A kind of preparation method of polyurethane synthetic leather for microfiber sofa furniture

A technology of polyurethane and synthetic leather, which is applied in the preparation of polyurethane synthetic leather for sofa furniture and the preparation of polyurethane synthetic leather for microfiber sofa furniture. Healthy environment, simple production process, and the effect of improving fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

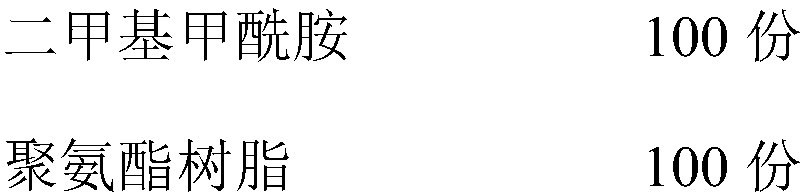

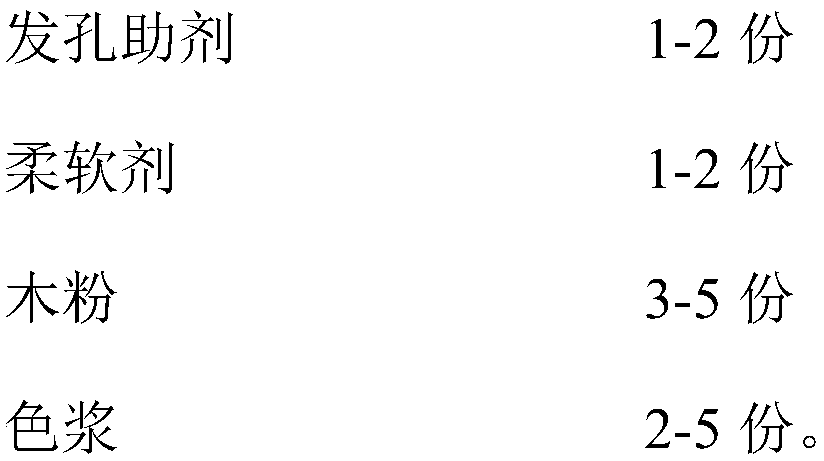

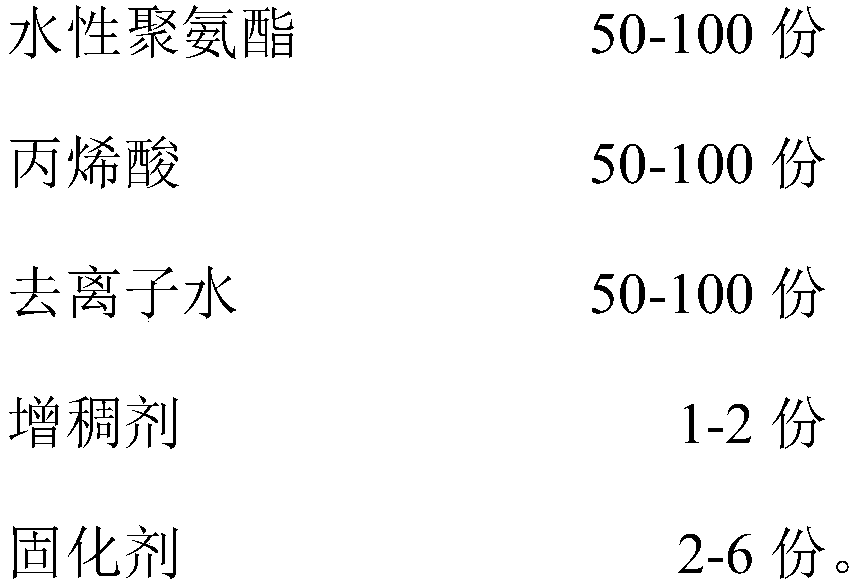

[0031] A kind of microfiber sofa furniture polyurethane synthetic leather of the present invention, concrete implementation comprises the following steps (wherein material components are counted by weight):

[0032] (1) Select the double-sided fiber-fiber fleece base as the wet-process production base fabric, the fiber length of the long-haired side is 3.5-5mm, and the fiber density is 3500-4500 fibers / cm 2 , the opening length of the short hair surface is 1.5-2mm, and the opening density is 5000-6000 fibers / cm 2 , and the long and short hairs are opposite to each other, and the thickness of the cloth base is 1.0-1.2mm;

[0033] (2) Pre-impregnation treatment

[0034] Use non-porous, non-film-forming impregnating resin to pre-impregnate the cloth base. The long-haired side is the front and smooth. The ratio of pre-impregnated materials is:

[0035] Dimethylformamide 300

[0036] SW-4028 100 (solid content 25%, modulus 30)

[0037] Color paste 2

[0038] Coagulation after ...

Embodiment 2

[0053] A kind of microfiber sofa furniture polyurethane synthetic leather of the present invention, concrete implementation comprises the following steps (wherein material components are counted by weight):

[0054] (1) Select the double-sided fiber-fiber fleece base as the wet-process production base fabric, the fiber length of the long-haired side is 3.5-5mm, and the fiber density is 3500-4500 fibers / cm 2 , the opening length of the short hair surface is 1.5-2mm, and the opening density is 5000-6000 fibers / cm 2 , and the long and short hairs are opposite to each other, and the thickness of the cloth base is 1.0-1.2mm;

[0055] (2) Pre-impregnation treatment

[0056] Use non-porous, non-film-forming impregnating resin to pre-impregnate the cloth base. The long-haired side is the front and smooth. The ratio of pre-impregnated materials is:

[0057] Dimethylformamide 300

[0058] SW-4028 100 (30% solid content, 40 modulus)

[0059] Color paste 5

[0060] Coagulation after ...

Embodiment 3

[0075] A kind of microfiber sofa furniture polyurethane synthetic leather of the present invention, concrete implementation comprises the following steps (wherein material components are counted by weight):

[0076] (1) Select the double-sided fiber-fiber fleece base as the wet-process production base fabric, the fiber length of the long-haired side is 3.5-5mm, and the fiber density is 3500-4500 fibers / cm 2 , the opening length of the short hair surface is 1.5-2mm, and the opening density is 5000-6000 fibers / cm 2 , and the long and short hairs are opposite to each other, and the thickness of the cloth base is 1.0-1.2mm;

[0077] (2) Pre-impregnation treatment

[0078] Use non-porous, non-film-forming impregnating resin to pre-impregnate the cloth base. The long-haired side is the front and smooth. The ratio of pre-impregnated materials is:

[0079] Dimethylformamide 300

[0080] SW-4028 100 (28% solid content, 35 modulus)

[0081] Color paste 3

[0082] Coagulation after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com