Acid leaching device for silicon ore purification

A technology of acid leaching and silicon ore, which is applied in the production field of silicon ore purification, can solve the problems of poor acid leaching effect, poor stirring effect, and long processing time, so as to shorten the acid leaching time, improve the acid leaching effect, and acid leaching good dip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

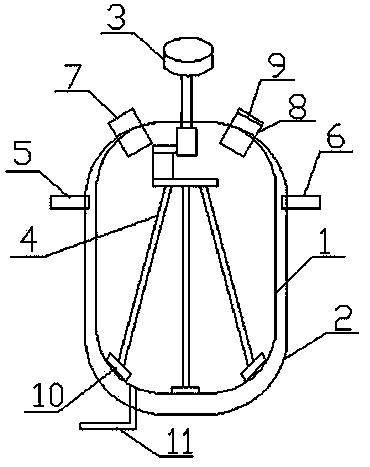

[0019] like figure 1 The acid leaching device shown for the purification of silicon ore includes an acid leaching barrel body 1, and the outside of the acid leaching barrel body 1 is provided with a jacket 2 that can be passed into a heating medium or a cooling medium, and the jacket 2 is provided with a medium Inlet 5 and medium outlet 6; the top of the acid leaching tank body 1 is provided with a feeding port 7 and an acid gas escape port 8; the top of the acid gas escape port 8 is provided with an acid gas filter layer 9, and the acid gas filter layer 9 The glass fiber sewing thread base cloth layer and glass fiber layer impregnated with PTFE are sequentially laminated; the top of the pickling barrel body 1 is fixed with a motor 3, and the motor 3 is connected to a stirring mechanism, and the stirring mechanism includes a stirring spindle And three stirring slave shafts 4, and each stirring slave shaft 4 is provided with a stirring block 10 below.

[0020] An acid disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com