Anode protection anticorrosion method for acid separating device

An anodic protection and anti-corrosion technology, applied in the field of electrochemical anti-corrosion anodic protection, can solve the problems of many changes in flow direction, many accessories, inability to protect the acid branch pipe and acid drop pipe, etc., and achieve the effect of reducing the weight of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

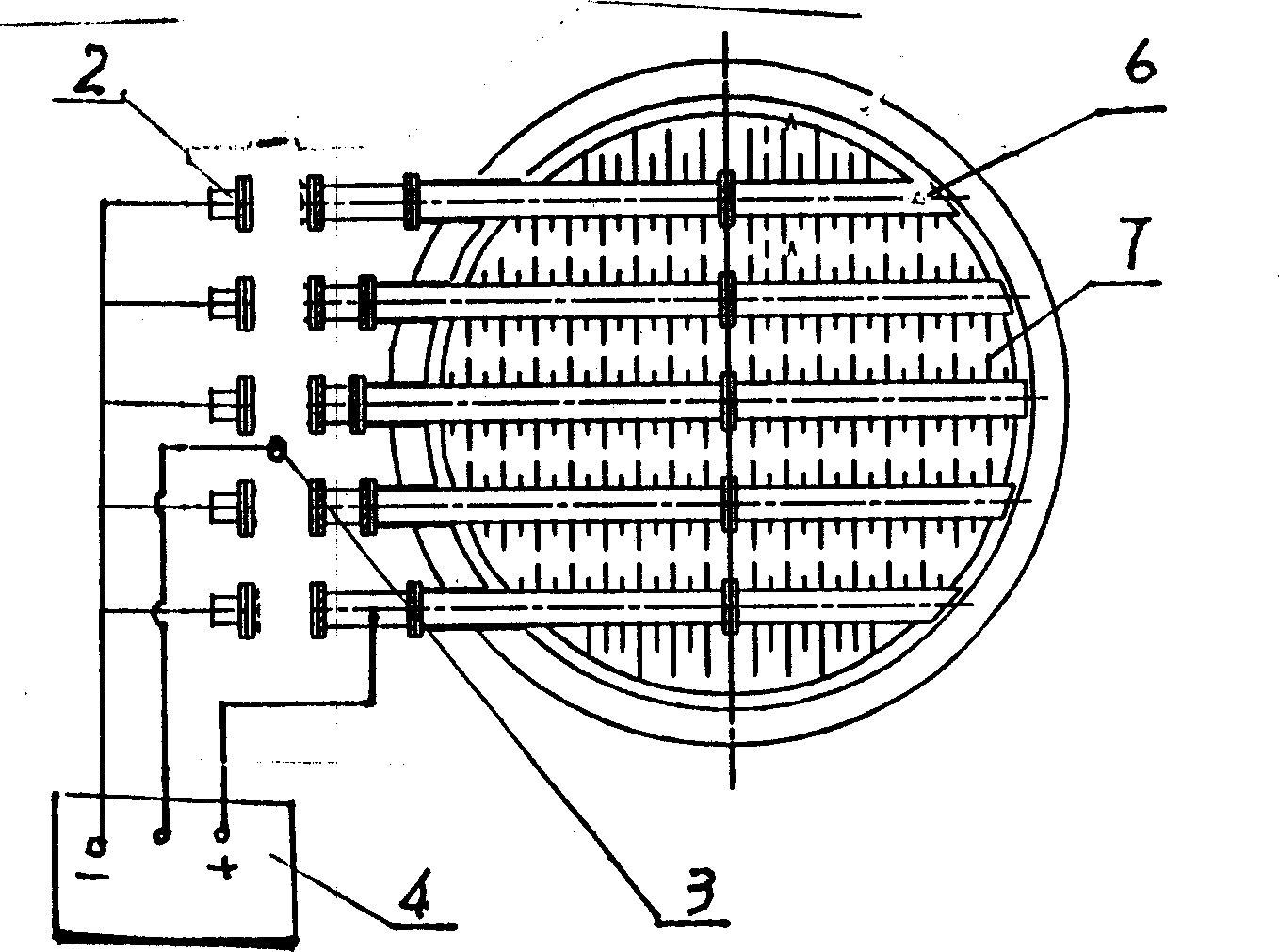

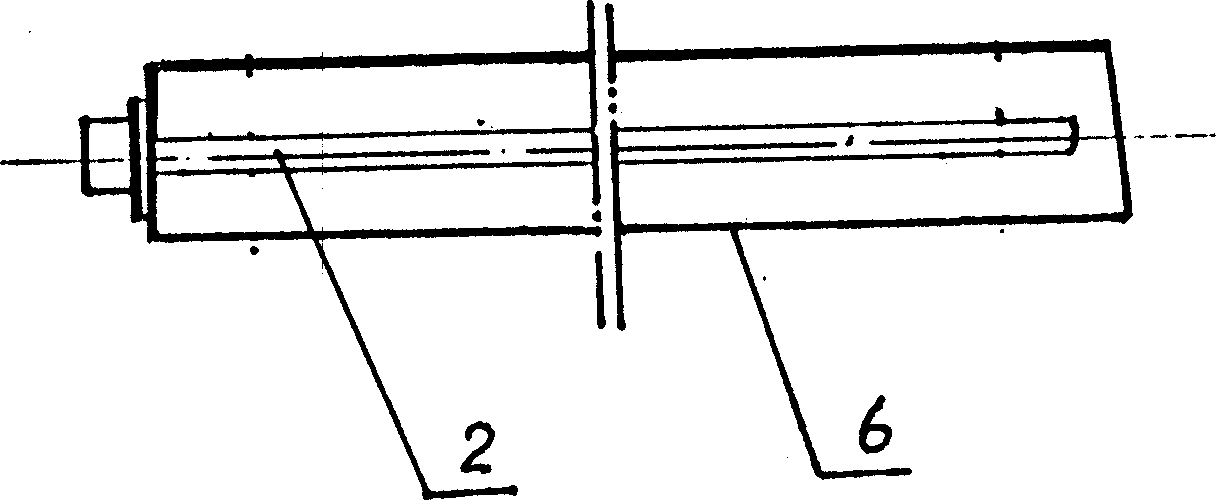

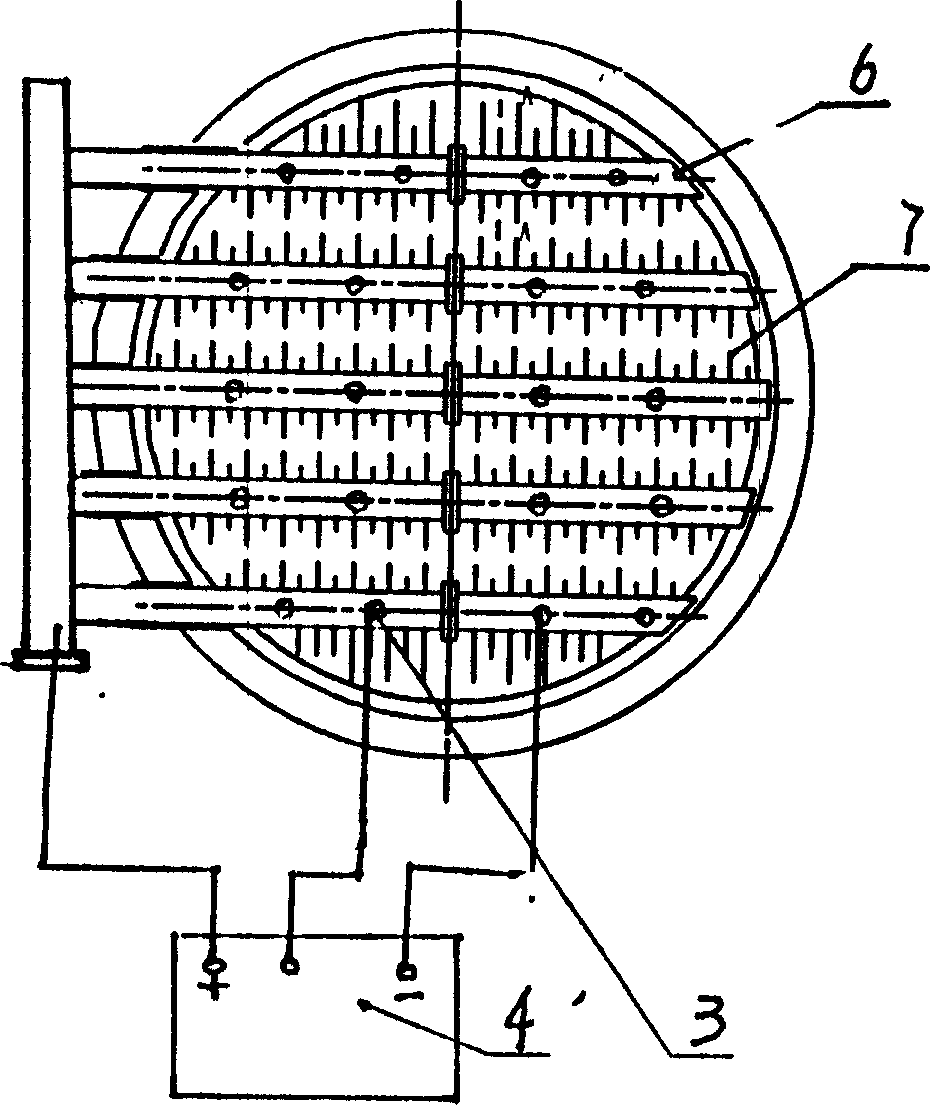

[0023] See figure 1 In Example 1 of the present invention, the acid distribution tank 6 and the acid fallout tube 7 of the cathode external trough type acid distribution device, the cathode 2, the reference electrode 3, the potentiostat 4, the acid distribution tank 6 and the acid fallout tube 7 pass through as the anode The wire is connected to the positive pole of the potentiostat 4 and the zero potential, the negative pole of the potentiostat 4 is connected to the cathode 2 of the five acid-distributing tanks of the acid-distributing device through a wire, and the reference junction of the potentiostat 4 is connected to the positive pole of the potentiostat 4 through a wire. On the reference electrode 3 located in the acid distribution tank. Cathode 2 is a super-elongated rod ( figure 2 ), located on the acid-distributing tank 6 outside the acid-dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com