A kind of suction pipe loading method

A technology for straws and blowing straws, which is applied in the field of straw loading methods and devices, and can solve the problems of expensive manipulators, waste of straws, and affecting downstream operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

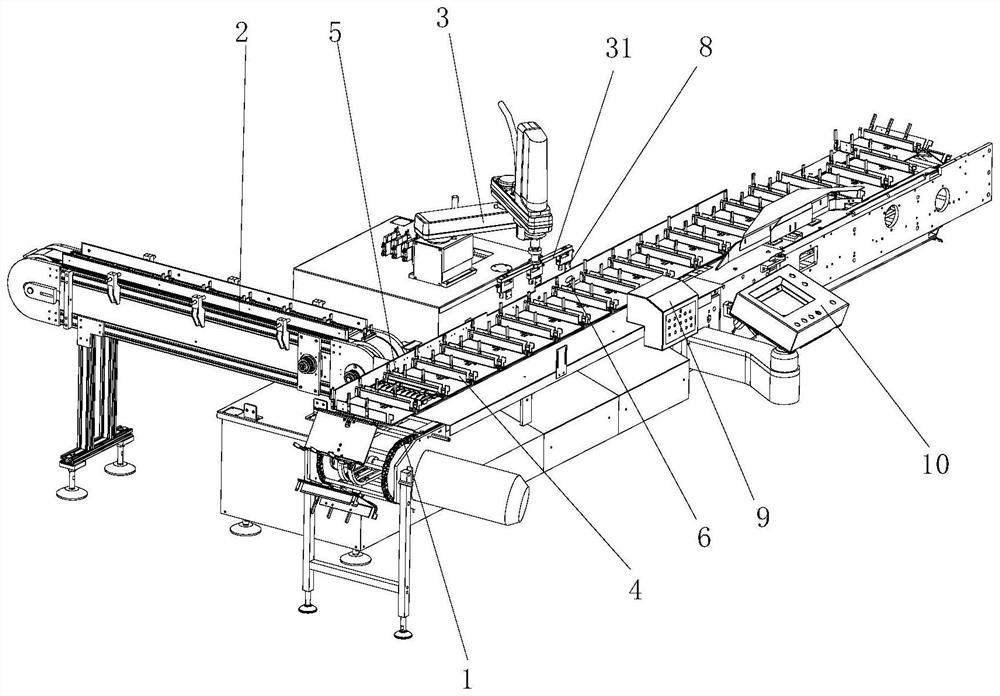

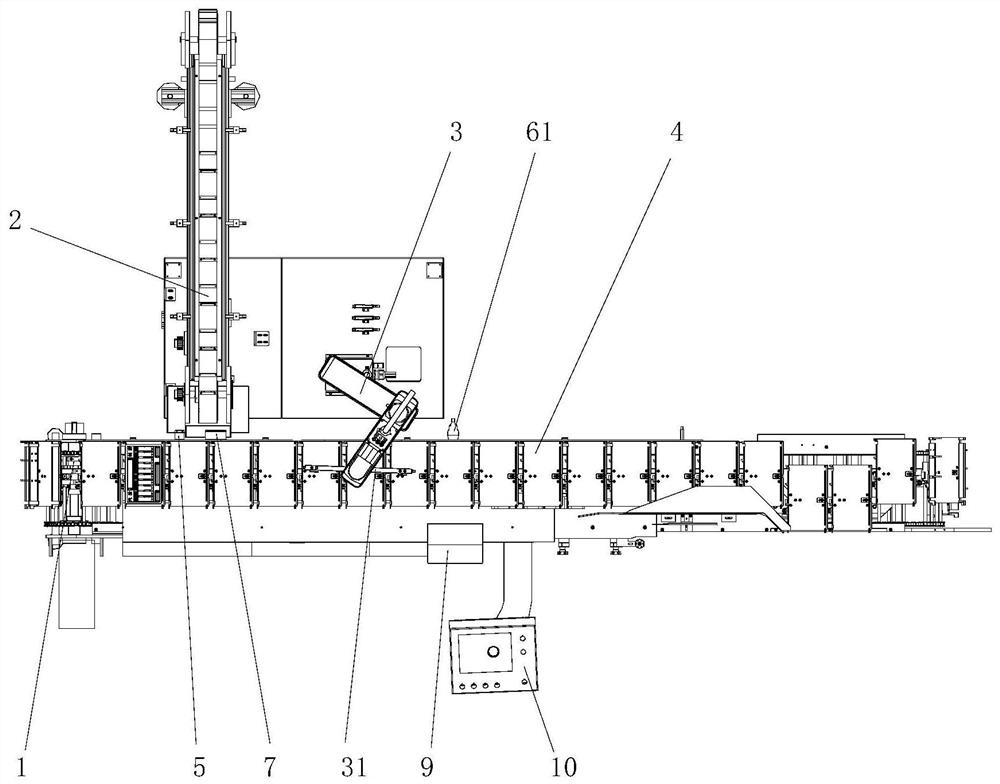

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

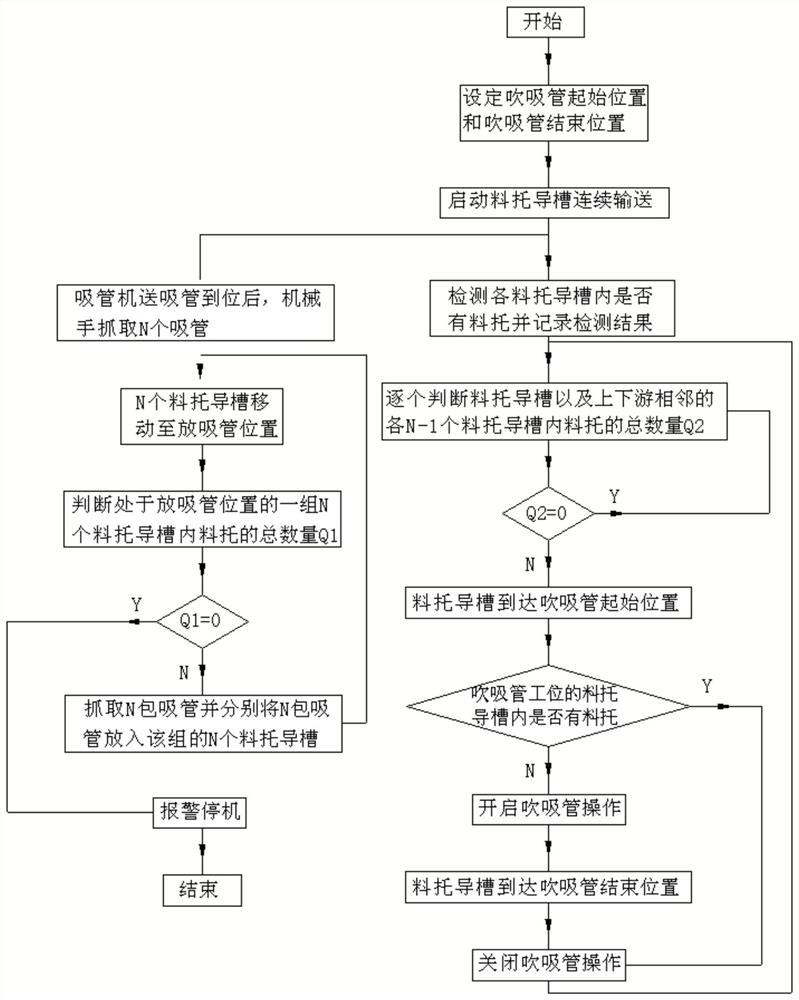

[0041] figure 1 Shows the flow chart of the straw loading method of the present invention. In the straw loading method, according to the conveying direction of the tray guide groove, the tray detection station, the location for placing the straw, the starting position of the suction pipe, and the end position of the suction pipe are sequentially provided. , including the following steps:

[0042] S1. Start the continuous conveying of the material support guide groove;

[0043] S2. Detect whether there is a material holder in each material holder guide groove passing through the material holder detection station, and record the detection result;

[0044] S3. Pick and place the straw:

[0045] S301. When each group of N receptacle guide grooves moves to the suction pipe position, N≥2, according to the detection results in step S2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com