Turbine oil additive composition

A technology of steam turbine oil and composition, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., which can solve the problems of high equipment speed, water ingress in the lubrication system, long operating cycle, etc., and achieve the effect of small corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] In a 250mL beaker, add the following components according to the amount:

[0035] C 4 / C 8 Alkyl substituted diphenylamine 10.0 g

[0036] Phenyl-α-naphthylamine 13.0 g

[0037] 2-ethyl-hexyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate 24.0g

[0038] Methyl di-n-butyldithiocarbamate 20g

[0039] N,N-Di-n-butylaminomethylenebenzotriazole 9.0g

[0040] Tris-m-cresyl phosphate 10.0g

[0041] Butyl octyl dithiophosphate dodecylamine salt 5.4g

[0042] Heptadecenyl imidazolidinyl succinate 2.0 g

[0043] Dodecenylsuccinic acid 4.0 g

[0044] Ethylenediaminetetrapolyoxypropylene 2.4g

[0045] Ethylene oxide-propylene oxide copolymer 0.2 g

[0046] C above 4 / C 8 Alkyl substituted diphenylamine contains 12-18% by mass of C 4 Alkyl monosubstituted diphenylamine, 22-26% by mass of C 8 Alkyl monosubstituted diphenylamine, 34-38% by mass of C 4 / C 8 Alkyl disubstituted diphenylamine, 10-20% by mass of C 8 / C 8 Alkyl disubstituted diphenylamines.

[0047] After a...

example 2

[0049] In a 250mL beaker, add the following components according to the amount:

[0050] C 4 / C 8 Alkyl substituted diphenylamine 15.0 g

[0051] Phenyl-α-naphthylamine 8.0 g

[0052] Methyl di-n-butyldithiocarbamate 20g

[0053] 2-ethyl-hexyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate 24.0g

[0054] N,N-Di-n-butylaminomethylenebenzotriazole 9.0g

[0055] Phosphonate (T451) 10.0g

[0056] Dibutyl propyl dithiophosphate 5.6 g

[0057] Heptadecenyl imidazolidinyl succinate 2.0 g

[0058] Dodecenylsuccinic acid 4.0 g

[0059] Ethylenediaminetetrapolyoxypropylene 2.2g

[0060] Ethylene oxide-propylene oxide copolymer 0.2 g

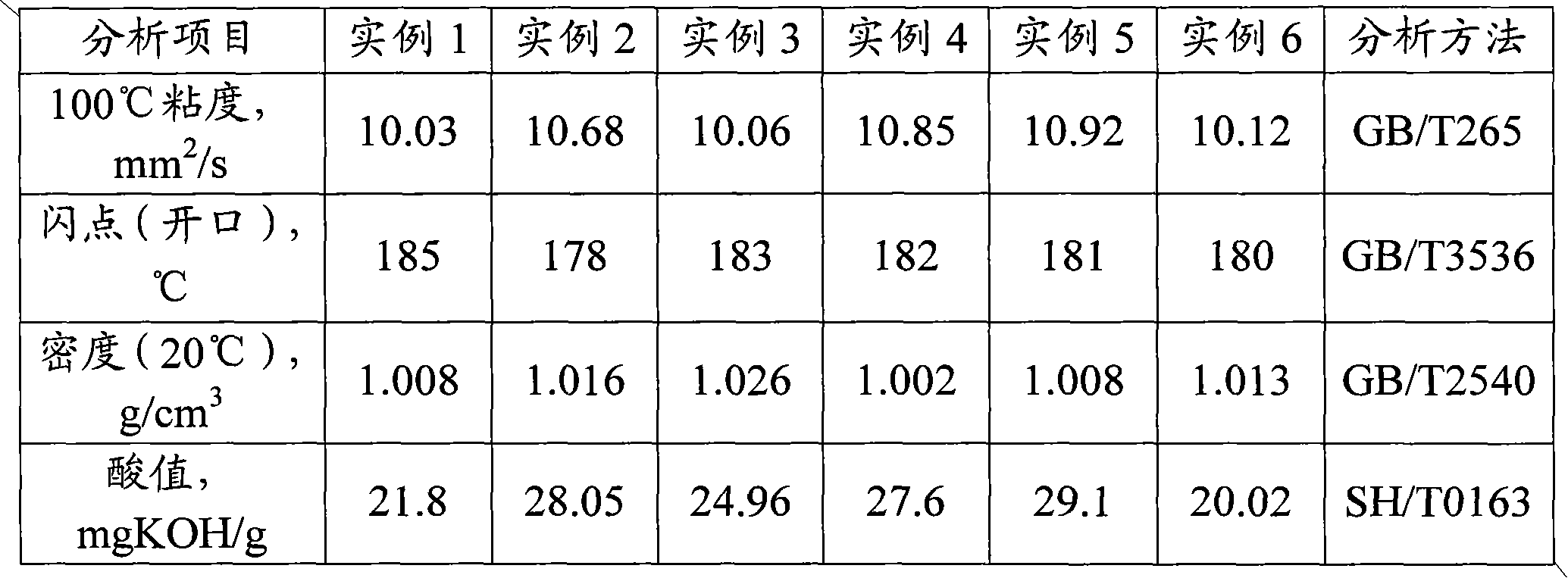

[0061] C above 4 / C 8 The composition of the alkyl-substituted diphenylamine is the same as in Example 1. After adding the components, stir and heat at 60° C. for 30 minutes to obtain a uniform and transparent brown-red liquid, which is the additive composition B of the present invention. The physical properties are shown in Table 1.

example 3

[0063] In a 250mL beaker, add the following components according to the amount:

[0064] C 4 / C 8 Alkyl substituted diphenylamine 12.6 g

[0065] Phenyl-α-naphthylamine 10.4 g

[0066] Methyl di-n-butyldithiocarbamate 23.4g

[0067] 2-ethyl-hexyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate 21.0g

[0068] N,N-Dioctylaminomethylenebenzotriazole 10.0g

[0069] Tris-m-cresyl phosphate 9.0g

[0070] Dibutyl propyl dithiophosphate 4.4 g

[0071] Dodecenylsuccinate Half Ester 4.0g

[0072] Dodecenylsuccinic acid 3.0g

[0073] Ethylenediaminetetrapolyoxypropylene 2.0g

[0074] Ethylene oxide-propylene oxide copolymer 0.2 g

[0075] C above 4 / C 8 The composition of the alkyl-substituted diphenylamine is the same as in Example 1. After adding the components, stir and heat at 60° C. for 30 minutes to obtain a uniform transparent brown-red liquid, which is the additive composition C of the present invention. The physical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com