Ammonium phosphate slurry filter press

A filter press and slurry technology, which is applied in the field of ammonium phosphate slurry filter press, can solve the problems of short service cycle of filter cloth of slurry filter press, difficulty in replacement and cleaning, and prolonged service life of filter cloth, etc. Good washing effect, reduce labor intensity, and avoid the effect of disassembly and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

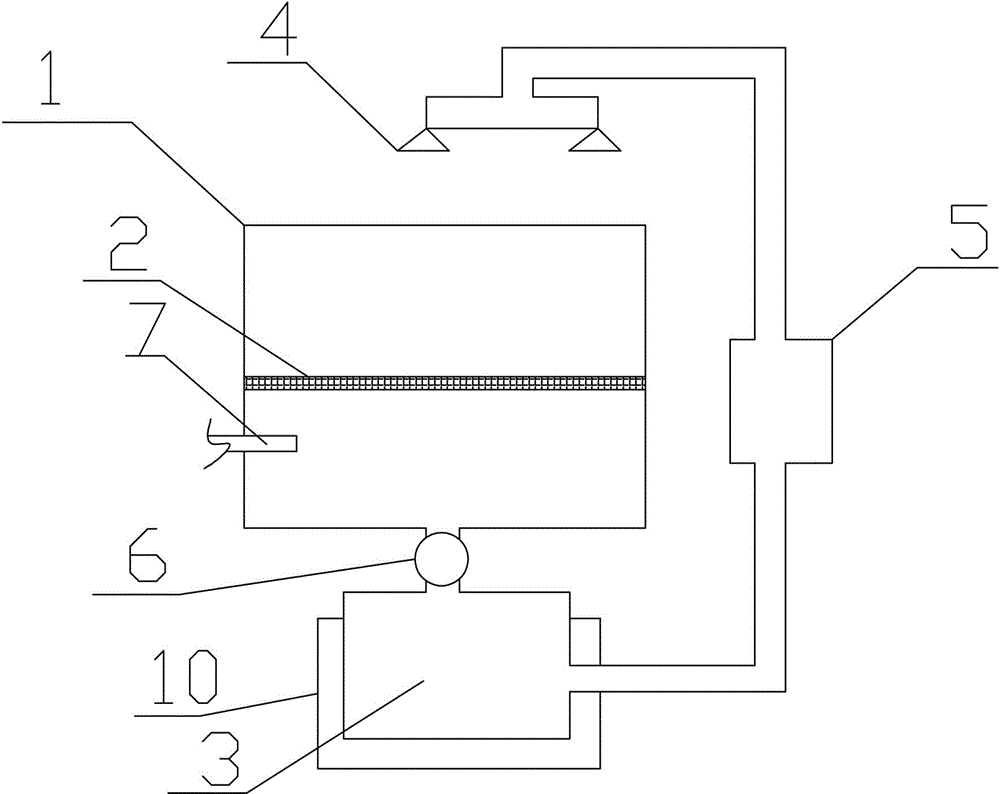

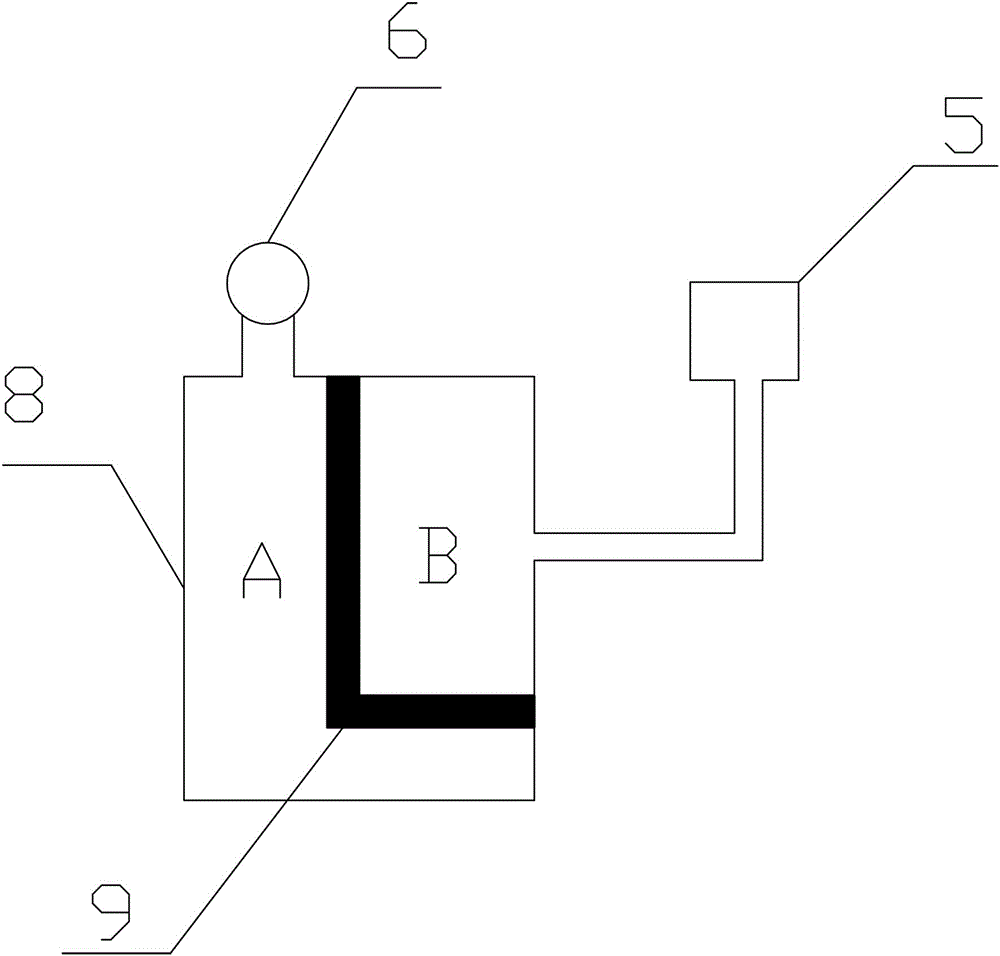

[0018] Such as figure 1 , an ammonium phosphate slurry filter press includes a box body 1, a filter cloth 2 arranged in the middle of the box body 1, a pickling circulation tank 3 arranged on the outer wall of the bottom of the box body 1, and a filter cloth arranged at the top of the box body 1 Two nozzles 4, nozzles 4 communicate with the pickling circulation tank 3 through the circulation pump 5;

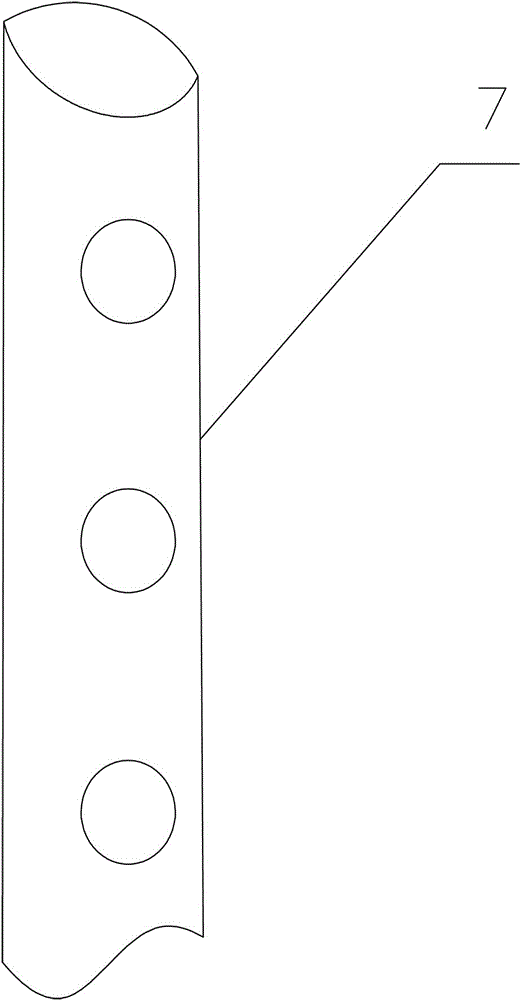

[0019] The side wall inside the box body 1 is provided with a ventilation rod 7, such as image 3 , the ventilation rod 7 is a hollow tube, and its outer surface is provided with air holes, and the ventilation rod 7 communicates with the gas source:

[0020] The bottom of the box body 1 communicates with the pickling circulation tank 3 through the solenoid valve 6;

[0021] A heating device 10 (heating coil) is provided on the outer wall of the pickling circulation tank 3, and phosphorus-sulfur mixed acid is installed in the pickling circulation tank 3, and the optimum ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com