Activated carbon pickler

A pickling device and activated carbon technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of difficult maintenance, poor use effect, difficult operation, etc., to avoid damage, improve pickling effect, and increase acidity The effect of washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

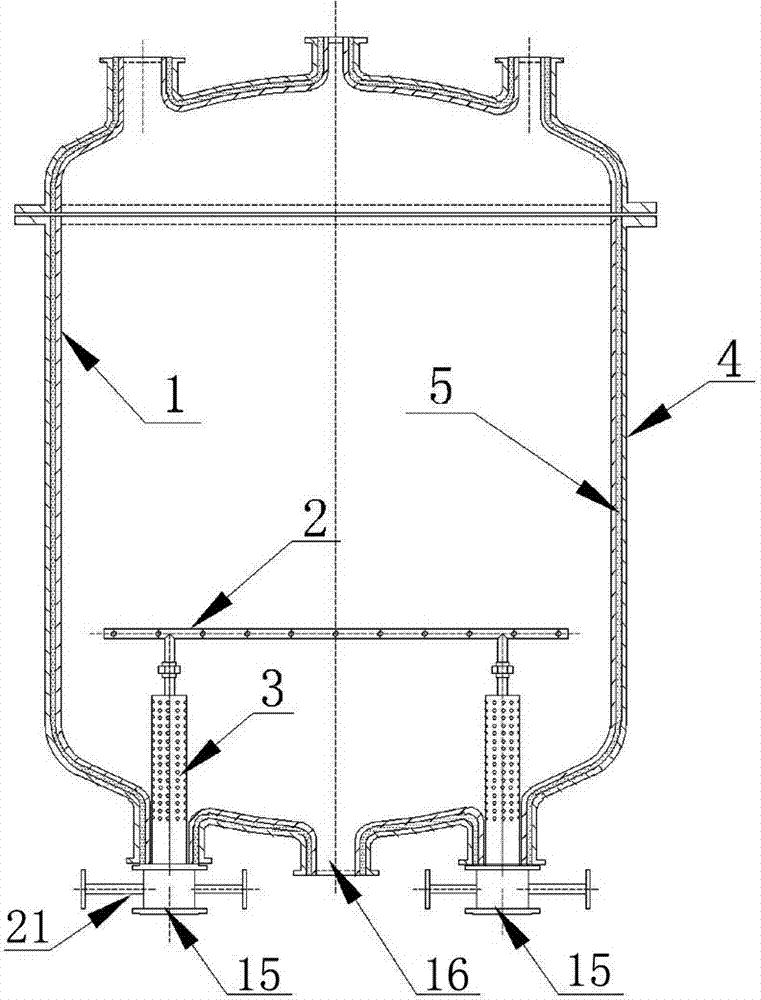

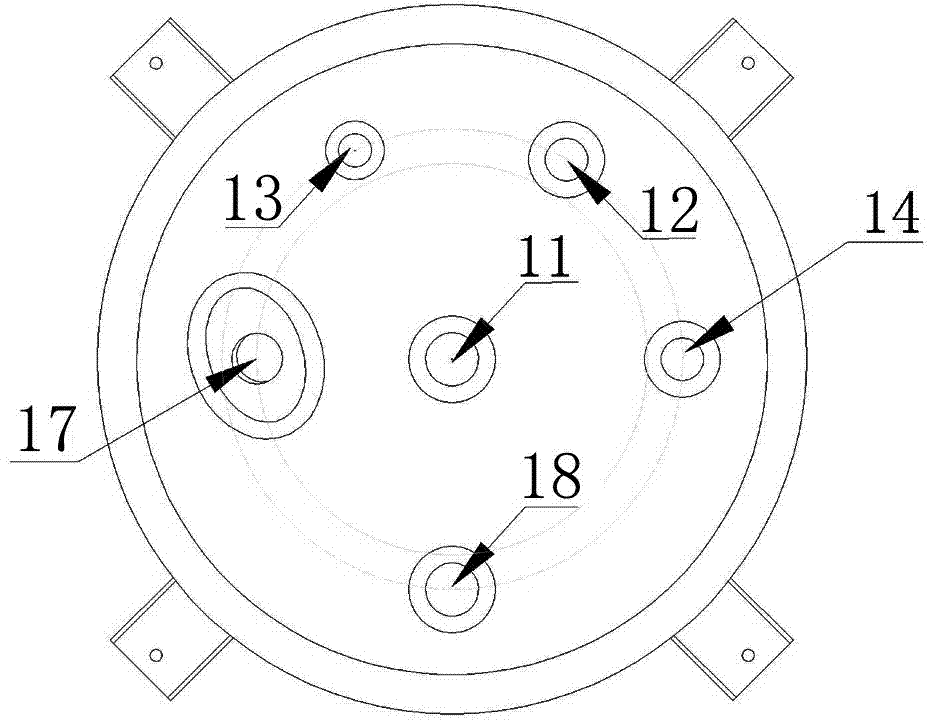

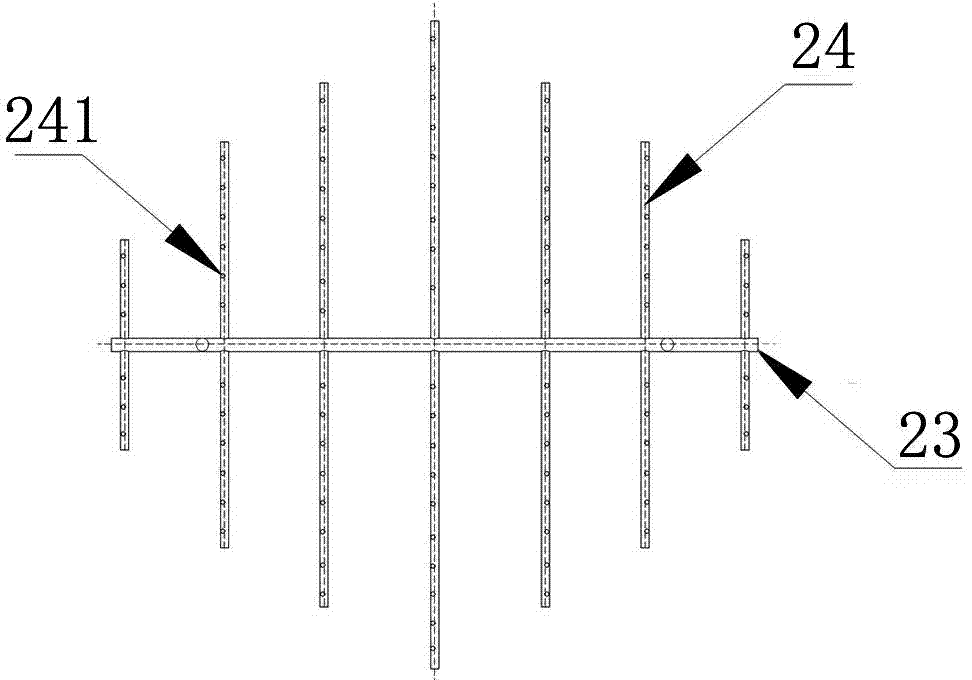

[0024] combine Figure 1 to Figure 6 As shown, an activated carbon pickling device includes: a cylinder 1, the top of the cylinder 1 is provided with a feed port 11, an acid inlet 12, a water inlet 13 and an exhaust port 14, and the bottom of the cylinder 1 is provided with There is a drain port 15 and a discharge port 16; the steam heating pipe 2 is located in the lower part of the cylinder body 1; the filter cartridge 3 is located in the cylinder body 1 and is connected to the drain port 15; the steam heating pipe 2 The air inlet 21 is led out through the inner space of the filter cartridge 3 .

[0025] in, figure 2 Among them, the top of the cylinder 1 is also provided with an observation port 17 and a sampling port 18 . The observation port 17 is a transparent window through which the naked eye can check the activated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com