Beryllium bronze oxidation film cleaning agent and preparation method thereof

A technology of oxide film and beryllium bronze, which is applied in the field of beryllium bronze oxide film cleaning agent and its preparation, can solve the problems of endangering workers' health, environmental hazards, and over-corrosion of beryllium copper surface, so as to improve the pickling effect, reduce pollution, and improve Effects on Performance and Appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Test piece: beryllium bronze alloy containing Be0.36, Ni2.1, Cu97.5, size 50mm×100mm×0.95mm.

[0061] Experimental method: After degreasing and washing the test piece, immerse it in the pickling solution for 10 seconds or 30 seconds, then take it out and wash it, then observe the surface of the test piece. Among them, the degreasing liquid adopts Henkel degreasing powder aqueous solution with a concentration of 2%, and the degreasing temperature is 60°C.

[0062] Evaluation symbol: ◎○△▲(good→bad)

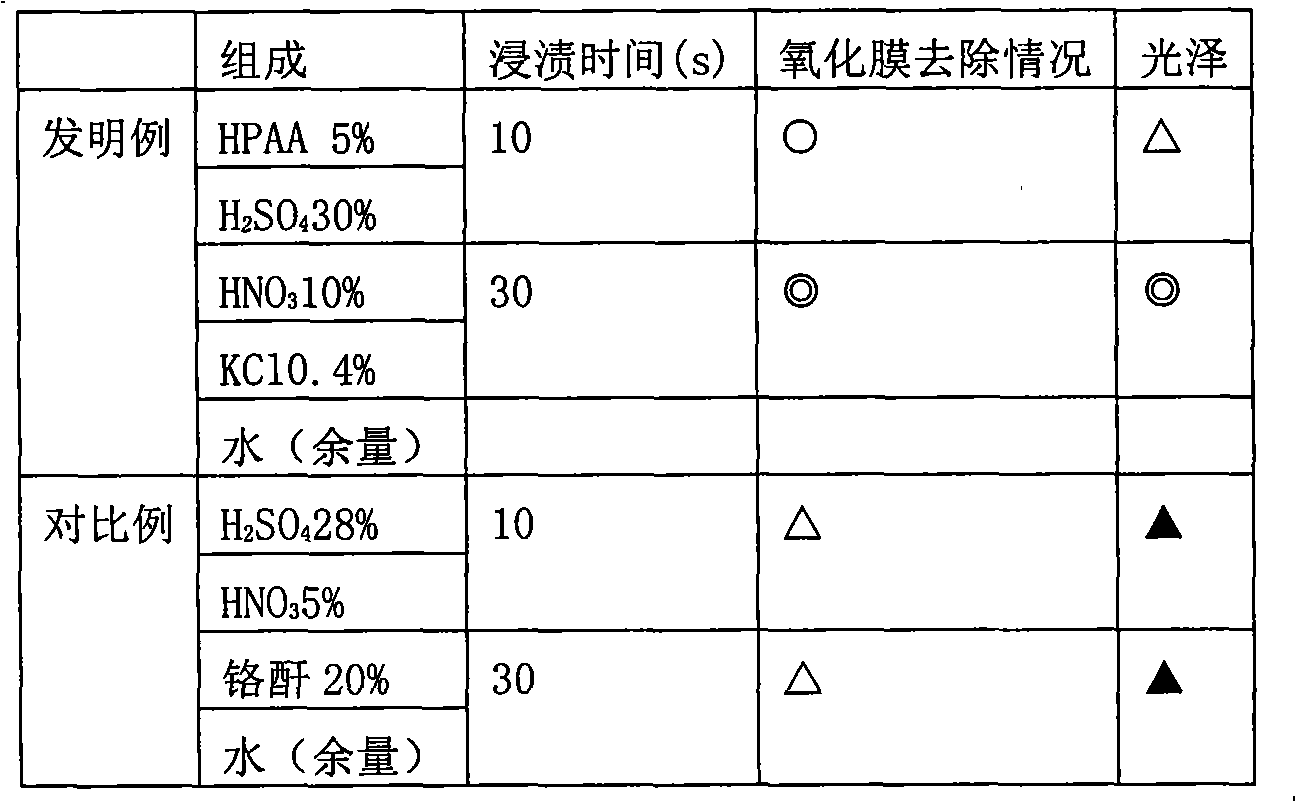

[0063] Table 1

[0064]

[0065] After cleaning with the beryllium bronze oxide film cleaning agent of the present invention for 30 minutes, the effect of removing the oxide film and the finally achieved gloss are better than those of cleaning with the existing cleaning agent.

Embodiment 2

[0067] Test piece, experimental method, evaluation symbol are equal to embodiment 1

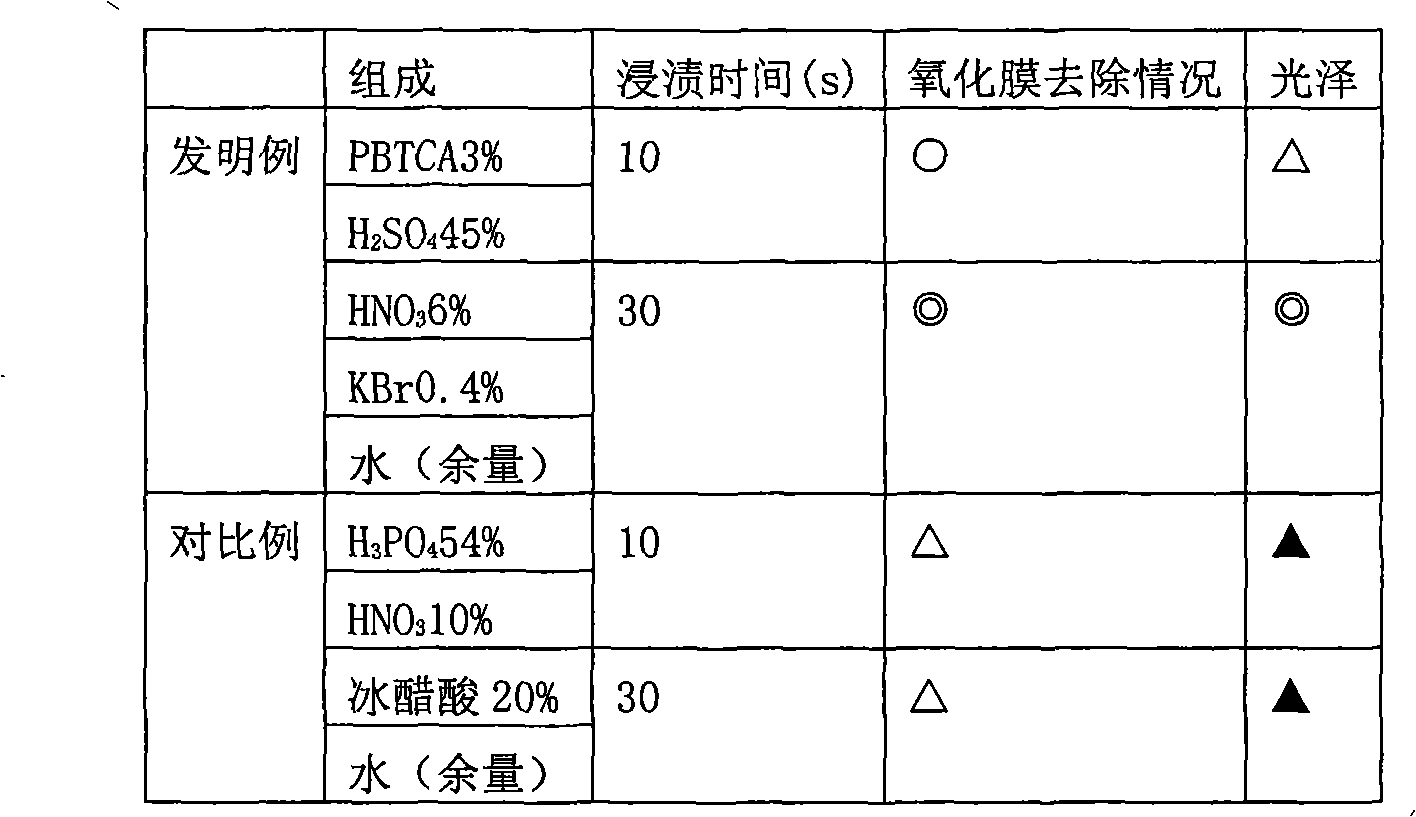

[0068] Table 2

[0069]

[0070] After cleaning with the beryllium bronze oxide film cleaning agent of the present invention for 30 minutes, the effect of removing the oxide film and the finally achieved gloss are better than those of cleaning with the existing cleaning agent.

Embodiment 3

[0072] Test piece, experimental method, evaluation symbol are equal to embodiment 1

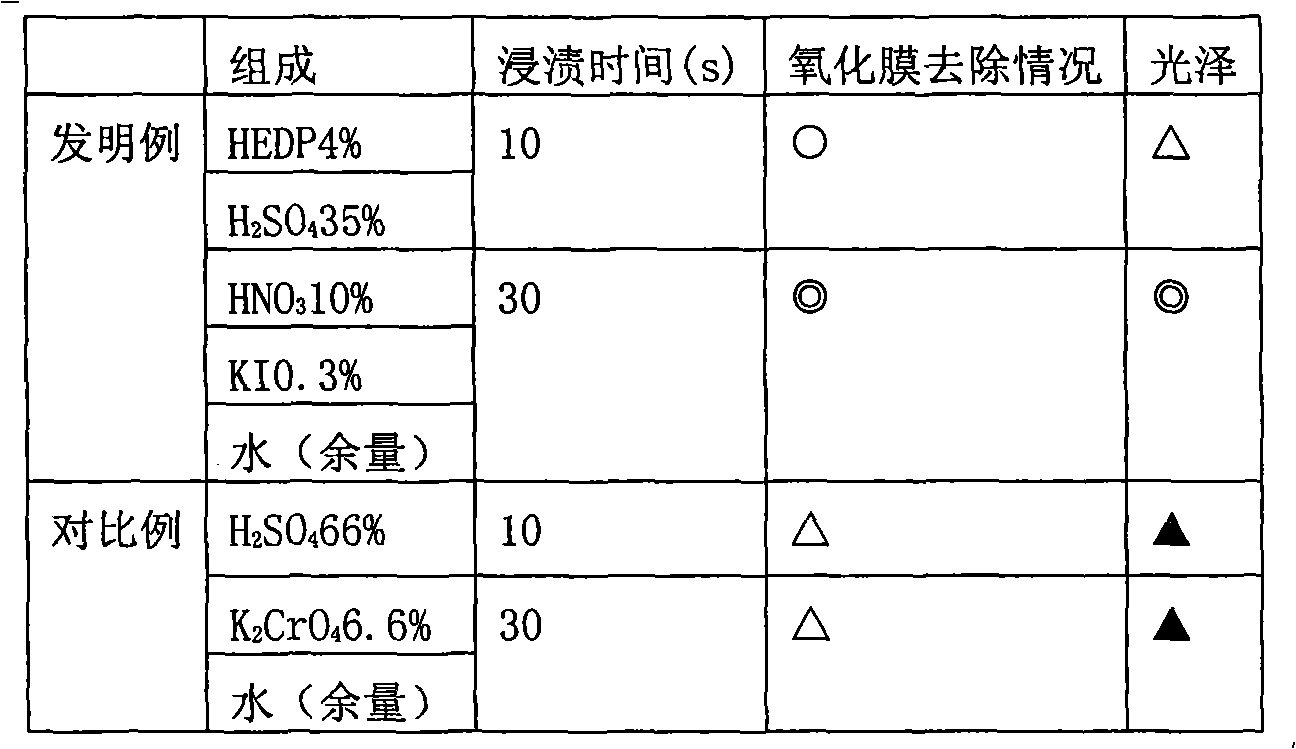

[0073] table 3

[0074]

[0075] After cleaning with the beryllium bronze oxide film cleaning agent of the present invention for 30 minutes, the effect of removing the oxide film and the finally achieved gloss are better than those of cleaning with the existing cleaning agent.

[0076]The composition of cleaning agent in the embodiment adopts 20% of sulfuric acid, 20% of nitric acid, 2% of hydroxyethylene diphosphoric acid, 1% of halide ion and water balance; or 50% of sulfuric acid, 20% of potassium nitrate, 2-hydroxyphosphonoacetic acid 10%, 0.8% of halide ions and the balance of water; or 25% of sulfuric acid, 5% of nitric acid, 8% of 2-phosphonobutane-1,2,4-tricarboxylic acid, 0.05% of halide ions and the balance of water; or Sulfuric acid 36%, sodium nitrate 7%, 2-phosphonic acid butane-1,2,4-tricarboxylic acid 3%, halogen ion 0.5% and water balance; or sulfuric acid 20%, nitric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com