Water-soluble chitosan phosphate, and preparation application and thereof

A chitosan phosphate, water-soluble technology, applied in the field of water-soluble chitosan phosphate and its preparation and application, to achieve the effect of high corrosion inhibition performance, low cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of chitosan phosphate:

[0018] Add chitosan to excess 1% acetic acid by volume to dissolve, add 20mL of phosphoric acid solution with 45% volume fraction dropwise, raise the temperature and add 20mL of formaldehyde solution with 45% volume fraction dropwise, and react under reflux for 4h when the temperature reaches 65°C After the reaction is completed, cool down, add 400-500 mL of ethanol solution with a volume fraction of 95%, filter with suction, wash with absolute ethanol, and dry in vacuum at 55° C. to obtain a white solid, which is water-soluble chitosan phosphate.

[0019] Wherein n=685 infrared spectrogram data are as follows:

[0020] 1159cm -1 and 877cm -1 It is the characteristic peak of chitosan sugar group, 1047cm -1 It is the characteristic peak of -C-O-C (glycosidic bond), 1638cm -1 Strong absorption peak for amino group; 2973cm -1 It is the methylene antisymmetric stretching vibration absorption band, 1350-1150cm -1 The pl...

Embodiment 2

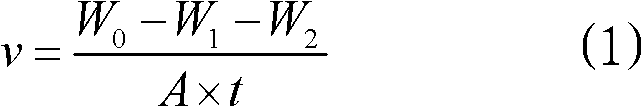

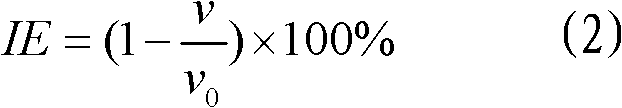

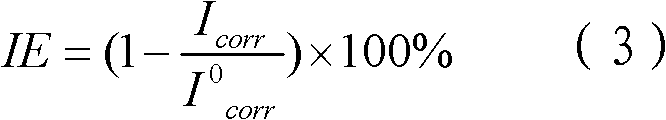

[0036] Conditions: the experimental material is Q235a carbon steel, the water-soluble chitosan phosphate ester obtained above is dissolved in seawater, and the corrosion inhibitor is obtained by ultrasonic dispersion for 20 minutes, and the concentration of the water-soluble chitosan phosphate ester in the corrosion inhibitor is 200mg / L. Then Q235a carbon steel was immersed in the above corrosion inhibitor at a temperature of 20°C, and the experiment period was 240h.

[0037] The corrosion inhibition efficiency obtained through the experimental test is: 83.82% in the weight loss experiment, and 48.15% in the dynamic potential polarization, which shows that it is a corrosion inhibitor with low dosage and high efficiency.

Embodiment 3

[0039] Conditions: the experimental material is Q235a carbon steel, the water-soluble chitosan phosphate ester obtained above is dissolved in seawater, and the corrosion inhibitor is obtained by ultrasonic dispersion for 20 minutes, and the concentration of the water-soluble chitosan phosphate ester in the corrosion inhibitor is 300mg / L. Then Q235a carbon steel was immersed in the above corrosion inhibitor at a temperature of 20°C, and the experiment period was 240h.

[0040] Conditions: The experimental material is Q235a carbon steel. Dissolve a certain amount of chitosan phosphate in seawater, disperse it with ultrasonic waves for 20 minutes, and prepare a medium containing 300mg / L of corrosion inhibitor. The temperature is 20°C, and the experiment period is 240h.

[0041] The corrosion inhibition efficiency obtained through the experimental test is 88.71% in the weight loss experiment and 60.02% in the dynamic potential polarization, which shows that it is a corrosion inhi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com