A high-efficiency, energy-saving and environment-friendly pickling device for hydraulic pipe fittings

A high-efficiency, energy-saving, pickling device technology, applied in the pickling field of high-precision hydraulic pipe pretreatment before cold rolling or cold drawing, can solve the problems of difficult to grasp the soaking time, incomplete removal of rust, and inability to remove attachments, etc. , to achieve the effect of avoiding excessive or insufficient pickling, good pickling effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

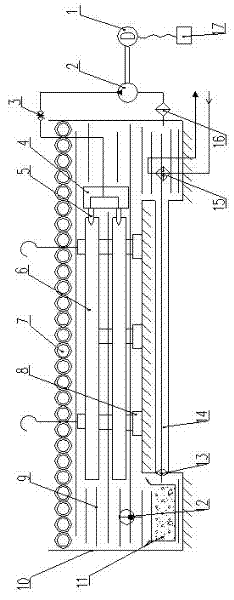

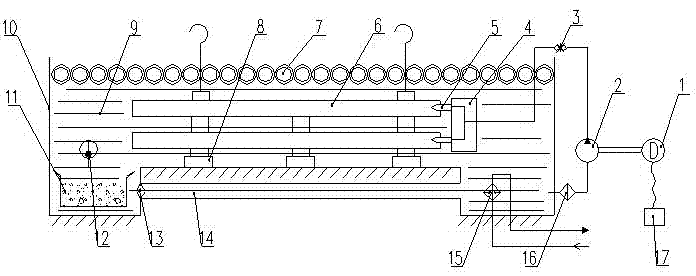

[0010] Such as figure 1 As shown, the high-efficiency, energy-saving and environment-friendly pickling device for hydraulic pipe fittings of the present invention includes a pickling tank assembly, a pickling solution circulation drive device, a bracket, an electric control system, and a heater 15 . The pickling tank assembly includes a pickling tank 10, a sediment frame 11, a return pipe 14, a float 7, and a filter screen 13; the pickling tank 10 is an acid-resistant tank generally in the shape of a rectangle, and the lower parts of both ends are concave, and the lower parts of the two ends are lower. The grooves are connected through the return pipe 14, the left end of the return pipe 14 is equipped with a filter screen 13, and the sediment frame 11 is arranged in the left groove of the pickling tank 10; the pickling solution 9 is injected into the pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com