A recyclable steel cage

A technology of steel cages and main bars, applied in construction, connecting components, infrastructure engineering and other directions, can solve the problems of polluting the underground space environment, affecting underground construction, changing construction plans, etc., to reduce corrosion, save electricity, and simplify the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

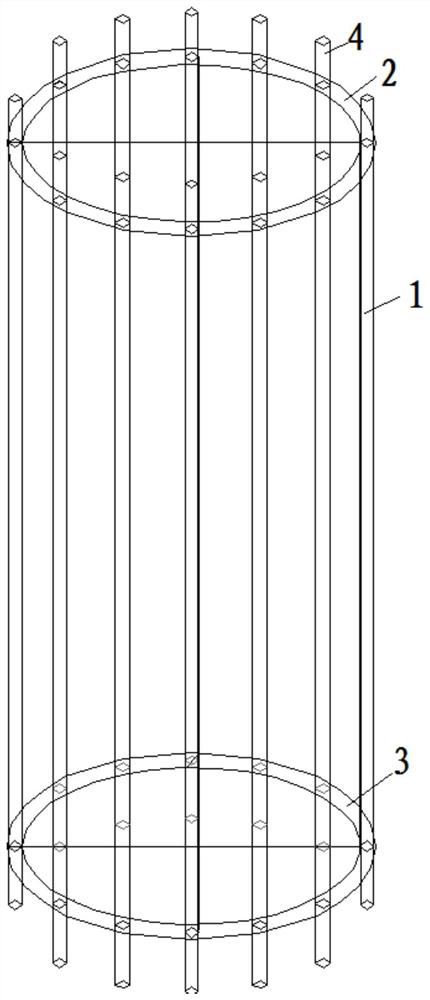

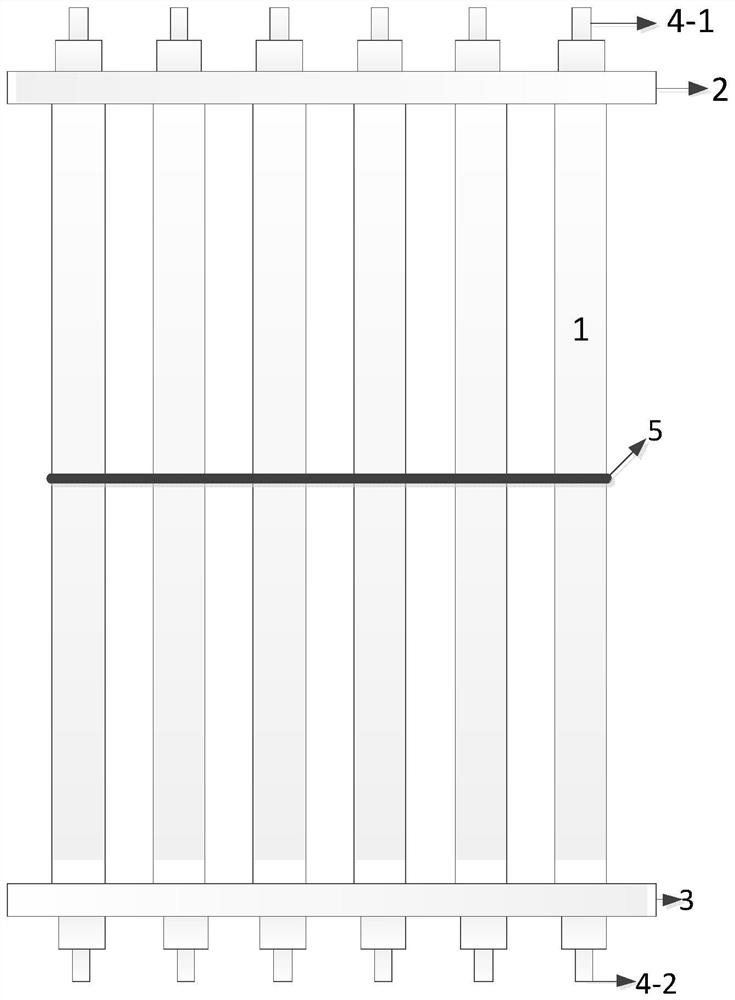

[0022] As shown in the figure, a recyclable reinforcement cage is characterized in that it includes a longitudinal main reinforcement (1), an upper flange (2), a lower flange (3) and a protective sleeve nut (4);

[0023] The upper flange (2) and the lower flange (3) are annular disks arranged in parallel, and holes are arranged on the annular disk, and the longitudinal main rib (1) can pass through the upper flange (2) and the lower flange plate (3), so that the longitudinal main ribs (1) are arranged in parallel;

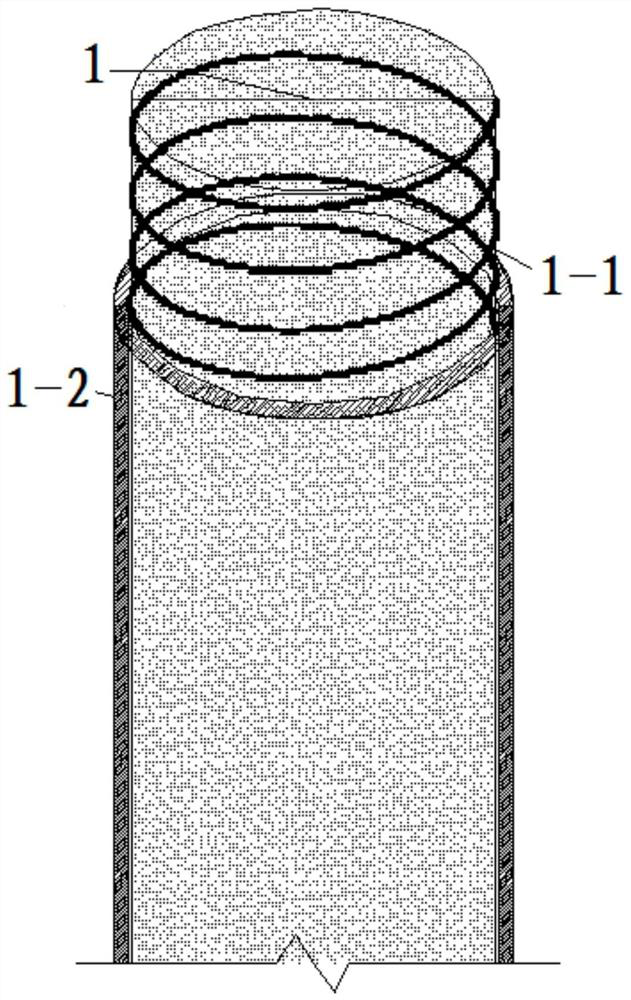

[0024] The parts of the upper and lower ends of the longitudinal main rib (1) protruding from the upper flange (2) and the lower flange (3) have thread (1-1), and the outside of the thread (1-1) has a nut protection sleeve ( 4).

[0025] The longitudinal main rib (1) is vertically arranged with the upper flange (2) and the lower flange (3).

[0026] The outer side of the longitudinal main rib (1) has a spacer sleeve (1-2).

[0027] The material of the isolation ...

Embodiment 2

[0034] As shown in the figure, a recyclable reinforcement cage is characterized in that it includes a longitudinal main reinforcement (1), an upper flange (2), a lower flange (3) and a protective sleeve nut (4);

[0035] The upper flange (2) and the lower flange (3) are annular disks arranged in parallel, and holes are arranged on the annular disk, and the longitudinal main rib (1) can pass through the upper flange (2) and the lower flange plate (3), so that the longitudinal main ribs (1) are arranged in parallel;

[0036] The parts of the upper and lower ends of the longitudinal main rib (1) protruding from the upper flange (2) and the lower flange (3) have thread (1-1), and the outside of the thread (1-1) has a nut protection sleeve ( 4).

[0037] The longitudinal main rib (1) is vertically arranged with the upper flange (2) and the lower flange (3).

[0038] The outer side of the longitudinal main rib (1) has a spacer sleeve (1-2).

[0039] The material of the isolation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com