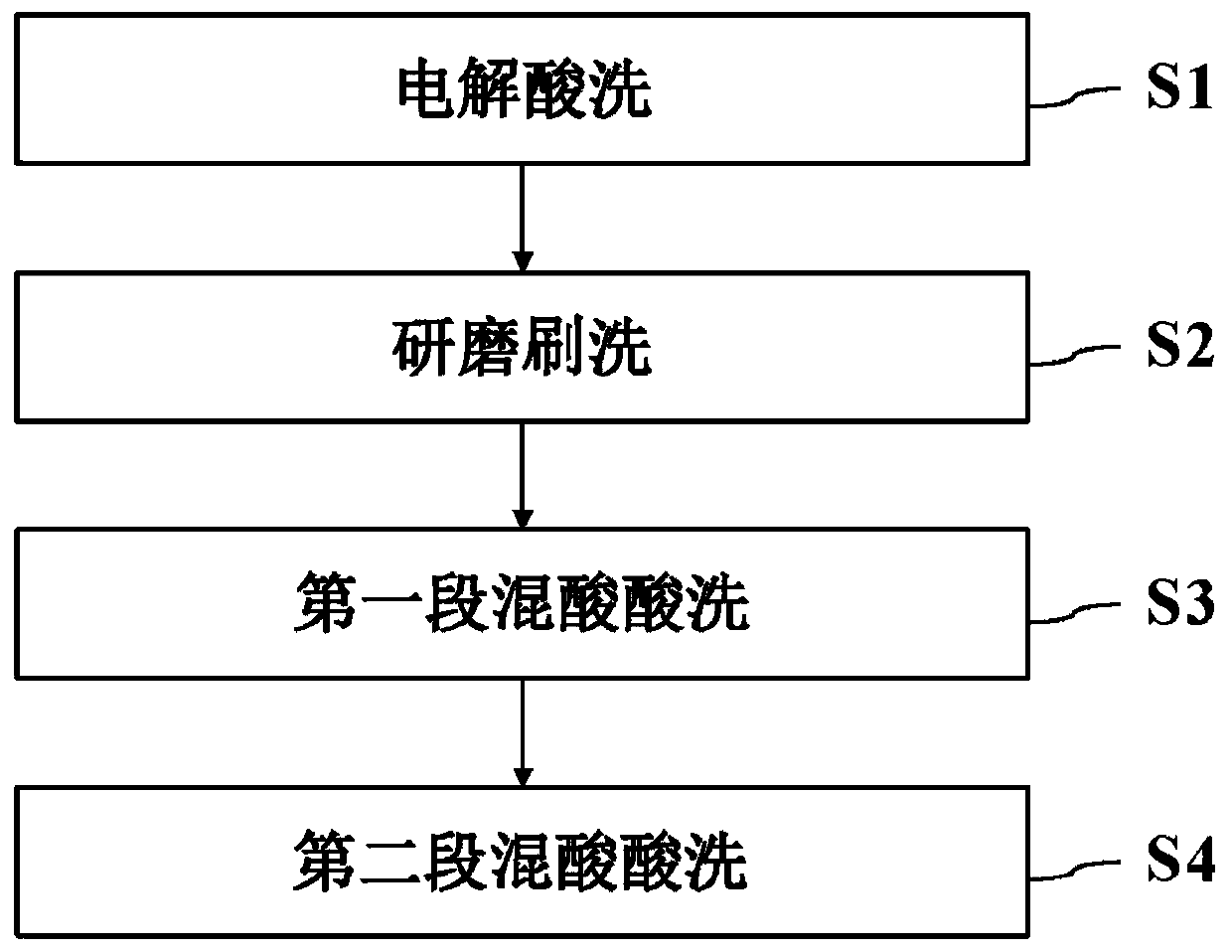

Cold-rolled 409L ferrite stainless steel strip steel acid pickling process

A technology of stainless steel strip and ferrite, applied in the field of cold-rolled stainless steel production, can solve the problems of high surface roughness of strip steel, shortened service life of acid solution, slow mixed acid pickling speed, etc. Wastewater treatment costs and the effect of reducing maintenance downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a pickling process for cold-rolled 409L ferritic stainless steel strip, the thickness of the strip to be treated is 1.4mm; the method comprises the following steps:

[0044] 1) Pickling is carried out by immersing the steel strip in an electrolytic cell with an electrolyte, the electrolyte being Na 2 SO 4 and H 2 SO 4 Mixture, where Na 2 SO 4 The concentration is 195g / L, by adding H 2 SO 4 Adjust the pH of the electrolyte to 3.2, the temperature of the electrolyte to 81°C, and the current density to 10A / dm 3 , The electrolytic pickling time is 15s.

[0045] 2) Grinding and scrubbing the strip steel after electrolytic pickling, the diameter of the roller brush used is 0.8mm, the bristles contain 180 mesh silicon carbide abrasives, the motor speed is set to 800rpm, and the motor current is 180A.

[0046] 3) The strip steel after grinding and brushing is immersed in the first mixed acid solution for pickling, in the first mixed acid ...

Embodiment 2

[0049] The present embodiment provides a pickling process for cold-rolled 409L ferritic stainless steel strip, the thickness of the strip to be treated is 1.2mm; the method comprises the following steps:

[0050] 1) Pickling is carried out by immersing the steel strip in an electrolytic cell with an electrolyte, the electrolyte being Na 2 SO 4 and H 2 SO 4 Mixture, where Na 2 SO 4 The concentration is 188g / L, by adding H 2 SO 4 Adjust the pH of the electrolyte to 2.8, the temperature of the electrolyte to 80°C, and the current density to 8.5A / dm 3 , The electrolytic pickling time is 14s.

[0051] 2) Grinding and scrubbing the electrolytic pickled steel strip, using a roller brush with a diameter of 0.8mm and containing 180 mesh silicon carbide abrasives, setting the motor speed to 700rpm, and the motor current to 175A.

[0052] 3) The strip steel after grinding and brushing is immersed in the first mixed acid solution for pickling, in the first mixed acid solution, HNO...

Embodiment 3

[0055] The present embodiment provides a pickling process for cold-rolled 409L ferritic stainless steel strip, the thickness of the strip to be treated is 1.1mm; the method comprises the following steps:

[0056] 1) Pickling is carried out by immersing the steel strip in an electrolytic cell with an electrolyte, the electrolyte being Na 2 SO 4 and H 2 SO 4 Mixture, where Na 2 SO 4 The concentration is 183g / L, by adding H 2 SO 4 Adjust the pH of the electrolyte to 2.6, the temperature of the electrolyte to 78°C, and the current density to 7.5A / dm 3 , The electrolytic pickling time is 14s.

[0057] 2) Grinding and scrubbing the electrolytic pickled steel strip, using a roller brush with a diameter of 0.8mm and containing 180-mesh silicon carbide abrasive, setting the motor speed to 600rpm, and the motor current to 170A.

[0058] 3) The strip steel after grinding and scrubbing is immersed in the first mixed acid solution for pickling. In the first mixed acid solution, HNO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com