Carbonaceous lead powder, its preparation method, battery lead paste and its application

A technology of lead powder and lead paste, which is applied in the field of battery preparation, can solve the problems of easy falling off and weak adhesion, and achieve the effects of improving electrical conductivity and cycle performance, preventing carbon particles from falling off, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

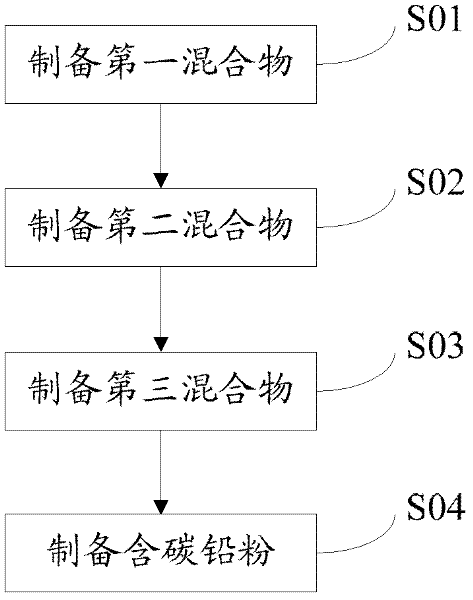

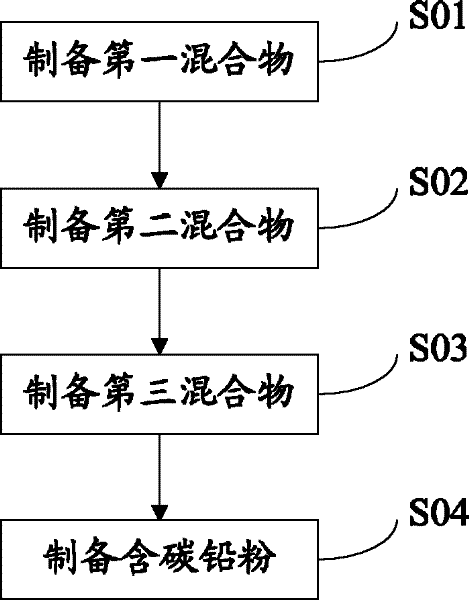

[0028] see figure 1 , figure 1 Show the embodiment of the present invention to carry the flow chart of the method for preparing carbon-lead powder, including the following steps:

[0029] Step S01, preparing the first mixture:

[0030] Mixing organic carbon source monomers and lead powder to obtain a first mixture, the mass ratio of the organic carbon source monomers and lead powder being 0.02 to 0.4:1;

[0031] Step S02, preparing a second mixture:

[0032] heat-treating the first mixture in an inert atmosphere at a temperature of 500-800°C for 3-8 hours to obtain a second mixture;

[0033] Step S03, preparing a third mixture:

[0034] activating the second mixture with carbon dioxide or water vapor at a temperature of 700-850° C. to obtain a third mixture;

[0035] Step S04, preparing carbon-containing lead powder:

[0036] The third mixture is dried and crushed to obtain carbon-containing lead powder.

[0037] Specifically, in step S01,

[0038] The lead powder is o...

Embodiment 1

[0060] The preparation method of the super battery containing the above-mentioned battery lead paste of the present invention comprises the following steps:

[0061] (1) Weighing 10Kg of glucose and 100Kg of lead powder, mixing with a suitable mixer, stirring for 2 hours, making it evenly mixed to obtain the first mixture;

[0062] (2) Put the above-mentioned first mixture into the sintering kiln, and under the ambient condition of the presence of argon, pyrolyze it at 600°C for 7 hours to complete the carbonization process and obtain the second mixture. Carbonization makes the glucose change from a close-packed structure to Activated carbon structure with developed micropore structure and huge specific surface area;

[0063] (3) activating the second mixture with water vapor at 750° C. for 7 hours to obtain a third mixture;

[0064] (4) The third mixture is dried at 110° C., if there are lumps, gently crush and sieve to obtain carbon-containing lead powder;

[0065] (5) Pre...

Embodiment 2

[0068] (1) Weighing 20Kg of glucose and 100Kg of lead powder, mixing with a suitable mixer, stirring for 2 hours, making it evenly mixed to obtain the first mixture;

[0069] (2) Put the above-mentioned first mixture into a sintering kiln, and in the presence of argon, pyrolyze it at 700°C for 6 hours to complete the carbonization process and obtain the second mixture. Carbonization makes the glucose change from a close-packed structure to Activated carbon structure with developed micropore structure and huge specific surface area;

[0070] (3) activating the second mixture with water vapor at 800° C. for 7 hours to obtain a third mixture;

[0071] (4) The third mixture is dried at 110° C., if there are lumps, gently crush and sieve to obtain carbon-containing lead powder;

[0072] (5) Prepare battery lead paste by the raw materials of following proportioning by weight: lead powder: 100Kg (carbon-containing lead powder weight ratio is 50%), sulfuric acid: 9Kg (sulfuric acid d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com