Pre-pickling acid liquor circulation system and method for hot-rolled stainless steel strip steel

A stainless steel strip and circulation system technology is applied in the field of hot-rolled stainless steel strip pre-pickling acid solution circulation system, which can solve the problems of not being found in time, large deviation of target concentration, affecting the pickling effect, etc., so as to achieve continuous control, Save investment cost and improve the effect of pickling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

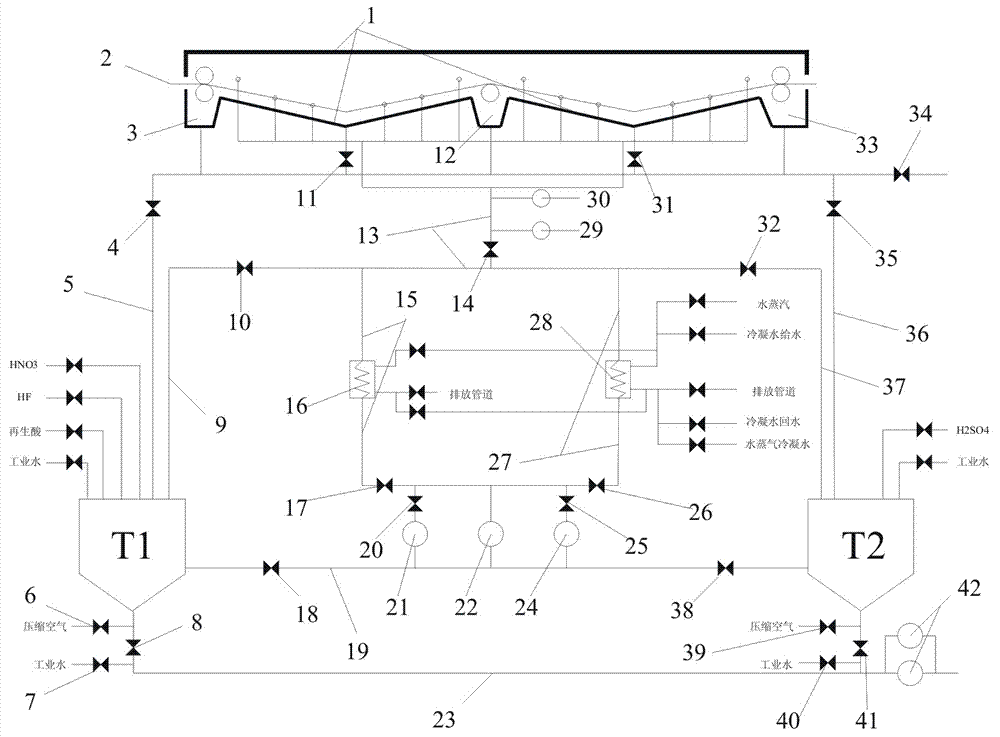

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, it includes a mixed acid pickling circulation tank T1, a sulfuric acid pickling circulation tank T2, a heat exchange device, and a pickling tank 2. The top of the mixed acid pickling circulation tank T1 is connected with the HNO3 acid distribution pipeline, the HF acid distribution pipeline, the regenerated acid acid distribution pipeline and the industrial water pipeline. The inlet of the device is connected, the bottom of the mixed acid pickling circulation tank T1 is connected with the waste acid discharge pipeline 23, the discharge of waste acid is controlled by the control valve 8, the waste acid discharge pipeline 23 is connected with the compressed air pipeline and the industrial water pipeline, and the control valve 6 is used to control the delivery of compressed air, and the control valve 7 is used to control the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com