A kind of stainless steel oxide scale removal method

A technology for stainless steel and oxide skin, which is applied in the field of removing oxide skin on stainless steel surface by combining molten salt method and pickling method, which can solve the problem that the complete removal of stainless steel surface oxide skin cannot be guaranteed, and achieve the effect of short pickling time

Active Publication Date: 2018-10-09

太仓市珠港金属制品有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is not suitable for non-forged or heated stainless steel parts, and the above method cannot guarantee complete removal of stainless steel surface oxide scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

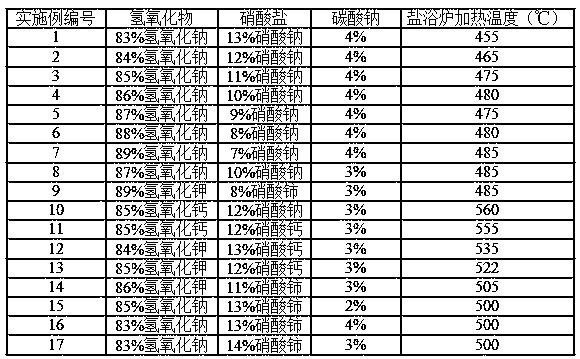

[0027] The content of the present invention is further described below by way of examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

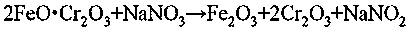

The invention discloses a removing method of a stainless steel oxide scale. The removing method comprises the following steps: step one, mixing the following components in percentage by mass: 82-89 percent of hydroxide, 7-13 percent of nitrate and 2-4 percent of sodium carbonate, heating in a salt bath furnace until the temperature is 455-560 DEG C, soaking a stainless steel product needing treatment in the salt bath furnace, and treating for 5-40m; step two, soak cleaning or cleaning the stainless steel product treated in the first step by utilizing a pickling liquor or a circulation liquid flow respectively until the surface of the stainless steel product is bright; and step three, repeatedly washing the stainless steel product treated in the second step by utilizing a high-pressure water flow at room temperature until no residue exists on the surface of the stainless steel product. The removing method can effectively remove the oxide scale on the surface of stainless steel without causing secondary corrosion on the surface of the stainless steel.

Description

technical field [0001] The invention relates to a method for removing scale on the surface of stainless steel, in particular to a method for removing scale on the surface of stainless steel by combining a molten salt method and a pickling method. Background technique [0002] During the process of smelting and using stainless steel, the surface is susceptible to different degrees of oxidation. The oxide scale on the surface of stainless steel has a dense structure and strong adhesion to the substrate. Moreover, since stainless steel always has a variety of alloy components, there are also a variety of oxide scales in the stainless steel. Oxide structure, including oxide, iron oxide, ferric oxide, chromium oxide, silicon dioxide, nickel spinel, etc. The oxide skin of stainless steel not only has no decorative appearance, but also accelerates the electrochemical corrosion rate of the stainless steel surface. At the same time, due to the difference in thermal expansion coeffici...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23G1/32C23G1/08

Inventor 李超林

Owner 太仓市珠港金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com