Sea sand recycled concrete member for hollow double-skin steel pipe

A technology of recycled concrete and steel pipes, which is applied in the direction of layered products, metal layered products, hydraulic material layered products, etc., to achieve the effects of improving bending resistance, saving construction costs, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

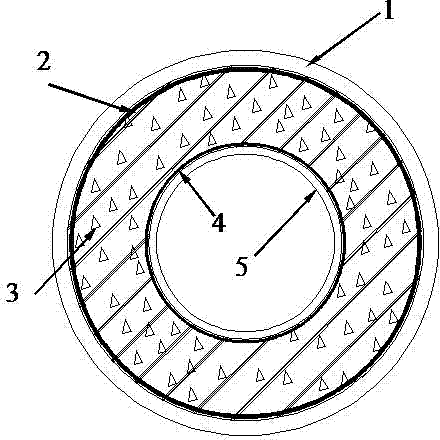

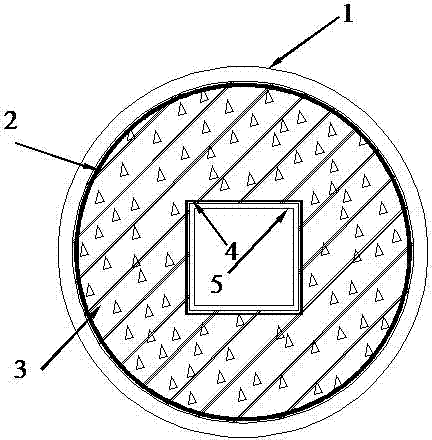

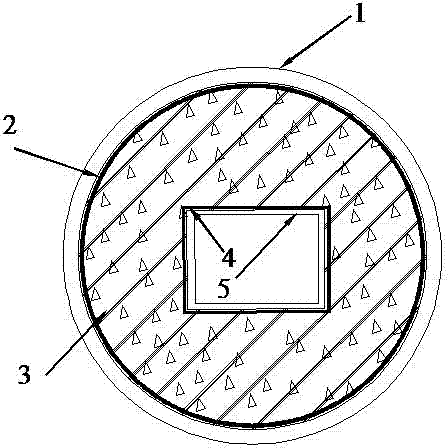

[0015] The patent of the present invention provides a new type of hollow interlayer steel pipe sea sand recycled concrete component. The specific implementation of the patent of invention will be further described below in conjunction with the accompanying drawings.

[0016] The structure of this component is: coating epoxy resin layer 2 on the inner surface of steel pipe 1, coating epoxy resin layer 4 on the outer surface of steel pipe 5, and filling sea sand recycled concrete 3 in the middle area of epoxy resin layer. The cross sections of the steel pipe 1 and the steel pipe 5 can be circular, square or rectangular. The steel pipe 1 and the steel pipe 5 can be seamless, welded or stainless steel pipes. The sea sand recycled concrete 3 includes recycled coarse aggregate concrete, sea sand, river sand, and ordinary concrete, and the sea sand, river sand, recycled coarse aggregate concrete, and ordinary concrete are evenly mixed.

[0017] Since the inner surface of steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com