A kind of engine coolant and preparation method thereof

A technology of engine coolant and content, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of easy corrosion of engine metal parts, cost and high freezing point, and achieve the effect of improving corrosion inhibition performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

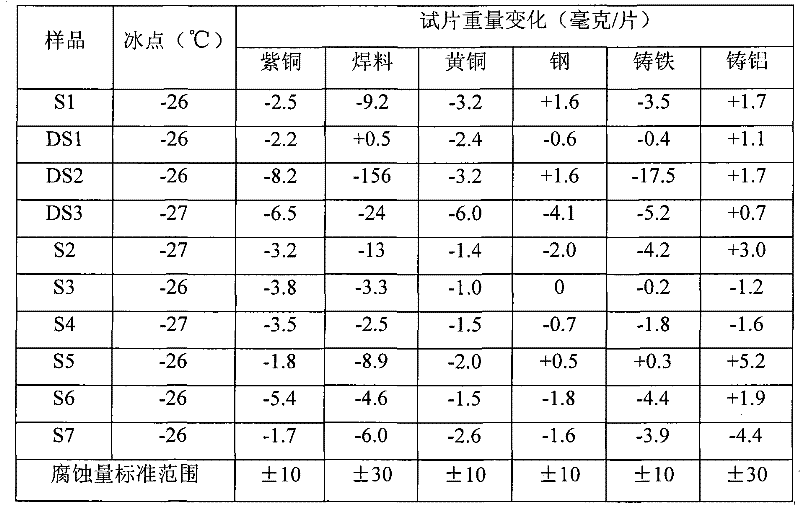

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of the engine coolant, comprising the following steps:

[0023] a. Dissolve carboxylic acid or carboxylate and additives with 1-2 carbon atoms in water, adjust the pH value to be not less than 9, and record it as solution A; the additives contain EDTA chelates of trivalent rare earth elements;

[0024] b. Dissolve the silicate in water to form a silicate solution; add the silicate solution into solution A, stir evenly, and record it as solution B;

[0025] c. filter the solution B, add ethylene glycol to the filtrate, and stir evenly to obtain the engine coolant.

[0026] According to the preparation method provided by the present invention, first dissolve the carboxylic acid or carboxylate with 1-2 carbon atoms and additives in part of the water, so that the pH value is not less than 9, and record it as solution A; in addition, the silicate solution Prepare a silicate solution in the remaining water, and then pour it into A ...

Embodiment 1

[0029] (1) Add 500 parts by weight of deionized water to the container, then add 50 parts by weight of potassium acetate, 0.1 part by weight of EDTA-La, 10 parts by weight of borax, 0.6 parts by weight of sodium molybdate, 1 part by weight of sebacic acid, and sodium benzoate 5 parts by weight, 1 part by weight of sodium nitrate, 1 part by weight of benzotriazole, 2 parts by weight of sodium hydroxide, stirred to dissolve; finally add silicate stabilizer modified siloxane N4144 (molecular formula is CH 3 O(CH 2 CH 3 O) 7.8 C 3 h 6 Si(OCH 3 ) 3 ) 0.3 parts by weight, stirred evenly to obtain solution A1.

[0030] (2) In another container, add 100 parts by weight of deionized water, then add 2 parts by weight of sodium silicate nonahydrate and stir until dissolved to prepare a sodium silicate solution; add the sodium silicate solution to solution A1, stir evenly, and obtain Solution B1.

[0031](3) Filter solution B1, add 327 parts by weight of ethylene glycol, 5 ppm sod...

Embodiment 2

[0042] (1) Add 500 parts by weight of deionized water to the container, then add 187 parts by weight of sodium formate, 0.9 parts by weight of EDTA-Ce, 9.6 parts by weight of borax, 0.3 parts by weight of sodium molybdate, 0.5 parts by weight of sebacic acid, and 6 parts by weight of sodium benzoate Parts by weight, 1 part by weight of sodium nitrate, 0.5 part by weight of benzotriazole, 1.9 parts by weight of sodium hydroxide, stirred until dissolved; finally added silicate stabilizer modified siloxane N4144 (molecular formula CH 3 O(CH 2 CH 3 O) 7.8 C 3 h 6 Si(OCH 3 ) 3 ) 0.3 parts by weight, stirred evenly to obtain solution A2.

[0043] (2) Quantitatively add 100 parts by weight of deionized water in another container, then add 2 parts by weight of sodium silicate nonahydrate and stir until dissolved to prepare a sodium silicate solution; add the sodium silicate solution into solution A2, stir evenly, Solution B2 is obtained.

[0044] (3) Filter solution B2, add 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com