Regeneration process for waste lubricating oil

A technology of waste lubricating oil and process method, which is applied in the direction of lubricating composition, etc., to achieve the effect of improving the effect, improving the quality of refining, and reducing the cost of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

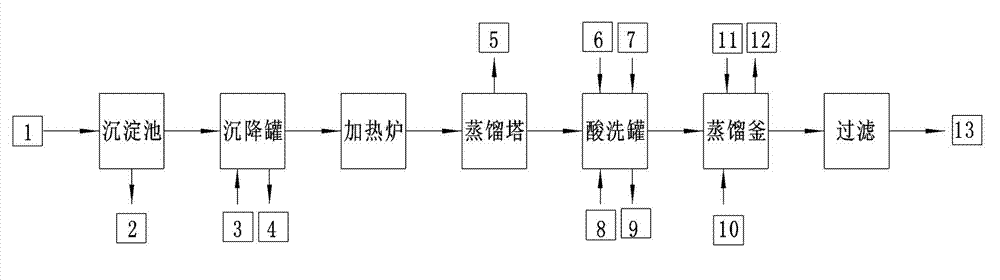

[0017] Embodiment 1: with reference to attached The figure is a schematic diagram of the process flow of Example 1 of the present invention. The waste lubricating oil 1 is classified and poured into the sedimentation tank, and part of the water and granular impurities 2 are removed through natural precipitation for more than 24 hours, and then the raw oil is Add it into the settling tank, heat it to 60-80°C, add 0.2-0.4 parts by weight of polyoxyethylene polyoxypropylene alkyl alcohol ether as a demulsifier and 0.05-0.15 parts by weight of polyacrylamide as a flocculant for every 100 parts by weight of waste lubricating oil , while feeding compressed air 3 for stirring, after stirring for 20-40 minutes, let it settle for 4-6 hours, discharge water and insoluble impurities 4, and the settled lubricating oil is heated to 260-270°C by a heating furnace and enters the distillation tower Distillation in medium, distill out the light fuel oil 5, the distilled lubricating oil is coo...

Embodiment 2

[0018] Example 2: Put the waste lubricating oil into the settling tank after 24 hours of natural precipitation in the settling tank, heat it to 60°C in the settling tank, add 0.4 parts by weight of demulsifier polyoxyethylene polyoxyethylene per 100 parts by weight of waste lubricating oil Propylene alkyl alcohol ether and 0.15 parts by weight of flocculant polyacrylamide are fed into the compressed air at the same time, stirred for 40 minutes, left to settle for 6 hours, water and impurities are discharged, and the settled lubricating oil is heated to 260°C in Distill in the distillation tower, distill the light fuel oil therein, the lubricating oil after distilling is cooled to 20 ℃ by heat exchanger, enters in the pickling tank, add 4 weight Parts of 120# solvent oil were diluted, and at the same time, high-pressure air was introduced to stir, and then 1 part by weight of 98% concentrated sulfuric acid was added, the temperature was controlled at 20°C, and stirring was con...

Embodiment 3

[0019] Example 3: The recovered waste lubricating oil enters the settling tank after 30 hours of natural precipitation in the settling tank, and is heated to 63°C in the settling tank, and 0.35 parts by weight of demulsifier polyoxyethylene is added per 100 parts by weight of waste lubricating oil Polyoxypropylene alkyl alcohol ether and 0.13 parts by weight of flocculant polyacrylamide, while feeding compressed air and stirring for 35 minutes, let it settle for 5.5 hours, drain water and impurities, and the settled lubricating oil is heated to 263 ℃ into the distillation tower for distillation, and the light fuel oil in it is distilled out. The distilled lubricating oil is cooled to 23°C through a heat exchanger and then enters the pickling tank. 3.5 parts by weight of 120# solvent oil are diluted, and at the same time, high-pressure air is introduced to stir, and then 1.5 parts by weight of 96% concentrated sulfuric acid is added, the temperature is controlled at 23°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com