Chemical pickling solution for removing surface oxide layer of high-temperature alloys containing elements Cr and Al and application of chemical pickling solution

A high-temperature alloy and surface oxidation technology, which is applied in the field of high-temperature alloy chemical method to remove oxide layer, to achieve high safety, bright surface and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

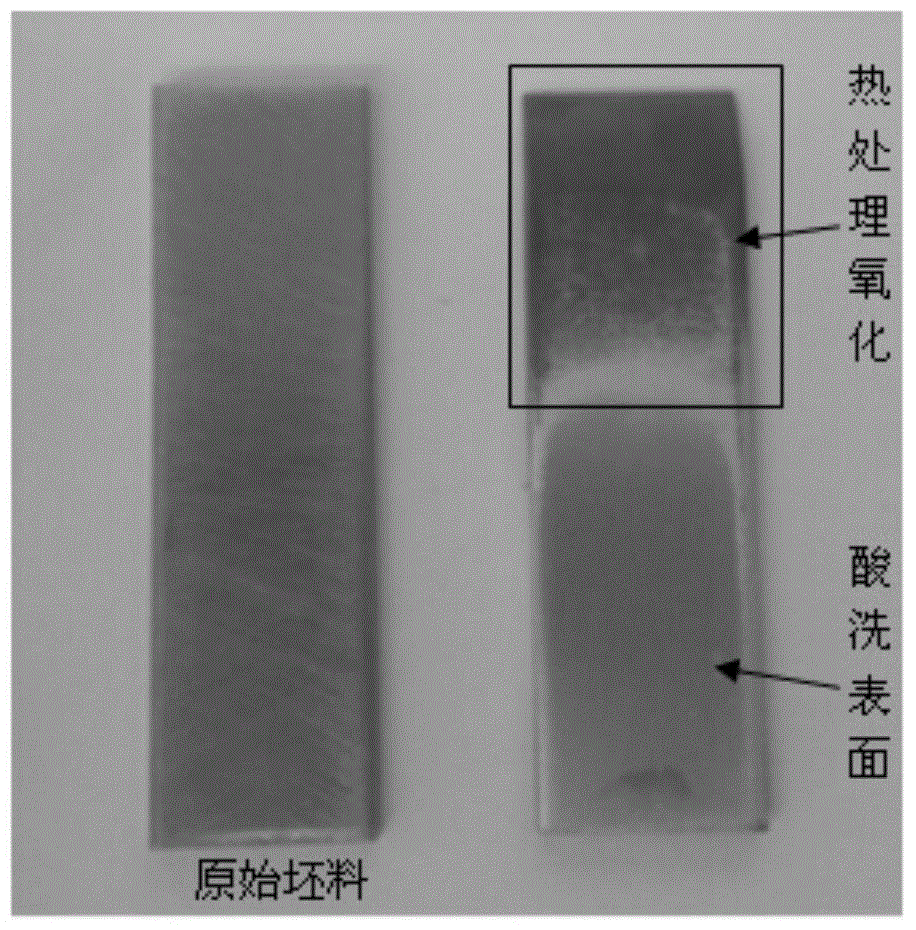

[0040] like figure 1 As shown, there is an oxide layer on the surface of the nickel-based superalloy IN 718 heat-treated test piece. This embodiment is for the pickling of the nickel-based superalloy IN 718 heat-treated test piece.

[0041] Using plastic fixtures, put the IN 718 alloy test piece after solid solution at 980°C for 10 hours directly into the container containing the pickling solution for pickling. The pickling solution is composed of: 350g / L hydrochloric acid, 410g / L nitric acid and 130g / L hydrogen peroxide, and the rest is water. The container is immersed in a constant temperature tank cooled by circulating water to ensure that the temperature of the pickling solution is lower than 30°C (generally 5°C to 20°C) during the pickling process, and vibrated in the pickling solution for 10 minutes. After the end, quickly move the test piece to the ethanol solution with a concentration of 99wt% for ultrasonic cleaning for 3 minutes, and then blow dry after washing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com