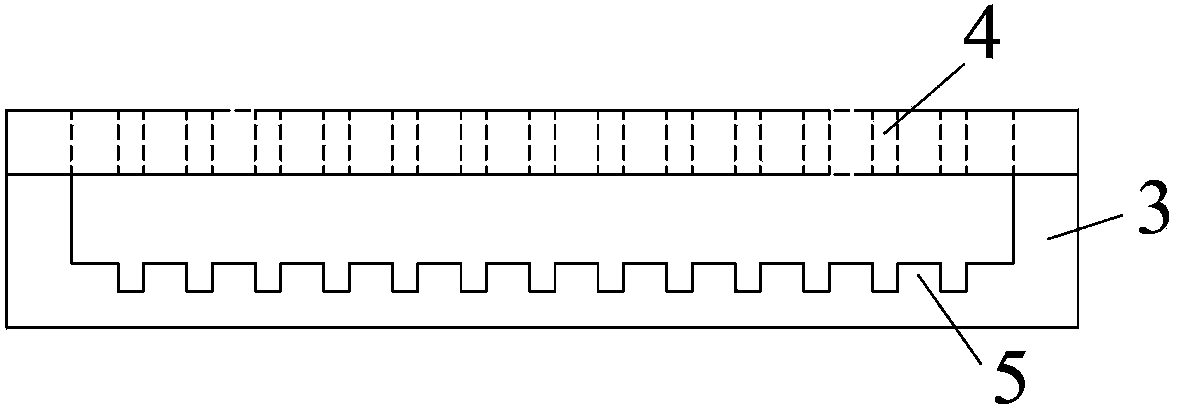

[0015] The sample rack for derusting as shown in the figure includes two door-shaped frames 1 and a crossbeam 2 arranged between the upper frames of the two door-shaped frames 1. The inner side of the door-shaped frame 1 is provided with a sample basket 3. The two side frames of the sample basket 3 are provided with a plurality of upper slots 4 in parallel, and the bottom of the sample basket 3 is provided with a lower slot 5 corresponding to the plurality of upper slots 4, so that the sample 7 can be inserted in the Corresponding upper card slot 4 and lower card slot 5. Wherein, the number of sample baskets 3 is 1-3. A support beam 6 is arranged in the door frame 1, and the two ends of the sample basket 3 are respectively placed on the support beam 6 in the two door frame 1, and the sample basket 3 can also be welded and fixed on the inside of the door frame 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com