Acid pickling method

A treatment method and pickling technology, applied in the field of pickling treatment, can solve the problems of general pickling effect and large waste, achieve good pickling effect, improve pickling quality, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

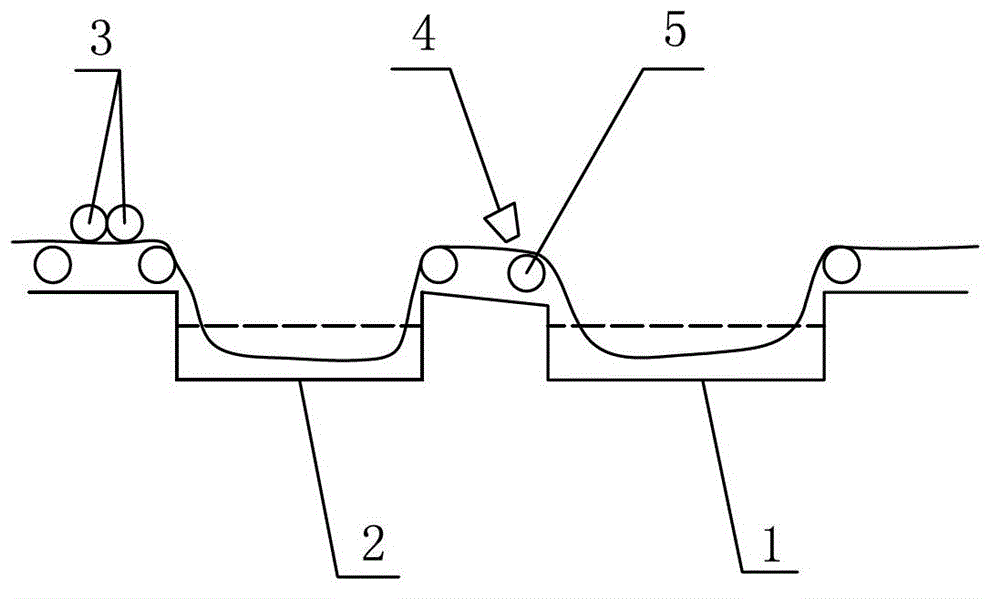

[0020] Such as figure 1 As shown, the pickling treatment method includes uncoiling the steel plate; (1) breaking the scale; (2) one-time pickling; (3) spray pickling; (4) neutralization; (5) drying.

[0021] When in use, the metal sheet enters the pickling machine through the feeding device, and on the basis of the original pickling, the spray pickling of the pickling nozzle is added to improve the pickling effect. The acid spray nozzle is connected to the pickling tank, uses the acid liquid in the pickling tank and can flow back to the pickling tank, which can improve utilization efficiency, save pickling costs, and improve pickling quality.

[0022] Perform a secondary pickling between step (3) spray pickling and step (4) neutralization.

[0023] Step (3) Spray pickling is to set a support roller on the body between the pickling tank and the neutralization tank, the support surface is inclined to the pickling tank, the support surface is provided with an acid spray nozzle, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com