Environment-friendly steel wire pickling bath

An environmentally friendly technology for pickling tanks, applied in the field of environmentally friendly steel wire pickling tanks, it can solve the problems of difficult maintenance, easy aging and deformation, and complicated wire threading process, so as to reduce acid consumption and water consumption, reduce production and The difficulty of maintenance and the effect of solving the problem of easy sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

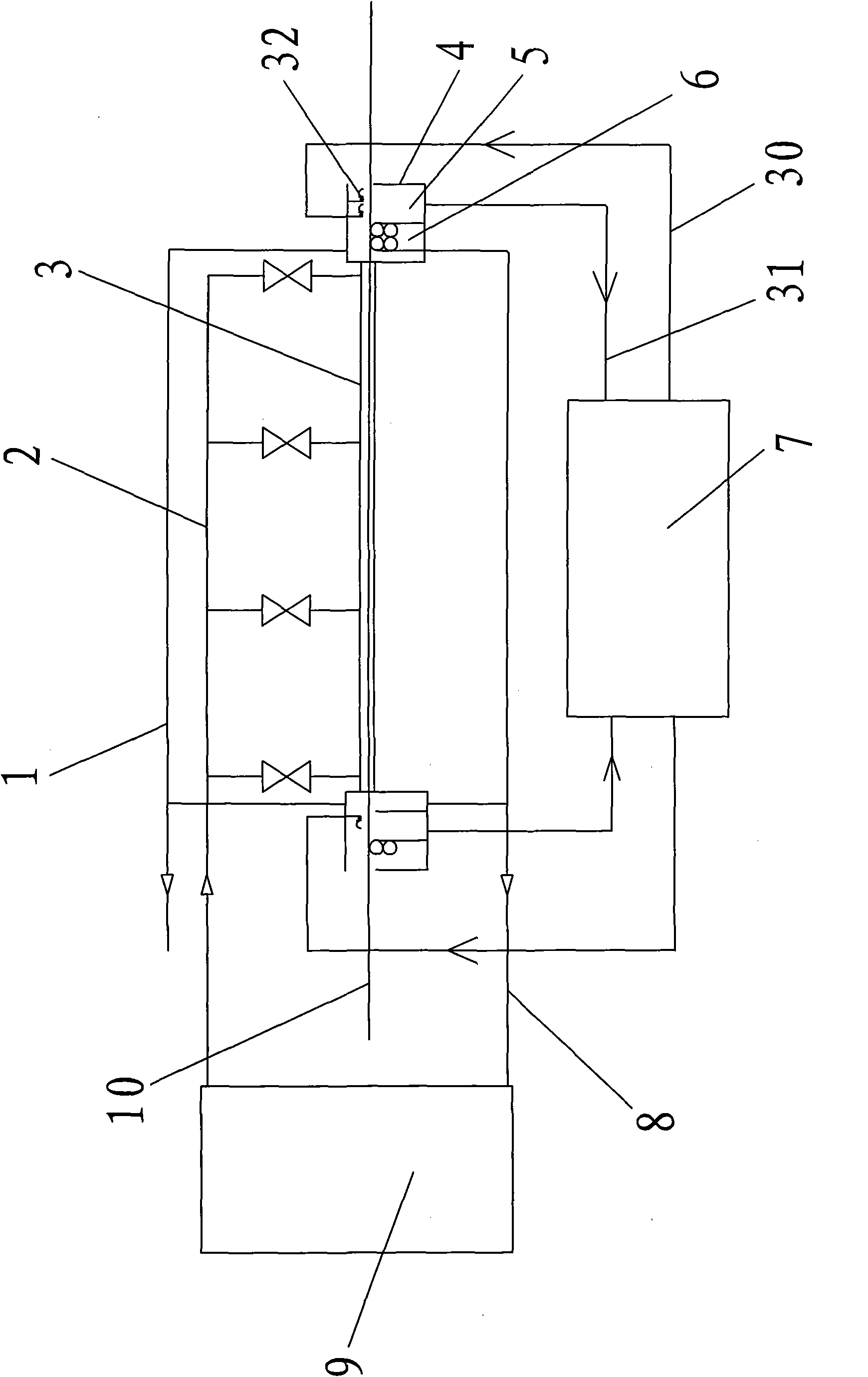

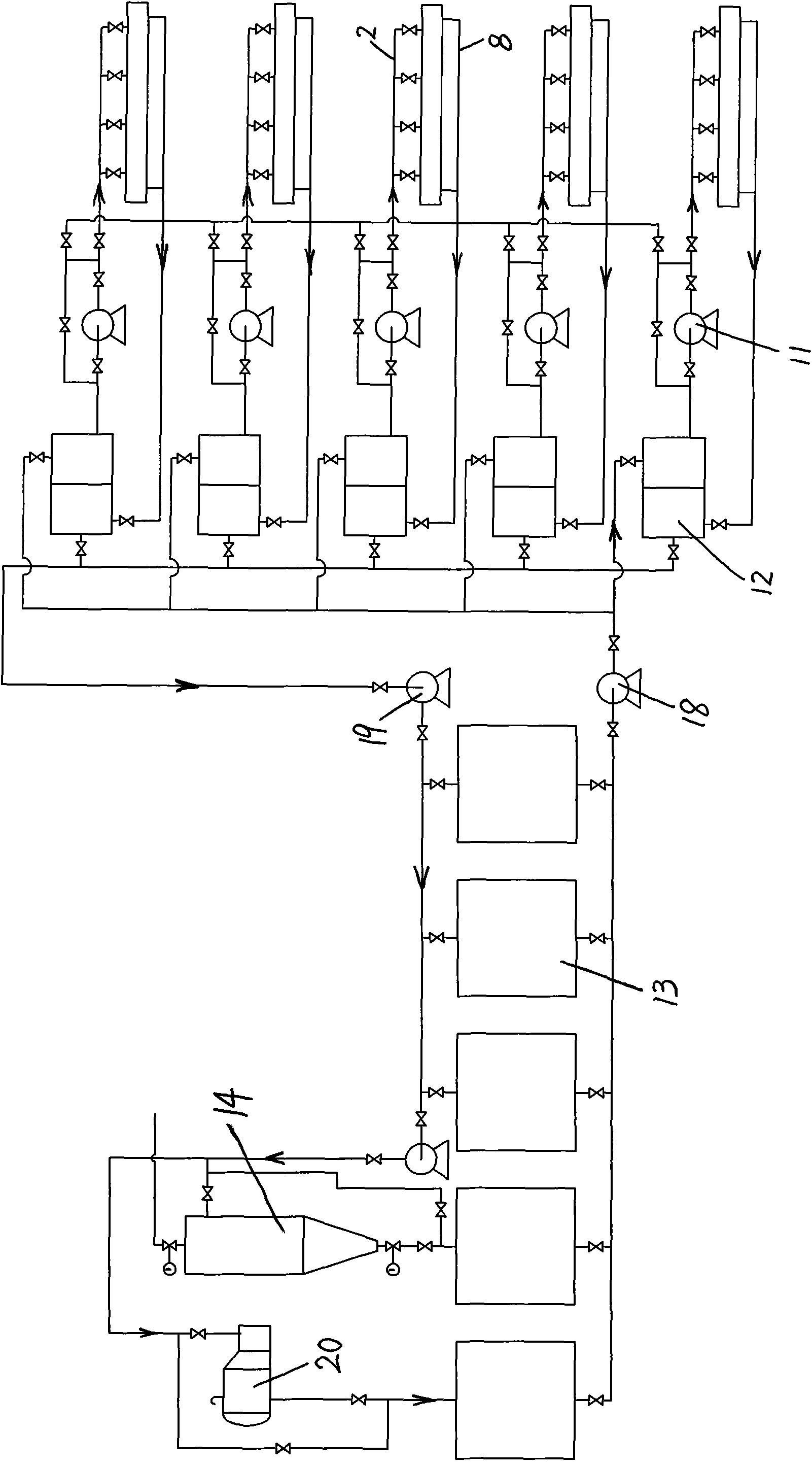

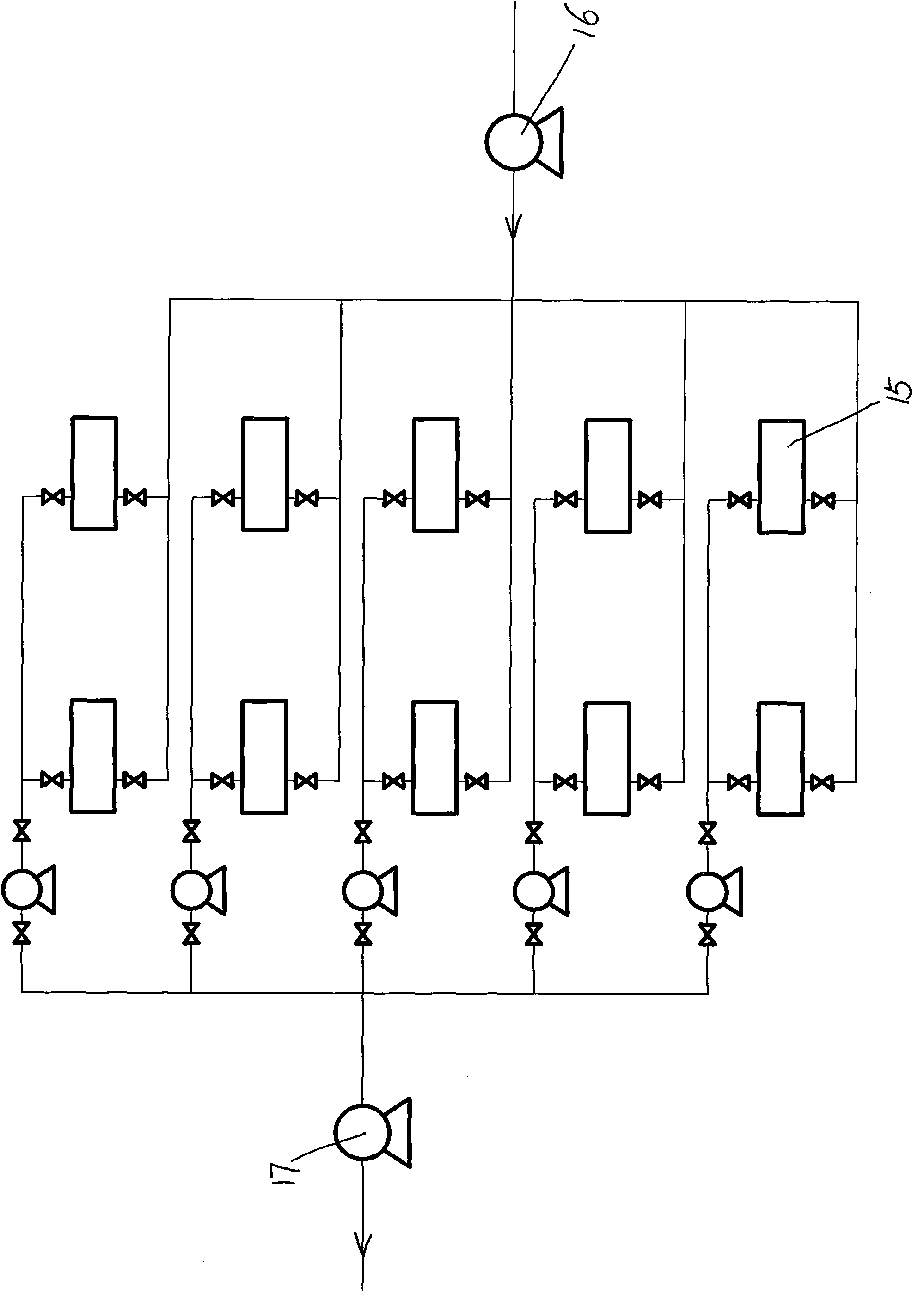

[0024] An environment-friendly steel wire pickling tank, such as figure 1 As shown, a water circulation device 7 and an acid liquid circulation device 9 are included.

[0025] According to the actual production, the pickling tank is composed of 20 pickling pipes 3 arranged horizontally with each other. In the transverse section, the 20 pipes are divided into one group, and the distance between adjacent pipes is 45mm. Several groups of pipes can be set . In order to ensure the life of the acid tank, the pickling pipeline 3 is made of PE pipe, and the inner wall of the pickling pipeline 3 is provided with a polyethylene UHMV-PE layer, so that the pickling pipeline 3 has good self-lubricating properties, high strength and high toughness And other advantages, from the surface to ensure that the entire pickling pipeline 3 wear-resistant, corrosion-resistant needs.

[0026] The top surface of the pickling pipeline 3 is evenly connected with the acid feeding pipe 2 at intervals, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com