Method for preparing cathode of external applied lead-carbon battery

A lead-carbon battery and negative electrode technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of ignoring the interaction between carbon and electrolyte, and the connection problem is not well solved, so as to improve the effective utilization rate , small internal resistance, enhanced connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The 60wt% specific surface area is 2000m 2 The mixed material of activated carbon, 30wt% polystyrene, and 10wt% acetylene black per gram is placed in first-grade water, heated to 110°C, heated and stirred at a constant temperature for 3 hours, cooled naturally and left to stand in an environment with an air humidity of 50% for 36 hours get carbon paste;

[0031] 90wt% of lead powder, 0.5wt% of humic acid, 3wt% of 40mm polyester staple fiber, 1.5wt% of barium sulfate, 3wt% of sodium lignosulfonate, and 2wt% of acetylene black are evenly mixed to make active substances , the mixed active substance is slowly added to the total weight of 10.0wt% water and 13wt% 2mL / s 4.7mol / L sulfuric acid and stirred evenly to form a lead paste;

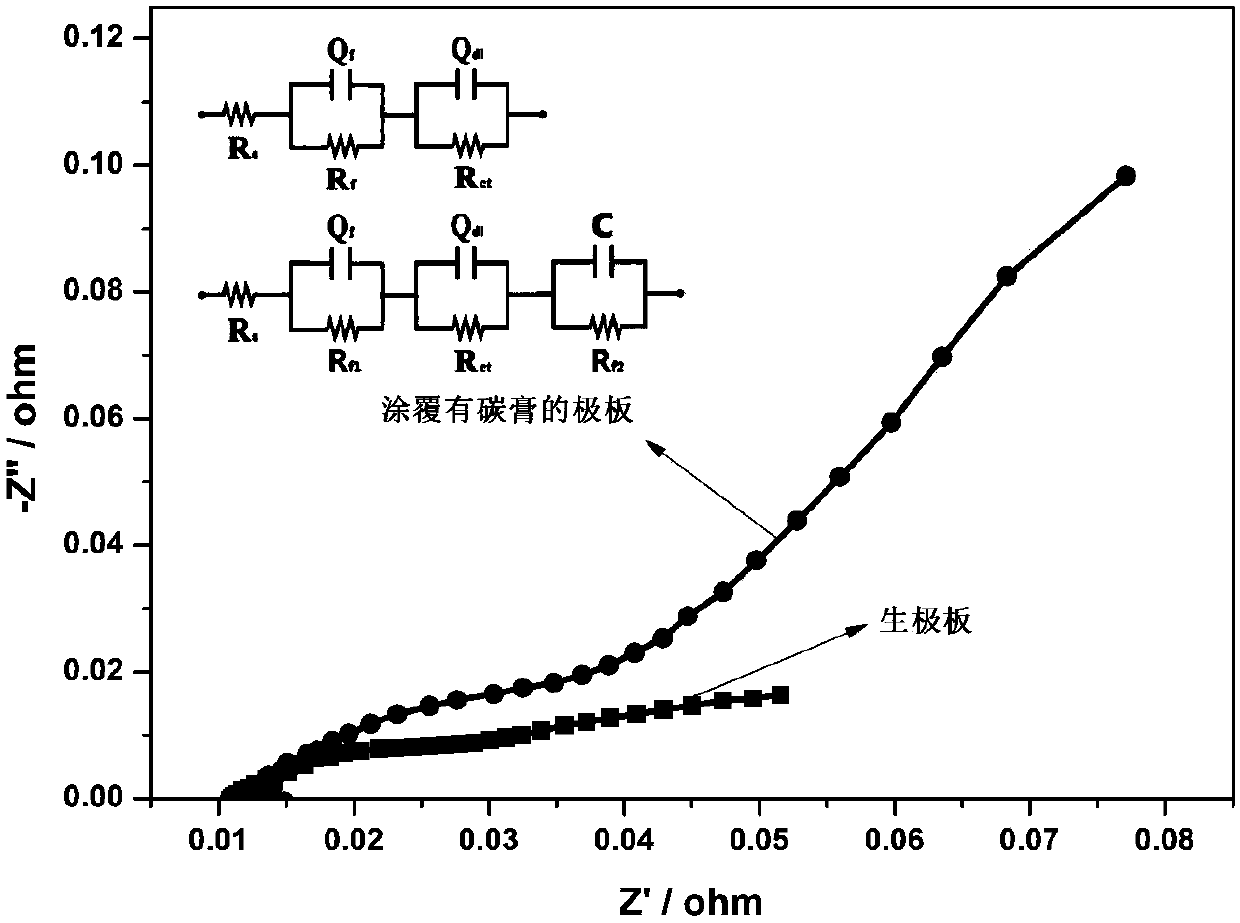

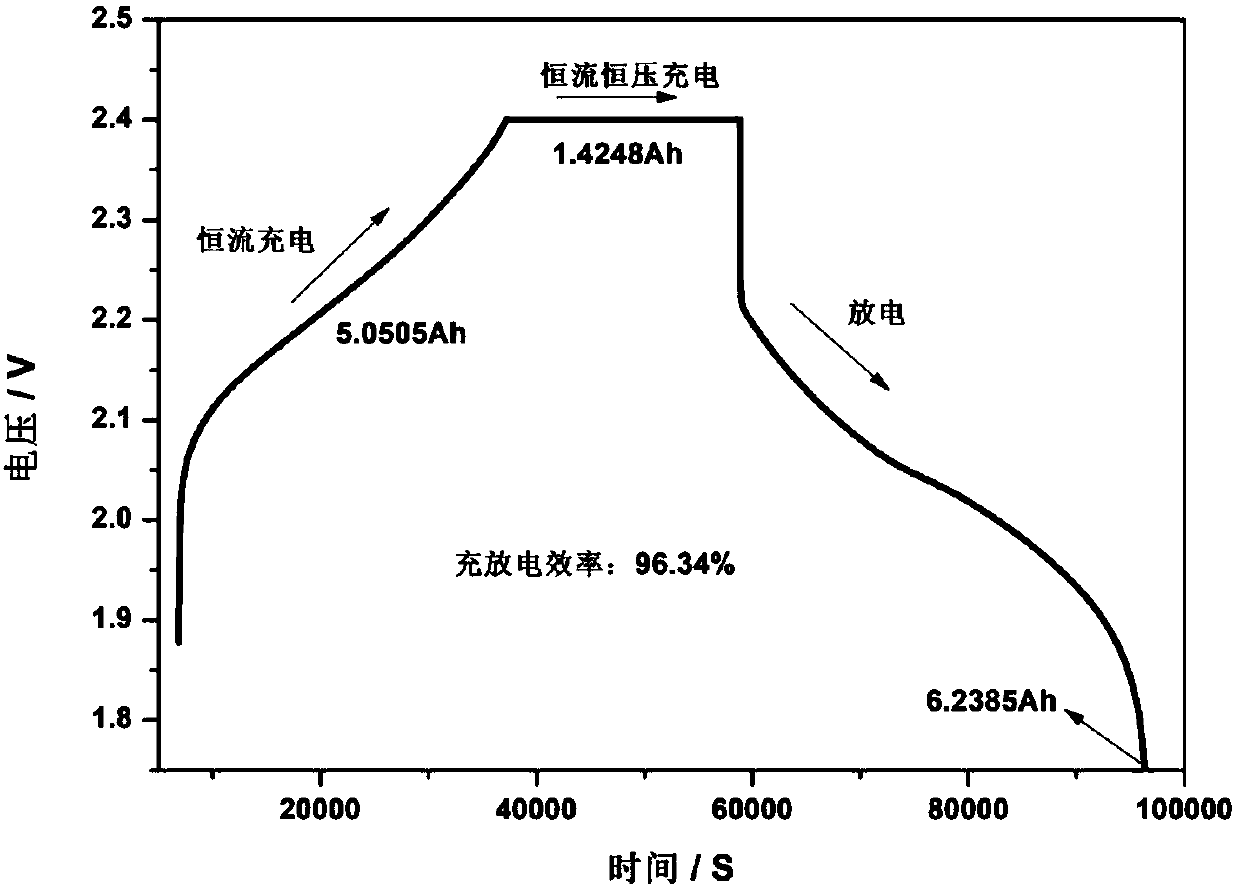

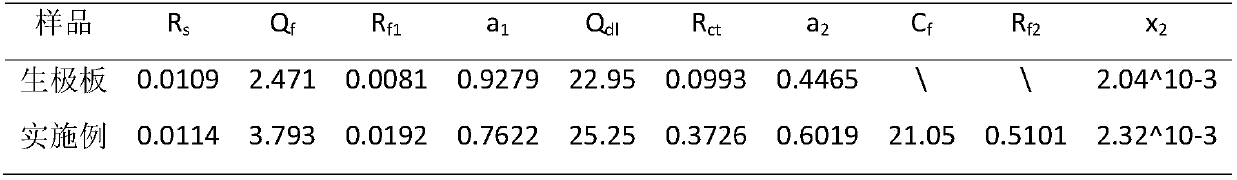

[0032] First apply the lead paste to the lead alloy grid, dry and solidify to prepare a green plate, and then apply the carbon paste at 0.3g / cm 2 The loading amount was evenly coated on the surface of the raw electrode plate, and dried for 24 h...

Embodiment 2

[0038] The 60wt% specific surface area is 100m 2 The mixed material of graphite carbon, 30wt% polystyrene, and 10wt% acetylene black per gram is placed in first-grade water, heated to 110°C, heated and stirred at a constant temperature for 3 hours, and left to stand in an environment with an air humidity of 50% for 36 hours after natural cooling After obtaining carbon paste;

[0039] 90wt% lead powder, 2wt% humic acid, 2wt% 40mm polyester staple fiber, 2wt% barium sulfate, 2wt% sodium lignosulfonate, 2wt% acetylene black are mixed uniformly to make active material, mix The final active substance was slowly added to its total weight of 10.0wt% water and 13wt% 2mL / s 4.7mol / L sulfuric acid and stirred evenly to form a lead paste;

[0040] First apply the lead paste to the lead alloy grid, dry and solidify to prepare a green plate, and then apply the carbon paste at 0.3g / cm 2 The loading amount was uniformly coated on the surface of the raw electrode plate, and dried for 24 hour...

Embodiment 3

[0046] The specific surface area of 70wt% is 2000m 2 The mixed material of activated carbon, 25wt% polystyrene, and 5wt% acetylene black per gram was placed in first-grade water, heated to 130°C, heated and stirred at a constant temperature for 3 hours, cooled naturally and left to stand in an environment with an air humidity of 50% for 48 hours. get carbon paste;

[0047]90wt% of lead powder, 1.5wt% of humic acid, 1.5wt% of 40mm polyester staple fiber, 2wt% of barium sulfate, 2wt% of sodium lignosulfonate, and 3wt% of acetylene black are evenly mixed to make active substances , the mixed active substance is slowly added to the total weight of 10.0wt% water and 13wt% 2mL / s 4.7mol / L sulfuric acid and stirred evenly to form a lead paste;

[0048] First apply the lead paste to the lead alloy grid, dry and solidify to prepare a green plate, and then apply the carbon paste at 0.3g / cm 2 The loading amount was evenly coated on the surface of the raw electrode plate, and dried for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com