Molten salt for chemical tempering of dental glass ceramics and use method thereof

A glass-ceramic and chemical tempering technology, which is applied in the field of molten salt for chemical tempering of dental glass-ceramics, can solve the high-efficiency and rapid requirements of dental restorations that cannot be strengthened with dental glass-ceramics, and KOH auxiliary reagents Toxicity and other issues, to achieve the effect of accelerating ion exchange, reducing steps, and stabilizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

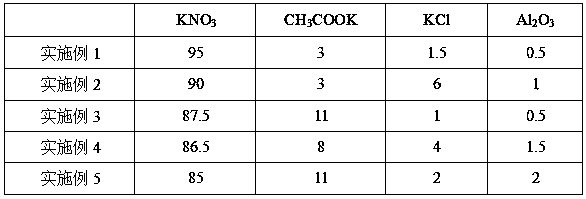

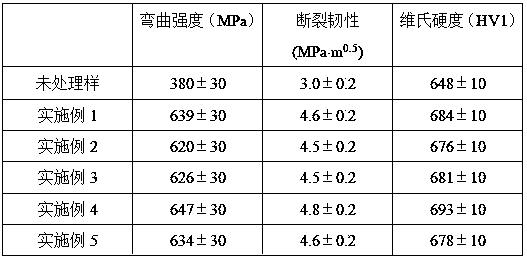

Embodiment 1

[0040] According to the ratio of each exchange reagent component in Table 1, weigh a certain amount of analytically pure raw materials, mix them evenly, put them into an alumina crucible, and cover the dental glass-ceramic sample. According to the steps mentioned above, put the crucible into the heating furnace, heat it to 450°C at a rate of 8°C / min and keep it for 1h, then take it out, and cool the sample in the air. After the samples were cleaned, various performance tests were performed, and the results are shown in Table 2. The three-point bending strength value is 639MPa, and the fracture toughness is 4.6MPa×m 0.5 , HV1 Vickers hardness value is 684. Compared with the untreated sample, the mechanical properties are greatly enhanced, which can meet the restoration requirements of parts with higher strength requirements such as posterior crowns. At the same time, the time required for ion exchange is 1 hour, which is greatly shortened compared with other patents.

Embodiment 2

[0042] According to the ratio of each exchange reagent component in Table 1, weigh a certain amount of analytically pure raw materials, mix them evenly, put them into an alumina crucible, and cover the dental glass-ceramic sample. According to the steps mentioned above, put the crucible into the heating furnace, heat it to 450°C at a rate of 8°C / min and keep it for 1h, then take it out, and cool the sample in the air. After the samples were cleaned, various performance tests were performed, and the results are shown in Table 2. The three-point bending strength value is 620MPa, and the fracture toughness is 4.5MPa×m 0.5 , HV1 Vickers hardness value is 676. Compared with Example 1, the mechanical properties are reduced.

Embodiment 3

[0044] According to the ratio of each exchange reagent component in Table 1, weigh a certain amount of analytically pure raw materials, mix them evenly, put them into an alumina crucible, and cover the dental glass-ceramic sample. According to the steps mentioned above, put the crucible into the heating furnace, heat it to 450°C at a rate of 8°C / min and keep it for 1h, then take it out, and cool the sample in the air. After the samples were cleaned, various performance tests were performed, and the results are shown in Table 2. The three-point bending strength value is 626MPa, and the fracture toughness is 4.5MPa×m 0.5 , HV1 Vickers hardness value is 681.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com