Patents

Literature

65results about How to "Improve pickling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

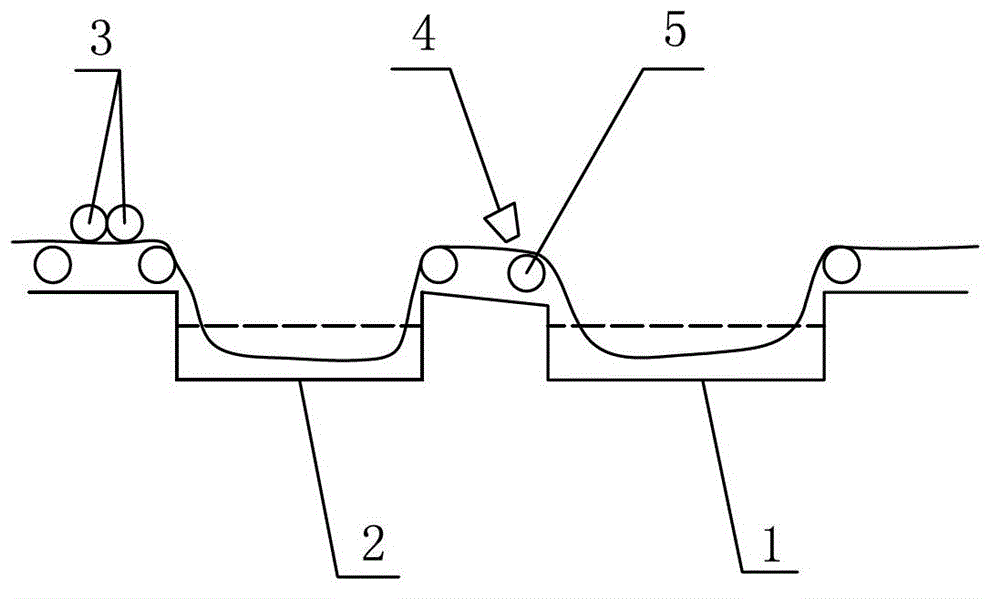

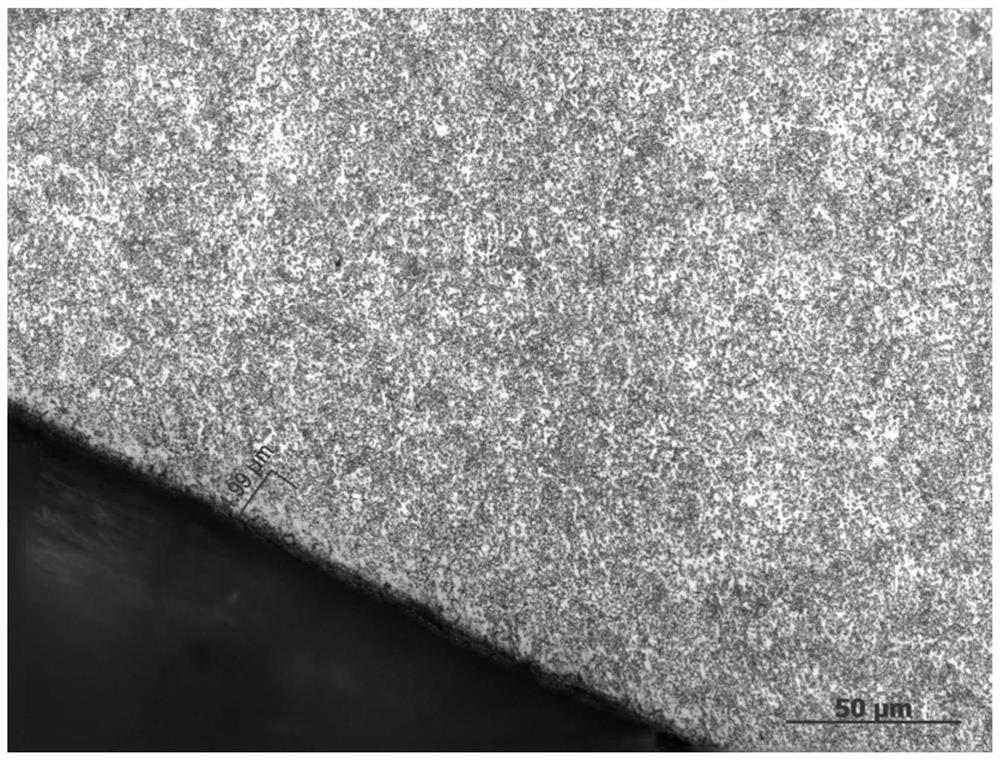

Method for removing scales on surface of hot-rolled stainless steel strip

InactiveCN102719831AAchieve mechanical picklingReduce consumptionWork treatment devicesMetal rolling arrangementsHydrofluoric acidAbrasive blasting

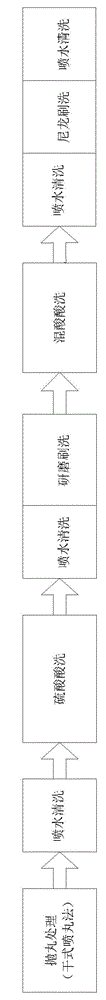

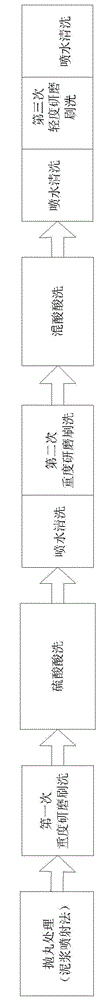

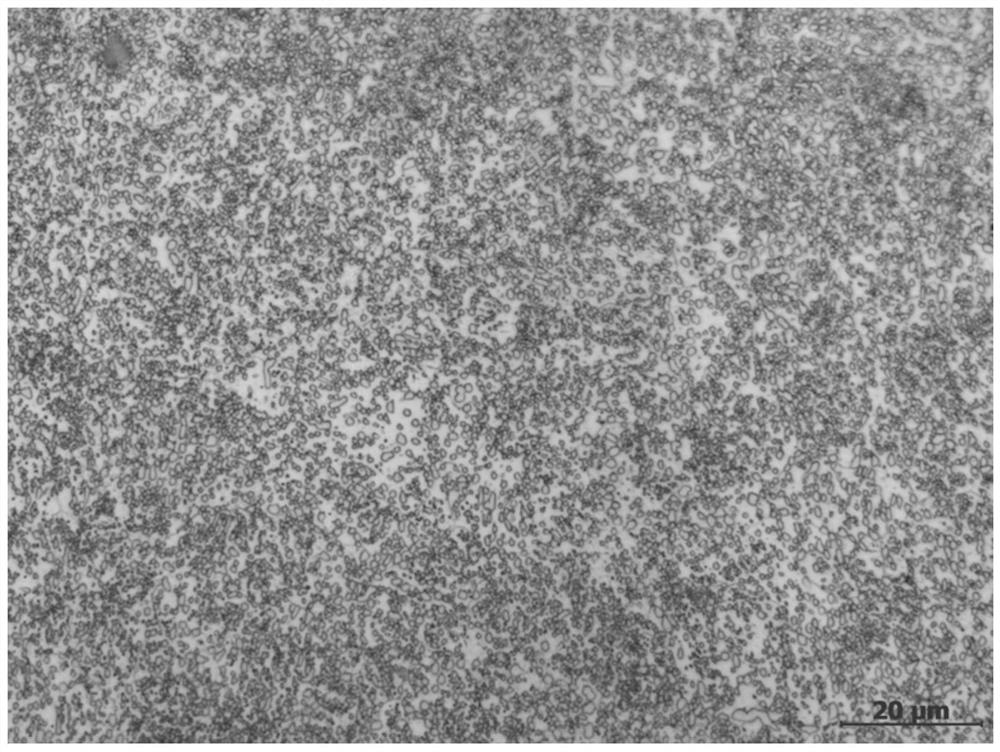

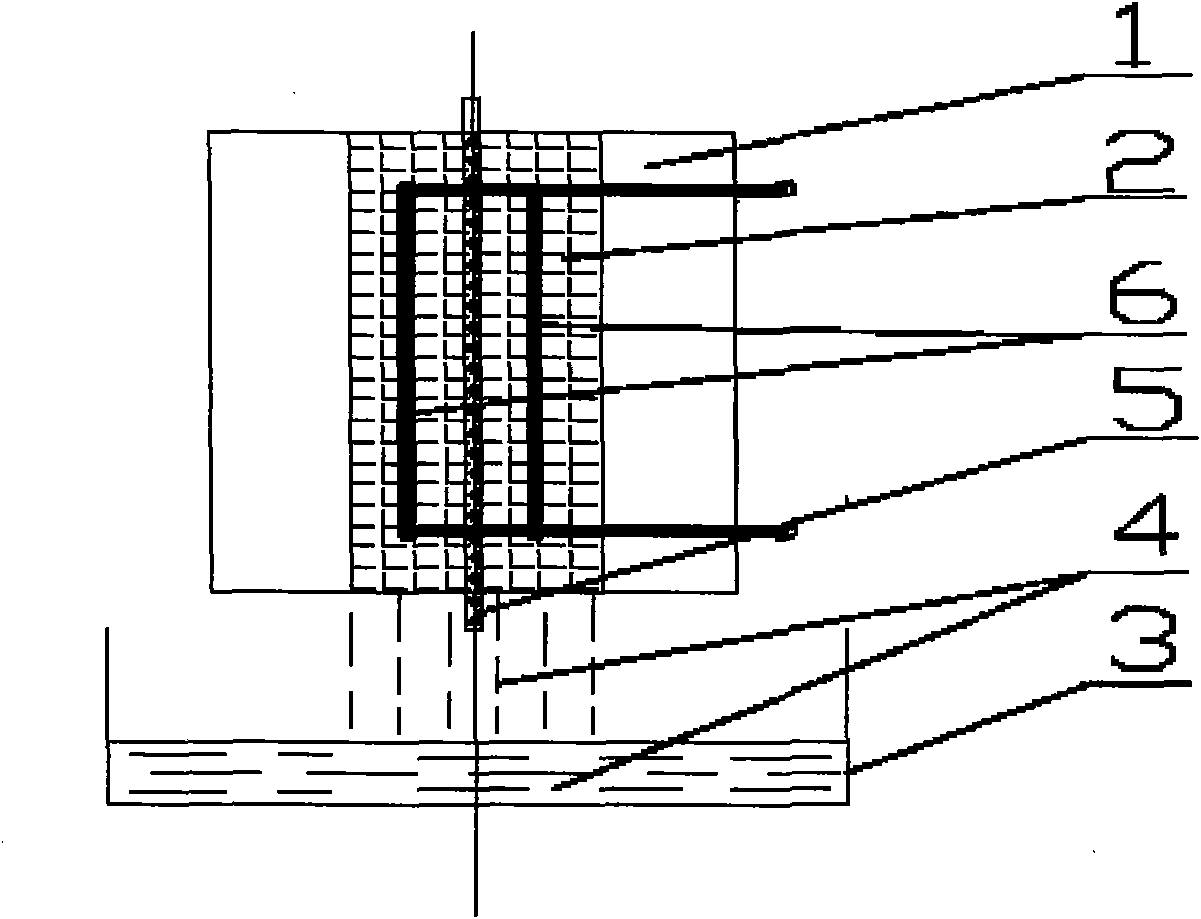

The invention discloses a method for removing scales on the surface of a hot-rolled stainless steel strip. The method comprises the following steps of: performing abrasive blasting treatment on the hot-rolled stainless steel strip to be treated, wherein the abrasive blasting treatment refers to spraying of mixed slurry of water and an abrasive material, and the percent by volume of the abrasive material in the slurry is 30%-40%; after the abrasive blasting treatment, performing primary grinding and scrubbing on the steel strip; after the primary grinding and scrubbing, performing acid-washing on the steel strip with diluted sulphuric acid; cleaning the steel strip subjected to acid-washing by the diluted sulphuric acid by water, and then performing secondary grinding and scrubbing on the steel strip; after the secondary grinding and scrubbing on the steel strip, performing acid-washing on the steel strip with mixed acid of nitric acid and hydrofluoric acid; and after the acid-washing with the mixed acid, cleaning the steel strip with water, then performing third grinding and scrubbing on the steel strip, and finally, washing the steel strip with water. With the slurry spraying technique, as the abrasive material is mixed with the water, the scales on the surface of the hot-rolled stainless steel strip can be removed more effectively; and the consumption quantity of acid in subsequent steps is greatly reduced.

Owner:WISDRI ENG & RES INC LTD

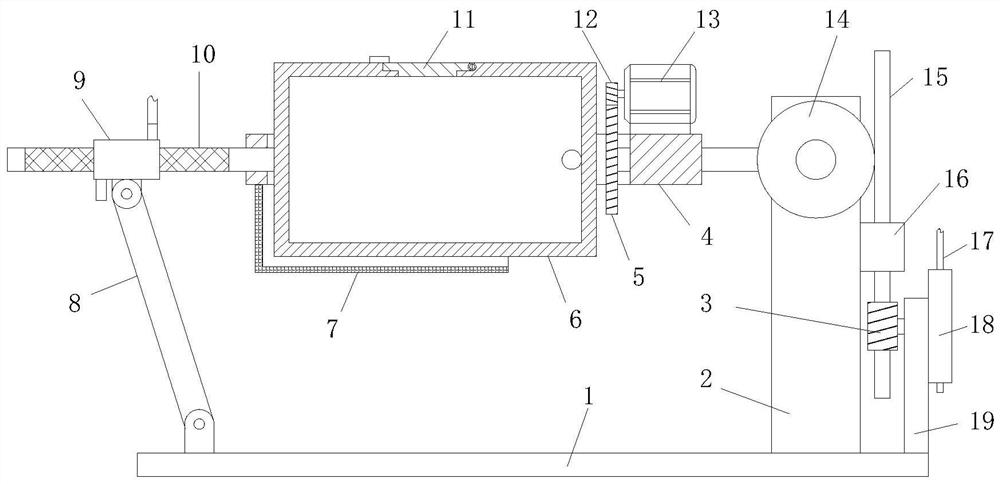

Diode pickling device

ActiveCN105390424AIncrease profitImprove pickling efficiencySemiconductor/solid-state device manufacturingEngineeringNet shape

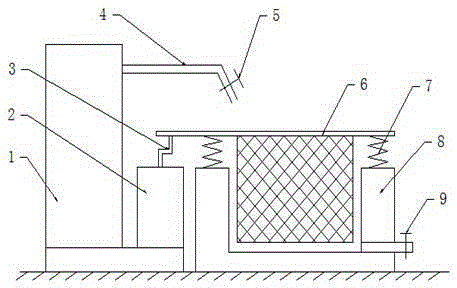

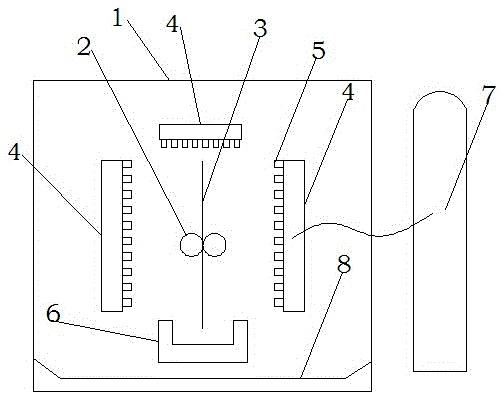

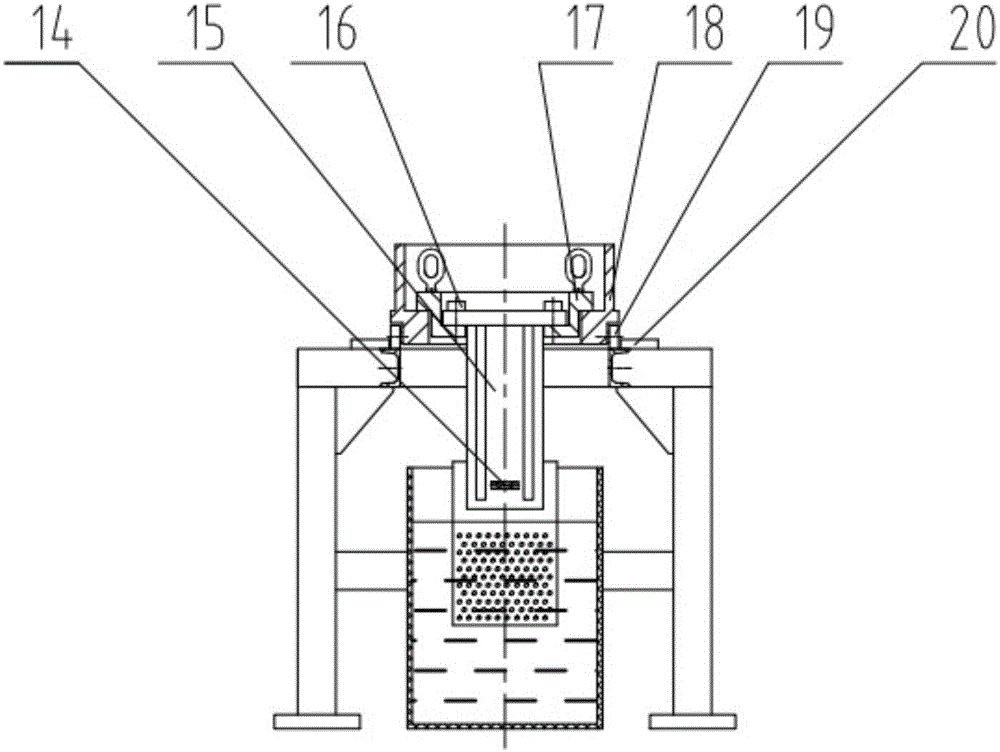

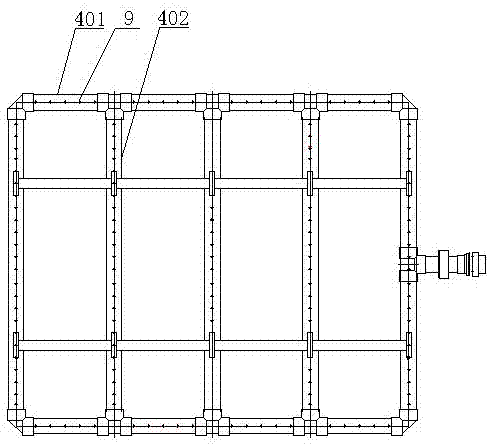

The invention discloses a diode pickling device belonging to the field of manufacturing of diodes. The diode pickling device comprises a pickling tank, a motor and a pickling box, wherein a pickling frame is arranged in the pickling tank; the side wall of the top end and the bottom surface of the pickling frame are in a net shape; a vibration frame is fixed at the top end of the pickling frame; the motor is located at one side of the pickling tank; a vibration device is fixed at an output end of the motor; the vibration frame is connected with the vibration device; the pickling box is located at one side, far away from the pickling tank, of the motor; the pickling box is connected with a liquid supply pipe; an outlet of the liquid supply pipe is located above the pickling tank; and a liquid supply valve is arranged at the outlet of the liquid supply pipe. According to the diode pickling device, the dosage of a pickling solution is controlled through the liquid supply valve; a diode fully contacts the pickling solution in the pickling process through the motor and the vibration device; pickling of the diode can be finished with only a little of pickling solution; the pickling solution is high in utilization rate and high in pickling efficiency; the surface of the diode is pickled evenly; and the pickling quality is good.

Owner:TAIZHOU DEZHONG ELECTRON CO LTD

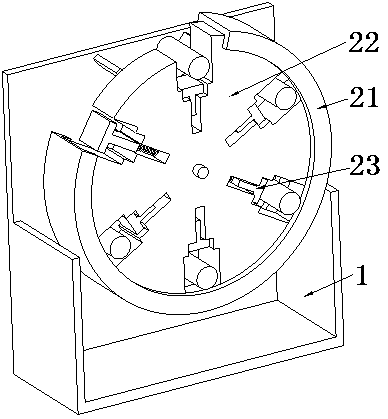

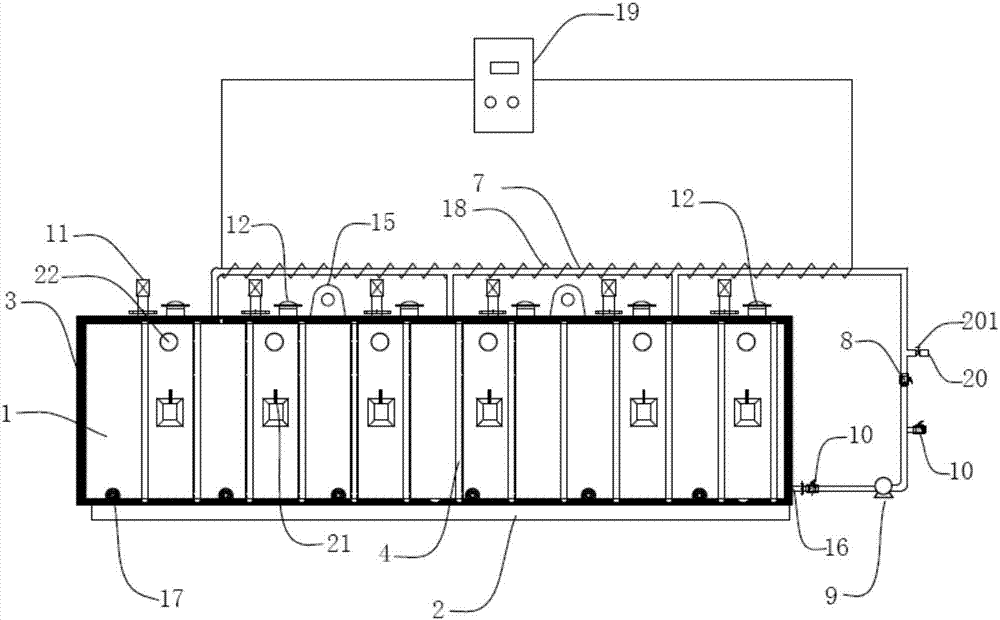

Pickling device for axial diode

ActiveCN106128981AAchieving immersion picklingRealize absorbing treatmentSemiconductor/solid-state device manufacturingWorking environmentEngineering

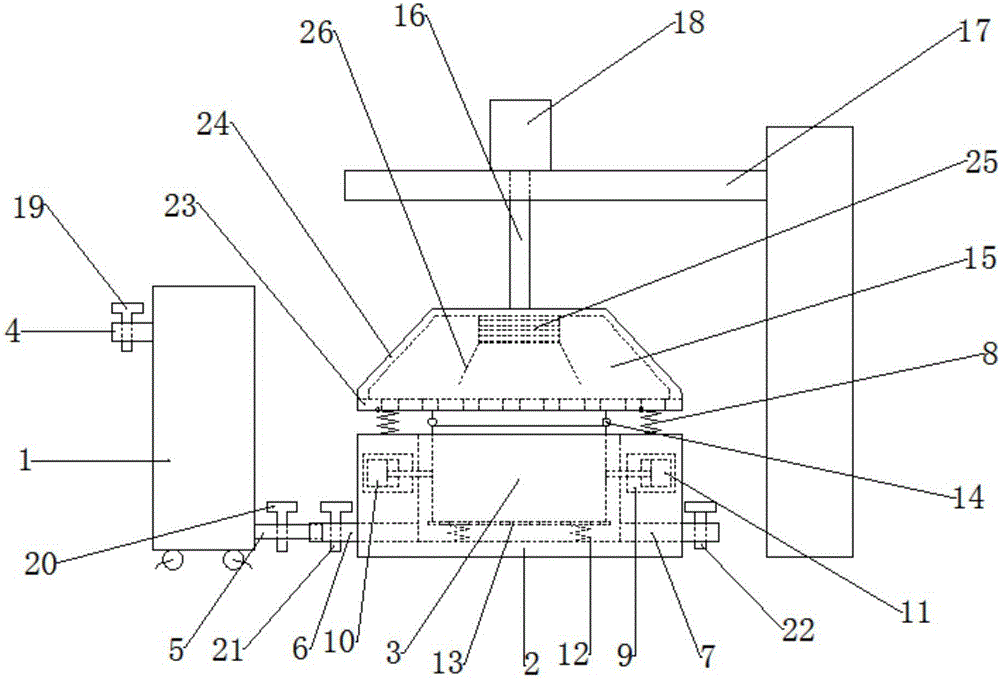

Provided in the invention is a pickling device for an axial diode. The pickling device comprises an acid liquor box, a pickling tank, and a pickling basket. First elastic elements are arranged at the upper ends of the two side walls of the pickling tank; hollow units are arranged inside the two side walls; and a first cylinder and a second cylinder are arranged inside the two hollow units. Besides, second elastic elements are arranged at the bottom inside the pickling tank and are fixedly connected with a perforated plate; the pickling basket is carried by the perforated plate; the outsides at the two sides of the pickling basket are connected with the first cylinder the second cylinder; and clamp rings are arranged at the upper edge of the basket. The clamp rings are connected with a demisting unit movably; and the demisting unit is connected with a lifting motor by a motor connecting shaft. According to the technical scheme, with the pickling device, full contact between the diode and the acid liquor can be guaranteed and the pickling quality is improved; and acid mist absorption processing is realized and the working environment is improved.

Owner:TIANJIN HANDEWEI PHARMA

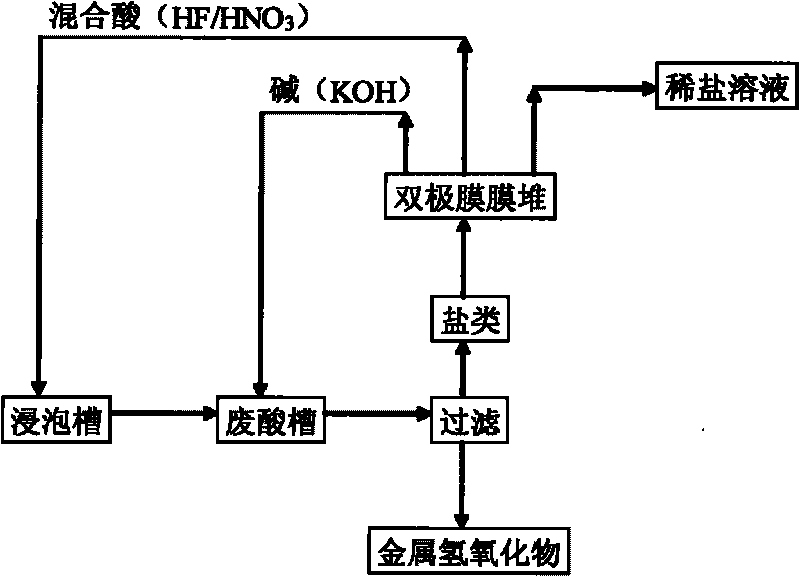

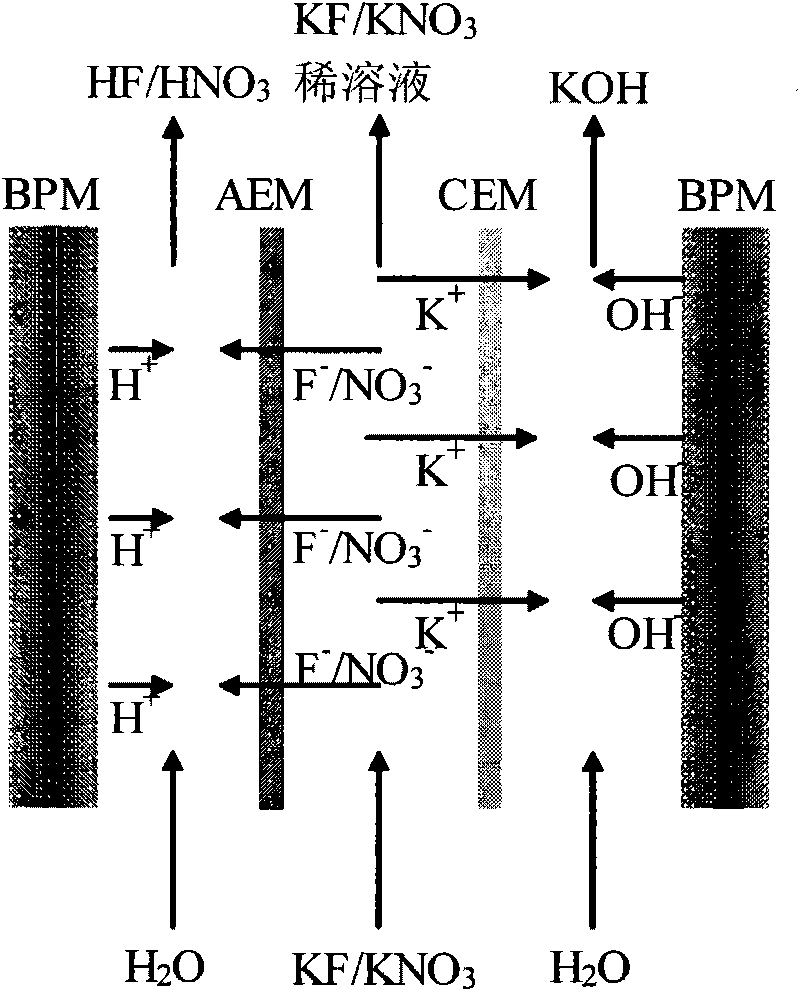

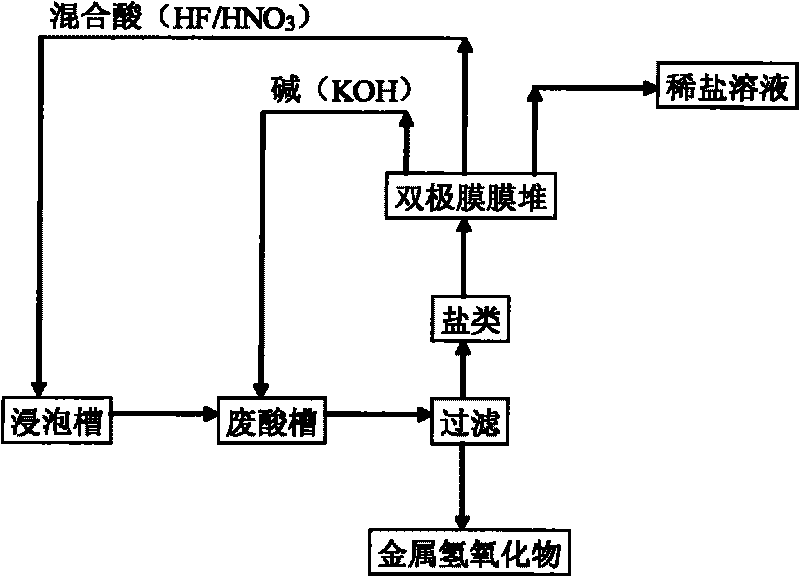

Recycling method of waste acid from stainless steel acid washing process

The invention relates to a recycling method of waste acid from a stainless steel acid washing process, comprising the following steps of: (1) adding water soluble alkali in waste acid to adjust the pH to alkalescence and enable metal ions to generate hydroxide deposition; (2) filtering the hydroxide deposition by adopting a press filtering method, discharging filter cakes outside and collecting the filtrate; and (3) pumping the filtrate into a bipolar-membrane membrane stack, applying electrolysis voltage at the two ends of the membrane stack to generate mixed acid, alkali and dilute salt solution to be respectively discharged through different pipelines. The mixed acid obtained from the method can be reused in an acid washing process, and the alkali can be reused for neutralizing the waste acid in the step (1). Therefore, the invention can realize regeneration of waste acid and the recycling of the alkali, avoid reducing acid washing quality, keep the stable components of acid washing solution and improve the acid washing quality. The invention also has the characteristics of reducing the acid consumption for acid washing, reducing the discharge of acid liquor, reducing the production cost, improving the environment, enhancing the production efficiency and the like.

Owner:TONGJI UNIV +1

Acid pickling method

The invention relates to an acid pickling method belonging to the field of steel plate acid pickling methods. The acid pickling method comprises the step of uncoiling a steel plate and is characterized by also comprising the following steps of: (1) scale breading; (2) primary acid pickling; (3) spray acid pickling; (4) neutralizing; and (5) drying. When the method is used, a metal sheet enters an acid pickling machine through a feeding device, and the spray acid pickling of an acid spray nozzle is additionally provided on the basis of the original acid pickling, so that the acid pickling effect is improved. The acid spray nozzle is communicated with an acid pickling tank, an acid liquid in the acid pickling tank can be returned to the acid pickling tank, so that the utilization efficiency can be increased, the acid pickling cost can be reduced, and the acid pickling quality can be improved. Through optimized design, the acid pickling method is good in acid pickling effect, capable of reducing acid pickling cost and increasing the production efficiency of the acid pickling machine.

Owner:山东全通精密薄板有限公司

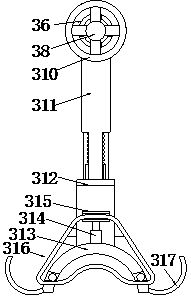

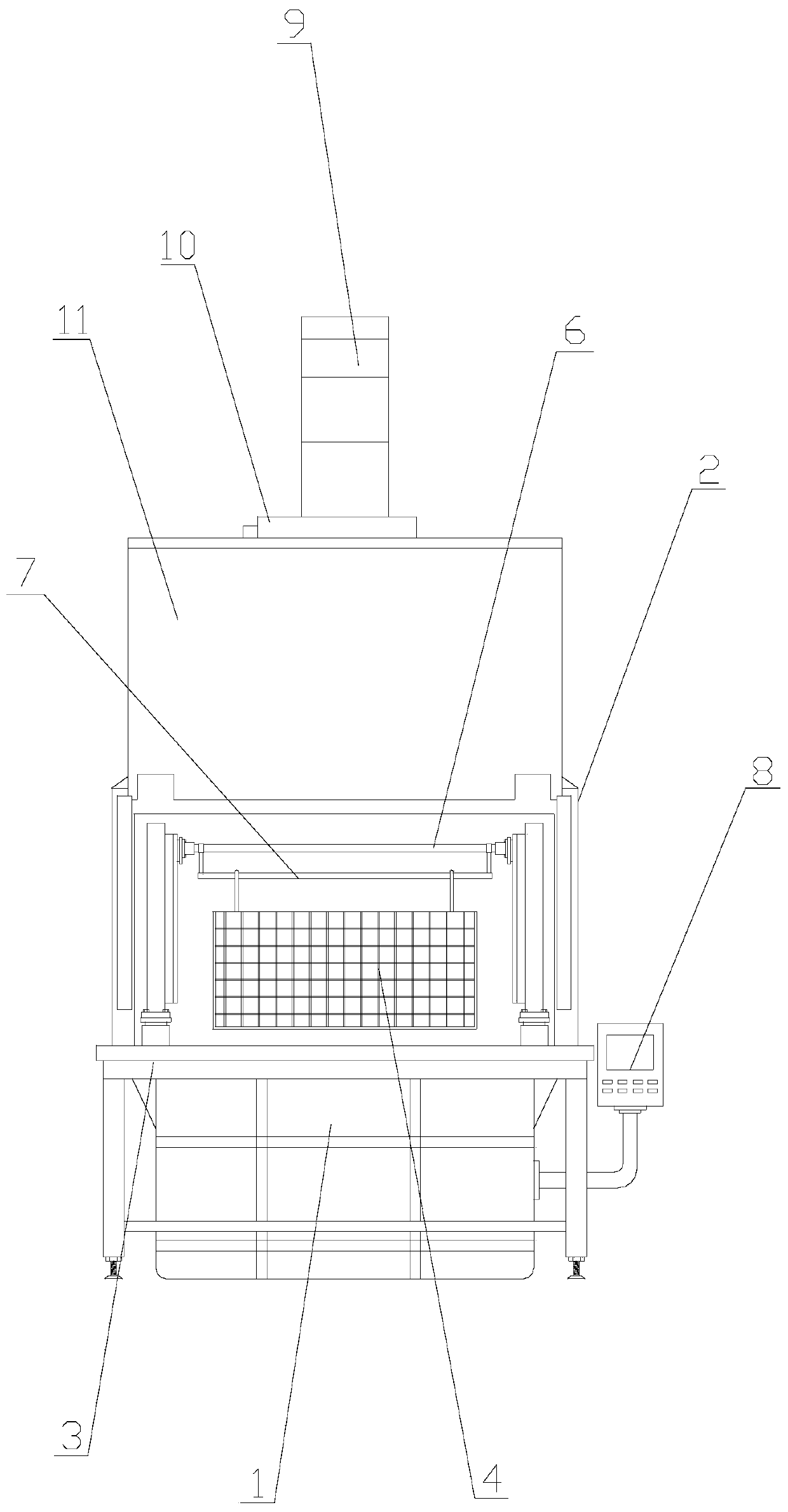

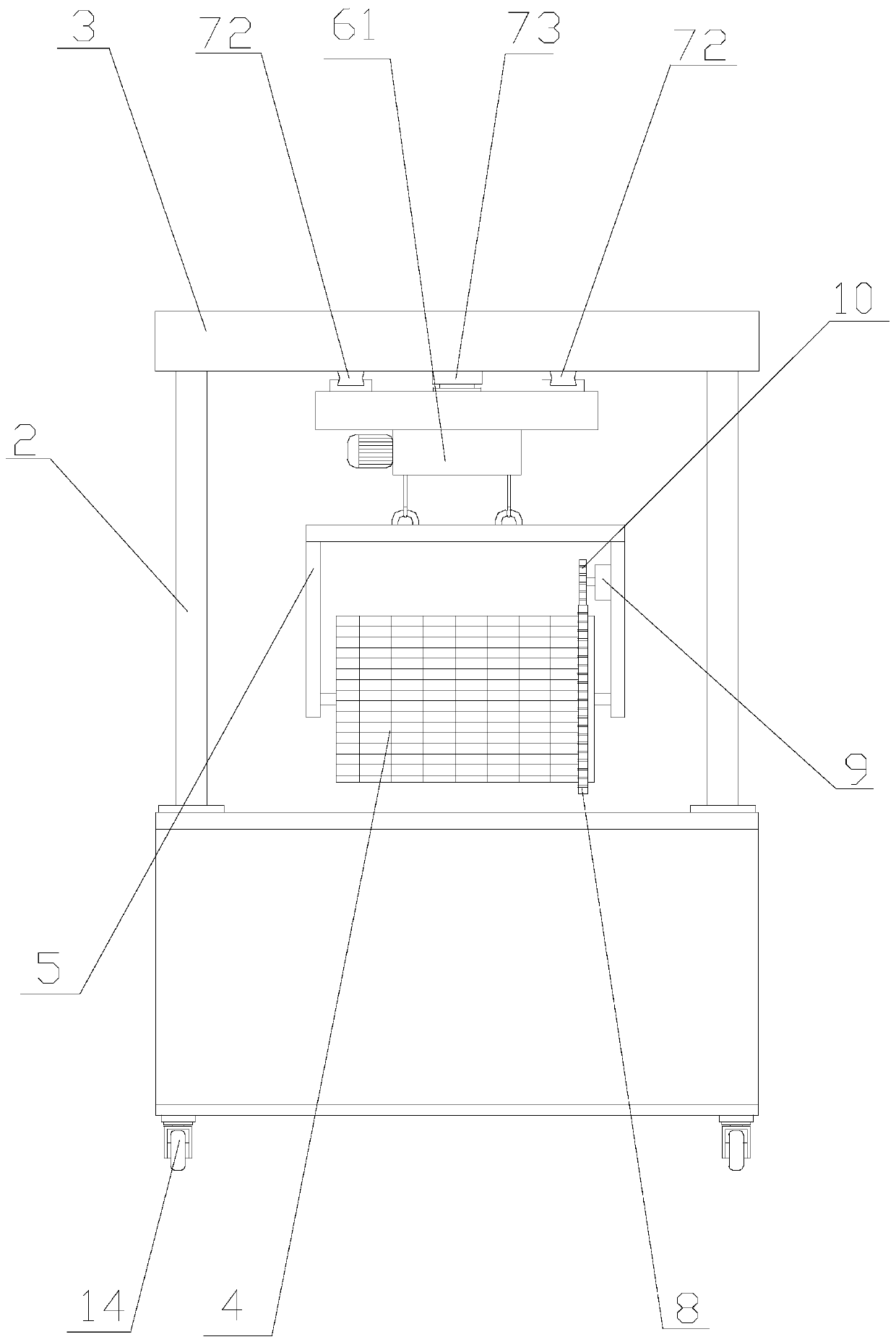

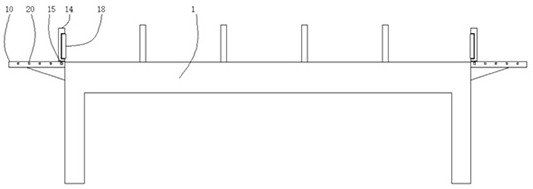

Surface treatment device for high-strength anti-slide wheel hub bolts

PendingCN110424019AReduce labor intensityImprove pickling efficiencyHigh intensityMechanical engineering

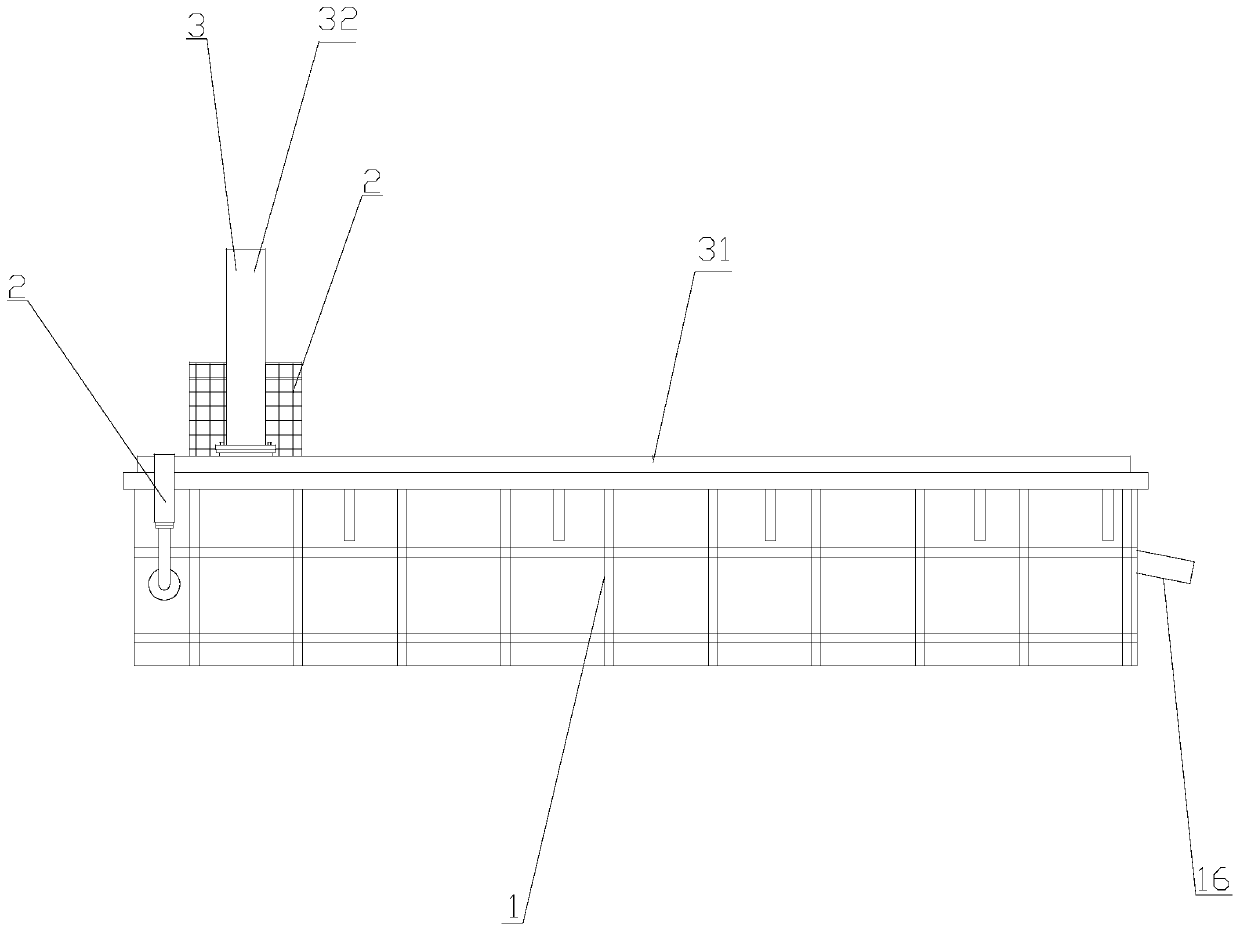

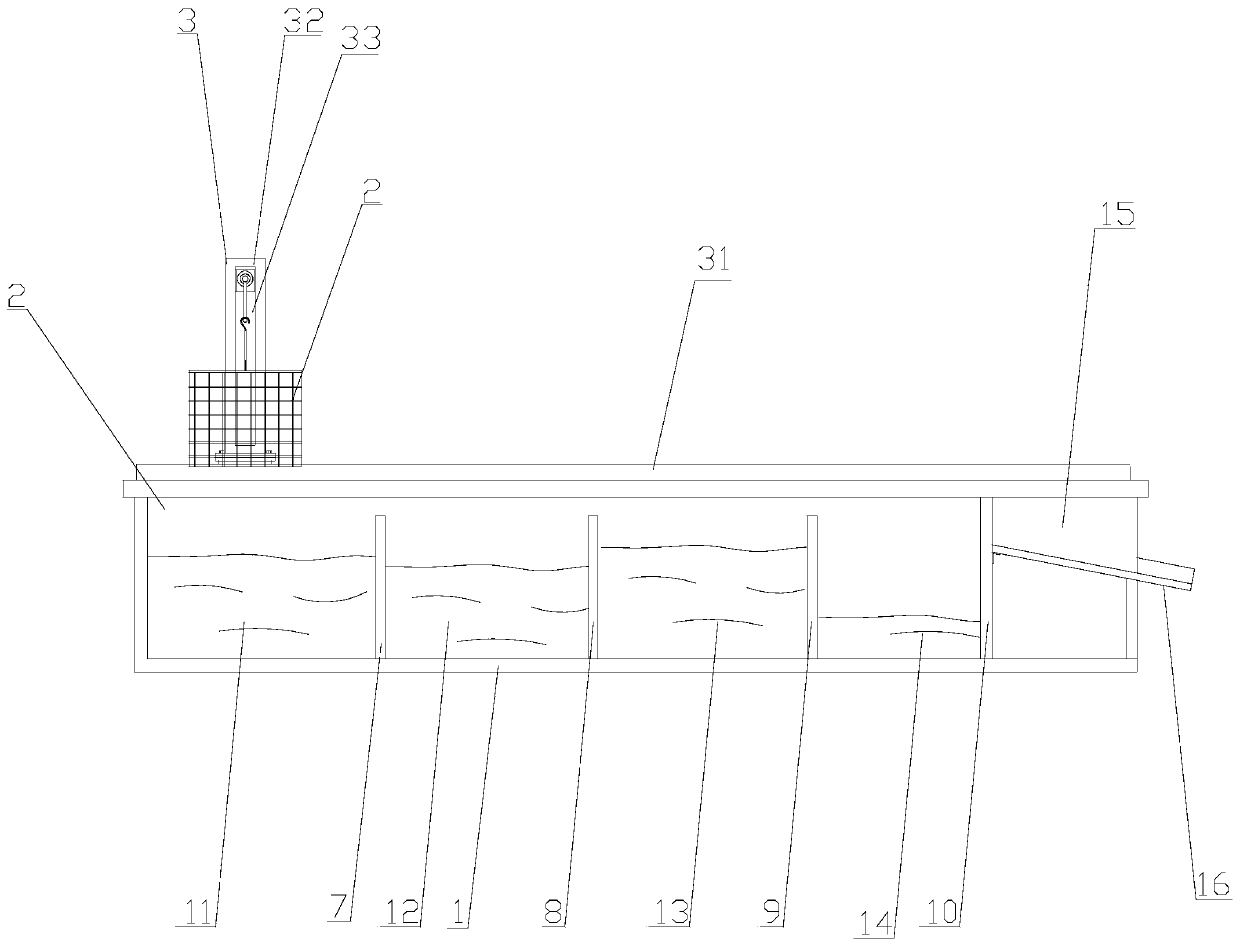

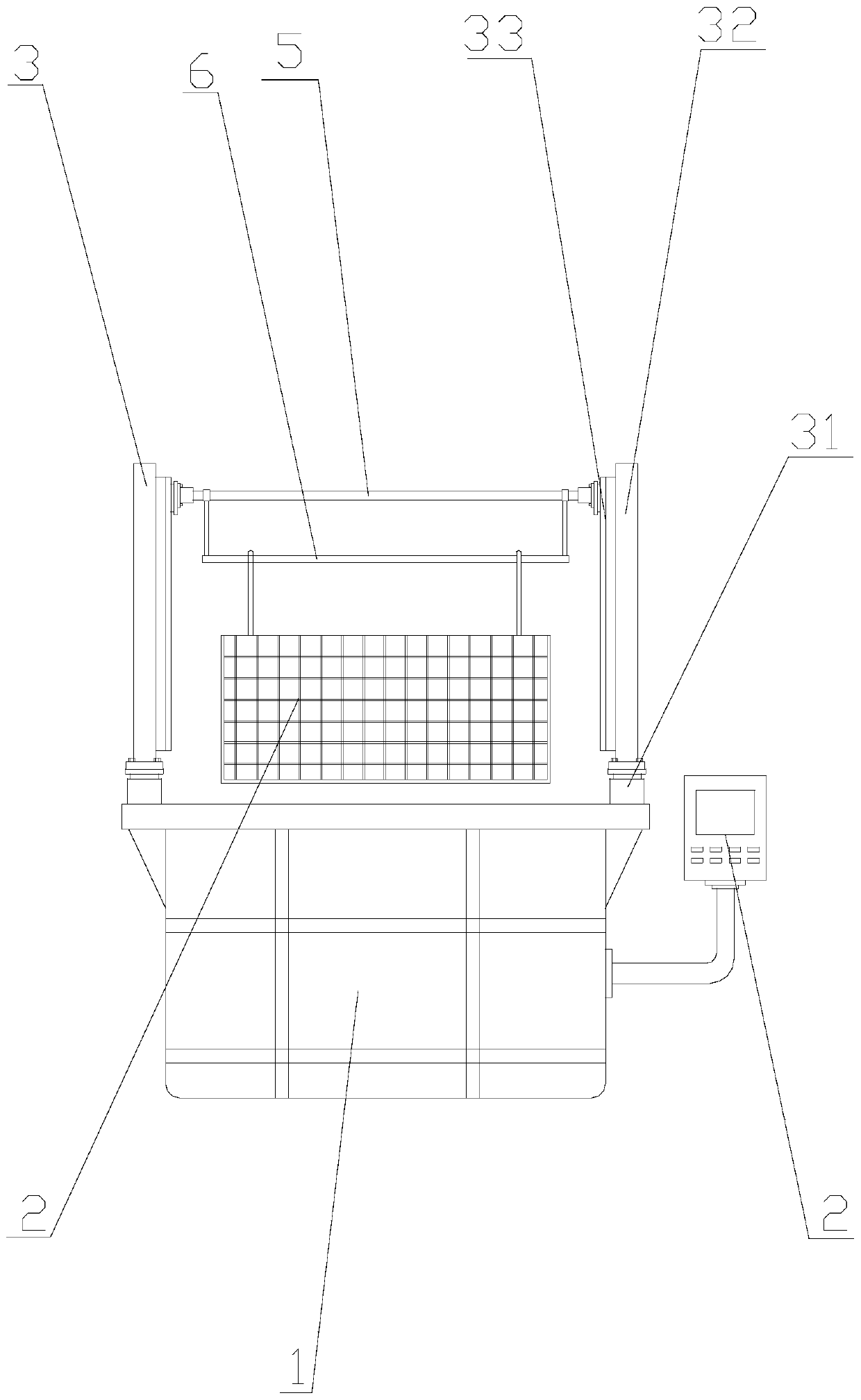

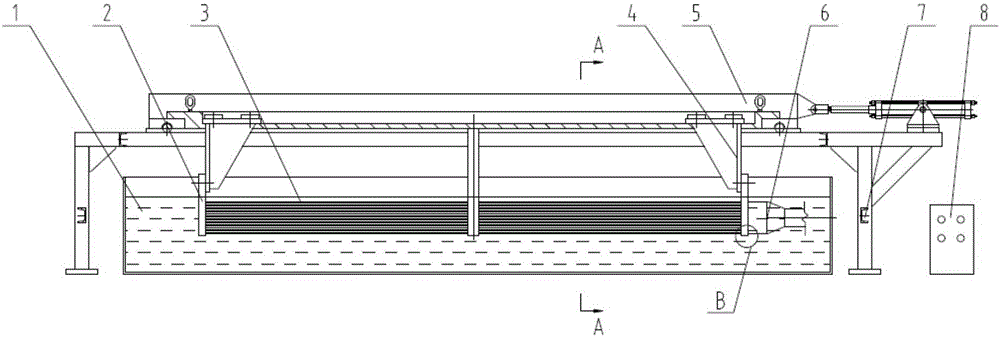

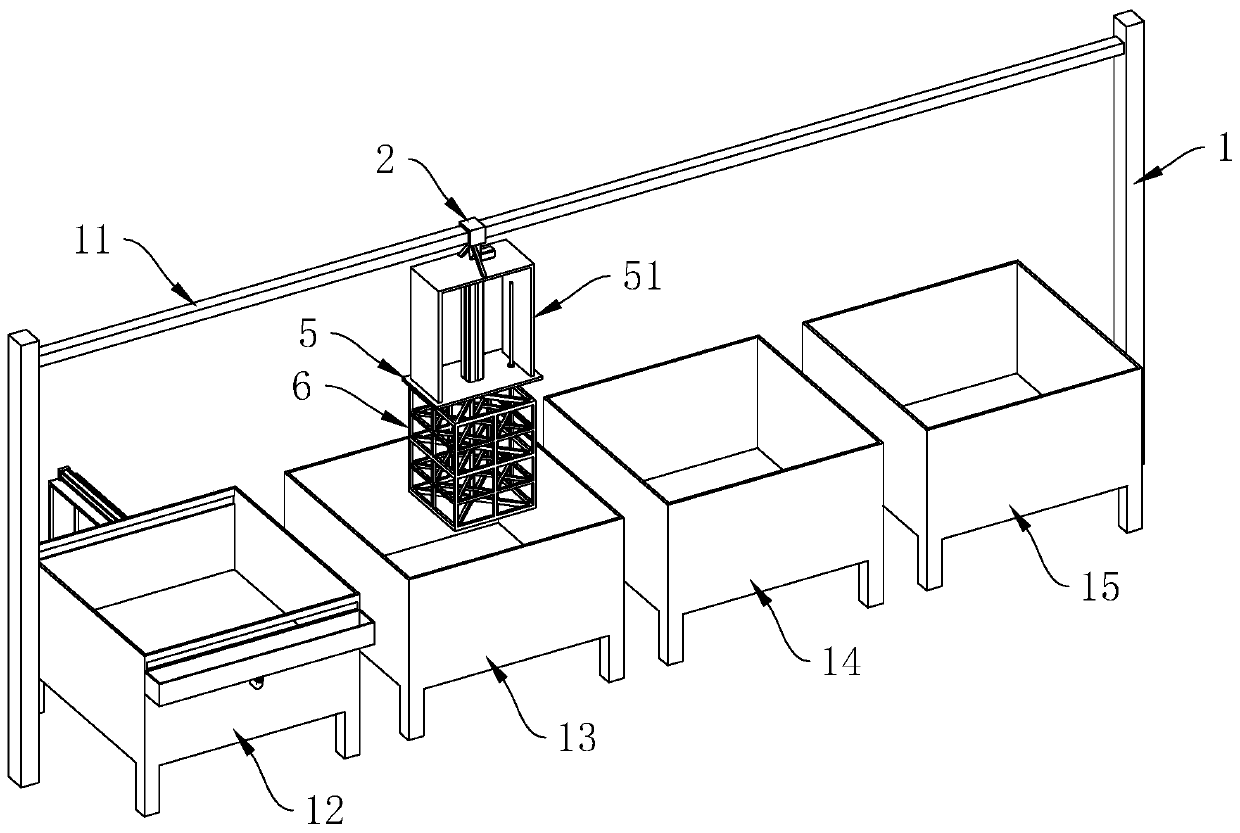

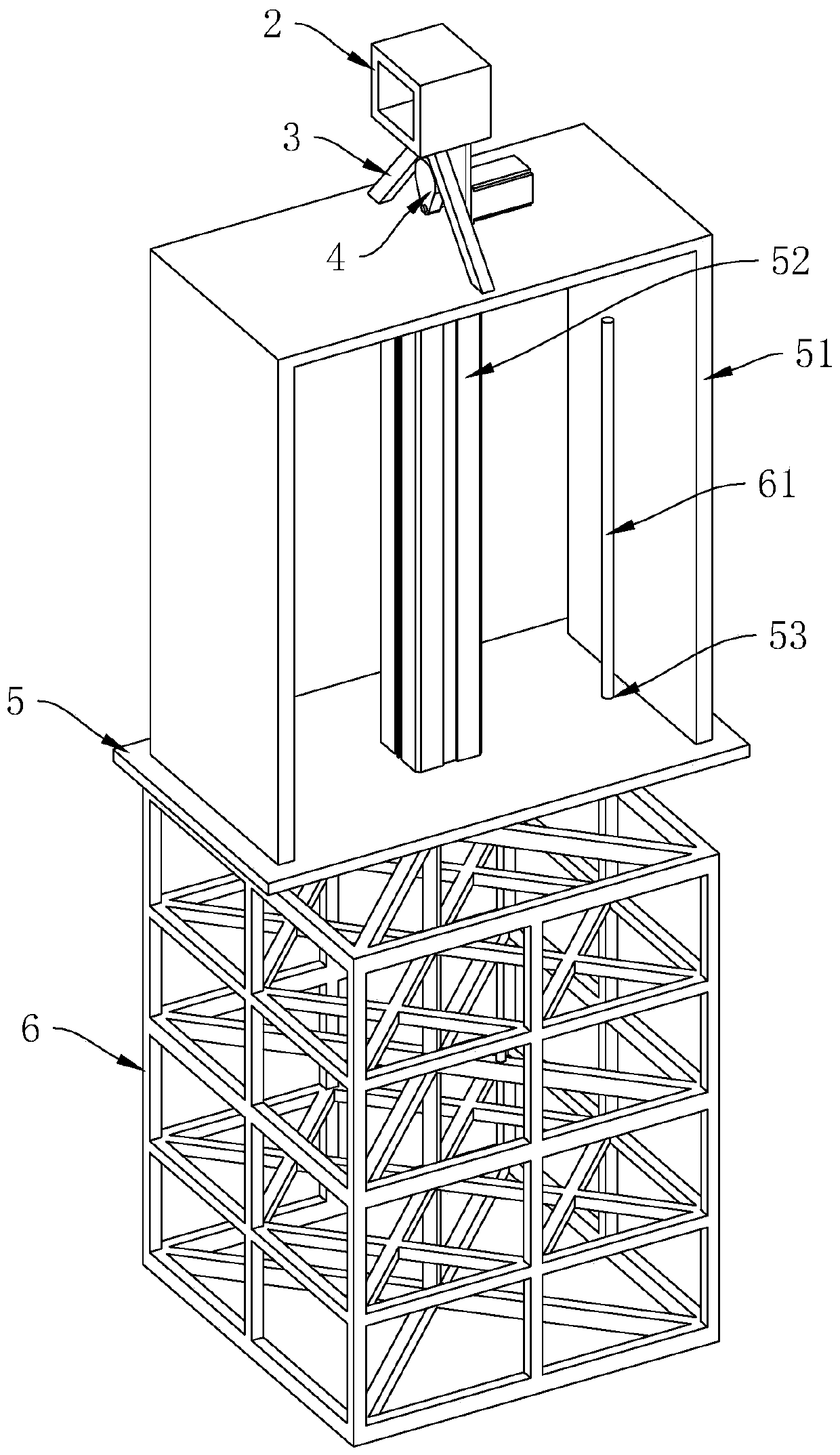

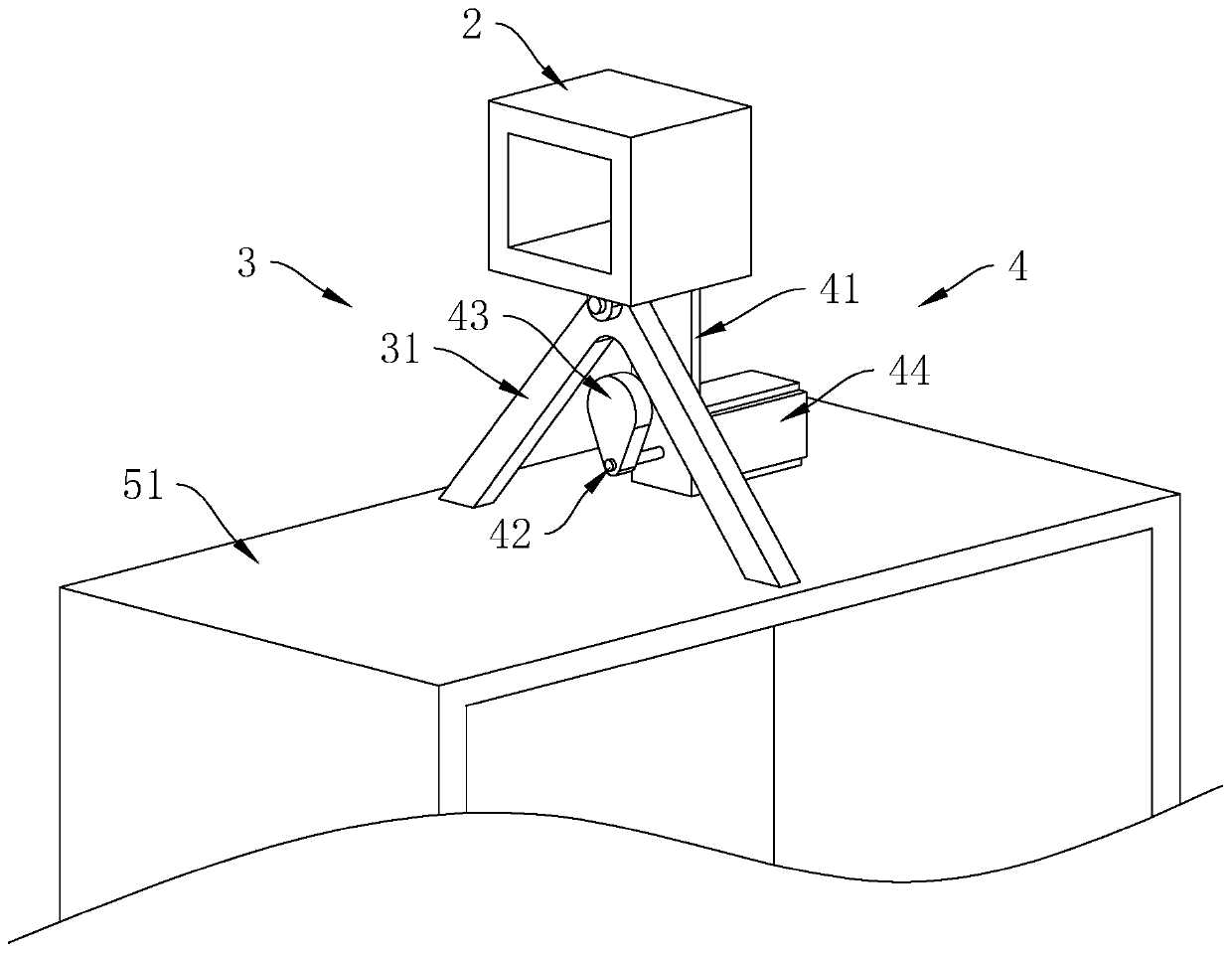

The invention discloses a surface treatment device for high-strength anti-slide wheel hub bolts. The surface treatment device comprises a pickling tank, a pickling basket, two pickling basket moving devices, a control panel, a cross bar and a pickling basket hanging bracket; the pickling tank is a rectangular tank; the upper end of the pickling tank is transversely provided with the pickling basket moving devices in the long edge direction of the pickling tank; the two pickling basket moving devices are symmetrically arranged on the side edges of the two sides of the upper end of the picklingtank correspondingly; and the cross bar is arranged between the two pickling basket moving devices. The pickling basket moving devices are arranged at the upper end of the pickling tank, the picklingbasket and the bolts in the basket can be driven by the pickling basket moving devices to reciprocally move laterally in the long edge direction of the pickling tank and move up and down, the picklingbasket moving devices drive the bolts to be pickled, cleaned and drained automatically, thus, the pickling efficiency is improved, the pickling quality is improved, the labor intensity of workers isrelieved, and the production cost is reduced.

Owner:海盐上宇紧固件科技股份有限公司

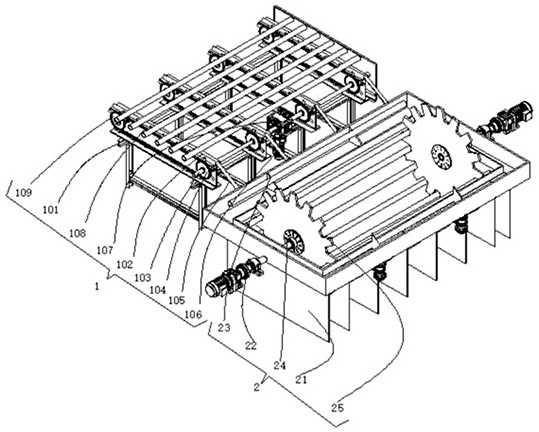

Steel pipe galvanizing pretreatment equipment

InactiveCN111139491AQuality assuranceImprove pickling qualityHot-dipping/immersion processesSurface cleaningEngineering

The invention belongs to the technical field of metal treatment, and particularly relates to steel pipe galvanizing pretreatment equipment which comprises a cleaning frame. Conveying units are arranged between the inner walls of the cleaning frame; a cleaning unit is arranged between the conveying units; and a drive unit is arranged on the inner wall of the lower side of the cleaning frame. The steel pipe galvanizing pretreatment equipment provided by the invention can solve the following problems existed in existing steel pipe acid pickling operation before galvanizing: (1) a steel pipe is simply placed into an acid pickling pool so as to be soaked, an oxidation layer and stains on the surface of the steel pipe cannot be cleaned during steel pipe soaking, and the surface of the steel pipeneeds to be wiped and cleaned after the steel pipe is taken out from the acid pickling pool, so that the steel pipe soaking operation and the comprehensive surface cleaning operation cannot be accomplished integrally, and the cost of steel pipe galvanizing is increased; and (2) in traditional steel pipe acid pickling operation, steel pipes in batch are concentratedly placed in the acid picking pool, and the single feeding quantity is large, so that the surfaces of the steel pipes cannot be ensured to comprehensively contact an acid pickling solution.

Owner:平顶山市中开防腐有限公司

Bearing steel pickling, phosphating and saponifying method

ActiveCN112359362APrevent decarbonizationAchieve quick-drying functionMetallic material coating processesProcess efficiency improvementOXALIC ACID DIHYDRATEWire rod

The invention belongs to the technical field of metallurgy, and particularly relates to a bearing steel pickling, phosphating and saponifying method. The bearing steel pickling, phosphating and saponifying method comprises the steps of pickling, washing, lime treatment, spheroidizing annealing, pickling, rinsing, secondary washing, oxalic acid treatment, phosphating, rinsing, saponifying and drying. Before annealing, a lime pickling process is added, so that oxide scales on the surface of a wire can be washed away, and a quick drying function is achieved; and during spheroidizing annealing, RXgas is added as a protective atmosphere for carburization, so that a stable and reliable furnace atmosphere can be formed, and zero decarburization of a bearing steel wire in a furnace can be achieved. According to bearing steel treated through the pickling, phosphating and saponifying method, decarburization can be controlled to be within 1D%, the pearlite spheroidized structure is at the level2-3, and the bearing steel is suitable for high-speed cold heading machining.

Owner:ZENITH STEEL GROUP CORP +1

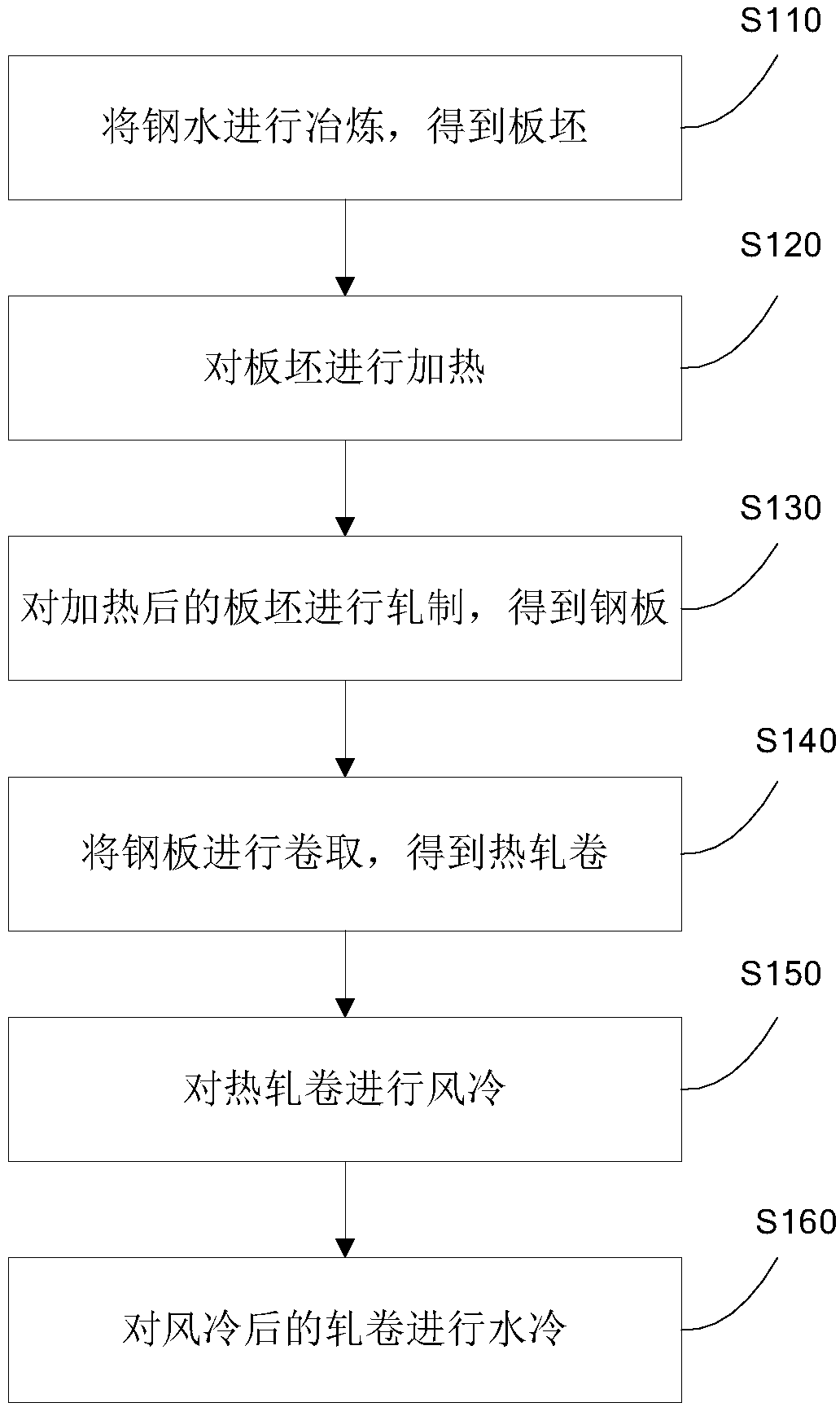

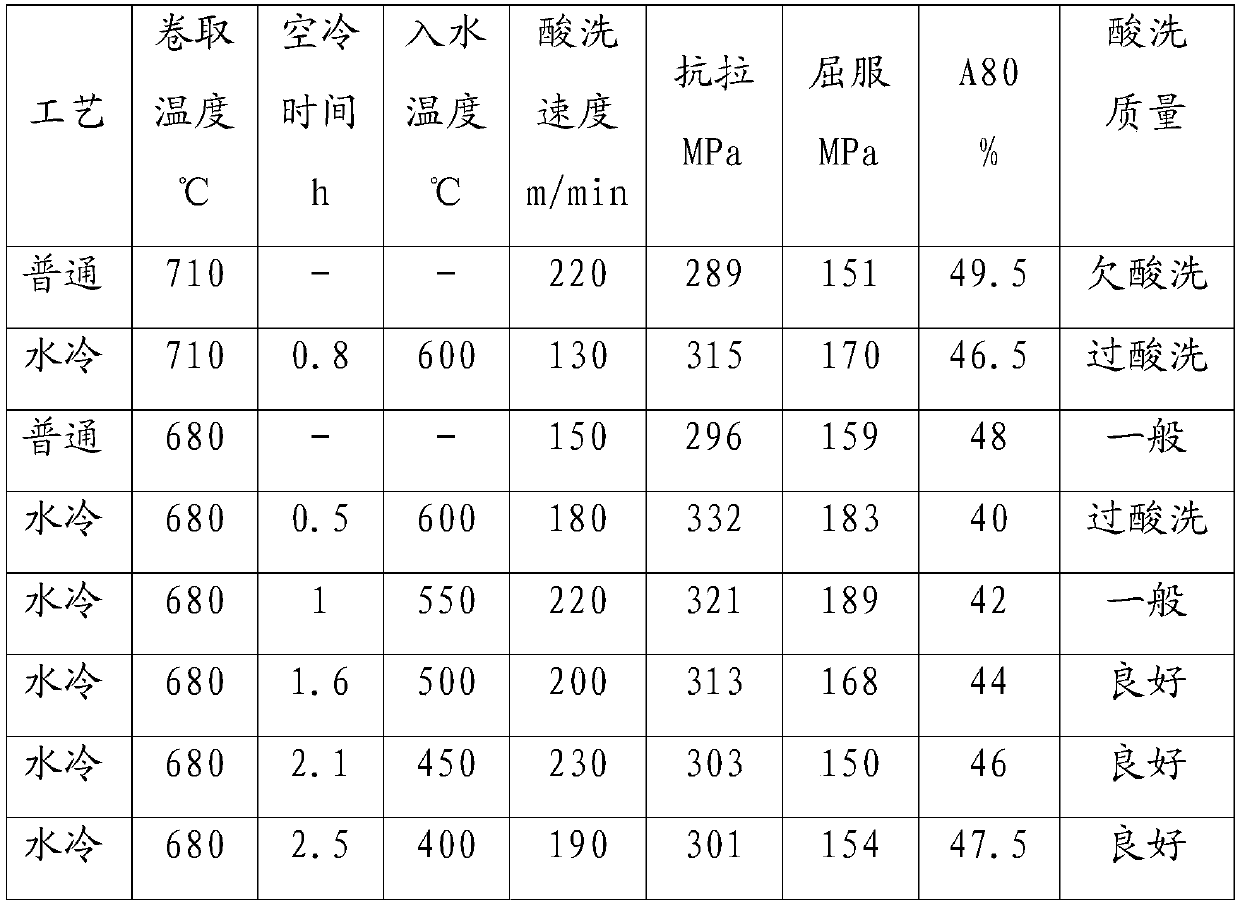

Cooling method used for improving steel coil quality

The invention discloses a cooling method used for improving the steel coil quality. The cooling method comprises the steps that molten steel is smelted, and a plate blank is obtained; the plate blankis heated; the heated plate blank is rolled, and a steel plate is obtained; the steel plate is reeled, and a hot rolling coil is obtained; the hot rolling coil is subjected to air cooling; and finally, the rolling coil subjected to air cooling is subjected to water cooling. The air cooling procedure and the water cooling procedure are carried out in sequence, the cooling speed is quickened, the technical problem that in the prior art, the hot coil high-temperature staying time is too long is solved, and the technical effects that the acid pickling quality is ensured, acid liquor is prevented from being excessively consumed, and the hot coil surface quality stability is ensured are achieved. Compared with normal rolling without adopting the method, under the condition that during water cooling coil acid pickling, the concentration and the temperature of the used acid liquor are not changed, the acid pickling speed can be improved by 30%.

Owner:SHOUGANG CORPORATION +1

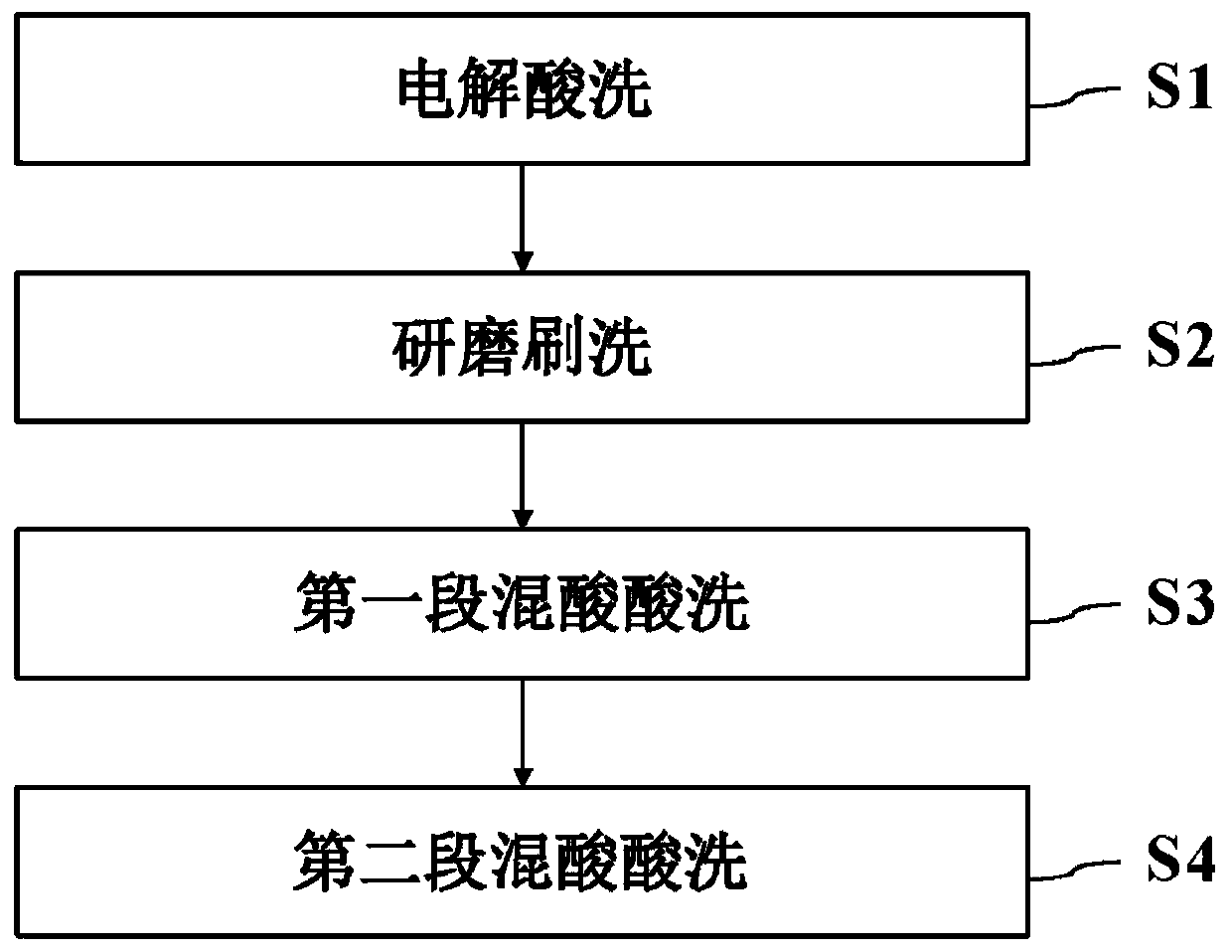

Cold-rolled 409L ferrite stainless steel strip steel acid pickling process

The invention relates to a cold-rolled 409L ferrite stainless steel strip steel acid pickling process. The cold-rolled 409L ferrite stainless steel strip steel acid pickling process comprises the following steps of S1, carrying out electrolytic pickling; S2, carrying out grinding and scrubbing; S3, carrying out first-stage mixed acid pickling; and S4, carrying out second-stage mixed acid pickling.In the step S1, strip steel is immersed in an electrolytic tank with an electrolyte for acid pickling; in the step S2, the strip steel after grinding and scrubbing is subjected to electrolytic pickling; in the step S3, the strip steel after grinding and scrubbing is immersed in a first mixed acid solution for acid pickling; and in the step S4, the strip steel after the first-stage mixed acid pickling is immersed in a second mixed acid solution for acid pickling. According to the process, not only can the acid pickling quality of the surface of the strip steel be improved, but also blockage ofa pipeline or a circulating tank is avoided, the shutdown maintenance frequency is reduced, and the production efficiency is improved.

Owner:WISDRI ENG & RES INC LTD

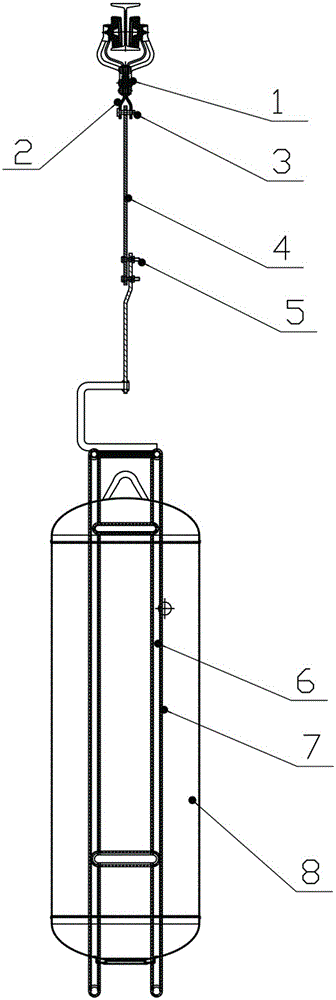

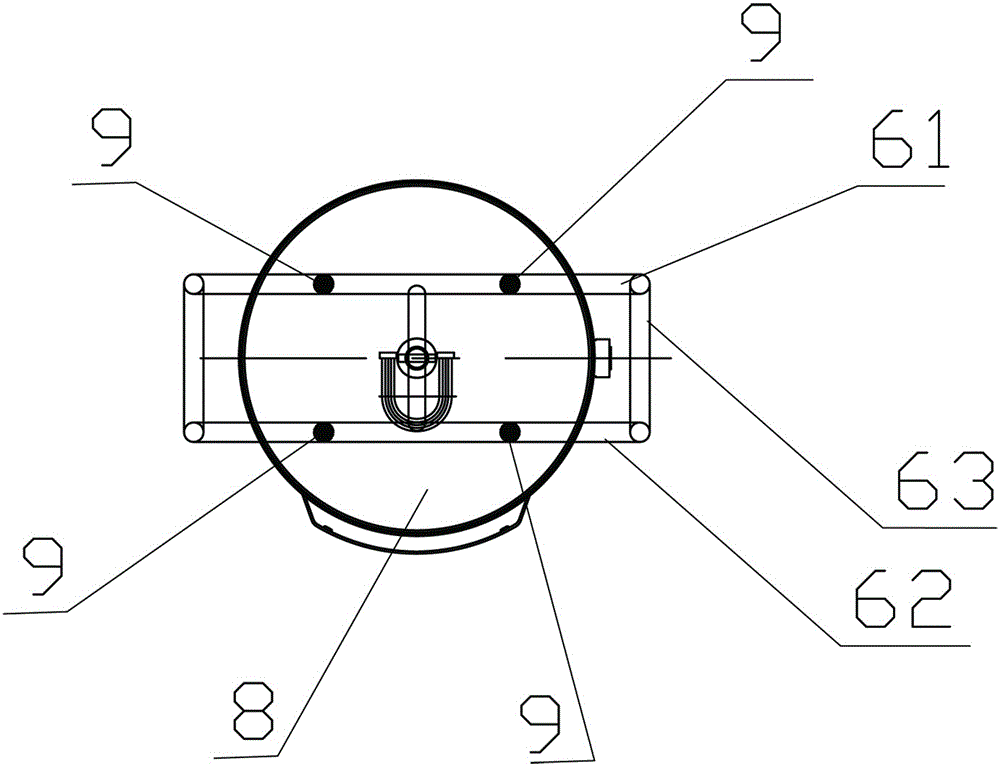

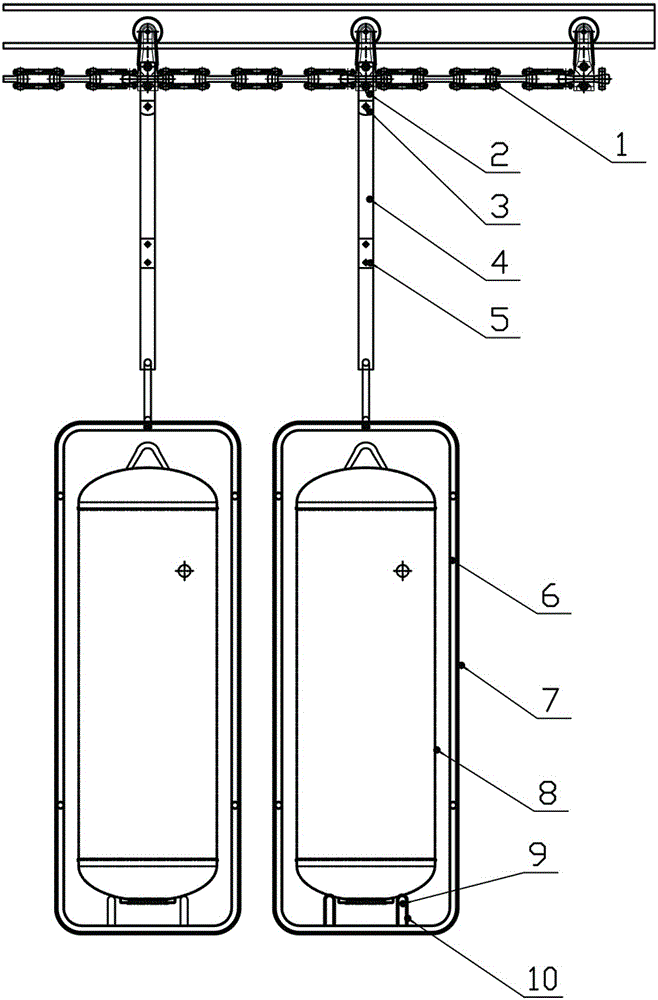

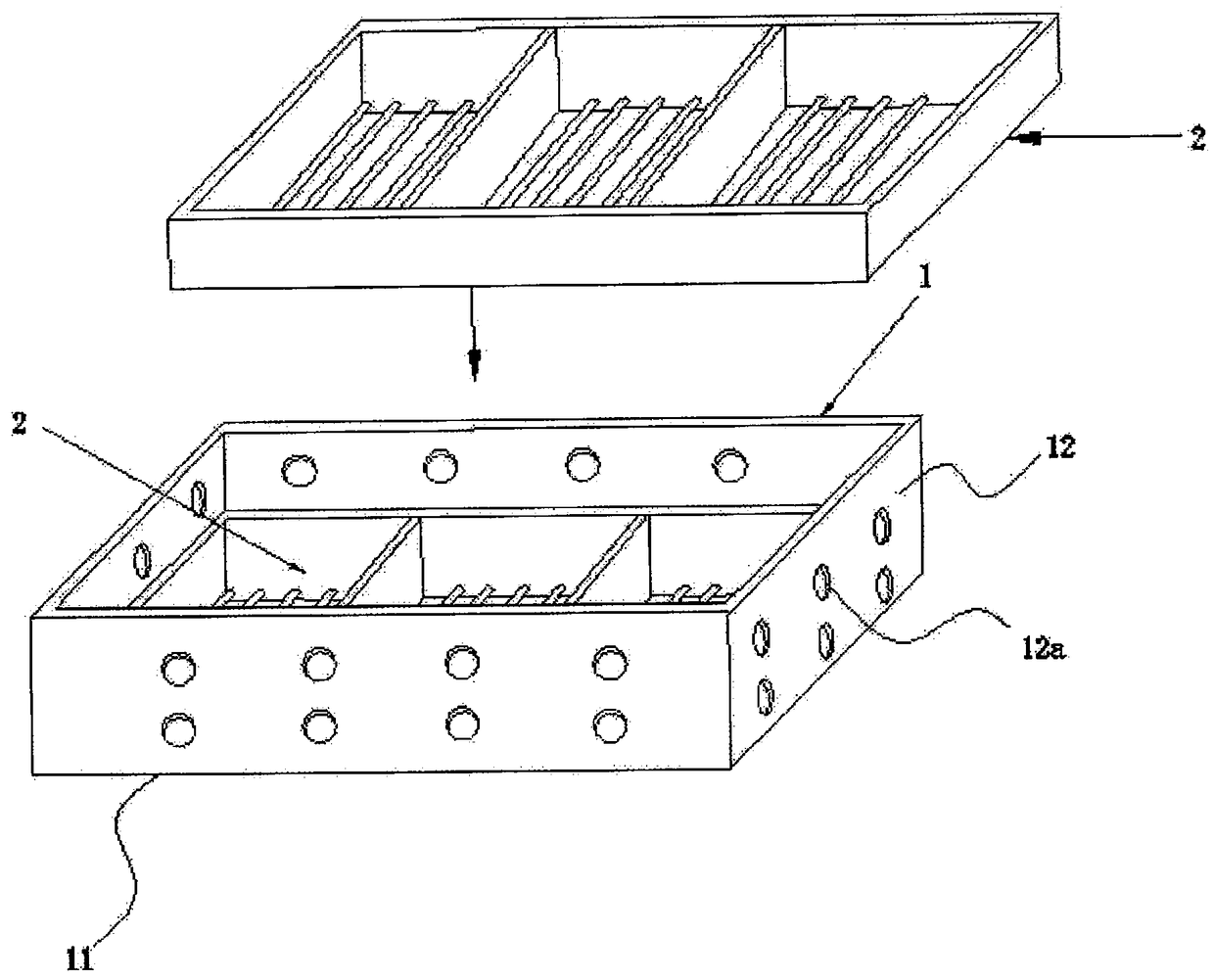

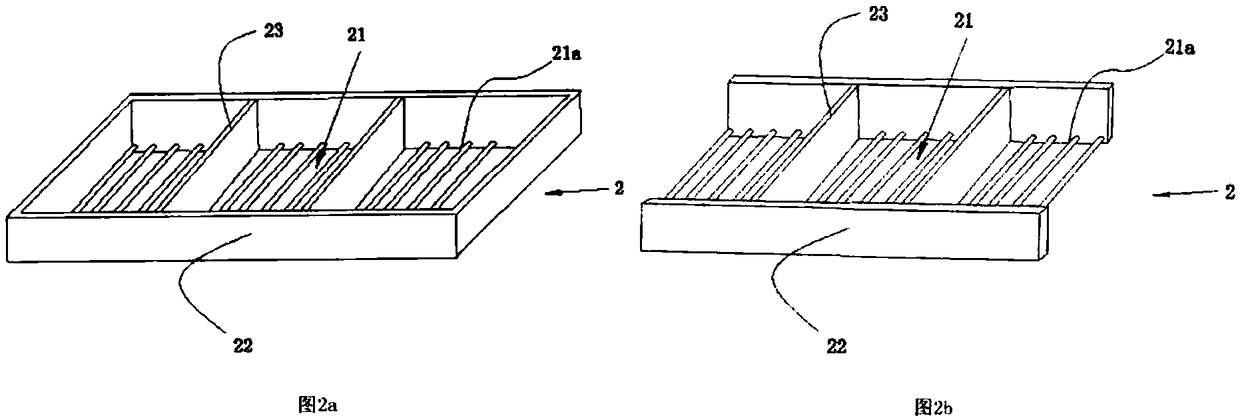

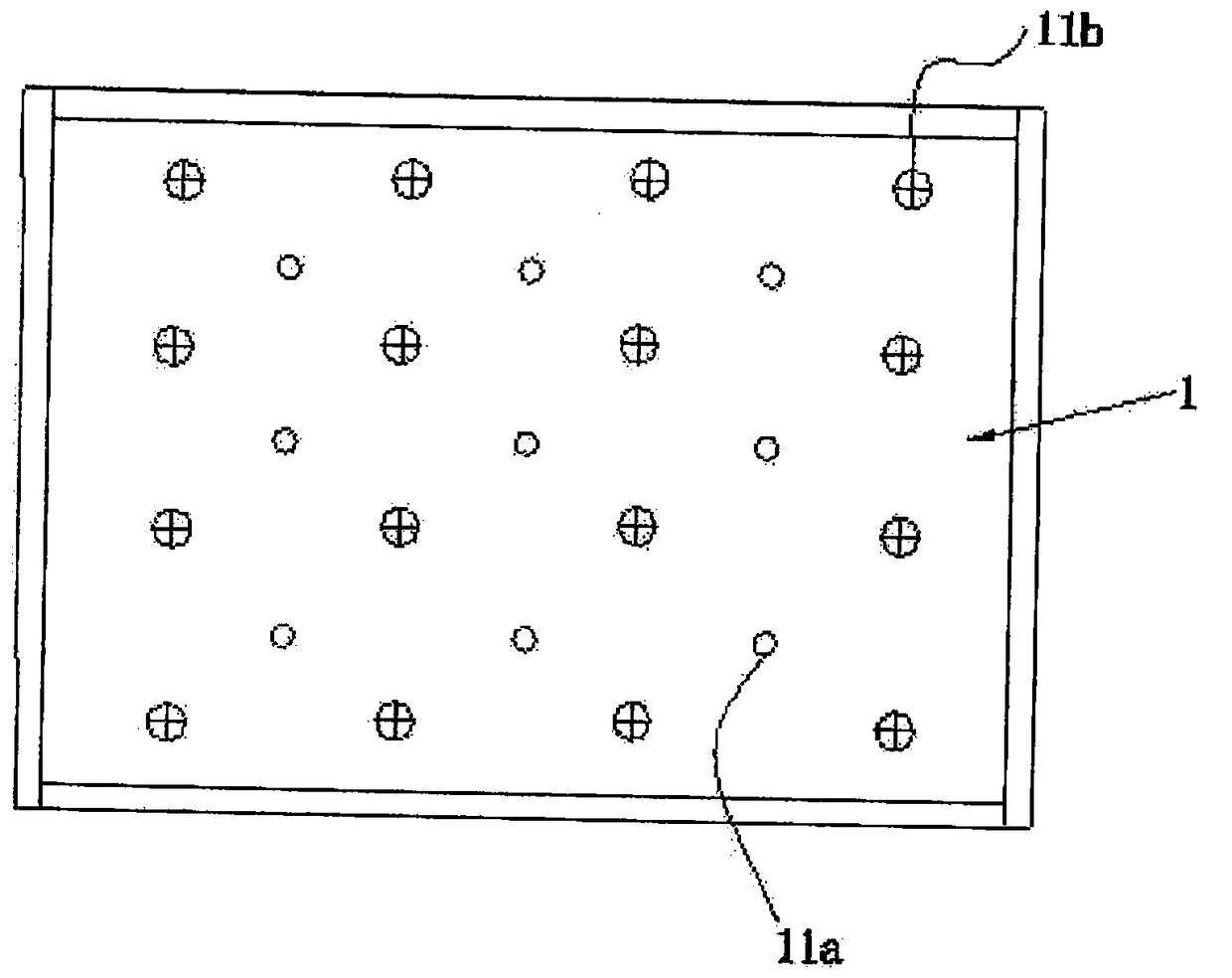

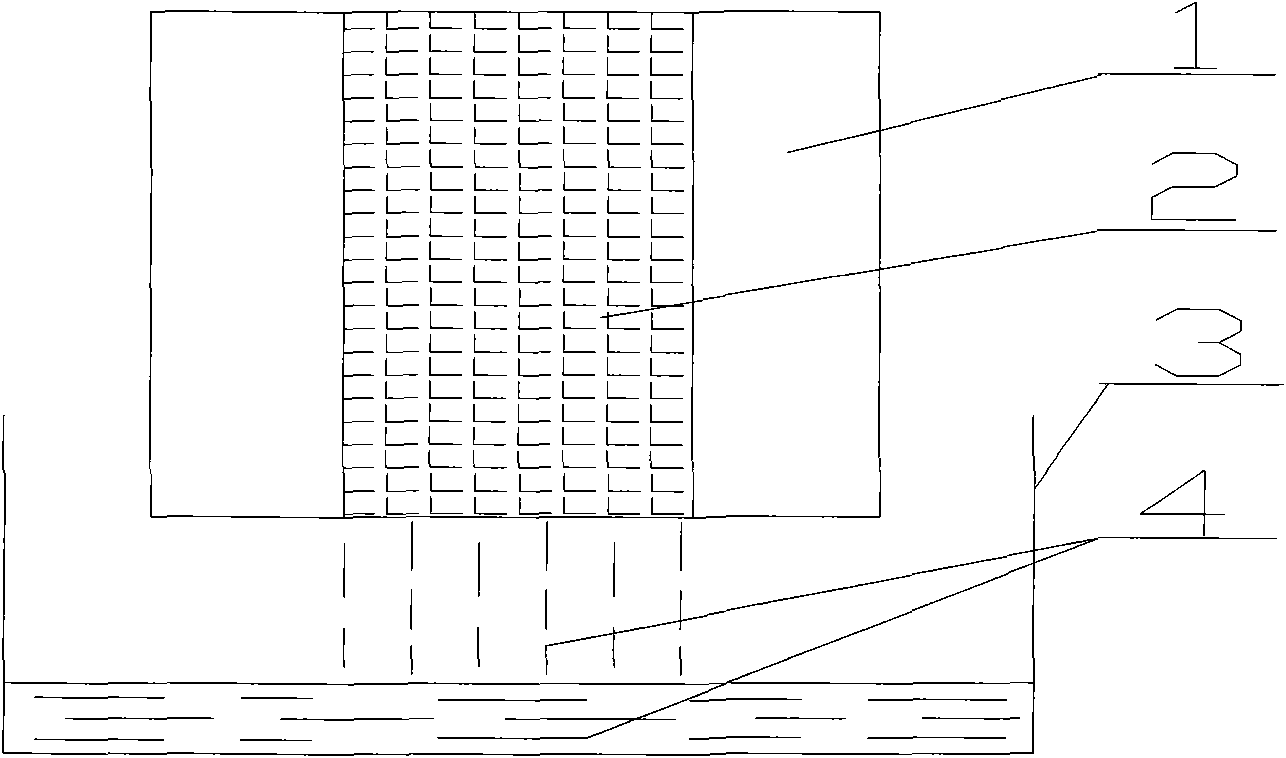

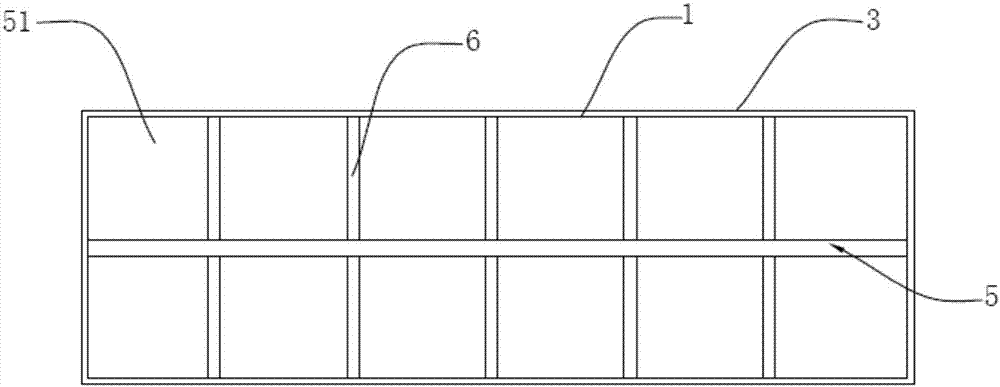

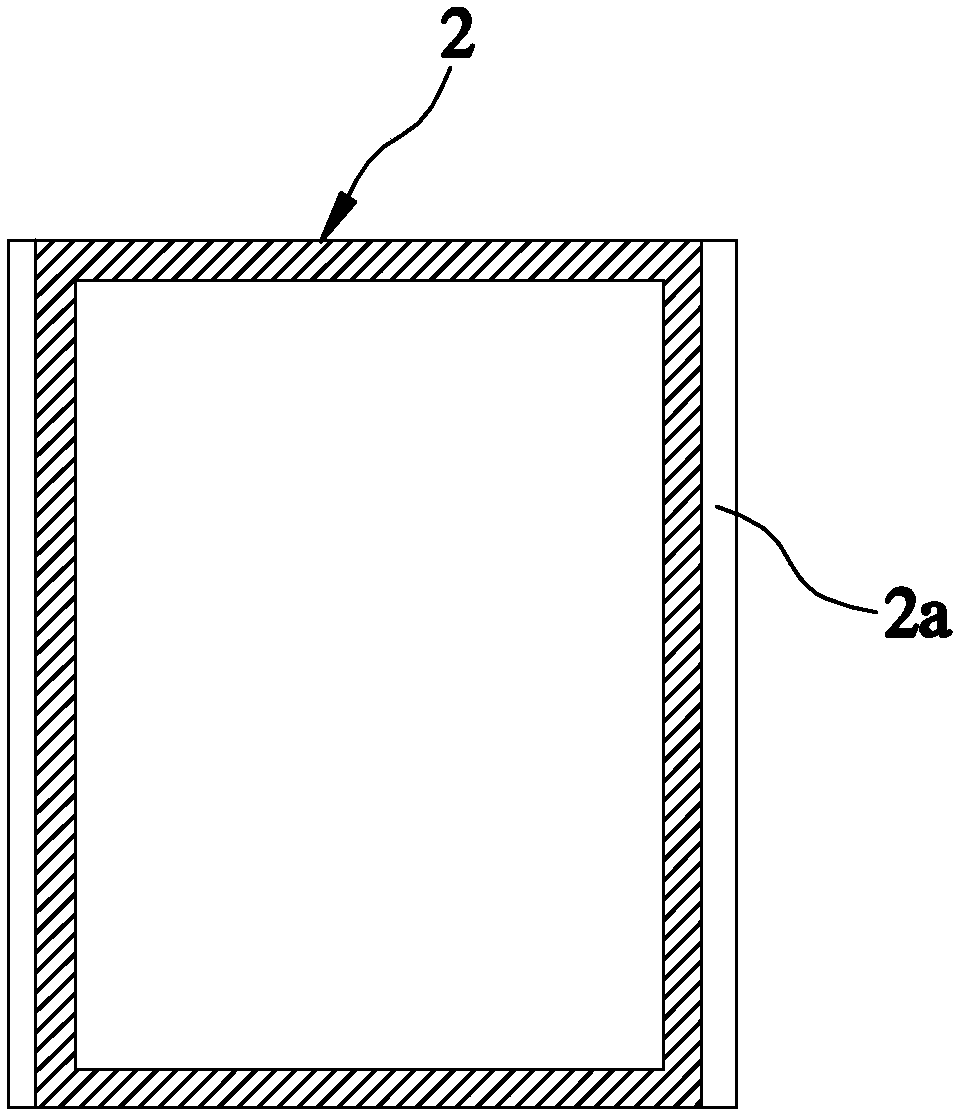

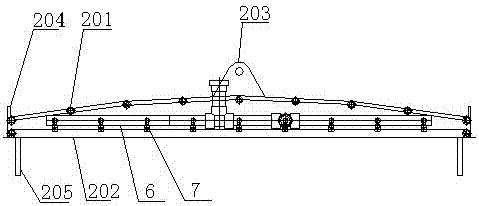

Automatic water heater inner container spray pickling pretreatment method and basket special for work-pieces

ActiveCN104988525AAccurate and sufficient amount of injectionImprove pickling qualityPretreatment methodMechanical engineering

The invention provides an automatic water heater inner container spray pickling pretreatment basket special for work-pieces. The basket comprises two frame bodies which are the same in structure and size. The two frame bodies are spaced by a preset distance and are fixedly connected into a whole through a connecting rod. A fixing plate is arranged at the inner side of the bottom face of each frame body. Each fixing plate is provided with three or more work-piece supporting legs which are distributed at intervals and extend into the rectangle; hanging rings are arranged at the outer sides of the upper sides of the frame bodies. The basket has the advantages that the prickling quality is good, and the service life of the basket is long.

Owner:东莞市天美新自动化设备有限公司

Comprehensive acid washing device for strip steel

InactiveCN105483735AReduce underpicklingReduce the phenomenon of over picklingAcid washingStrip steel

The invention discloses a comprehensive acid washing device for strip steel. The device comprises an acid washing tank; a transmission rubber roller is arranged in the acid washing tank, and is provided with the strip steel; the strip steel is vertically arranged; acid washing sprayers are arranged on left and right two sides and the upper side of the strip steel; an acid liquid rail is formed rightly below the strip steel; the acid washing sprayers are connected with acid mist tanks; and a waste liquid tank is formed in the bottom of the acid washing tank. Through the mode, the comprehensive acid washing device for strip steel, provided by the invention, adopts different acid washing modes for different oxidation degrees of all directions of the strip steel, adopts immersion type acid washing for the bottom edge of the strip steel, adopts acid mist spraying acid washing for the middle of the strip steel, is high in pertinency, effectively reduces the phenomenon of under acid washing or over acid washing of the strip steel, and improves the strip steel acid washing quality.

Owner:无锡华工薄板有限公司

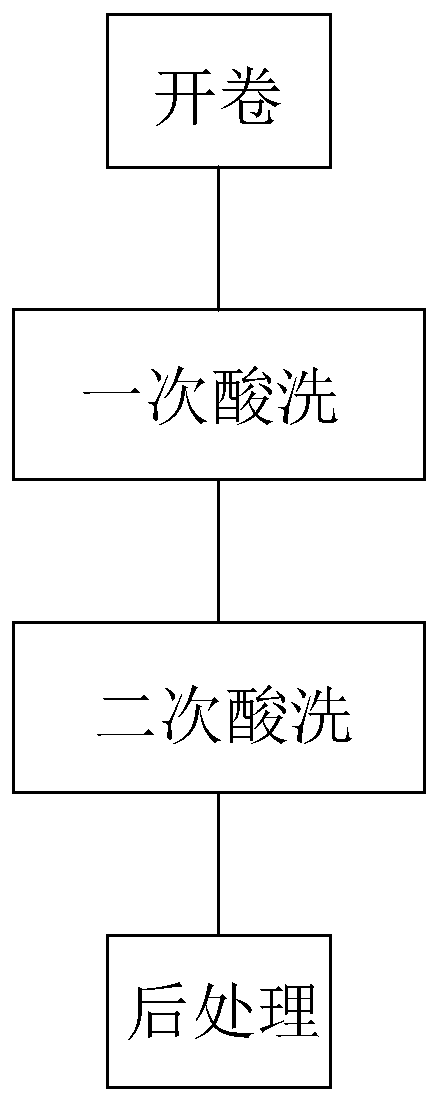

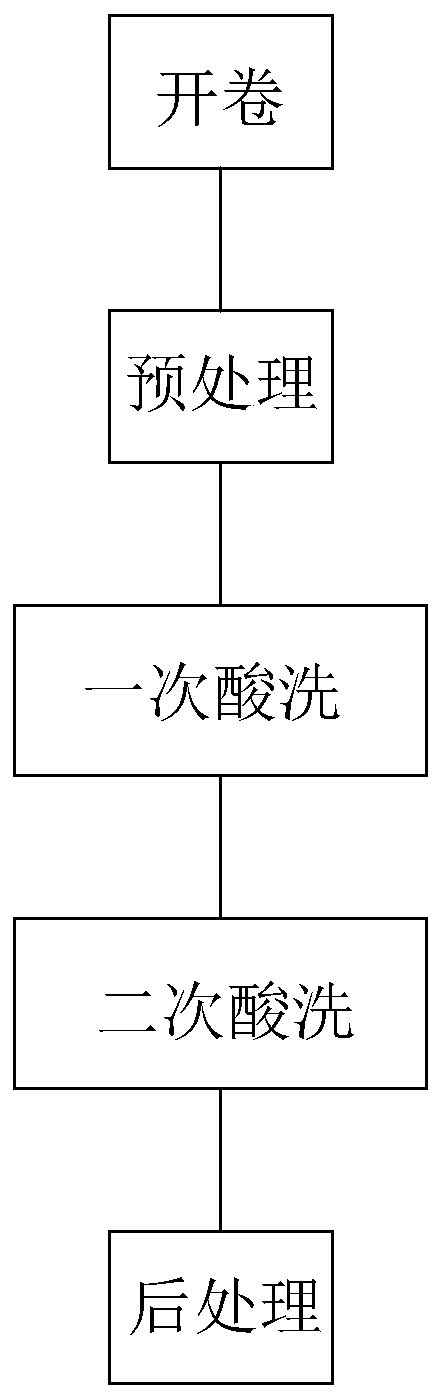

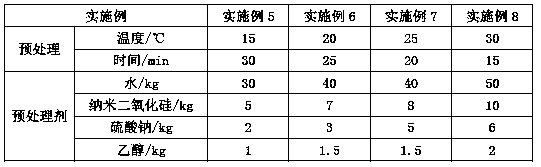

Pickling coil preparation technology

The invention discloses a pickling coil preparation technology, and belongs to the technical field of metal material processing. According to points of the technical scheme, the preparation technologycomprises the following steps that uncoiling is conducted; primary pickling is conducted, specifically, a pickling solution is used for pickling for a preprocessed straightening steel strip at 30-50DEG C for 5-10min, and then residual pickling solution is cleared with clear water; secondary pickling is conducted, specifically, the pickling solution is used for pickling for the preprocessed straightening steel strip at 30-50 DEG C for 5-10min, and then residual pickling solution is cleared with clear water; and post-processing is conducted, specifically, moisture on the surface of the straightening steel strip sequentially subjected to primary acid pickling and secondary acid pickling is dried by hot air, and rust preventing oil is sprayed onto the surface of the straightening steel strip. According to the preferred scheme, after uncoiling, the preprocessing step is included before primary acid pickling, specifically, a preprocessing solution is used for soaking processing to the straightening steel strip at 15-30 DEG C for 15-30min, and then cold water clearing is conducted. The preparation technology has the advantages of being short in processing procedures, low in energy consumption, and high in pickling processing quality.

Owner:浙江协和薄钢科技有限公司

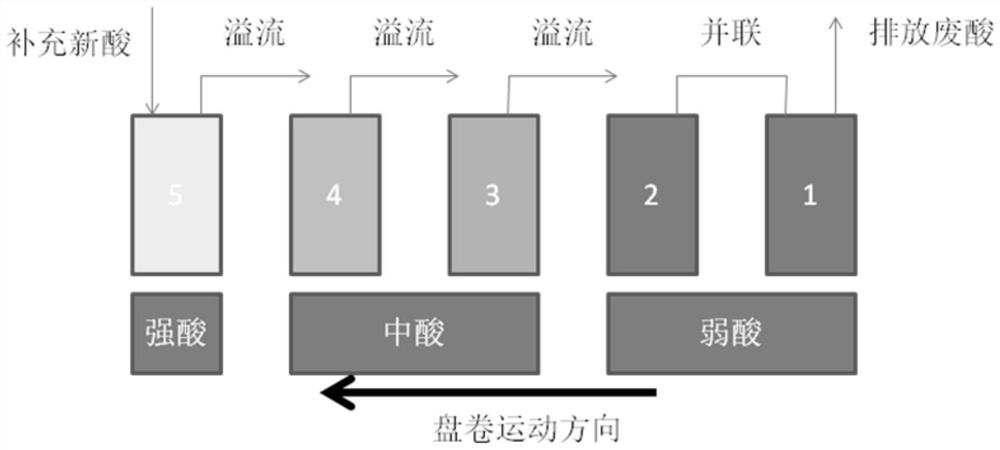

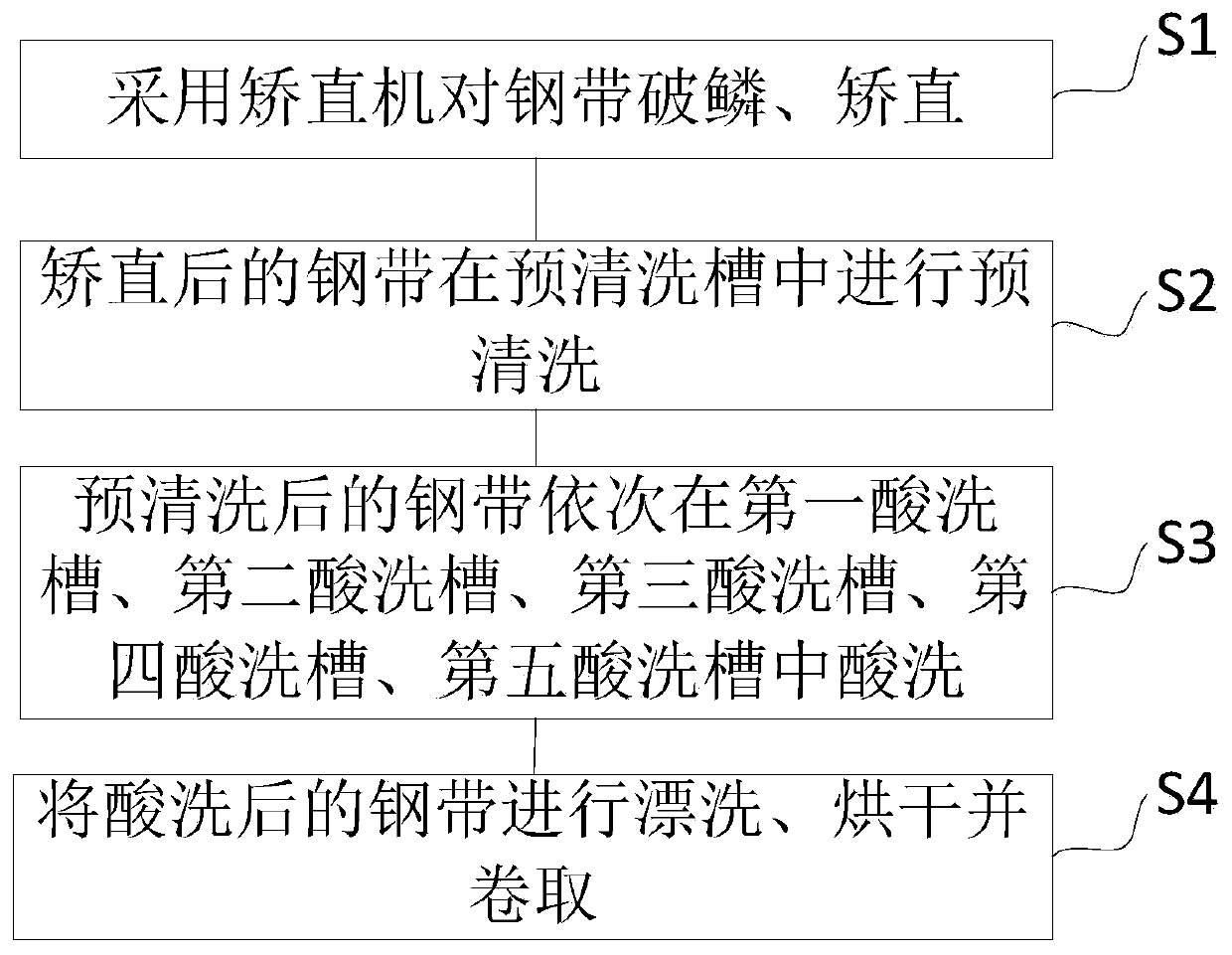

Pickling method of complex phase steel

The invention discloses a pickling method of complex phase steel. The method comprises pickling. A steel strip passes a first pickling groove, a second pickling groove, a third pickling groove, a fourth pickling groove and a fifth pickling groove arranged successively. Hydrochloric acid solutions are contained in the first pickling groove, the second pickling groove, the third pickling groove, thefourth pickling groove and the fifth pickling groove. Concentrations of hydrochloric acid are successively 40-50 g / L, 60-80 g / L, 80-100 g / L, 100-120 g / L and 130-160 g / L. Temperatures of hydrochloricacid are successively 75-85 DEG C, 73-83 DEG C, 70-80 DEG C, 70-80 DEG C and 70-80 DEG C. The pickling method reduces the probability of black spots and under-pickling quality defect in the pickling process greatly, is good in application effect, can lower the production cost greatly, improves the market competitiveness of a product and has good application value.

Owner:BEIJING SHOUGANG CO LTD

Silicon briquette washing method and application

ActiveCN108946738AEasy cleaning processImprove pickling efficiencySilicon compoundsFluorhydric AcidMetallic impurities

The invention discloses a silicon briquette washing method and application, and belongs to the technical field of silicon briquette washing. The method comprises the steps of sequentially pickling, rinsing, cold soaking and hot soaking, wherein the pickling solution used in pickling is prepared from nitric acid and hydrofluoric acid; the pickling step is performed in three acid solutions having the nitric acid proportion increased in a gradient way, and the acid solution used in first pickling contains nitric acid and hydrofluoric acid in a ratio of (9-11):1v / v. According to the method, the silicon briquette is pickled by sequentially using three acid solutions having the nitric acid proportion increased in a gradient way, the silicon briquette washing process is optimized, the silicon pickling efficiency and product quality can be improved, and the technical problems of non-uniform pickling, acid spotting and chromatic aberration, high content of metal impurities and large content fluctuation of metal impurities caused by washing a single-proportion pickling tank can be relieved.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +3

Pickling method of stainless steel covered by acid-proof cloth

The invention introduces a pickling method of stainless steel covered by acid-proof cloth; the method comprises the following steps: covering multi-layer acid-proof cloth on the surface of the stainless steel, supplying pickling solution on the surface of the acid-proof cloth and continuously updating, adding the updated original pickling solution into a solution recovery tank; ensuring that the concentration of the pickling solution is in the optimal process range through changing the concentration of the original pickling solution in the solution recovery tank and continuously updating the acid in the pickling cloth. the temperature of the pickling solution can also be ensured within the optimal process range by removing the bubbles under the cloth by the acid-proof tool and heating and controlling the pickling temperature to. The method can ensure the optimal pickling temperature and concentration, the pickling has good quality; the method can remove an oxidation film thoroughly without overpickling; after pickling, the steel plate has uniform color and metal gloss on the surface; the pickling cloth and pickling solution can be used repeatedly, the pickling cost is low; thus avoiding environmental pollution caused by the waste pickling paste.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

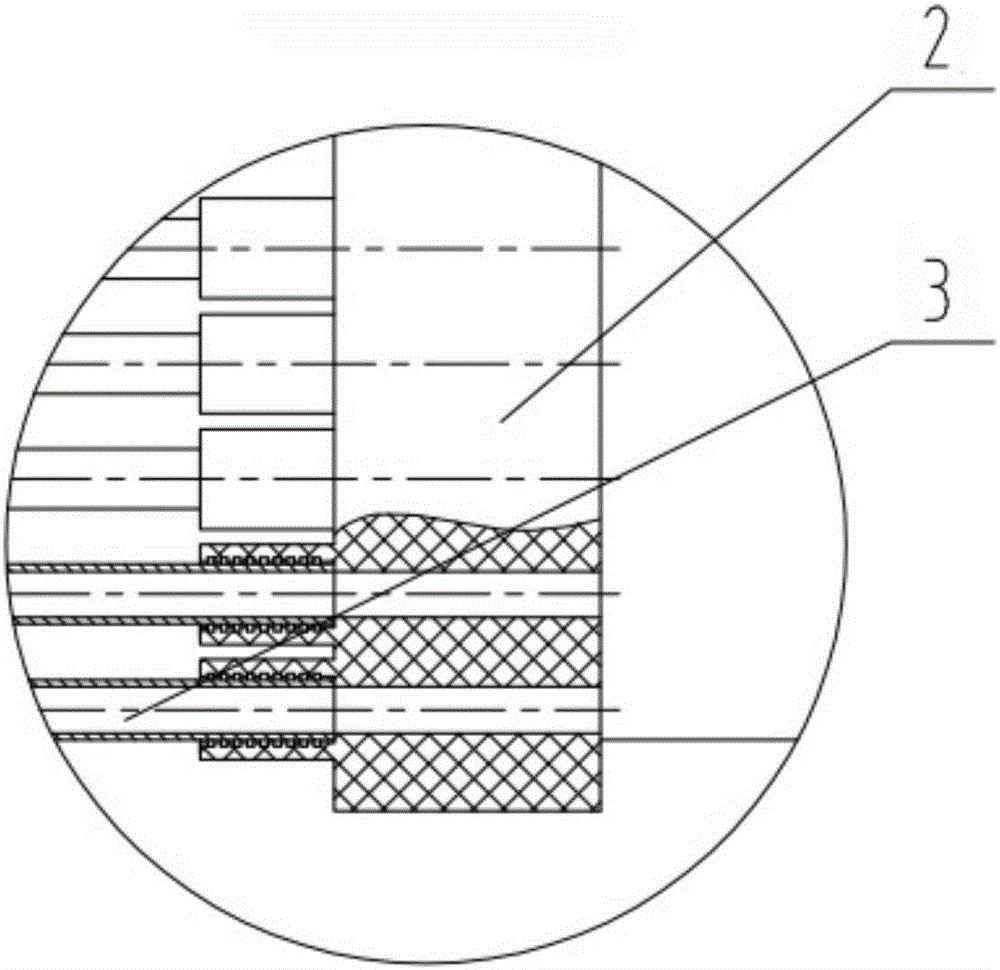

Method for pickling inner and outer surfaces of pipe

The invention discloses a method for pickling the inner and outer surfaces of a pipe. The method comprises the following steps: (1) mounting the pipe to be cleaned in a pipe fixture device, and connecting the pipe fixture device with a fixture clamping mechanism; (2) injecting a pickling solution into an acid tank, and soaking the pipe into the pickling solution; (3) letting a transverse moving device drive the fixture clamping mechanism, so as to drive the pipe to do reciprocating motion in the acid tank, wherein an acid conveying pipeline jets the pickling solution to the inner wall of the pipe; (4) after cleaning is completed, taking out the pipe from the acid tank, and removing the pipe from the pipe fixture device. According to the method, the soaking pickling method is combined with the jetting pickling method, so that a plurality of pipes can be pickled at one time; the method is high in production efficiency, safe, reliable, and high in pickling quality; meanwhile, the chance that a worker gets close to the pickling solution is reduced; the method is suitable for production of small-diameter pipes, in particular for production of precision pipes.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Production process for oil tank

ActiveCN110919300AImprove qualityImprove corrosion resistanceMetallic material coating processesStationary filtering element filtersPunchingProcess engineering

The invention discloses a production process for an oil tank and relates to the field of oil tank machining. The production process comprises the following steps of S1, plate shearing; S2, stamping; S3, edge shearing; S4, punching; S5, welding; S6, airtightness detection; S7, cleaning; and S8, plastic spraying. The production process for the oil tank has the following advantages and effects that the oil tank is subjected to acid pickling, neutralizing, phosphating and water washing in sequence to form a layer of phosphating film on the surface of the oil tank, the later adhesive force of a paint film and the corrosion resistant capability of the surface of the oil tank are improved, and therefore, the product quality of the produced oil tank is improved.

Owner:杭州樱多电器有限公司

Bolt acid pickling device with good closed waste gas collection effect

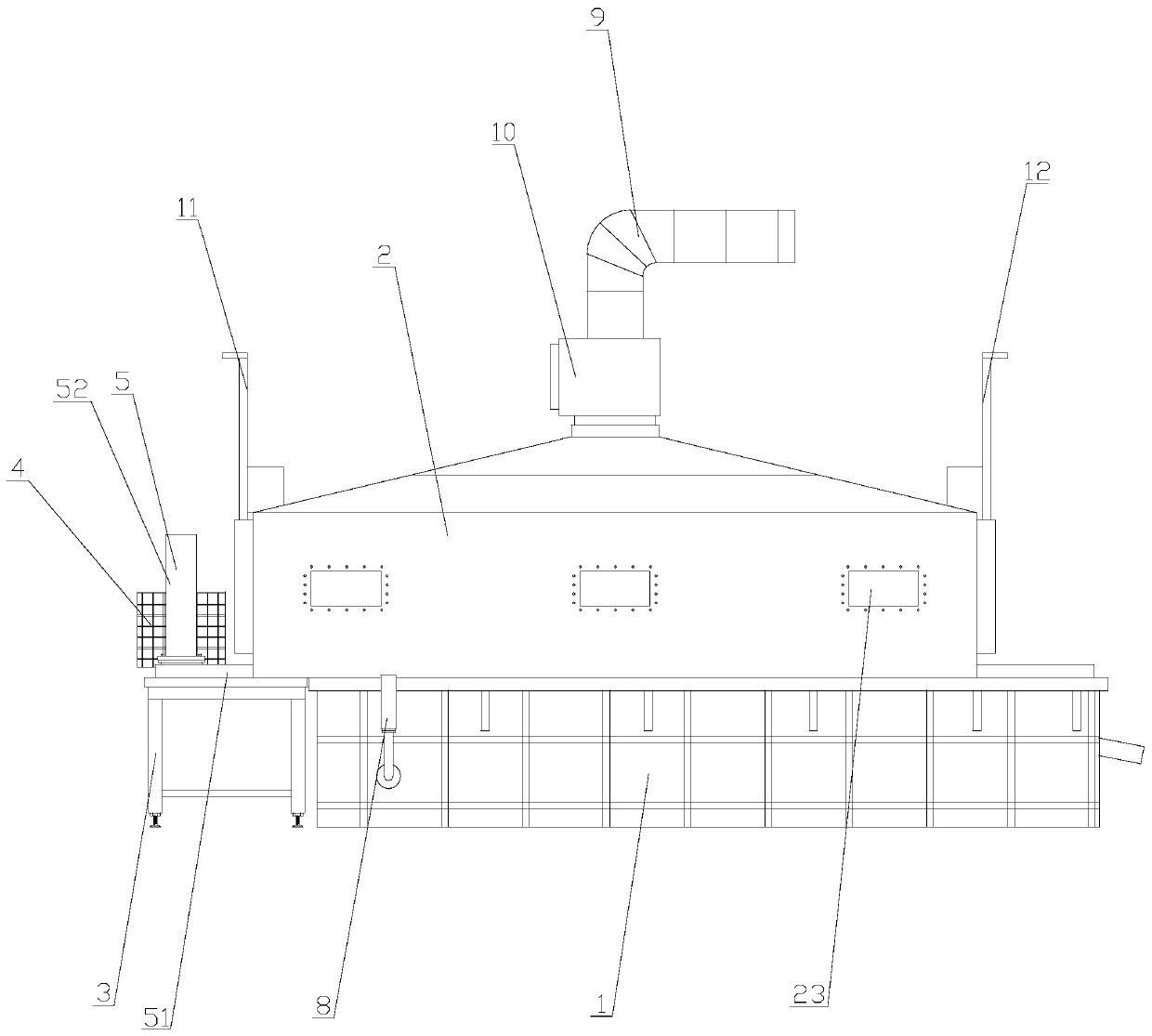

PendingCN110408942AImprove pickling efficiencyImprove pickling qualityDirt cleaningChimneyPulp and paper industry

The invention discloses a bolt acid pickling device with a good closed waste gas collection effect. The device comprises an acid pickling tank, an acid pickling tank upper cover, a feeding rack, an acid pickling basket, an acid pickling basket moving device, a cross rod, an acid pickling basket hanging bracket, a control panel, an exhaust chimney and an exhaust fan. The acid pickling tank is a rectangular tank body, and the feeding rack is arranged at the transverse end in the long edge direction of the acid pickling tank. The acid pickling basket moving device is arranged at the upper end ofthe acid pickling tank, the acid pickling basket moving device drives the acid pickling basket and bolts in the acid pickling basket to transversely move in the long edge direction of the acid pickling tank back and forth and ascend and descend, and the acid pickling basket moving device drives the bolts to be subjected to acid pickling, washing and drainage automatically, so that the acid pickling efficiency is improved, the acid pickling quality is improved, the labor intensity of workers is reduced, the production cost is reduced, the sealing performance is good in the acid pickling process, waste gas generated in the acid pickling process can be collected and guided into waste gas treatment equipment, and the harm of the waste gas to the human body and the environment is reduced.

Owner:海盐上宇紧固件科技股份有限公司

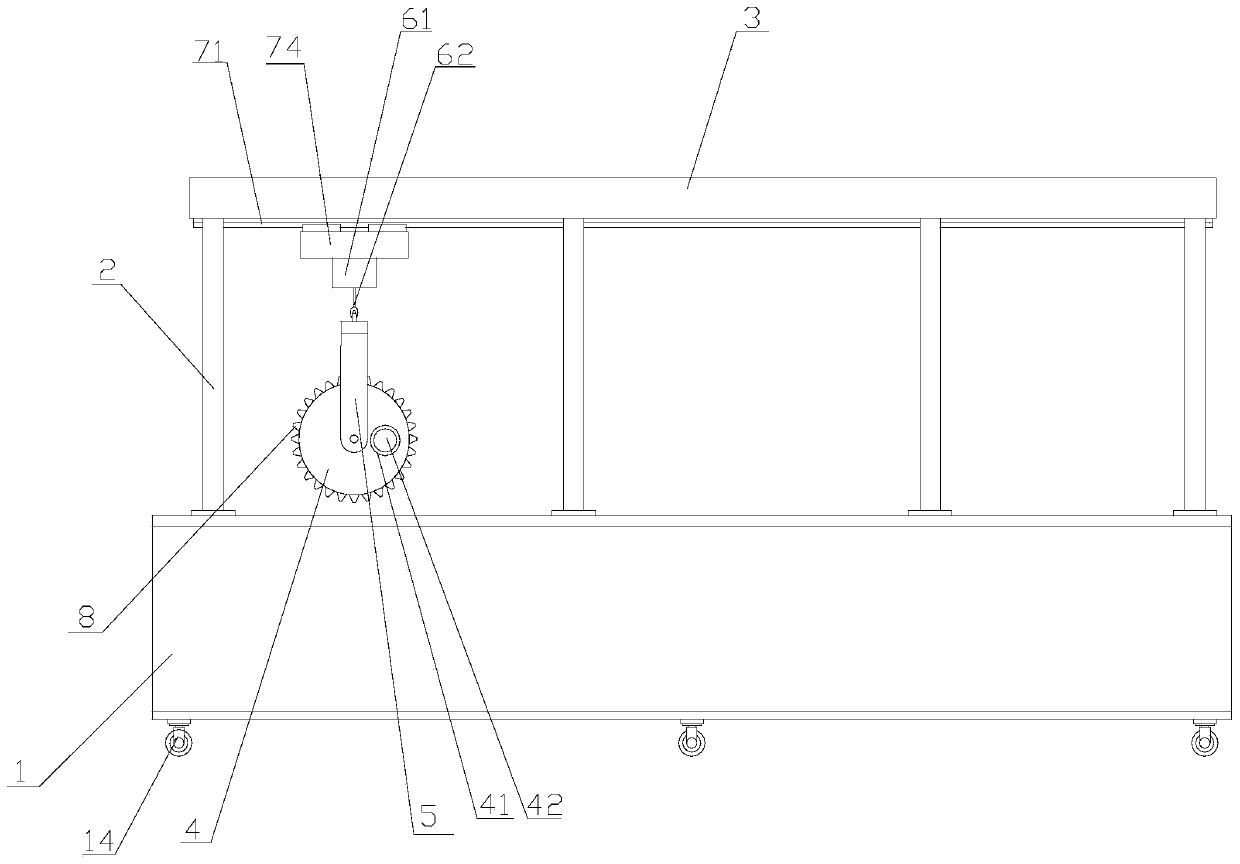

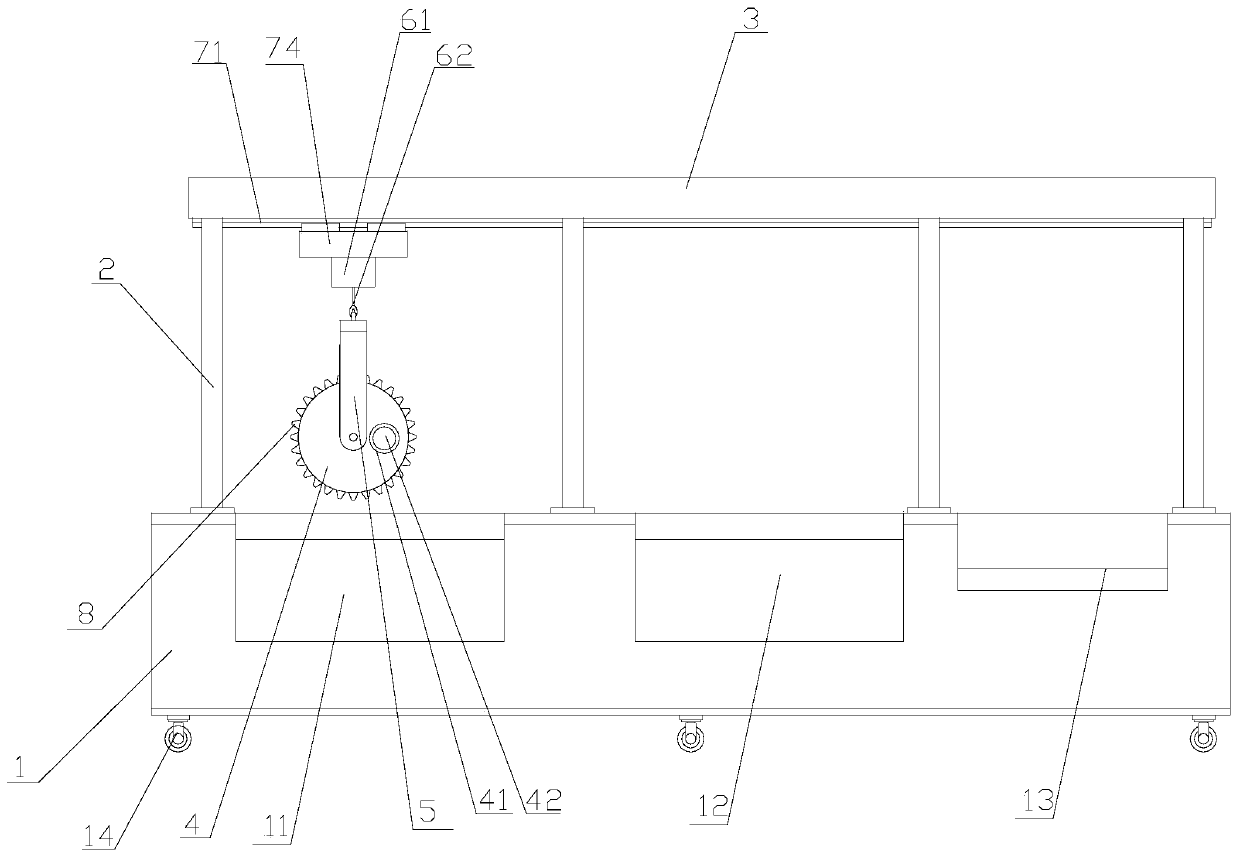

Acid washing equipment for hardware production

The invention discloses acid washing equipment for hardware production. The equipment comprises a main frame, multiple support rods, an upper support plate, a rolling cage, a rolling cage fixed support frame, a lifting device, a transverse moving device, an annular rack, a rotating motor and a motor gear; three pool bodies are transversely arranged at the upper end of the main frame in sequence, and are respectively an acid washing pool, a clear water pool and a drained water collecting pool; acid washing liquid is filled in the acid washing pool; clear water is filled in the clear water pool;the multiple support rods are arranged on two sides of the upper end of the main frame; the upper support plate is horizontally arranged at the upper ends of the support rods; the transverse moving device is transversely arranged at the lower end of the upper support plate; and the lifting device is arranged at the lower end of the transverse shifting device. The rolling cage is arranged at the upper end of the frame; through cooperation between the rolling cage and the acid washing pool, the acid washing is performed on screws; and through rotation of the rolling cage, the uniform contact between the surfaces of the screws and acid washing solution is facilitated, so that the acid washing quality is improved, and the acid washing efficiency is improved.

Owner:嘉兴莱福精密机械有限公司

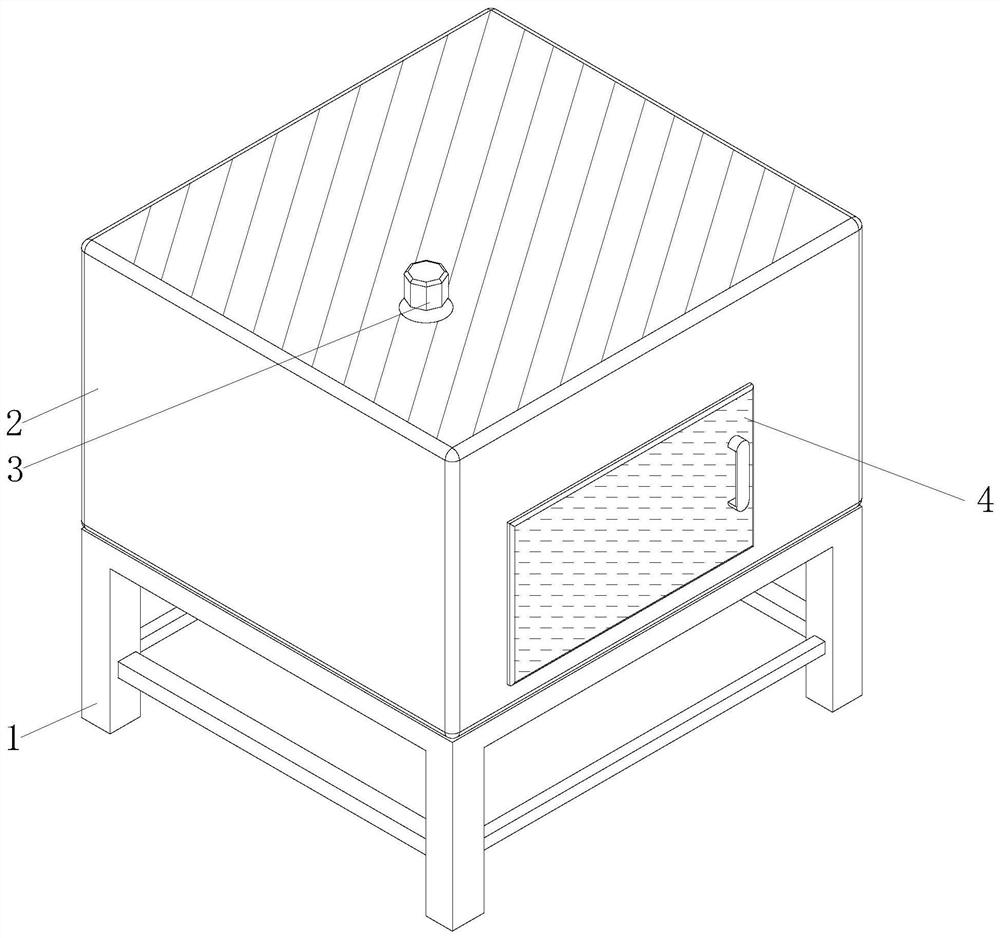

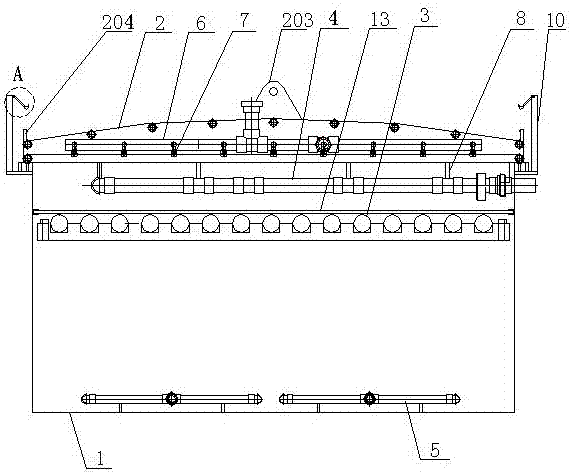

Quick pickling cabinet

The invention belongs to the technical field of food processing equipment, and in particular relates to a quick pickling cabinet, which includes a cabinet body, the outer wall of the cabinet body is provided with a heat preservation cover, and the cabinet body is provided with a food shelf, the food shelf, etc. A plurality of partitions are arranged at intervals, and the partitions divide the food storage rack into multiple food storage chambers, and each food storage chamber is equipped with a tray, a heating device, an openable chamber cover, a feeding port, an overflow outlet, exhaust port, circulation feed port, discharge port and sewage discharge port, the discharge port and the circulation feed port are connected with the feed-liquid circulation pipeline, and the feed-liquid circulation pipeline is provided with a circulation valve and a circulation pump and a discharge valve, an electromagnetic coil is wound outside the material-liquid circulation pipeline, and the electromagnetic coil is electrically connected to the electromagnetic heating control cabinet. The invention has the advantages of simple structure and easy operation, can pickle different food materials at the same time, has short pickling cycle, good bactericidal effect, accurate temperature control, good pickling quality, high edible safety, light weight, and is easy to move.

Owner:王爱军

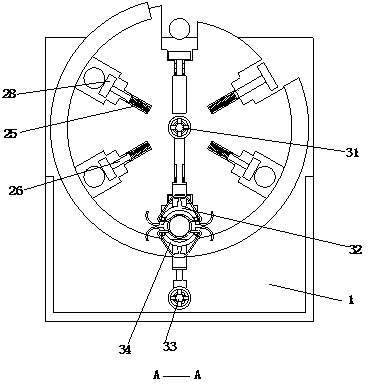

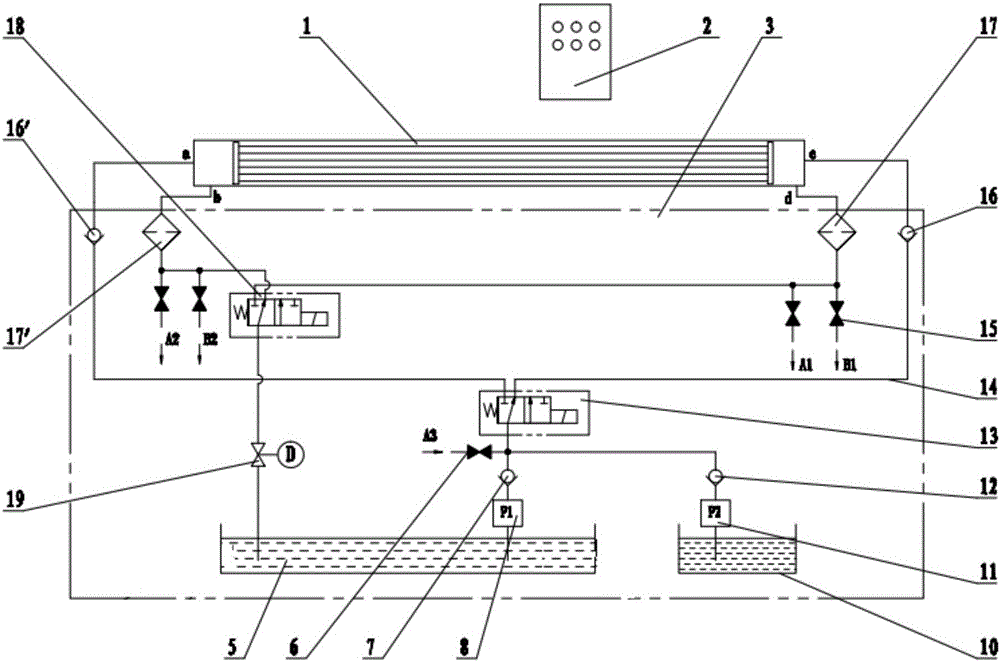

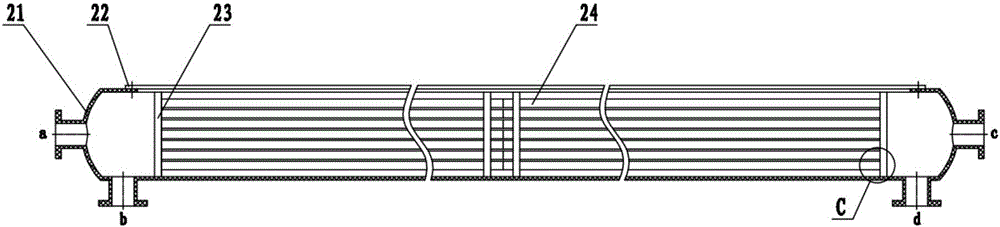

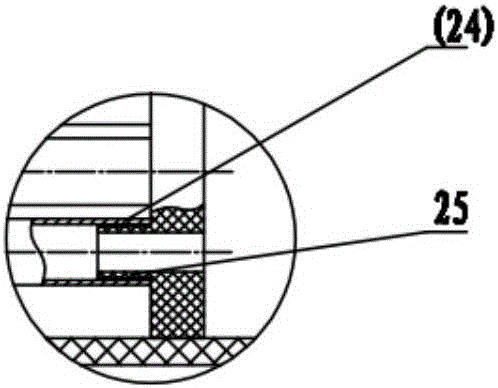

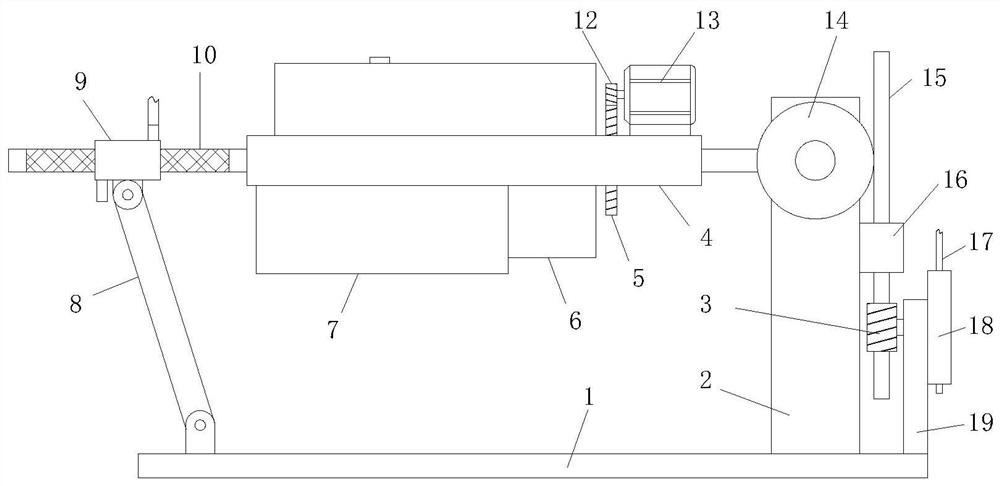

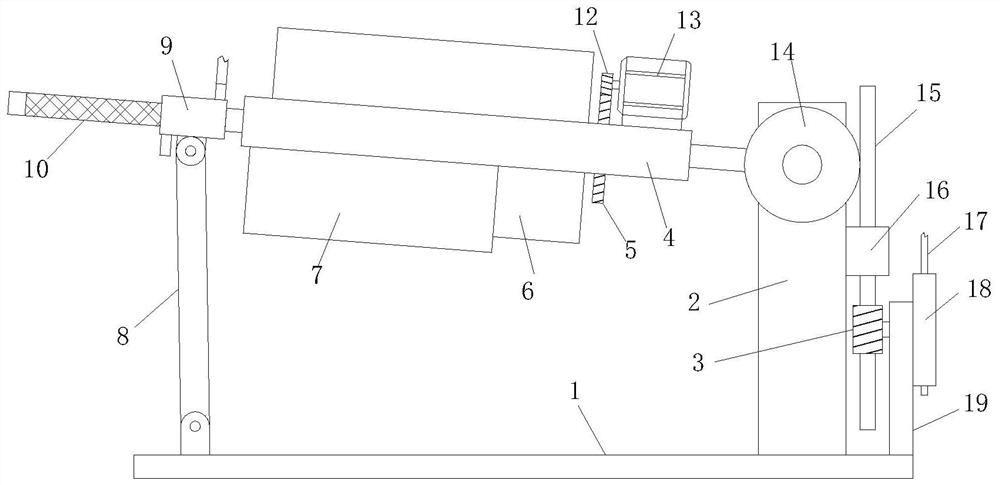

Multifunctional pipe pickling device and picking method

ActiveCN105839126AReduce the possibility of leaksImprove pickling efficiencyControl systemElectric control

The invention discloses a multifunctional pipe pickling device and a pickling method. The pickling device comprises a pickling tank assembly, an acid storage tank and an electric control system, wherein a liquid inlet and a liquid outlet are formed in each of two ends of the pickling tank assembly; the liquid inlets in the two ends of the pickling tank assembly are separately connected with a first reversing valve through a check valve; the first reversing valve is connected with the acid storage tank through an acid pump; the liquid outlets in the two ends of the pickling tank assembly are both connected with a second reversing valve; the second reversing valve is connected with the acid storage tank through an adjusting valve; the first reversing valve and the second reversing valve are both connected with the electric control system; the pickling tank assembly comprises a pickling tank, a cover plate and fixture mechanisms; the fixture mechanisms are located on two ends of the pickling tank; and pipes are located on the fixture mechanisms. The multifunctional pipe pickling device is applicable to multiple pickling requirements of pipes; the requirements of only pickling outer surfaces, only pickling inner surfaces or pickling inner and outer surfaces synchronously can be met; the production efficiency is high; the multifunctional pipe pickling device is safe and reliable; environment protection is facilitated; and the pickling quality is high.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

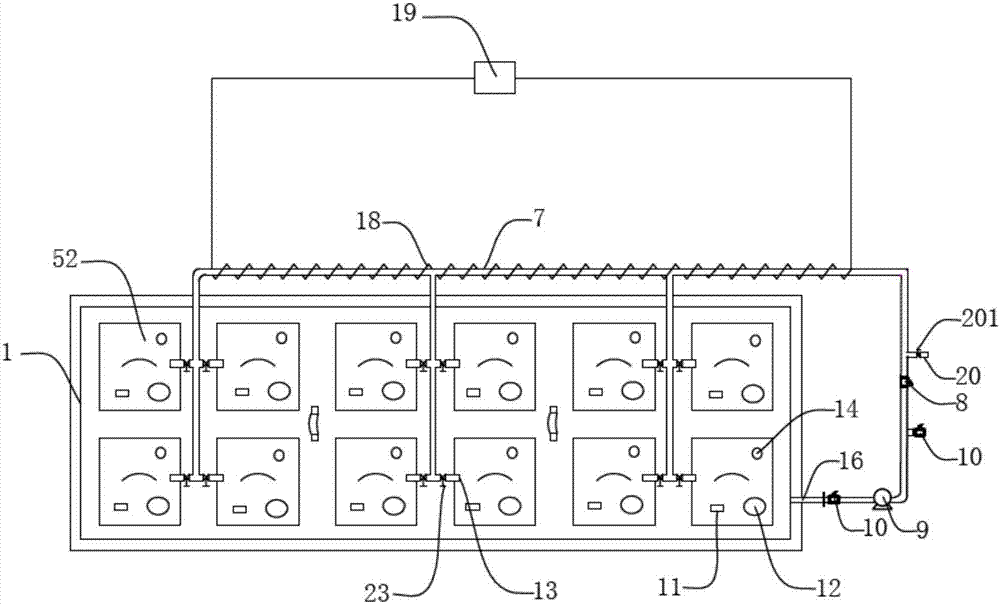

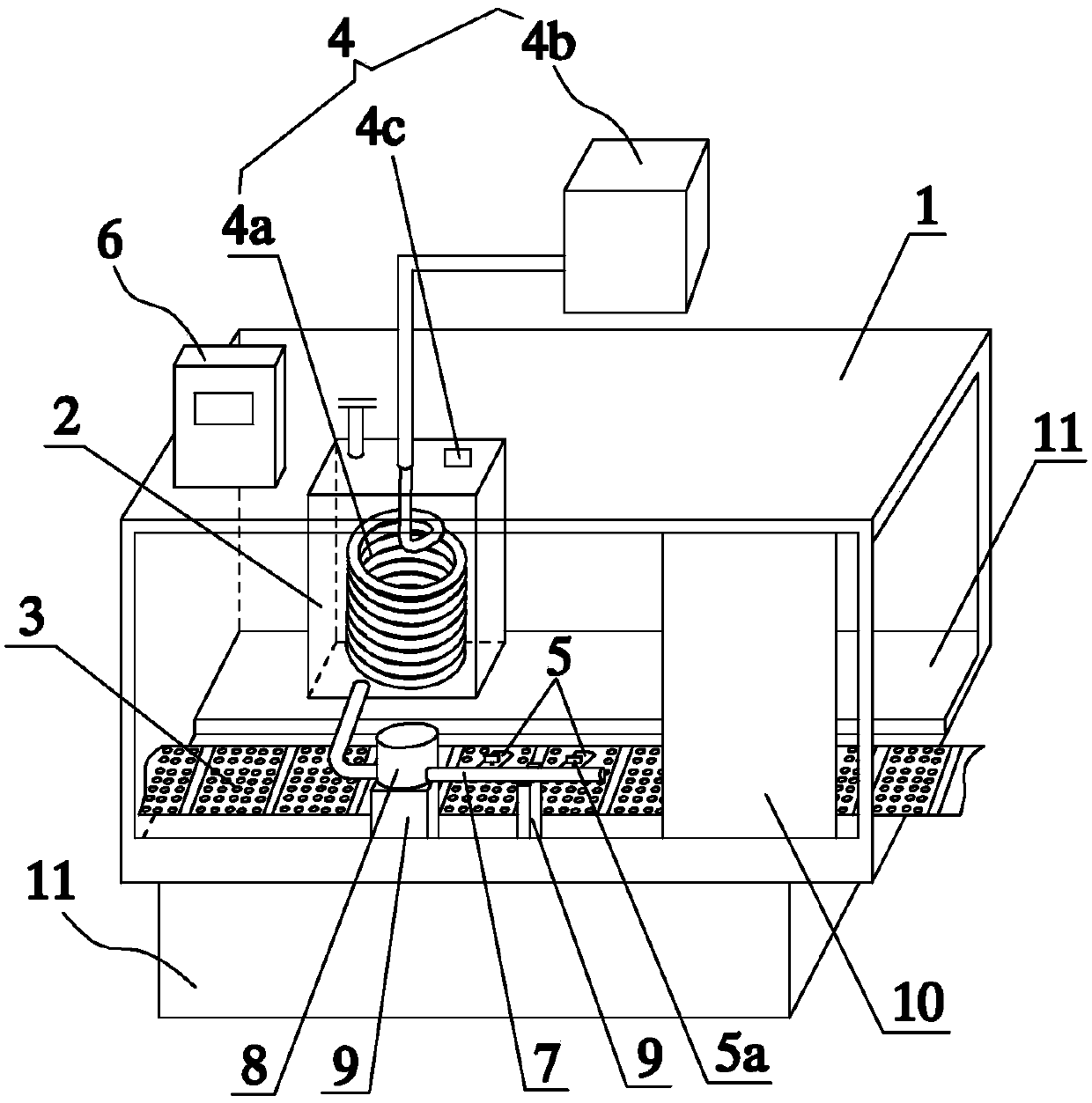

Diode chip pickling equipment

PendingCN107658251AImprove pickling qualityStable temperatureSemiconductor/solid-state device manufacturingTemperature controlSolenoid valve

The invention discloses diode chip pickling equipment. The equipment comprises a working bin, a pickling box, a pickling disc, a temperature control apparatus, a nozzle and a controller. The picklingbox and the pickling disc are distributed in the working bin. The temperature control apparatus comprises a refrigeration and heating coil, a compression outer machine and a temperature sensor. The refrigeration and heating coil is installed in the pickling box and is connected to the compression outer machine arranged outside the working bin. The temperature sensor is arranged in the pickling box. The nozzle is arranged on one side of the pickling disc and is connected to the pickling box through a connection pipe. The connection pipe is provided with a solenoid valve. The controller is arranged on the working bin and forms electric connection control with the temperature control apparatus and the solenoid valve. Through setting the temperature control apparatus, temperature monitoring and refrigeration and heating can be performed in the pickling box in real time; a temperature of acid in the pickling box is kept to be constant; and diode chip pickling quality is guaranteed.

Owner:重庆长捷电子有限公司

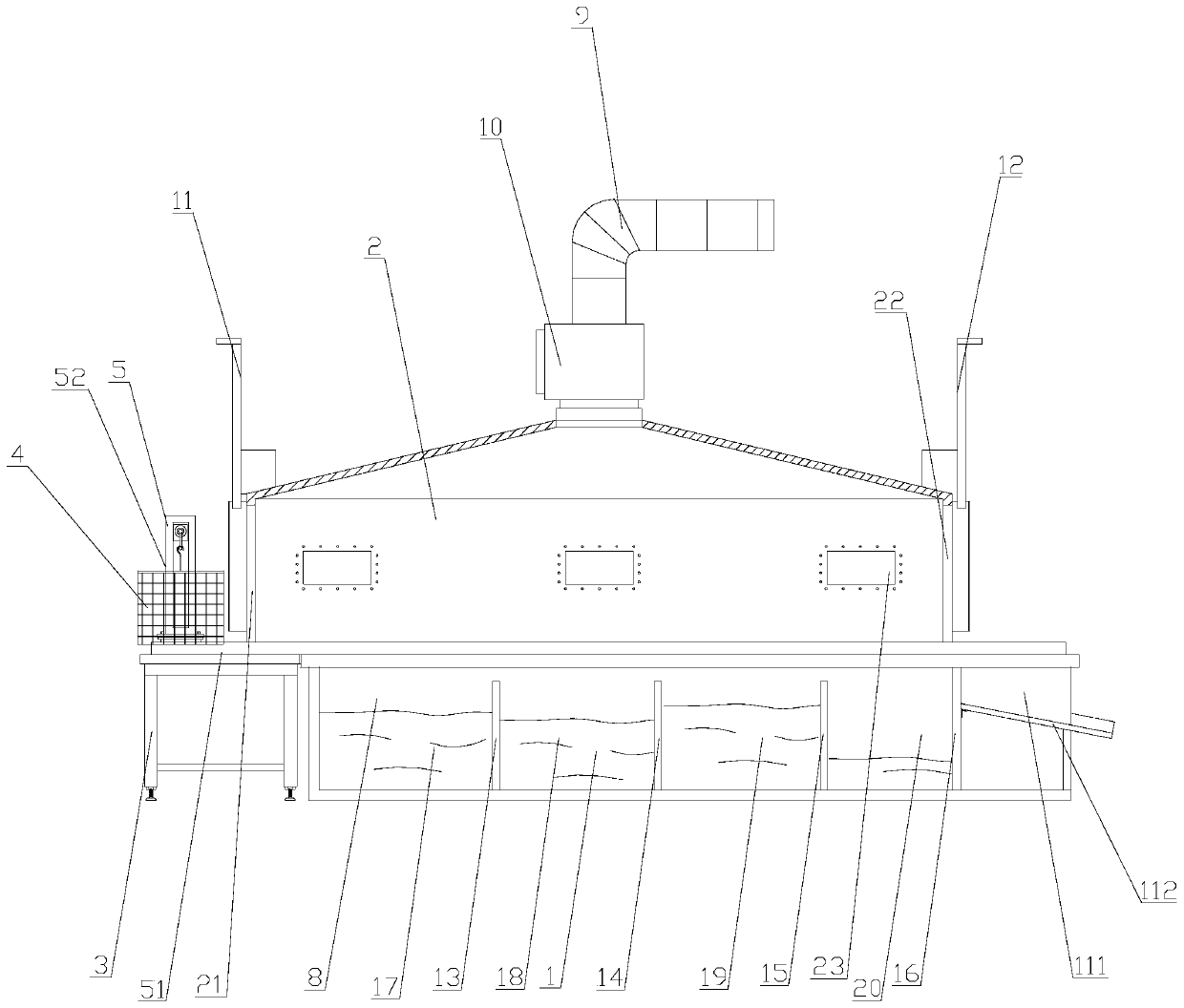

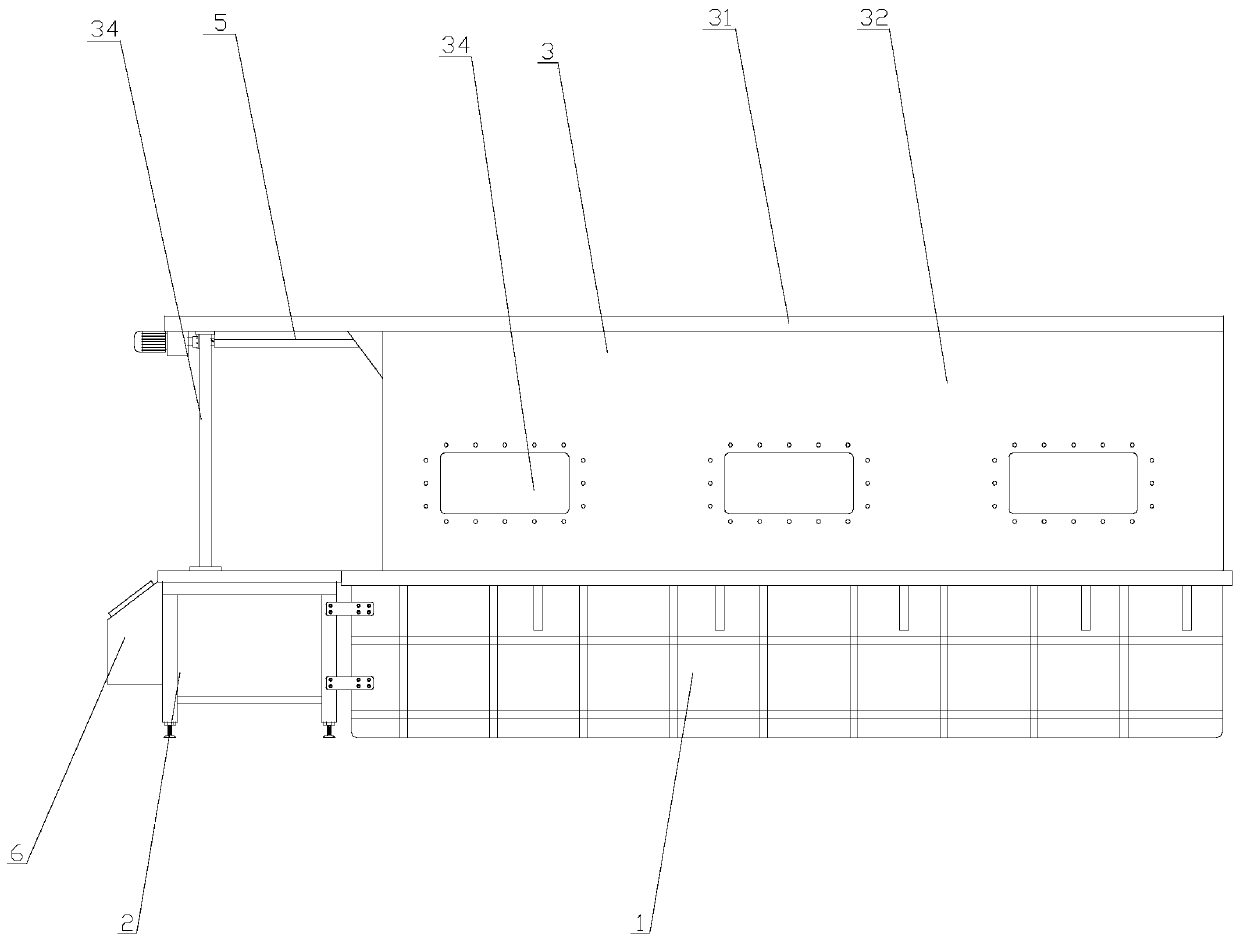

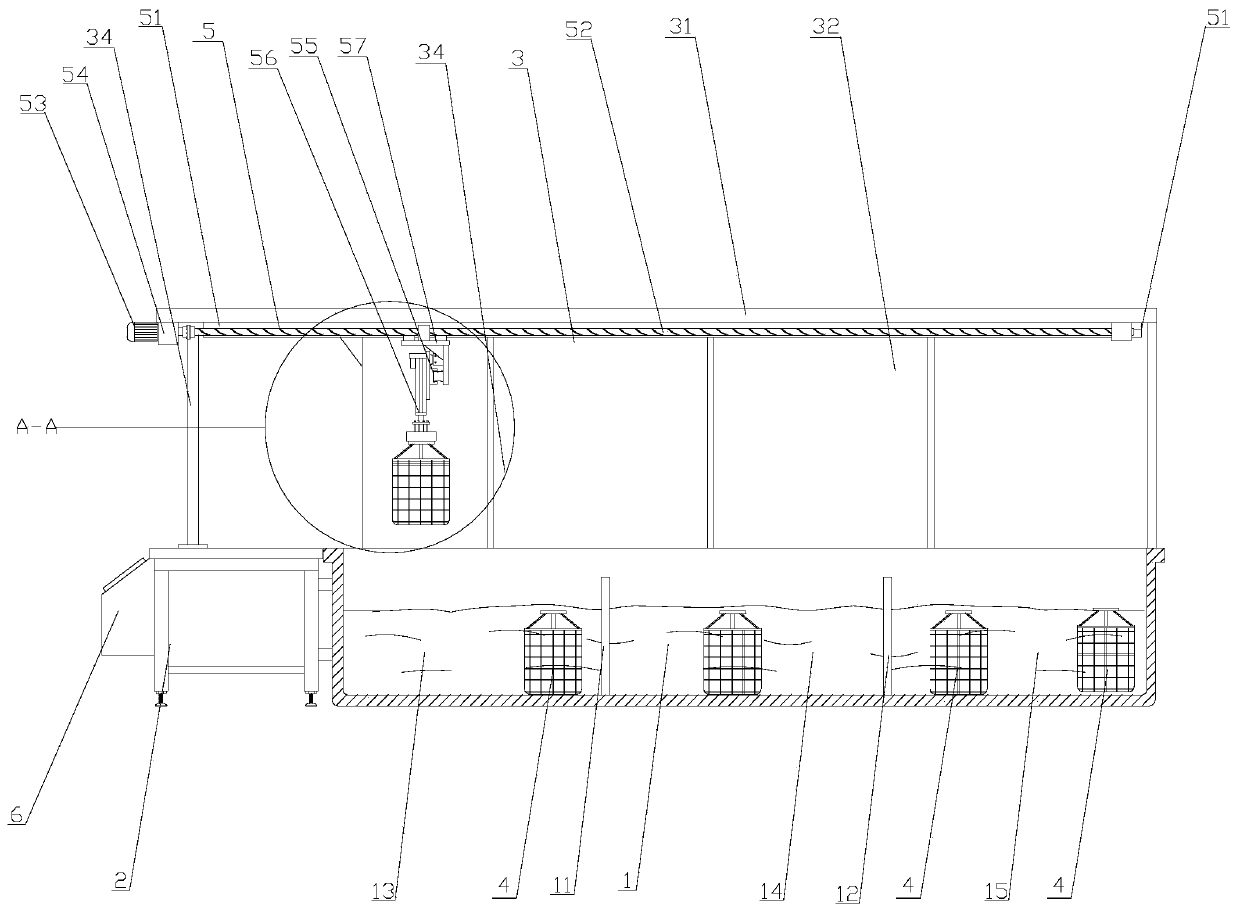

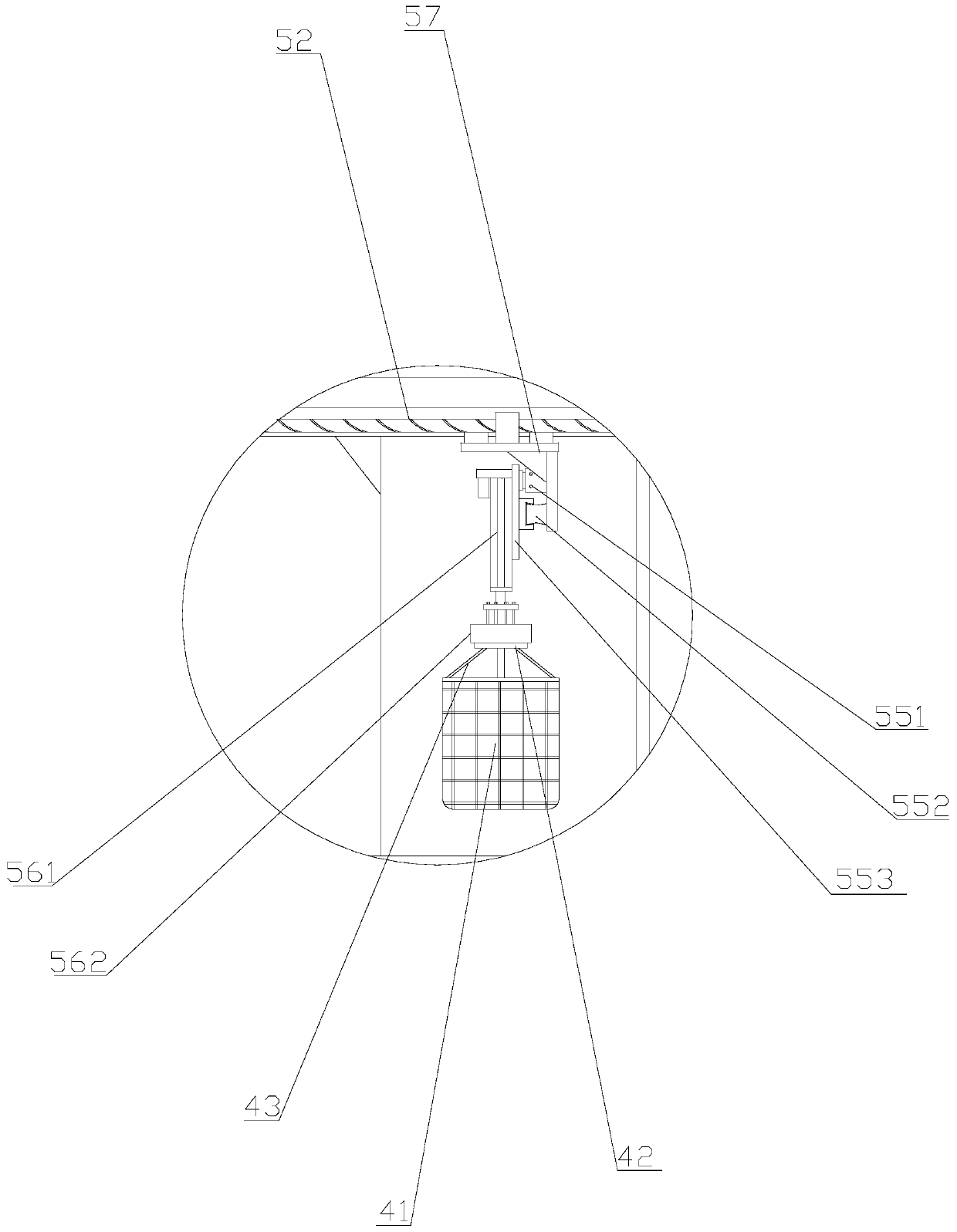

Linear reciprocating type tunnel pickling device

The invention discloses a linear reciprocating type tunnel pickling device. The linear reciprocating type tunnel pickling device comprises a pickling tank, a rack, a tunnel type upper cover, a plurality of pickling part hanging baskets, a pickling part hanging basket moving device and a control panel; and the pickling tank is a rectangular tank body with an opening in the upper end, the rack is arranged at one end of the pickling tank in the long edge direction, and the tunnel type upper cover which can be matched with the pickling tank is arranged at the upper end of the pickling tank. According to the linear reciprocating type tunnel pickling device, the tunnel type upper cover is arranged at the upper end of the pickling tank, the pickling part hanging basket moving device is arranged in the tunnel type upper cover, the pickling part hanging basket moving device can be conveniently matched with the pickling part hanging baskets, the pickling part hanging basket and pickling parts inthe pickling part hanging baskets can be conveniently carried, the pickling efficiency can be improved, the pickling part hanging baskets and the pickling part hanging basket moving device are connected through electromagnets, so that carrying and unloading are convenient, the pickling quality is improved, multiple pickling parts can be pickled at the same time, the automation degree is high, andthe labor intensity of workers is relieved.

Owner:嘉兴兴通五金科技股份有限公司

High-stability paint processing technology

PendingCN112981424AImprove stabilityHigh hardnessCleaning using toolsMetallic material coating processesCleansing AgentsSlow cooling

The invention relates to the technical field of paint, and discloses a high-stability paint processing technology. The high-stability paint processing technology comprises the following steps that 1) a to-be-sprayed metal part with alkali liquor is cleaned, and greasy dirt on the surface of the to-be-sprayed metal part is removed through a brush. (1) Akali liquor is a metal cleaning agent solution, the metal cleaning agent is prepared into an aqueous solution with the concentration of 2-3% (mass percent), the metal cleaning agent can be used at room temperature, and the heating use effect is better; According to the high-stability paint processing technology, through plasticizing treatment, auxiliaries and low-molecular-weight polymers in paint can be removed through plasticizing, primer and a metal part act, the bonding strength is improved, the adhesive force of the primer is guaranteed, intermediate paint plays an indirect transition role, finish paint is smoother and smoother, and finally, a paint coating with considerable strength and high hardness can be obtained through slow cooling, so that the stability of the paint processing technology is further improved, and the effect of high stability is achieved.

Owner:云南万里化工制漆有限责任公司

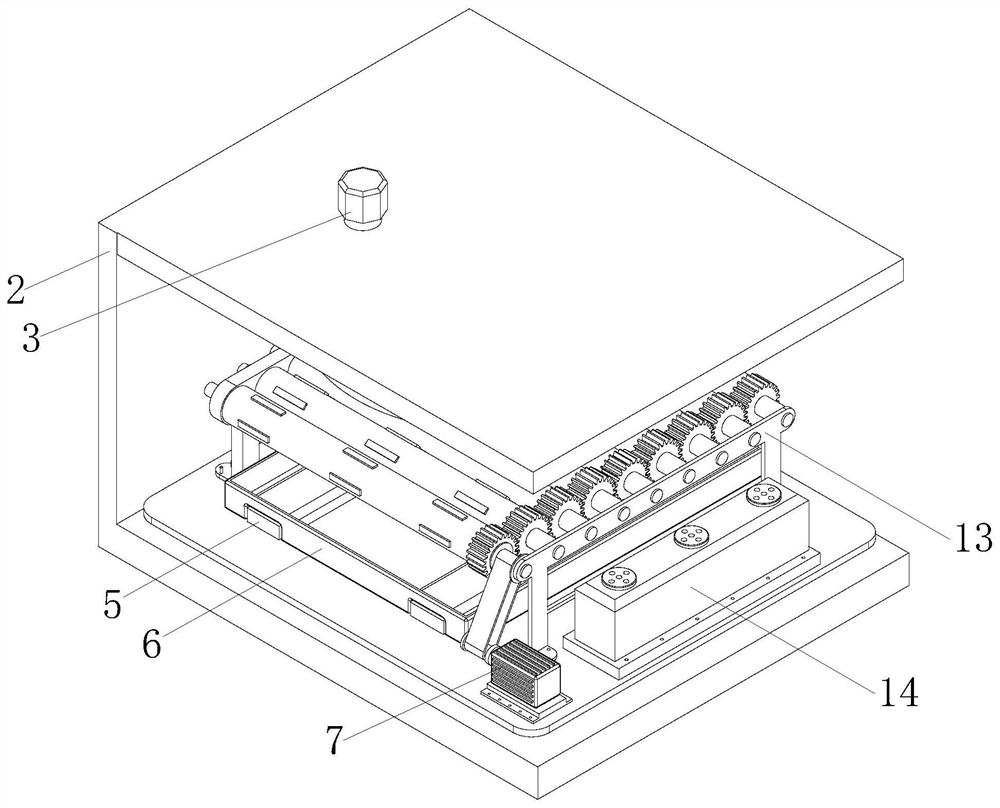

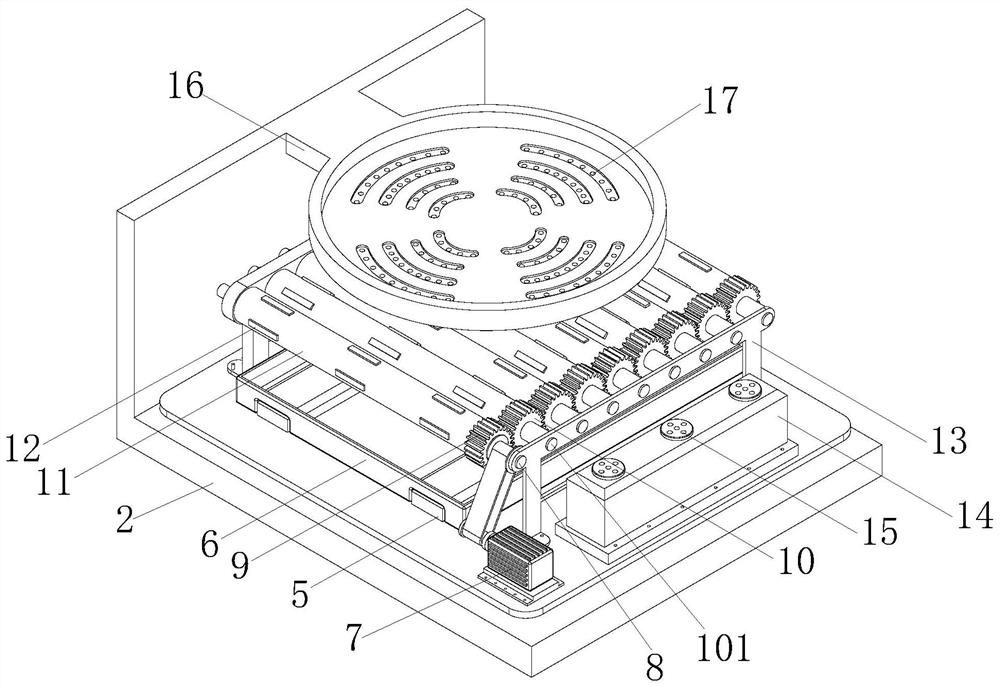

Pickling processing device for reducing harmful substance formation in ham production

InactiveCN111820384AReduce the presence of hazardous substancesAvoid uneven marinatingFood shapingGear wheelElectric machinery

The invention discloses a pickling processing device for reducing harmful substance formation in ham production. The pickling processing device comprises a supporting frame, wherein a pickling box isfixedly installed at the top of the supporting frame; a salt adding pipe is installed at the top of the pickling box in a penetrating mode; a box door is movably installed on the surface of the pickling box, and a limiting edge is arranged at the inner bottom of the pickling box; a collecting groove is clamped to the top of the limiting edge; and a first motor is fixedly mounted at the inner bottom of the pickling box. According to the pickling processing device for reducing harmful substance formation in ham production, by arranging a plurality of driven gears which are engaged with one another, hams on the surfaces of turning rods can be turned through a plurality of turning rods and turning edges which are engaged and correspondingly connected among the driven gears, so that uneven pickling of the hams is avoided, and the pickling quality is improved; and by arranging a plurality of turning edges, the turning rods can be assisted to fully turn the ham, so that the surface of the hamis in full contact with pickling materials, and the pickling quality of the ham is improved.

Owner:NANTONG YUTU GROUP

Suspended glass fiber cloth pickling tank

InactiveCN107460679AIncrease the amount of picklingImprove pickling qualityTextile treatment containersTextile treatment machine arrangementsTextileGlass fiber

The invention discloses a suspended glass fiber cloth pickling tank, which comprises a tank body and an upper cover. The tank body is provided with a hanging cloth rod and an acid spraying pipe. The acid spraying pipe includes an upper acid pipe and a lower acid pipe. The pipe and the lower acid pipe are respectively arranged at the upper and lower ends of the tank, the top of the tank is provided with a cover, the bottom of the cover is provided with a water spray pipe, the bottom of the water spray pipe is evenly distributed with atomizing nozzles, and the upper acid pipe passes through the connecting rod and The upper cover is threaded, and through holes are evenly distributed on the upper acid pipe and the lower acid pipe. In the present invention, when the glass fiber cloth is hung on the hanging cloth rod for pickling, the cycle mode of acid feeding in the lower acid pipe and acid discharge in the upper acid pipe is adopted, which can effectively increase the pickling amount and pickling quality of the glass fiber cloth; pickling After the completion, the acid liquid is discharged through the acid pipe. Since the glass fiber cloth is exposed, it can be atomized by spraying water. On the one hand, it can cool the glass fiber cloth, and on the other hand, it can prevent the acid from solidifying on the surface of the glass fiber cloth, thereby improving Improve production efficiency and ensure product quality.

Owner:JIANGSU HENGZHOU SPECIAL GLASS FIBER MATERIAL

Efficient pickling device for black pork processing

ActiveCN113412916AImprove pickling efficiencyImprove pickling qualityMeat/fish preservation by dryingPork meatEngineering

The invention relates to the field of black pig meat processing equipment, in particular to an efficient pickling device for black pig meat processing, the device comprises a base and further comprises a rotary material turning mechanism which is used for turning black pork and marinade and is arranged on the base; a shaking mechanism which is arranged on the base, wherein the shaking mechanism is in transmission connection with the rotary material turning mechanism; the shaking mechanism shakes the black pork and the marinade up and down in a reciprocating manner under the driving of the rotary material turning mechanism; a pressure relief mechanism which is arranged on the rotary material turning mechanism, wherein the pressure relief mechanism is in transmission connection with the rotary material turning mechanism and is used for discharging steam generated when the black pork in the rotary material turning mechanism flows out of water. According to the efficient pickling device for black pork processing, the black pork is continuously turned over through the material turning mechanism during pickling, so that water in the pork is favorably removed, the marinade can better permeate into the black port and the pickling efficiency and quality are improved.

Owner:张家界婉嘉生态农业有限公司

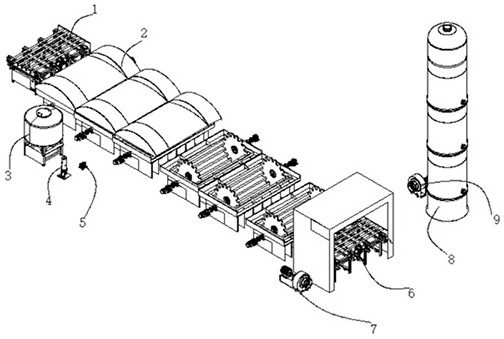

Automatic novel steel pipe rapid pickling and cleaning line

PendingCN112663072APickling uniformNo spillageHot-dipping/immersion processesDrying gas arrangementsLiquid storage tankProcess engineering

The invention discloses an automatic novel steel pipe rapid pickling and cleaning line. The automatic novel steel pipe rapid pickling and cleaning line comprises a feeding device, six cleaning devices, a liquid storage tank, a water pump, a discharging assembly, a drying fan, an acid mist purification tower and an acid mist suction fan, the six cleaning devices are sequentially arranged on the right side of the feeding device, the output end of the liquid storage tank communicates with a filter through a liquid conveying pipeline, and the output end of the filter communicates with the input end of the water pump through the liquid conveying pipeline. The invention relates to the technical field of steel pipe pickling. According to the automatic novel steel pipe rapid pickling and cleaning line, steel pipes are pickled one by one, and hot water flushing and galvanizing treatment are conducted, so that the steel pipes are pickled more evenly, the pickling quality is improved, automatic cleaning is achieved, the production efficiency is greatly improved, the production continuity is guaranteed, and the adaptability is high; and acid mist generated in the acid pickling process is conveyed to the acid mist purification tower through the acid mist suction fan for centralized treatment, installation and production are achieved, energy conservation and environmental protection are achieved, and cleaning is convenient and environmentally friendly.

Owner:沈阳嘉欣环保设备有限公司

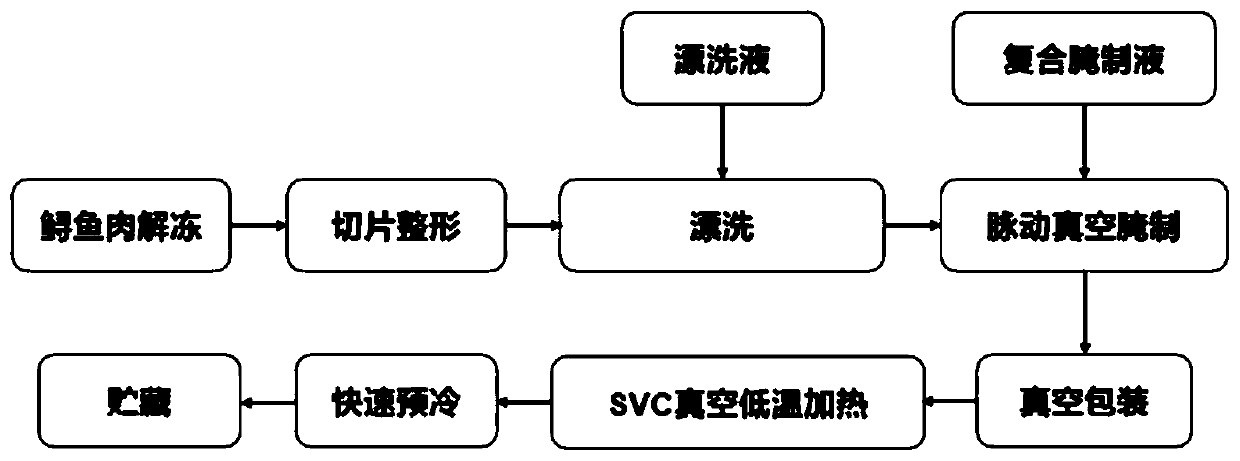

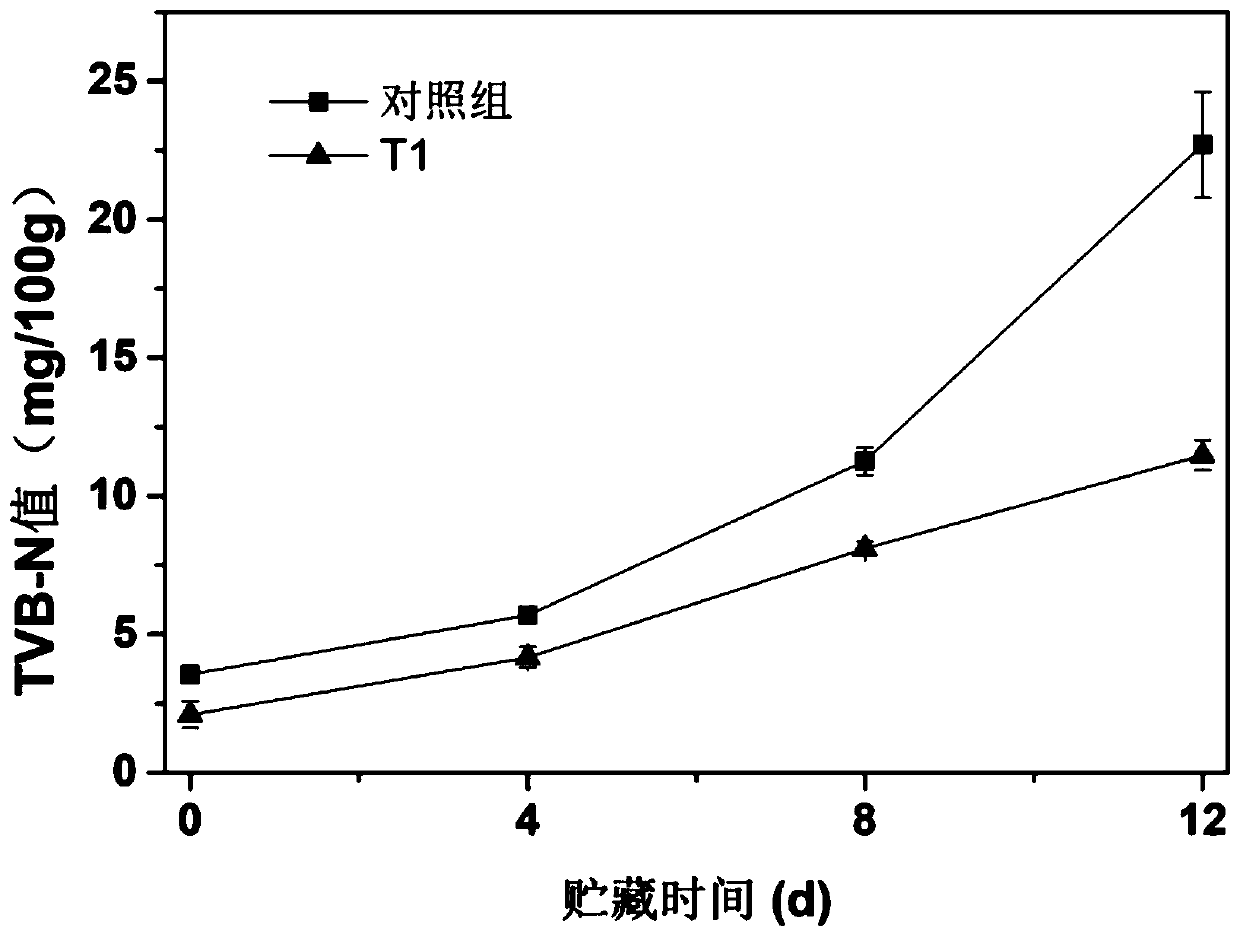

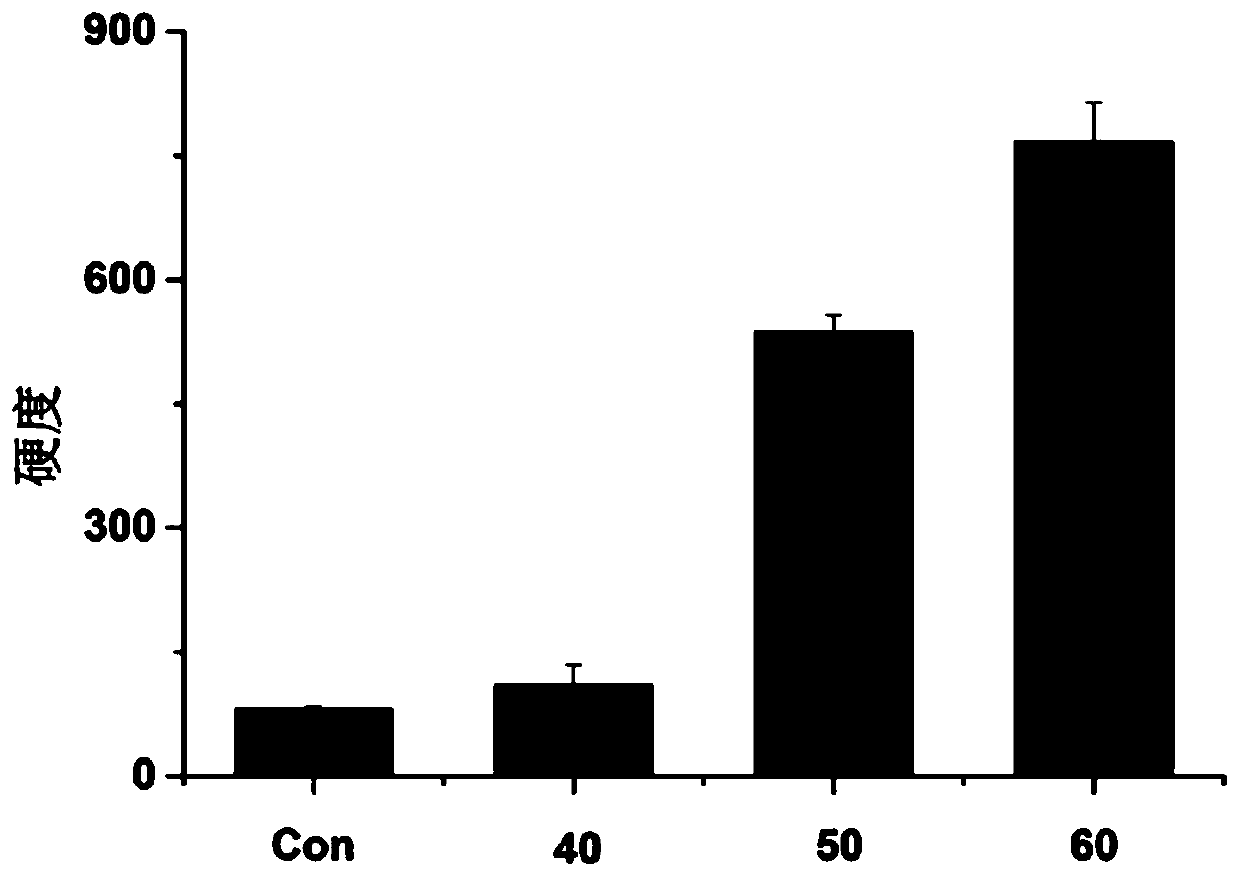

SVC-prefabricated sturgeon product processing method based on sous vide cooking technology

PendingCN110604269AImprove pickling qualityProtein oxidation slows downFood scienceProduct processingTreatment time

The invention discloses an SVC-prefabricated sturgeon product processing method based on a sous vide cooking technology. According to the method, sturgeon is adopted as a main raw material, and flowing water freezing, shaping rinsing, pulse vacuum pickling, vacuum packaging, sous vide cooking, fast precooling and other novel food processing technologies are adopted so as to process the ready-to-eat sturgeon product. Through the method, the brightness and whiteness of the fish flesh can be improved effectively, the flexibility of the fish flesh is increased, the pickling efficiency is improvedsignificantly, and meanwhile a good fish tissue state is maintained; through coordinated adjustment of the vacuum degree, temperature and heat treatment time in the SVC technology, protein oxidation during heating is reduced, and the shelf life of the sturgeon product is prolonged; and the evaporation rate of water on the surface of the fish flesh which is obtained after SVC treatment is performedis reduced effectively through fast precooling. The sturgeon product which is produced by using the method has the advantages of convenient cooking, a long storage period of time, good retention of taste and nutrition and the like, and the method can be applied to product development of sturgeon.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com